Harmonic Drive CSF-3 Series User manual

For Precision Control

HarmonicDriveSpeed Reducer

CSF-3 Series Manual

●Thank you very much for your purchasing our HarmonicDrive

CSF-3 series.

●Be sure to use sufficient safety measures when installing and

operating the equipment so as to prevent an accident resulting in

a serious physical injury damaged by a malfunction or improper

operation.

●Product specifications are subject to change without notice for

improvement purposes.

●Keep this manual in a convenient location and refer to it

whenever necessary in operating or maintaining the units.

●The end user of the driver should have a copy of this manual.

ISO14001

ISO9001

SAFETY GUIDE

For HarmonicDrive®component and unit

Read this manual thoroughly before designing the application, installation, maintenance or inspection of the actuator.

SYSTEMS

Indicates a potentially hazardous situation,

which, if not avoided, could result in death

or serious personal injury.

Indicates a potentially hazardous situation, which, if

not avoided, may result in minor or moderate personal

injury and/or damage to the equipment.

WARNING

CAUTION

LIMITATION OF APPLICATIONS:

The equipment listed in this document may not be used for the applications listed below:

Space equipment Amusement equipment

Aircraft, aeronautic equipment Machine or devices acting directly on the human body

Nuclear equipment Instruments or devices to transport or carry people

Household apparatus Apparatus or devices used in special environments

Vacuum equipment Instruments or devices to prevent explosion

Automobile, automotive parts

Safety measures are essential to prevent accidents resulting in death, injury or damage of the equipment due to

lfunction or faulty operation.ma

Design Precaution: Be certain to read the catalog when designing the equipment.

Use only in a specified environment.

●Please ensure the following environmental conditions

are complied with:

- Ambient temperature 0 to 40°C .

- No contamination by water, oil

- No corrosive or explosive gas

- No dust such as metal powder

Install the equipment in a specified manner.

●Carry out assembly precisely in the specified order

according to the catalog.

●Observe our recommended tightening methods (such

as bolts used).

●Operating the equipment without precise assembly can

cause troubles such as generation of vibration,

reduction of life, deterioration of precision and

breakdown. Use the specified lubricant.

Install the equipment in a specified precision.

●Design and assemble parts to keep the

recommended installation precision on the catalog.

●Failure to keep the precision can cause troubles such

as generation of vibration, reduction of life,

deterioration of precision and breakdown.

Use the specified lubricant.

●Using other lubricant than our recommended products

can reduce the life. Replace the lubricant in a specified

condition.

●Grease is sealed in a unit product. Do not mix other

kinds of grease.

Operational Precaution: Be certain to read the catalog before operating the equipment.

Be careful in handling products and parts.

●Do not give strong shock to parts and units with a

hammer. Do not scratch or bruise them. Possible

damage is assumed.

●If you use the equipment in a damaged condition, the

specified performance may not be retained. It can

also cause troubles such as breakdown.

Apply torque within the allowable range.

●Do not apply torque exceeding the instantaneous

allowable max. torque. Applying excess torque can

cause troubles such as loose tightening bolts,

generation of backlash and breakdown.

●Striking an arm directly attached to the output shaft can

damage the arm and make the output shaft

uncontrollable.

Do not change a set of parts.

●The product is manufactured with sets of parts. the

specified performance may not be retained if you

have used mixed sets of parts.

Do not break down unit products.

●Do not break down and reassemble unit products.

Original performance may not be reproduced.

Handling lubricant

Precautions on handling lubricant

●Lubricant got in the eye can cause an inflammation.

Wear protective glasses to prevent it from getting in

your eye when you handle it.

●Lubricant coming in contact with the skin can cause

an inflammation. Wear protective gloves to prevent it

from contacting your skin when you handle it.

●Do not eat it (to avoid diarrhea and vomiting).

●When you open the container, you might have your

hand cut by it. Wear protective gloves.

●Keep lubricant off children.

Treatment of waste oil and containers

●Treatment methods are obliged by law. Treat wastes

appropriately according to the law. If you are unsure

how to treat them, you should consult with the dealer

before treating them.

