Harmonic Drive CSD-2A Component Sets Dimension Guide

11019659 11/2014

QUICKLINK

www.harmonicdrive.de/3060

Engineering Data

CSD-2A Component Sets

21019659 11/2014

Contents

1. General ....................................................................................................................................................03

1.1 Description of Safety Alert Symbols ......................................................................................................................................04

1.2 Disclaimer and Copyright ........................................................................................................................................................04

2. Safety and Installation Instructions......................................................................................................05

2.1 Hazards ....................................................................................................................................................................................05

2.2 Intended Purpose ....................................................................................................................................................................06

2.3 Non Intended Purpose.............................................................................................................................................................06

2.4 Declaration of Conformity....................................................................................................................................................... 07

3. Technical Description..............................................................................................................................08

3.1 Product Description .................................................................................................................................................................08

3.2 Ordering Code ..........................................................................................................................................................................09

3.3 Technical Data...........................................................................................................................................................................10

3.3.1 General Technical Data..................................................................................................................................................10

3.3.2 Dimensions.....................................................................................................................................................................11

3.3.3 Minimum Housing Clearance........................................................................................................................................14

3.3.4 Accuracy.........................................................................................................................................................................14

3.3.5 Torsional Stiness ........................................................................................................................................................14

4. Actuator Selection Procedure.................................................................................................................15

4.1 Selecting Harmonic Drive® Gears............................................................................................................................................. 17

4.1.1 Torque Based Dimensioning.........................................................................................................................................18

4.1.2 Life of the Wave Generator Bearing............................................................................................................................ 20

4.1.3 Stiness Based Dimensioning.....................................................................................................................................21

4.2 Calculation of the Torsion Angle............................................................................................................................................. 23

4.3 Eciency Versus Load ............................................................................................................................................................ 24

4.3.1 Eciency Calculations................................................................................................................................................. 24

4.3.2 Eciency Tables........................................................................................................................................................... 25

4.4 Free Load Torques ................................................................................................................................................................... 26

4.4.1 No Load Running Torque ............................................................................................................................................. 26

4.4.2 No Load Starting Torque...............................................................................................................................................27

4.4.3 No Load Back Driving Torque........................................................................................................................................27

4.5 Lubrication ............................................................................................................................................................................... 28

4.5.1 Grease Lubrication ....................................................................................................................................................... 28

4.5.2 Oil Lubrication ..............................................................................................................................................................30

4.6 Axial Forces at the Wave Generator........................................................................................................................................ 31

