Harken Hoister SUP User manual

7808: 45 lb (20 kg) System

SUP

SUP

SAVE TIME! READ THE ENTIRE MANUAL BEFORE BEGINNING HOISTER INSTALLATION.

Harken, Inc. • N15W24983 Bluemound Rd, Pewaukee, WI 53072-4974 • Tel: 262-691-3320 • Fax: 262-701-5780 • Email: hoister@hoister.com • Web: www.hoister.com

IMPORTANT SAFETY INFORMATION

• NEVER USE TO LIFT A PERSON.

• DISABLE AUTOMATIC GARAGE DOOR OPENER

when installing, raising, or lowering Hoister.

• READ ENTIRE MANUAL CAREFULLY BEFORE

starting installation. It will save you time.

• DO NOT UNTIE ANY ROPES

System comes ready to install.

Leave F, G and H together.

• DO NOT RAISE OR LOWER HOISTER

with anyone standing under object.

Welded screw eye

HCP1443

Pigtail lag screws

HCP1444

Drop black ropes

HCP1447/HCP1448

Rope Organizer Components

WARNING! Strictly follow all instructions to avoid an accident, damage to property,

personal injury or death. See www.harken.com/manuals for additional safety information.

WARNING! This product is not to be used for human suspension. Components may fail

causing person to fall, possibly resulting in serious injury or death.

DO NOT UNTIE

DO NOT UNTIE

(G1) Cleat

7758ASSY

224A

TOOLS

Drill Plumb line Safety glasses

Drill bits: 5/32" (4 mm)

7/32" (6 mm)

5/16" (8 mm

Pencil Tape measure

Stud finder Wrench (box end or

ratcheting) 7/16" (11 mm)

Stepladder

B

Pulleys

224A

D

A

Shackle

072

C

H

Lag bolts

HFS908

IOrganizer plates

H-28375A

K

Washers

HFS913

J

Organizer pulleys

H-52010

L

Webbing straps with buckles

HCP1459.SET

E

Single black/red hoisting rope

HCP1483

F

Block and tackle*

G

KIT INCLUDES

A1Welded screw eye

B4Pigtail lag screws

C1Shackle

D4Pulleys

E2Webbing straps with buckles

7' (2.13 m)

F1Single black/red hoisting rope

G1Block and tackle with

cleat (G1) and rope

H4Black drop ropes: 2 long, 2 short

I4Lag bolts 1/4" x 21/2" (6 x 63 mm)

J4Washers 1/4" (6 mm

K2Organizer plates

L2Organizer pulleys

PURCHASE SEPARATELY IF NEEDED –

See “Note” Step 1b

1Pine board (riser) (grade 2)

2" x 6" x 7" (50 mm x 152 mm

x 180 mm) Not used for rafters

running sideways

2Pine boards (grade 2) 2" x 6" x 6'

(50 mm x 152 mm x 1.83 m)

8Lag bolts and washers 5/16" x 4"

(8 x 100 mm)

PURCHASE ADDITIONAL FOR RAFTERS

RUNNING SIDEWAYS – See Step 2A

1Pine board (grade 2) 2" x 4" x 6'

(50 mm x 100 mm x 1.83 m)

2Lag bolts and washers 5/16" x 31/2"

(8 mm x 90 mm)

Pigtail

Lag Screw

(B)

Long Black

Drop Ropes

(H)

Short Black

Drop Ropes

(H)

Webbing Straps (E)

Pulley

(D)

Welded

Screw Eye

(A)

Rope

Organizer

Pulleys (L)

Plates (K)

Lag Bolts (I)

Washers (J)

Shackle

(C)

Single

Red/Black

Hoisting

Rope

(F)

Garage

Door

Front

Wall

Cleat

(G1)

Front

2" x 6"

Mounting Board

Back

2" x 6"

Mounting Board

Block and Tackle (G)

INSTALLATION OVERVIEW

STEP 1 DETERMINE HOISTER LOCATION

STEP 2 INSTALL MOUNTING BOARDS

STEP 3 INSTALL PIGTAIL LAG SCREWS

STEP 4 INSTALL ROPE ORGANIZER

STEP 5 ASSEMBLE HOISTER SYSTEM

STEP 6 OPERATING HOISTER SYSTEM

MAINTENANCE & WARRANTY

Top

View ORGANIZER

GARAGE DOOR

FRONT WALL

TOP PLATE

PIGTAIL

LAG SCREW

PIGTAIL

LAG SCREW

PIGTAIL

LAG SCREW

PIGTAIL

LAG SCREW

RAFTER

2" x 6" x 6' MOUNTING BOARD

2" x 6" x 6' MOUNTING BOARD

2" x 6" x 7" RISER BOARD

Rafters run other way? See steps 1B and 2A.

