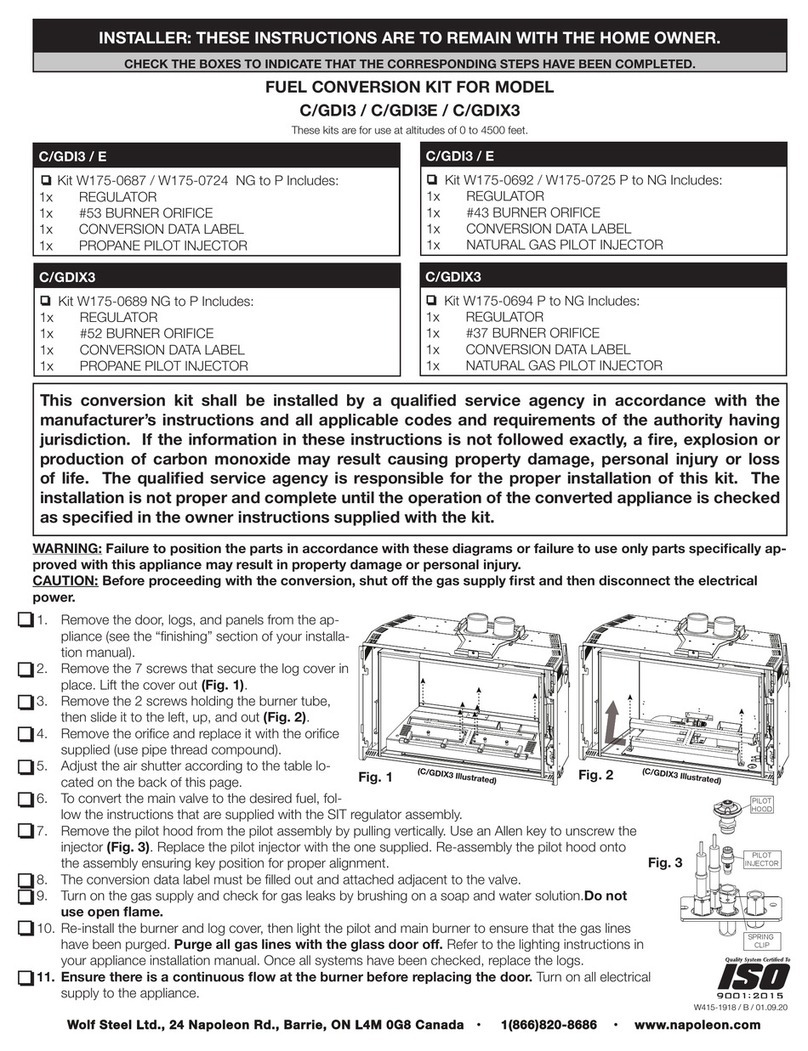

WARNING: This appliance assembly contains burner orifices specifically for the input

gas and Btu rating. Modifying or failure to use the factory orifice may cause property

damage, personal injury or loss of life.

1. It is recommended that adults be present when this gas appliance is operating. It is recommended that this unit

is not left burning when unattended or while anyone is sleeping.

2. Do not use a natural gas set for propane or a propane set for natural gas. If the gas type is not correct. DO NOT

INSTALL. Contact your dealer for immediate assistance.

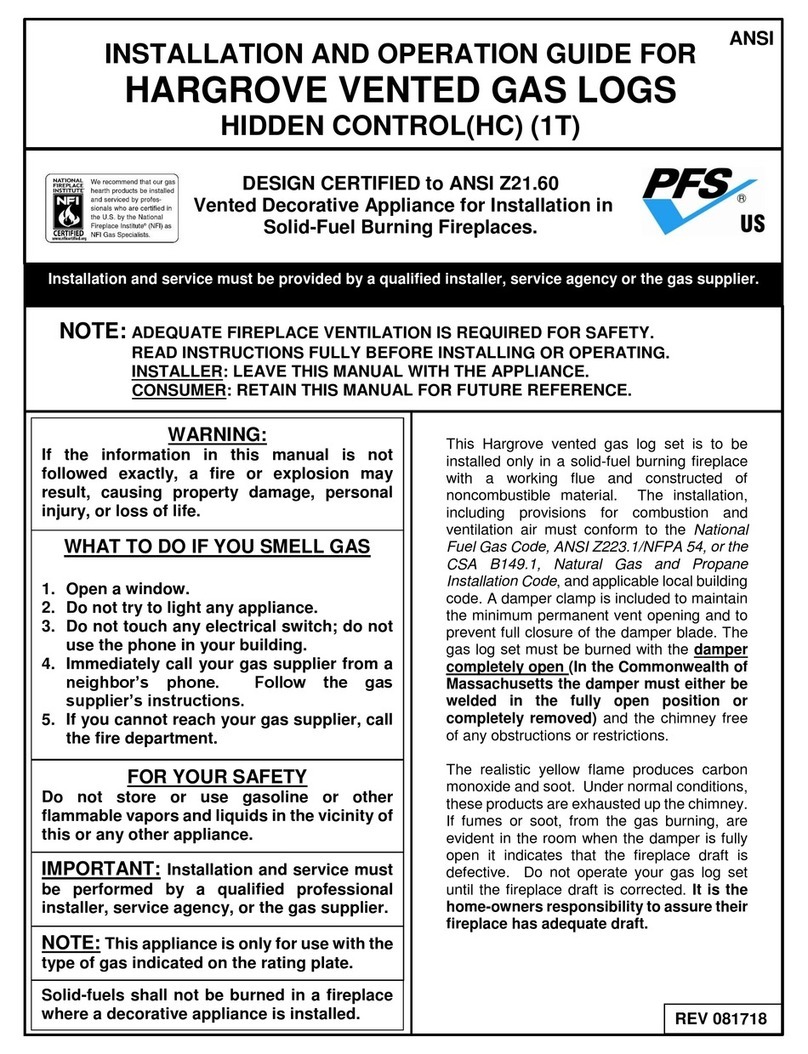

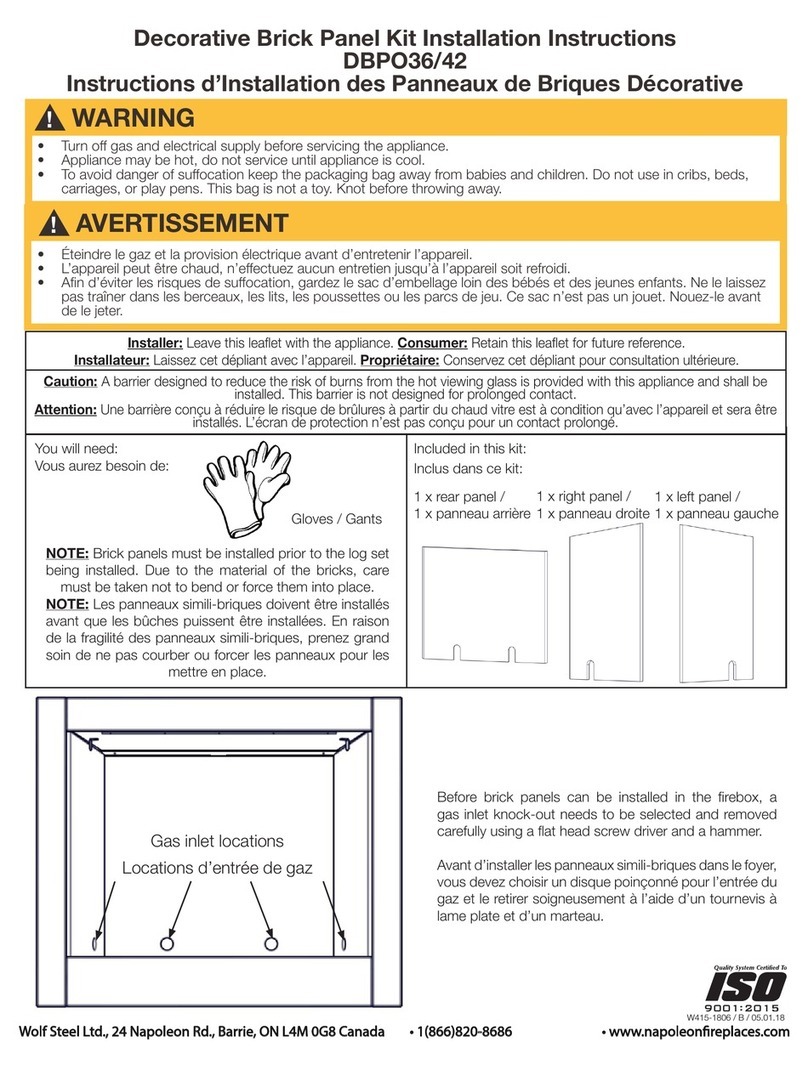

3. There are many different local codes for gas fire logs. The installation and the provision for combustion and

ventilation air must conform to local codes and, or in the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 –(most current revision).

4. Gas log sets must be installed by personnel qualified for installing gas appliances.

5. This appliance must be installed only in a solid-fuel burning fireplace with a working flue and constructed of

noncombustible materials. Solid fuels are not to be burned in a fireplace where a decorative appliance has

been installed.