●Do not apply pressure on an empty container. The

container may blow up.

●Do not weld, heat, drill or cut the container. The

remainder may ignite with an explosion.

First-aid

●If lubricant gets in your eye, you should wash your

eye with clean water for 15 minutes and submit to

medical treatment.

●If lubricant comes in contact with your skin, you

should thoroughly wash it with water and soap.

●If you swallowed it, you should immediately submit to

medical treatment without throwing it up by

constraint.

Storage

●Tightly plug the container after use to prevent intrusion

of dusts and water. Avoid direct sunlight to store

lubricant in a dark place.

Disposal

Please discard as industrial waste.

●Please discard as industrial waste when discarding.

C

A

U

TI

O

N

C

A

U

TI

O

N

CAUTION

C

A

U

TI

O

N

CAUTION

C

A

U

TI

O

N

WARNIN

G

WARNIN

G

C

A

U

TI

O

N

C

A

U

TI

O

N

C

A

U

TI

O

N

C

A

U

TI

O

N

C

A

U

TI

O

N

CSF-3 series manual

- Contents 1 -

Contents

Chapter 1 Outlines of CSF-3 series..................................................................................................... 1

1-1 Model and sign.......................................................................................................................... 1

1-2 Model ........................................................................................................................................ 1

1-3 External drawing ....................................................................................................................... 2

Chapter 2 Installing of Motor................................................................................................................ 3

2-1 Checking procedure.................................................................................................................. 3

2-2 Main bearing specification ........................................................................................................ 3

2-3 How to obtain the maximum load moment load........................................................................ 4

2-4 How to obtain the average load................................................................................................ 4

2-5 How to obtain the radial load coefficient (X) and axial load coefficient (Y)............................... 5

2-6 How to obtain the life................................................................................................................. 5

2-7 How to obtain the life under oscillating movement ................................................................... 6

2-8 How to obtain the static safety coefficient.................................................................................6

Chapter 3 Efficiency characteristics ................................................................................................... 7

3-1 Double-axial unit type (1U) ....................................................................................................... 7

3-2 Gear head type (1U-CC)........................................................................................................... 8

Chapter 4 No-load running torque..................................................................................................... 10

Chapter 5 Starting torque and Overdrive starting torque ................................................................11

Chapter 6 Ratcheting torque and Buckling torque.......................................................................... 12

Chapter 7 Angle transmission accuracy........................................................................................... 13

Chapter 8 Vibration ............................................................................................................................. 14

Chapter 9 Rigidity................................................................................................................................ 15

Chapter 10 Design and Precautions on assembly........................................................................... 17

10-1 Embedding accuracy of gear head type (1U-CC)................................................................... 17

10-2 Tolerable load of input shaft of double-shaft unit type (1U) .................................................... 18

10-3 Mounting in system................................................................................................................. 19

10-4 Mechanical accuracy .............................................................................................................. 20

10-5 Lubricant ................................................................................................................................. 20

CSF-3 series manual

- Contents 2 -

Memo

Chapter 1 Outlines of CSF-3 series

- 1-

This supplementary technical data incorporates technical data that is not included in our CSF-3

Series Catalog.

Please use this data hand in hand with the CSF-3 Series Catalog when you study the use of

Harmonic Drive products in the design of your products.

Chapter 1 Outlines of CSF-3 series

1-1 Model and sign

Model and sign of CSF-3 series are described as follows:

CSF-3 B-50-1U-CC-□□

①②③④⑤⑥

①

Model name

HarmonicDrive CSF series

②

Model No.

3

③

Desing

Version

B

(

New Version

)

④

Reduction ratio

30:1/30 50:1/50 100:1/100

⑤

Model

1U:Double-shaft unit type

1U-CC:Gear head type

⑥

Specification

None=standard product

SP=special specifications

such as shapes

and performance

1-2 Model

Model Reduction

ratio

Rated torque at

input 2000r/min

Peak torque at

start/stop

Allowable

max. value of

ave. load

torque

Instantaneous

Allowable

max. torque

Allowable

max. input

rotational

speed

Allowable

ave. input

rotational

speed

Inertia moment

(1/4GD2)

Nm

kgf m

Nm

kgf m

Nm

kgf m

Nm

kgf m

r/min

r/min

kgcm2

3

30

0.06

0.006

0.13

0.013

0.10

0.010

0.22

0.022

10000 6500 1U:5.3×10-7

1U-CC:7.0×10-7

50

0.11

0.011

0.21

0.021

0.13

0.013

0.41

0.040

100

0.15

0.015

0.30

0.029

0.23

0.023

0.57

0.056

Note) Upper part of inertia moment is the value of 1U type, whereas, lower part is the value 1U-CC type.

Note) See the catalog in description of terms on the rated table.

Chapter 1 Outlines of CSF-3 series

- 2-

1-3 External drawing

■Double-shaft unit type【CSF-3-XX-1U】

Unit: mm

Mass: 13.7g

■Gear head type【CSF-3-XX-1U-CC】

Unit: mm

Mass: 11.4g

Note) Please confirm the dimensions specification drawing issued by us for detail.

4-M1.6 tap 3.2

evenly spaced

4-M1.6 tap 3.2

evenly spaced

Maximum diameter of rotation part

Maximum diameter of rotation part

4-M1.4 tap 2.8

evenly spaced

Chapter 2 Installing of Motor

3

Chapter 2 Installing of Motor

A precision cross roller bearing is built in the unit type and the gear head type to directly support the

external load (output flange) (precision 4-point contact ball bearing for the CSF-mini series).

Check the maximum load moment load, life of the bearing and static safety coefficient to fully bring out

the performance of the unit type.

2-1 Checking procedure

(1) Checking the maximum load moment load

Obtain the maximum load moment load (Mmax).

⇓

Maximum load moment load (Mmax)

≤

permissible moment (Mc)

(2) Checking the life

Obtain the average radial load (Frav) and the average axial load (Faav).

⇓

Obtain the radial load coefficient (x) and the axial load coefficient (y).

⇓

Calculate the life and check it.

(3) Checking the static safety coefficient

Obtain the static equivalent radial load coefficient (Po).

⇓

Check the static safety coefficient.

2-2 Main bearing specification

Table 1 Specification

Model No.

Ball pitch

circle

diameter

(dp)

Offset

(R)

Basic rated load Moment

load Moment rigidity Tolerable radial

load

Tolerable

thrust load

Basic dynamic

rated load

Basic static rated

load

m m ×102N ×102N Nm Nm/rad N N

3 0.0077 0.0041 6.65 4.24 0.27 0.9×10236 130

Chapter 2 Installing of Motor

4

2-3 How to obtain the maximum load moment load

How to obtain the maximum load moment load is shown below. Check Mmax <=Mc.

●Formula (1)

Symbol of Formula (1)

Frmax

Maximum radial

load

N(kgf) See Figure 1.

Famax

Maximum axial

load

N(kgf) See Figure 1.

Lr ,La

――――

m

See Figure 1.

R Offset amount m

See Figure 1

and Table 1.

2-4 How to obtain the average load

(Average radial load, average axial load, average output rotational frequency)

If the radial load and the axial load fluctuate, they should be converted into the average load to check the

life of the 4-point contact bearing.

●Formula (2) How to obtain the average radial load (Frav)

Note that the maximum radial load within the t1 section is Fr1

and the maximum radial load within the t2 section is Fr2.

●Formula (3) How to obtain the average axial load (Faav)

Note that the maximum axial load within the t1 section is Fa1

and the maximum axial load within the t2 section is Fa2.

●Formula (4) How to obtain the average output rotational frequency (Nav)

Mmax=Frmax(Lr+R)+Famax・La

Figure 1External load influence diagram

n

n

nnn

av

tntntn

Fr(t

nFr(tnFr(tn

Fr

2211

222111

3

+++

+

=

+

333

)))

nn

nnn

av

tntntn

Fa(tnFa(tnFa(tn

Fr

2211

222111

3

+++

+

=

+

333

)))

n

nn

av

ttt

tntntn

N

21

2211

+++

+++

=

Axial load

output

rotational

frequency

Graph: Load pattern and output

rotational frequency

Radial load

Time

Time

Time

Fixed

Lr

R

L

L/2

F

R

La

dp

Radial load Fr

Axial load Fa

Chapter 2 Installing of Motor

5

2-5 How to obtain the radial load coefficient (X) and axial

load coefficient (Y)

●Formula (5) Table 2

X

Y

1.5

La)/dpFaR)

(Lr(Fr

Fr

Fa ≤

⋅++

+

avavav

av

2

1 0.45

1.5

La)/dp

FaR)(Lr(FrFr

Fa >

⋅

+++

avavav

av

2

0.67 0.67

Symbol of Formula (5)

Frav

Average radial load

N(kgf)

See “Average load.”

Faav

Average axial load

N(kgf)

See “Average load.”

Lr ,La

―

m

See Figure 1.

R

Offset amount

m

See Figure 1 and Table 1.

dp

Pitch circle diameter of a roller

m

See Figure 1 and Table 1.

2-6 How to obtain the life

Obtain the life of the 4-point contact bearing by Formula (6).

You can obtain the dynamic equivalent radial load (Pc) by Formula (7).

●Formula (6)

Symbols of Formula (6)

LB-10

Life

hour

Nav

Average output rotational speed

r/min

See “How to obtain the average load.”

C

Basic dynamic load rating

N(kgf)

See Table 1.

Pc

Dynamic equivalent radial load coefficient

N(kgf)

See Formula (7).

fw

Load coefficient

―

See Table 3.

Table 3 Load coefficient

Load status

fw

During smooth operation without shock or vibration

1

~

1.2

During normal operation

1.2

~

1.5

During operation with shock and vibration

1.5

~

3

●Formula (7)

Symbols of Formula (7)

Frav

Average radial load

N(kgf)

See “How to obtain the average load.”

Faav

Average axial load

N(kgf)

See “How to obtain the average load.”

dp

Pitch circle diameter of a roller

m

See Figure 1 and Table 1.

X

Radial load coefficient

See Table 2.

Y

Axial load coefficient

See Table 2.

Lr,La

m

See Figure 1.

R

Offset amount

m

See Figure 1 and Table 1.

)

Pc•fw

C

(×

N×

=

L

B

3

6

10

60

10

av

Fa•Y+)

dp

)La•Fa+)R+

Lr(Fr(

(•X=Pc av

avav2

Chapter 2 Installing of Motor

6

2-7 How to obtain the life under oscillating movement

Obtain the life of the bearing under oscillating movement by Formula (8).

●Formula (8)

Symbols of Formula (8)

Loc

Rated life under oscillating

movement

hour

n1

Number of reciprocating

oscillations per minute

cpm

C

Basic dynamic load rating

N(kgf)

See Table 1.

Pc

Dynamic equivalent radial

load coefficient

N(kgf) See Formula (7).

fw

Load coefficient

See Table 3.

θOscillating angle/2

Angl

e

See Figure 2.

2-8 How to obtain the static safety coefficient

In general, the basic static load rating (Co) is considered to be the permissible limit of the static

equivalent load. However, obtain the limit based on the operating and required conditions.

Obtain the static safety coefficient of the cross roller bearing by Formula (9). General values under the

operating condition are shown in Table 4. You can obtain the static equivalent radial load (Po) by

Formula (10).

●Formula (9)

Symbols of Formula (9)

Co

Basic static load rating

N(kgf)

See Table 1.

Po

Static equivalent radial load coefficient

N(kgf)

See Formula (10).

Table 4 Static safety coefficient

Operating condition of the roller bearing

fs

When high rotation precision is required

≧

3

When shock and vibration are expected

≧

2

Under normal operating condition

≧

1.5

●Formula (10)

Symbols of Formula (10)

Frmax

Maximum radial load

N(kgf)

See “How to obtain the maximum load moment

load”

Famax

Maximum axial load

N(kgf)

Mmax

Maximum load moment load

Nm(kgfm)

dp

Pitch circle diameter of a roller

m

See Figure 1 and Table 1.

)

Pc

•

fw

C

(×

θ

×

n×

=Loc

3

6

90

160

10

Po

Co

=fs

Fa.+

dp

M

+Fr=Po max

max

max 440

2

Figure 2 Oscillating movement

Oscillating angle

Chapter 3 Efficiency characteristics

- 7-

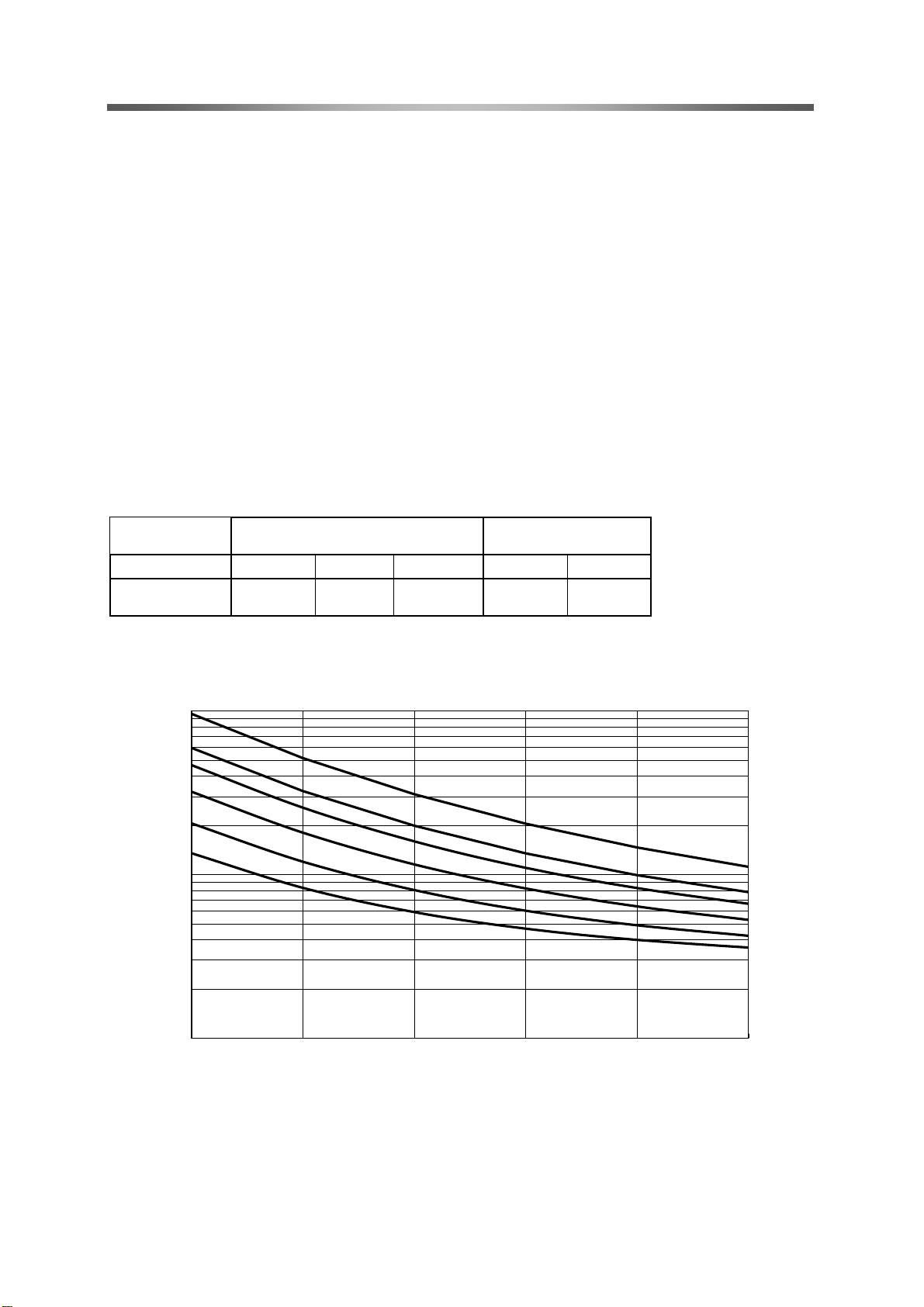

Chapter 3 Efficiency characteristics

The efficiency varies depending on the following conditions.

●Reduction ratio ●Input rotational speed ●Load torque

●Temperature ●Lubrication condition (type and quantity of lubricant)

●Measuring condition

Load torque

The rated torque shown in the ratings

(see the corresponding pages on each series)

Measuring

condition

Grease lubrication

Harmonic grease SK-2

Application quantity: Appropriate application quantity

3-1 Double-axial unit type (1U)

●Reduction ratio: 30

●Reduction ratio: 50

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

-10 010 20 30 40

温度 (℃)

効率(%)

500r/min

1000r/min

2000r/min

3500r/min

5000r/min

10000r/min

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

-10 010 20 30 40

温度 (℃)

効率(%)

500r/min

1000r/min

2000r/min

3500r/min

5000r/min

10000r/min

100

90

80

70

60

50

40

30

20

10

0

100

90

80

70

60

50

40

30

20

10

0

Efficiency(%)

Efficiency(%)

Temperature(°C)

Temperature(°C)

Chapter 3 Efficiency characteristics

- 8-

●Reduction ratio: 100

3-2 Gear head type (1U-CC)

●Reduction ratio: 30

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

-10 010 20 30 40

温度 (℃)

効率(%)

500r/min

1000r/min

2000r/min

3500r/min

5000r/min

10000r/min

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

-10 010 20 30 40

温度 (℃)

効率(%)

500r/min

1000r/min

2000r/min

3500r/min

5000r/min

10000r/min

100

90

80

70

60

50

40

30

20

10

0

100

90

80

70

60

50

4

0

30

20

10

0

Efficiency(%)

Temperature(°C)

Efficiency(%)

Temperature(°C)

Chapter 3 Efficiency characteristics

- 9-

●Reduction ratio: 50

●Reduction ratio: 100

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

-10 010 20 30 40

温度 (℃)

効率(%)

500r/min

1000r/min

2000r/min

3500r/min

5000r/min

10000r/min

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

-10 010 20 30 40

温度 (℃)

効率(%)

500r/min

1000r/min

2000r/min

3500r/min

5000r/min

10000r/min

100

90

80

70

60

50

40

30

20

10

0

100

90

80

70

60

50

40

30

20

10

0

Efficiency(%)

Temperature(°C)

Efficiency(%)

Temperature(°C)

Chapter 4 No-load running torque

- 10 -

Chapter 4 No-load running torque

No-load running torque means the torque required to put CSF-3 under a no-load condition.

* Please contact your Harmonic Drive sales representative for more details.

●Measuring condition

Model: CSF-3-100-1U-CC (Gear Head Type)

Reduction ratio: 100

Measuring condition: Grease lubrication (Harmonic grease SK-2)

The torque value is the value after a trial run of at two hours at an input of 2000 r/min.

●Correction amount by reduction ratio

No-load running torques of Harmonic Drive vary in accordance with the reduction ratio. The values in

Graph 1 below are the values for the gear head type (1U-CC, reduction ratio 1/100). Other reduction

ratios can be calculated by adding correction amounts shown in Table 1.

Table 1 Unit: cNm

Double-axial unit type

(1U) Gear head type

(1U-CC)

Reduction ratio 30 50 100 30 50

Correction

amount 0.026 0.023 0.006 0.020 0.017

Graph 1 No-load running torque of gear head type (1U-CC, reduction ratio 1/100)

0.01

0.10

1.00

-10 0 10 20 30 40

温度 (℃)

無負荷ランニングトルク(cNm)

10000r/min

5000r/min

3500r/min

2000r/min

1000r/min

500r/min

Temperature °C

No-load runnin

g

tor

q

ue cNm

Chapter 5 Starting torque and Overdrive starting torque

- 11 -

Chapter 5 Starting torque and Overdrive

starting torque

●Starting torque

Starting torque means the instantaneous “starting torque” that the output side (low-speed side) starts

rotation when a torque is applied on the input side (high-speed side)

Double axial unit type(1U) Unit: cNmGear head type(1U-CC) Unit: cNm

Reduction Ratio

Starting torque

Reduction Ratio

Starting torque

30

0.34

30

0.32

50

0.30

50

0.28

100

0.26

100

0.24

●Overdrive starting torque

Overdrive starting torque means the instantaneous “starting torque” that the input side (high-speed side)

starts rotation when a torque is applied on the output side (low-speed side)

Double axial unit type(1U) Unit: cNmGear head type(1U-CC) Unit: cNm

Reduction Ratio

Overdrive

starting torque

Reduction Ratio

Overdrive

starting torque

30

0.14

30

0.12

50

0.14

50

0.11

100

0.16

100

0.13

●Measuring condition

No-load, ambient temperature: +20ºC

* Use values on the following table as reference values as they vary depending on the usage conditions.

Chapter 6 Starting torque and Overdrive starting torque

- 12 -

Chapter 6 Ratcheting torque and

Buckling torque

●Ratcheting torque

When excess impact torque is applied during operation, the engagement of the teeth between the

circular saline and the flexspline may be put momentarily out of alignment instead of damaging the

flexspline.This phenomenon is called ratcheting, and the torque is called ratcheting torque (see values

on the corresponding page of each series).0peraling the drive withoutfixing ratcheting will result in

earlier abrasion of the teeth and shorter lifespan of the wave generator bearing due to the effect of the

grinding powder generated by ratcheting.

Unit:Nm

●Buckling torque

When excess torque is applied lo the flexspline (output) with the wave generator fixed, the flexspline

causes elastic deformation,buckles on the body before long and will be destroyed. The torque at

the time is called buckling torque.

Unit:Nm

All reduction ratio

Buckling torque

3.7

Reduction ratio

Ratcheting torque

30

0.88

50

0.83

100

0.74

Chapter 7Angle transmission accuracy

- 13-

Chapter 7Angle transmission accuracy

Angle transmission accuracy indicates the difference between the logical rotating angle and the actual

rotating angle as the angle transmission error when any rotating angle is given as an input.

Example of measurement

R

=er 1

2-θ

θθ

θer ……………Angle transmission error

θ1……………Input rotating angle

θ2……………Actual output rotating angle

R……………Reduction ratio of Harmonic Drive (i=1:R)

Angle transmission accuracy (Full speed ratio)

Unit

Angle transmission

accuracy (Full speed ratio)

×10-3rad 2.9

arc min 10

Chapter 8Vibration

14

Chapter 8Vibration

The angle transmission error elements of Harmonic Drive may appear as rotating vibration of the load

side inertia.

Especially when the characteristic frequency of the vibration system including Harmonic Drive overlaps

that of the chassis or load inertia, it generates a resonant condition that amplifies angle transmission

error elements of Harmonic Drive. Observe Chapter 9 Design and Precautions on assembly.

Two angle transmission error elements of Harmonic Drive correspond to a cycle of the input shaft from

the mechanical viewpoint ofHarmonic Drive. Therefore, the frequency is double the input frequency as it

is the main element of the error.

If the characteristic frequency of the vibration system including Harmonic Drive is F=15 Hz, the input

rotating speed (N) is expressed as shown below.

N =15/2・60 = 450r/min

The resonant condition is generated in the rotating speed area (450 r/min).

●How to obtain the characteristic frequency of the vibration system including Harmonic Drive

J

K

•=f π

2

1

Symbol of the calculation formula

fThe characteristic frequency of the vibration system including Harmonic Drive : Hz

KSpring constant of Harmonic Drive: Nm/rad

JLoad inertia: kg・m2

Chapter 9 Rigidity

15

Chapter 9 Rigidity

Rigidity and backlash of the drive system greatly affects the performance of the servo system. A detailed

review of these items is required before designing the equipment and selecting a model number.