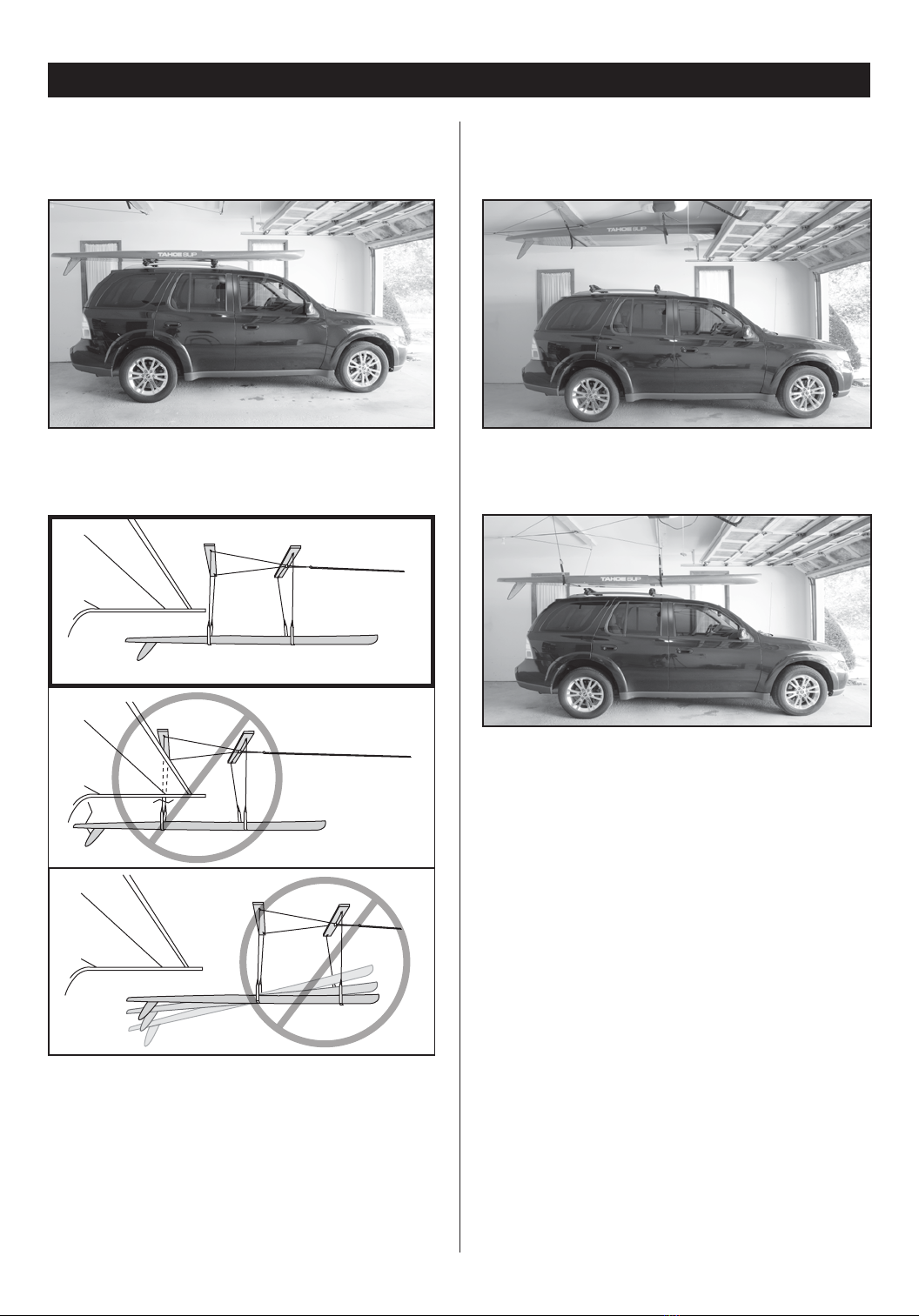

A. PLAN THE INSTALLATION

Pull car into garage with object on car rack.

Measure length of object. Position Hoister so garage

door can open with object lowered.

