pg. 8

Table of Contents

Contents

IMPORTANT SAFETY INSTRUCTIONS...............................................................................................................................................2

TABLE OF CONTENTS .........................................................................................................................................................................8

WHAT’S NEW?.................................................................................................................................................................................10

SUPPORTS MULTIPLE HARMAN PROTOCOLS NATIVELY ................................................................................................................................10

HCONTROL .....................................................................................................................................................................................10

STANDARD LANGUAGE SCRIPTING SUPPORT ............................................................................................................................................10

DUET MODULE AND DRIVER DESIGN MODULE SUPPORT ............................................................................................................................10

USB HOST......................................................................................................................................................................................10

USB-C PROGRAM PORT ....................................................................................................................................................................10

ICSLAN IMPROVEMENTS ....................................................................................................................................................................10

FEATURES........................................................................................................................................................................................11

MU-SERIES CONTROLLER FEATURES .....................................................................................................................................................11

MU-1000 .........................................................................................................................................................................................12

MU-1000 SPECIFICATIONS ................................................................................................................................................................12

MU-1300 .........................................................................................................................................................................................14

MU-1300 SPECIFICATIONS ................................................................................................................................................................14

MU-2300 .........................................................................................................................................................................................16

MU-2300 SPECIFICATIONS ................................................................................................................................................................16

MU-3300 .........................................................................................................................................................................................18

MU-3300 SPECIFICATIONS ................................................................................................................................................................18

MOUNTING THE CONTROLLER.........................................................................................................................................................20

MOUNTING THE MU-2300 AND MU-3300 ..........................................................................................................................................20

INSTALLING THE CONTROLLER INTO AN EQUIPMENT ..................................................................................................................................20

RACK MOUNT SAFETY INSTRUCTIONS FOR MU-2300 AND MU-3300..........................................................................................................20

MOUNTING THE MU-1000 AND MU-1300 ..........................................................................................................................................20