Rigidity

Fixing the input side (wave generator) and applying torque to the

output side (flexspline) generates torsion almost proportional to

the torque on the output side. Figure O18-1 shows the torsional

angle quantity on the output side when the torque applied on the

output side starts from zero, increases up to +T0 and decreases

down to –T0. This is called the “Torque – torsional angle diagram,”

which normally draws a loop of 0-A-B-A’-B’-A. The slope described

in the “Torque – torsional angle diagram” is represented as the

spring constant for the rigidity of Harmonic Drive (unit: Nm/rad).

As shown in Figure 020-2, this “Torque – torsional angle diagram”

is divided into 3 partitions, and the spring constants in the area are

represented as K1, K2 and K3.

K1 – The spring constant when the torque changes from [zero] to

[T1]

K2 – The spring constant when the torque changes from [T1] to

[T2]

K3 – The spring constant when the torque changes from [T2] to

[T3]

Torsional angle can be calculated by the following formulas.

* φ: torsional angle

◆Torque T is T1 or less:

◆Torque T is between T1 and T2:

◆Torque T is between T2 and T3:

The following table shows average values of T1 to T3, K1 to K3 and θ1 to θ2.

Spring constant

Model

No.

Sign

Unit

Reduction

ratio 30

Reduction

ratio 50

Reduction

ratio 100

3

T1

Nm

0.016

0.016

0.016

kgf m

0.0016

0.0016

0.0016

K1

Nm/rad

27

30

34

×10-4kgf m/arc min

8

9

10

θ1

×10-4rad

5.9

5.3

4.7

arc min

2.0

1.8

1.6

T2

Nm

0.05

0.05

0.05

kgf m

0.005

0.005

0.005

K2

Nm/rad

40

47

54

×10-4kgf m/arc min

12

14

16

θ2

×10-4rad

12.5

10.6

9.3

arc min

4.2

3.6

3.1

K3

Nm/rad

51

57

67

×10-4kgf m/arc min

15

17

20

3

2

2K

TT −

+θ

=ϕ

2

1

1K

TT −

+

θ=ϕ

1K

T

=ϕ

Figure 1

ね

じ

り

角

ヒステリシスロス

トルク

0

B’

B

A

+T0

-T0

A’

ね

じ

り

角

K3

K2

K1

T1

T2

トルク

0

θ1

θ2

Torsional angle

Torsional angle

Torque

Torque

Hysteresis

loss

Chapter 9 Rigidity

16

Hysteresis loss

As shown in Figure 020-1, when the torque is applied up to the rated value and is brought back to [zero],

the torsional angle does not become absolutely [zero] and a small amount remains. This is called

hysteresis loss.

Hysteresis amount

Reduction

ratio

Unit

Hysteresis amount

30

×10

-4

rad

1.3

arc min

4.5

50

×10

-4

rad

1.2

arc min

4

100

×10

-4

rad

1.2

arc min

4

Backlash

CSF-3 wave generators are of the rigid type (solid type) and are backlash free.

Table of contents

Other Harmonic Drive Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs PGV100RS-F200-B16-1,5M manual

Siemens

Siemens SINUMERIK ONE NCU 1760 Equipment manual

Doosan

Doosan 7/124 Operation & maintenance manual

MoldMaker

MoldMaker MMC-11 user manual

Global Industrial

Global Industrial B237006 Assembly instructions

M-system

M-system M8DY1 instruction manual

FRANKLINWH

FRANKLINWH aPbox Installation and operation manual

Siemens

Siemens SIMATIC NET RUGGEDCOM RX1500 installation manual

ITW Dynatec

ITW Dynatec DYNAMINI 4-HOSE Technical documentation

CBE

CBE PT642 user manual

DOYMA

DOYMA Curaflex Nova Uno/M/Z installation instructions

Martin

Martin PIT VIPER installation instructions