STEP 1: DETERMINE HOISTER LOCATION

OPTION 1. Above Garage Door: Clearance to lift and store

object above open garage door.

OPTION 2. Below Garage Door: Use if not enough clearance

for Above Garage Door Storage (Option 1). Object has

clearance to lift and store below open garage door.

STORAGE OPTIONS

Measure height of object. Make sure object can be

stored above or below the open garage door.

DIAGRAM 1. Position object above car with clearance to

open garage door. If Hoister is mounted too close to

garage door, there may not be clearance to open door.

Mounted too far forward, object may not balance or

lower onto car.

Opened

Garage Door

Opened

Garage Door

Opened

Garage Door

Opened

Garage Door

Garage

Door

STEP 1B

1) Measurement between

center points on

mounting boards _________

(Calculation above)

STEP 5A

2) Measurement from center

of front mounting board

to front wall _________

3) Measurement from front

mounting board to

lowest drop point _________

If measurement 2 is less than

measurement 3, refer to

Step 5A, Diagram 12.

Front

Wall

Step 1B

Mounting

Board

Placement

Step 5A

Welded

Eye Screw

Placement

Ceiling

Plan Location of Mounting Boards and Welded Eye Screw

2

3

1Front Mounting Board

Back Mounting Board

Top Plate

DIAGRAM 3. Distance of mounting boards from front wall is important, as it affects the position of the welded screw eye in Step 5A.

DIAGRAM 2. Center object under mounting points. Position

mounting boards far enough apart so object is stable.

STEP 1 CONTINUED: DETERMINE HOISTER LOCATION

WARNING! Do not screw into laminated rafters.

They are not intended to accept fasteners. Consult

rafter maker for recommendations. Screwing

into laminated rafters may considerably weaken

system, causing load to fall which may cause

an accident.

Garage

Door

Front

Wall

2

3

1

DIAGRAM 3a. Alternate position for rafters running sideways.

Check to make sure 6' (1.83 m) boards are long enough.

Alternate

position

B. PLAN LOCATION OF MOUNTING BOARDS

Mounting boards are used to position Hoister directly

above object to be lifted.

Note: Mounting boards may not be necessary for

nstallation in ceiling with exposed rafters. In ceilings

with exposed rafters, system can be installed on rafters.

Position Hoister directly above object to be lifted. If

installing without mounting boards, go to step 3.

DISTANCE BETWEEN MOUNTING BOARDS

Distance between mounting boards should be 1/3 of

object’s length.

Exception: Distance between mounting boards for long

SUPs will be less than 1/3 object’s length.

Calculate distance between mounting boards using

formula or chart below.

_________________ x .33 = _________________

Object length 33% Mounting distance

LOCATE CEILING MOUNTING BOARD POSITION

DIAGRAM 4. Mark center-to-center distance between rafters on mounting boards. Attach mounting boards to rafters.

Top

View

Rafters

Rafter

Center-to-Center

Distance

Rafter

Center-to-Center

Distance

Rafter

Center-to-Center

Distance

Mounting Boards

STEP 2: INSTALL MOUNTING BOARDS

DIAGRAM 4A. For Alternate Position attach board for mounting

organizer using 5/16" (8 mm) 31/2" (90 mm) lag bolts and

washers (not included). See Step 3a to determine distance

between mounting boards.

Top

View

Rafters Rafter

Center-to-Center

Distance

Mounting Boards

2" X 4" For Mounting Organizer – No Riser Board Used

Alternate Position for Rafters that Run Sideways

Front Wall

2" x 6"

A. DRILL CEILING RAFTER ATTACHMENT POINTS

LOCATE CEILING RAFTERS

Mounting boards must attach to ceiling rafters (see

diagram 4 and 4a). On finished ceilings, locate rafters

using stud finder. Follow manufacturer’s instructions.

Mark center of ceiling rafters. Drill 7/32" (5.5 mm) holes.

B. DRILL MOUNTING BOARD

Measure center-to-center distance between rafters.

Mark distance on mounting boards. Mark drill points

in the center of the board. Drill 5/16" (8 mm) holes

completely through the mounting boards.

C. ATTACH MOUNTING BOARDS TO CEILING

Attach mounting boards using 5/16" (8 mm) lag bolts

and washers (not included).

Do not over-tighten.

Other manuals for SUP

1

This manual suits for next models

4

Table of contents

Other Harken Hoister Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction