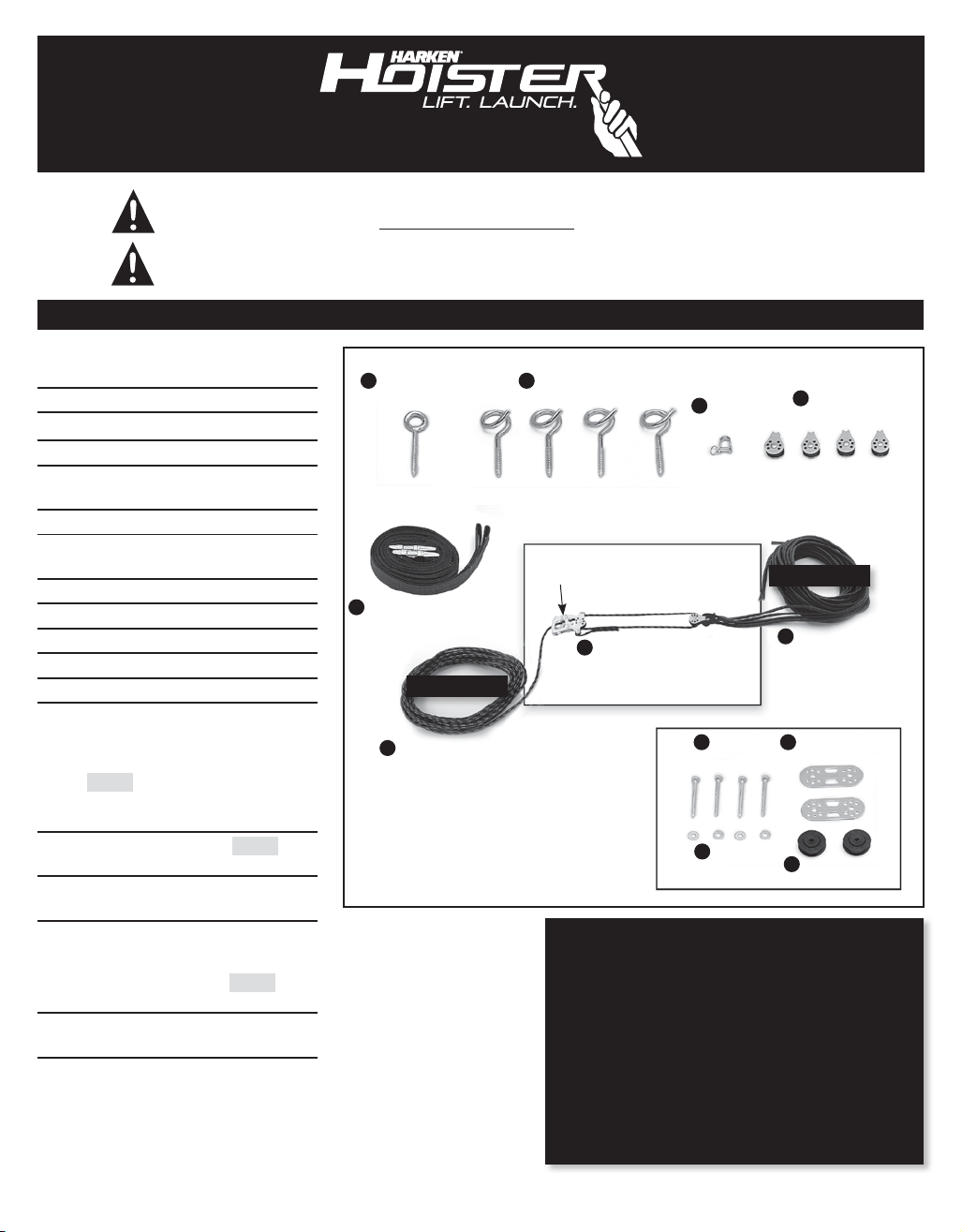

SAVE TIME! READ THE ENTIRE MANUAL BEFORE BEGINNING HOISTER INSTALLATION.

Harken, Inc. • N15W24983 Bluemound Rd, Pewaukee, WI 53072-4974 • Tel: 262-691-3320 • Fax: 262-701-5780 • Email: hoister@hoister.com • Web: www.hoister.com

IMPORTANT SAFETY INFORMATION

• NEVER USE TO LIFT A PERSON.

• DISABLE AUTOMATIC GARAGE DOOR OPENER

when installing, raising, or lowering Hoister.

• READ ENTIRE MANUAL CAREFULLY BEFORE

starting installation. It will save you time.

• DO NOT UNTIE ANY ROPES

System comes ready to install.

Leave F, G, and H together.

• DO NOT RAISE OR LOWER HOISTER

with anyone standing under object.

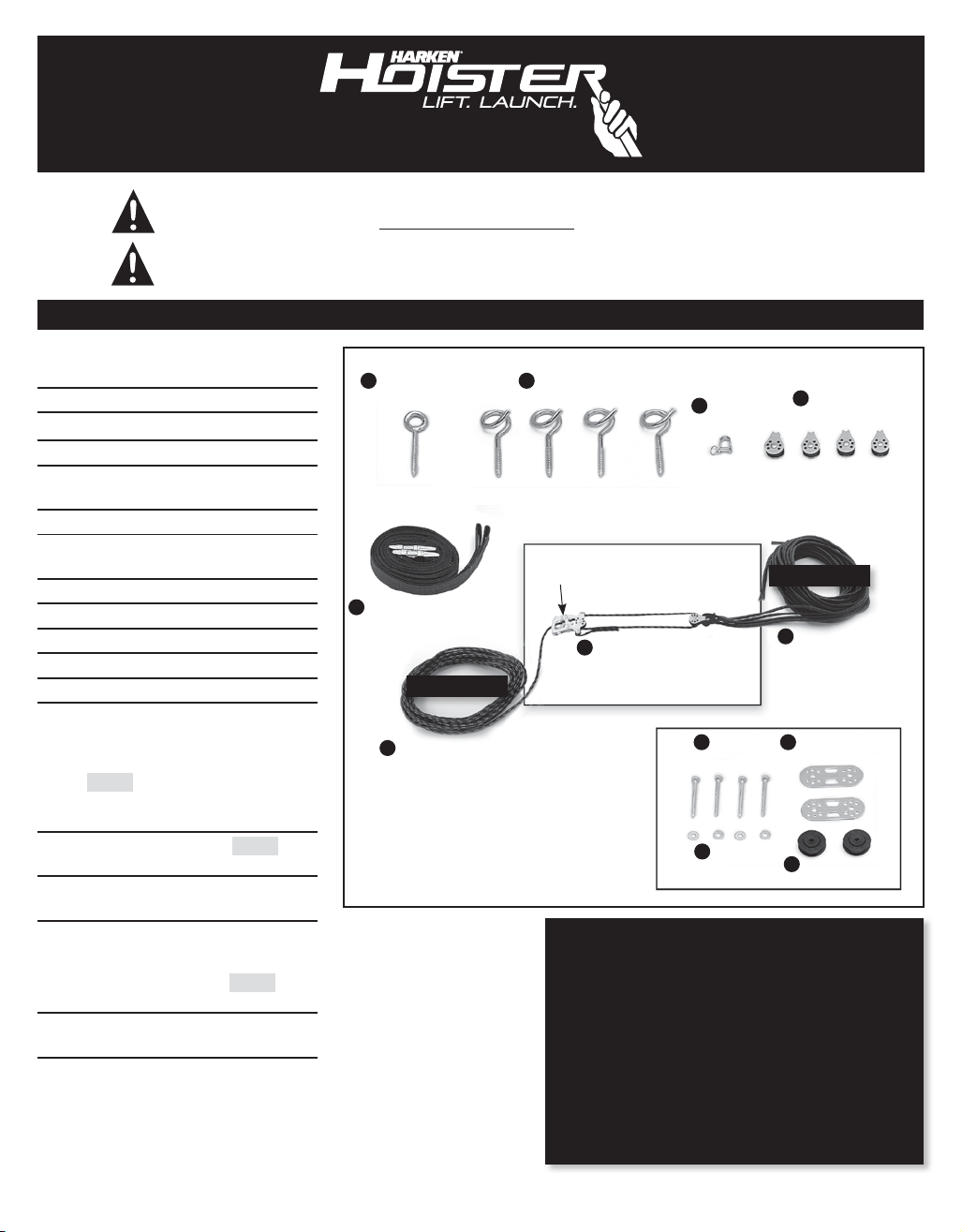

Welded screw eye

HCP1443

Pigtail lag screws

HCP1444

Drop black ropes

HCP1447/HCP1448

Rope organizer components

WARNING! Strictly follow all instructions to avoid an accident, damage to property,

personal injury or death. See www.harken.com/manuals for additional safety information.

WARNING! This product is not to be used for human suspension. Components may fail

causing person to fall, possibly resulting in serious injury or death.

DO NOT UNTIE

DO NOT UNTIE

(G1) Cleat

7758ASSY

224A

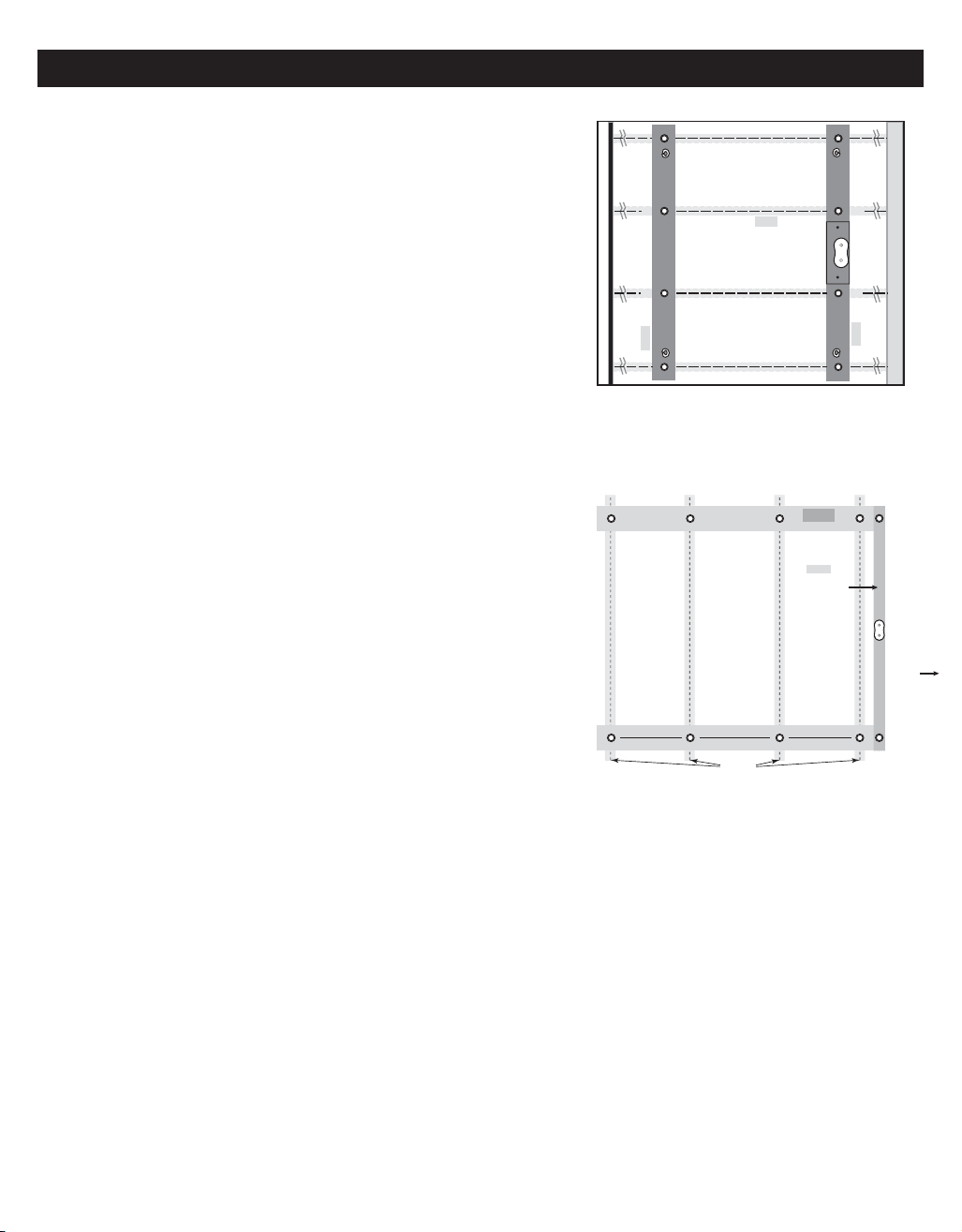

TOOLS

Drill Plumb line Safety glasses

Drill bits: 5/32" (4 mm)

7/32" (6 mm)

5/16" (8 mm

Pencil Tape measure

Stud finder Wrench (box end or

ratcheting) 7/16" (11 mm)

Stepladder

B

Pulleys

224A

D

A

Shackle

072

C

H

Lag bolts

HFS908

IOrganizer plates

H-28375A

K

Washers

HFS913

J

Organizer pulleys

H-52010

L

Webbing straps with buckles

HCP1459.SET

E

Single black/red hoisting rope

HCP1483

F

Block and tackle*

G

KIT INCLUDES

A1welded screw eye

B4pigtail lag screws

C1shackle

D4pulleys

E2webbing straps with buckles

7' (2.13 m)

F1single black/red hoisting rope

G1block and tackle with

cleat (G1) and rope

H4black drop ropes: 2 long, 2 short

I4lag bolts 1/4" x 21/2" (6 x 63 mm)

J4washers 1/4" (6 mm)

K2organizer plates

L2organizer pulleys

PURCHASE SEPARATELY IF NEEDED –

See “note” Step 1B, page 6.

1pine board (riser) (grade 2)

2" x 6" x 7" (50 mm x 152 mm

x 180 mm) not used for rafters

running sideways

2pine boards (grade 2) 2" x 6" x 6'

(50 mm x 152 mm x 1.83 m)

8lag bolts and washers 5/16" x 4"

(8 x 100 mm)

PURCHASE ADDITIONAL FOR RAFTERS

RUNNING SIDEWAYS – See Step 2A, page 7

1pine board (grade 2) 2" x 4" x 6'

(50 mm x 100 mm x 1.83 m)

2lag bolts and washers 5/16" x 31/2"

(8 mm x 90 mm)