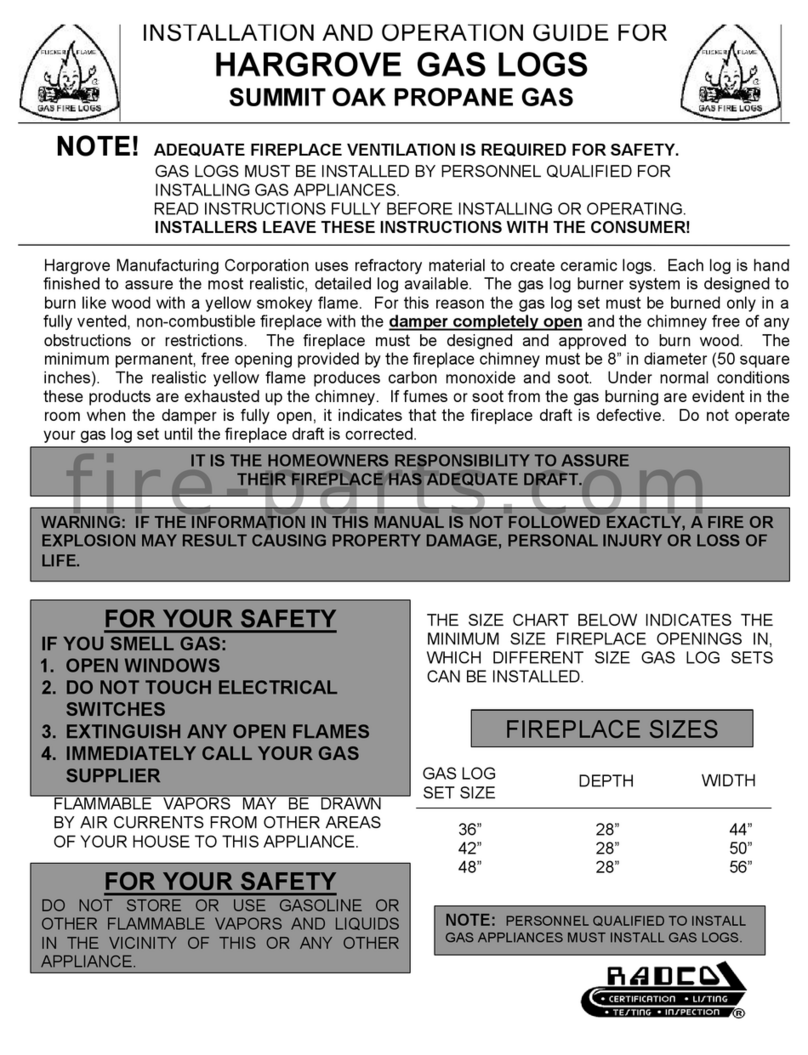

6. A permanent free opening must be provided by either the fireplace chimney or chimney damper to vent flue

gasses. Any chimney damper must be fixed in a manner, which will maintain the permanent free opening at all

times. Use Table II to determine the minimum permanent free opening based on chimney height and the

appliance Btu input rating. Refer to the Damper Stop section for additional directions.

7. The minimum free opening is based only on two factors; chimney height and Btu input rating. Many other

factors affect the fireplace drafting. It is the homeowner’s responsibility to assure their fireplace has adequate

draft. If fumes or soot from the gas burning are evident in the room when the damper is fully open, it indicates

that the fireplace draft is defective. Do not operate your gas log set until the fireplace draft is corrected. Consult

your fireplace specialist.

8. A fireplace screen must be in place when the appliance is operating and, unless other provisions for combustion

air are provided, the screen shall have an opening(s) for introduction of combustion air.

9. When glass fireplace doors are used, always operate gas log set with the doors fully open to allow for proper

combustion air and to keep control valves from overheating.

10. The minimum inlet supply pressure for the purpose of input adjustment is 5.0 inches (natural gas) 11 inches

(propane gas) in water column. The maximum inlet supply pressure is 10.5 inches (natural gas) 13 inches

(propane gas) in water column.

11. The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psig (3.5kPa). The appliance must be

isolated from the gas supply piping system by closing its individual manual valve during pressure testing equal

to or less than 1/2 psig (3.5kPa).

12. The fireplace chimney or venting system should be examined annually and cleaned as required by a qualified

agency.

13. After burning for several hours the logs become fragile and should not be handled. Knocking or rubbing logs

can cause concrete to crumble and is not covered under the warranty.

14. To clean the logs, use a soft dry paintbrush for periodic dusting of the gas fire logs.

15. To clean the burner, shut off the gas supply, remove the burner pan media, and vacuum the burner ports. After

cleaning, replace burner pan media and light the pilot according to the lighting instructions.

IMPORTANT PRE-INSTALLATION AND FIREPLACE SAFETY INFORMATION