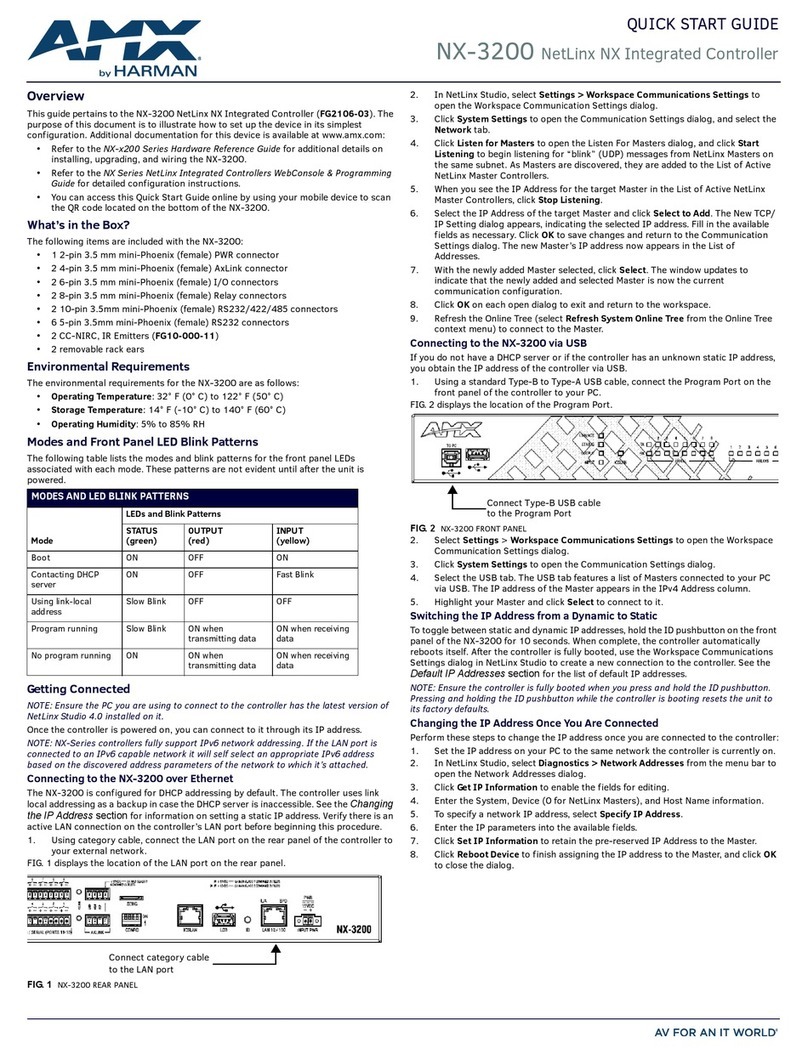

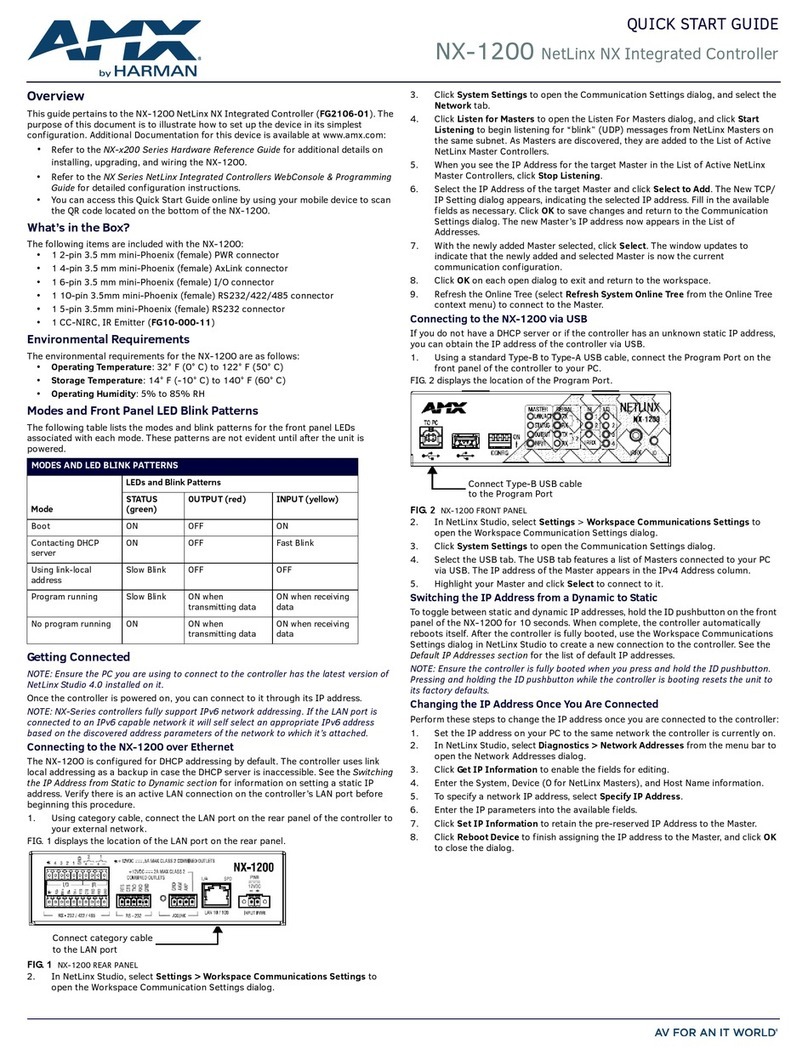

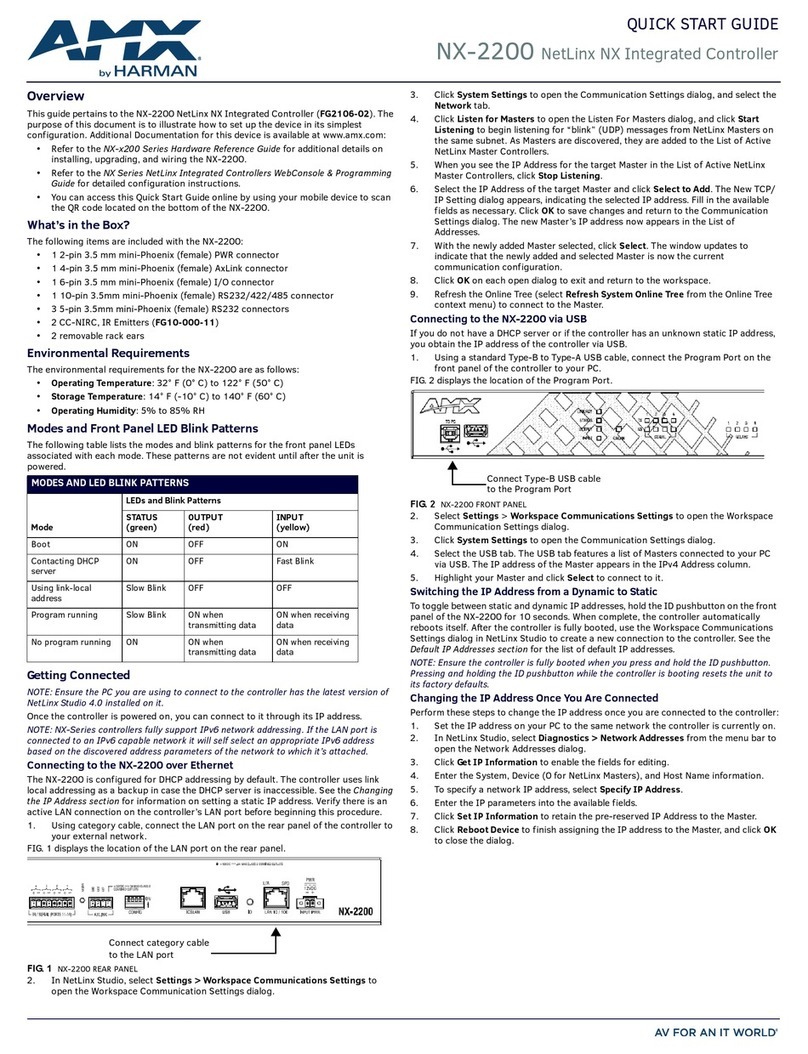

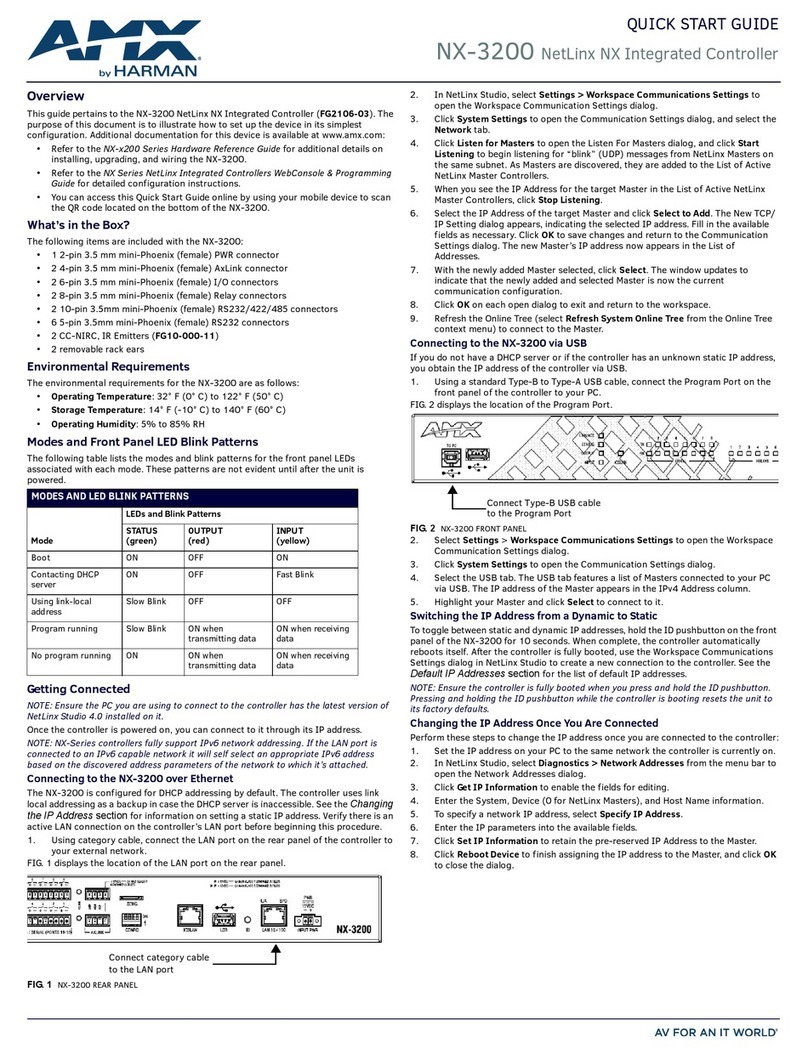

FRONT PANEL COMPONENTS ..........................................................................................................................................................21

PROGRAM PORT ..............................................................................................................................................................................21

USB PORT......................................................................................................................................................................................21

LEDS.............................................................................................................................................................................................21

General Status LEDs.................................................................................................................................................................21

SERIAL LEDs .............................................................................................................................................................................22

RELAYS LEDs ............................................................................................................................................................................22

IR/SERIAL LEDs.........................................................................................................................................................................22

I/O LEDs...................................................................................................................................................................................22

WIRING AND CONNECTIONS ...........................................................................................................................................................23

OVERVIEW......................................................................................................................................................................................23

SERIAL PORTS ..................................................................................................................................................................................23

RS-232 Ports ............................................................................................................................................................................23

RS-232/422/485 Ports..............................................................................................................................................................23

RELAY PORTS...................................................................................................................................................................................24

I/O PORTS......................................................................................................................................................................................24