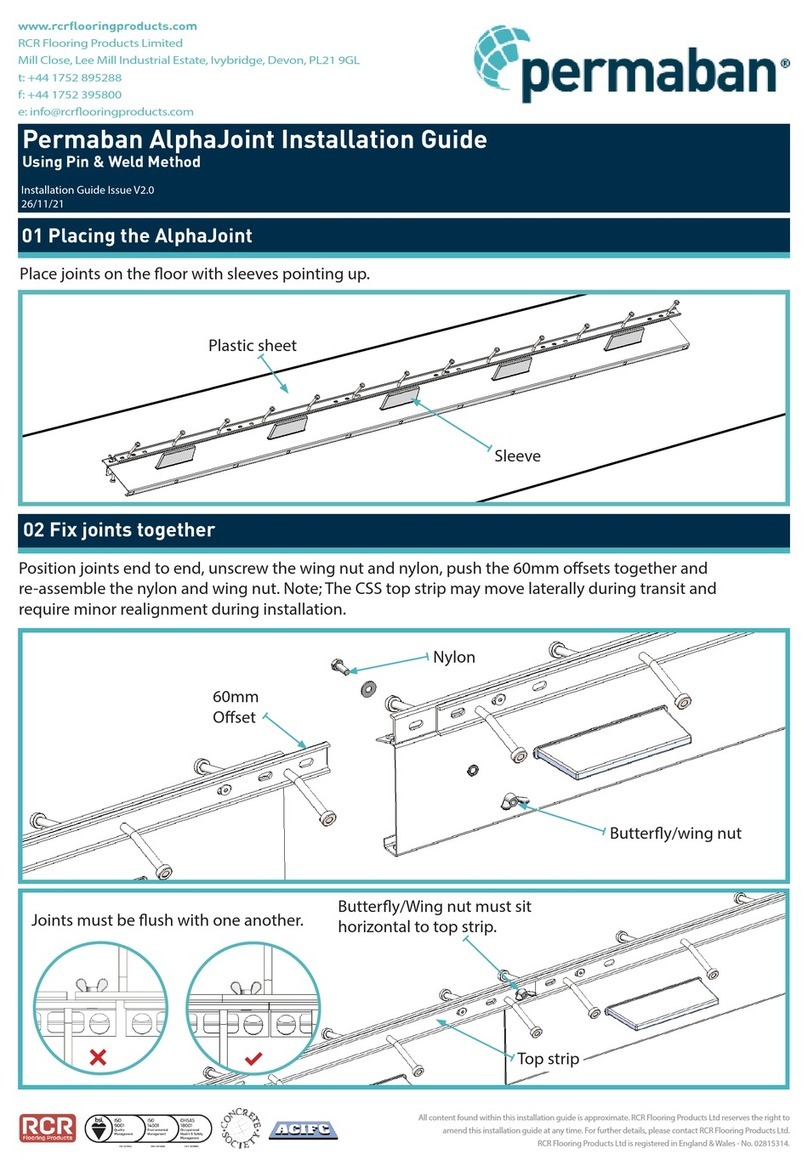

5. Installation and Operation..................................................................................................................... 32

5.1 Transportation and Storage .................................................................................................................................................... 32

5.2 Gear Conditions at Delivery..................................................................................................................................................... 32

5.3 Assembly Instructions............................................................................................................................................................. 33

5.4 Recommended Tolerances for Assembly ................................................................................................................................37

5.5 Lubrication ............................................................................................................................................................................... 38

5.5.1 Grease Lubrication .......................................................................................................................................................38

5.5.2 Grease Reservoir ..........................................................................................................................................................40

5.5.3 Grease Change..............................................................................................................................................................40

5.5.4 Oil Lubrication ...............................................................................................................................................................41

5.6 Preparation .............................................................................................................................................................................. 42

5.7 Assembly.................................................................................................................................................................................. 43

5.7.1 Assembly of the Circular Spline (CS)........................................................................................................................... 43

5.7.2 Assembly of the Flexspline (FS)..................................................................................................................................44

5.7.3 Assembly of the Wave Generator (WG) to the Input Shaft ...................................................................................... 45

5.7.4 Check before Assembly of the Wave Generator......................................................................................................... 45

5.7.5 Assembly of the Wave Generator (WG) into the Flexspline (FS) .............................................................................. 45

5.7.6 Assembly Control......................................................................................................................................................... 45

31019659 11/2014

1. General

About this documentation

This document contains safety instructions, technical data and operation rules for servo actuators and servo motors of

Harmonic Drive AG.

The documentation is aimed at planners, project engineers, commissioning engineers and machine manufacturers, oering

support during selection and calculation of the servo actuators, servo motors and accessories.

Rules for storage

Please keep this document for the entire life of the product, up to its disposal. Please hand over the documentation when

re-selling the product.

Additional documentation

For the configuration of drive systems using the products of Harmonic Drive AG, you may require additional documents.

Documentation is provided for all products oered by Harmonic Drive AG and can be found in pdf format on the website.

www.harmonicdrive.de

Third-party systems

Documentation for parts supplied by third party suppliers, associated with Harmonic Drive® components, is not included in

our standard documentation and should be requested directly from the manufacturers.

Before commissioning servo actuators and servo motors from Harmonic Drive AG with servo drives, we advise you to obtain

the relevant documents for each device.

Your feedback

Your experiences are important to us. Please send suggestions and comments about the products and documentation to:

Harmonic Drive AG

Marketing and Communications

Hoenbergstraße 14

65555 Limburg / Lahn

Germany

E-Mail: info@harmonicdrive.de

6. Glossary...................................................................................................................................................46

6.1 Technical Data..........................................................................................................................................................................46

6.2 Labelling, Guidelines and Regulations ................................................................................................................................... 52

41019659 11/2014

1.1 Description of Safety Alert Symbols

Symbol Meaning

Indicates an imminent hazardous situation. If this is not avoided, death or

serious injury could occur.

Indicates a possible hazard. Care should be taken or death or serious injury

may result.

Indicates a possible hazard. Care should be taken or slight or minor injury

may result.

Describes a possibly harmful situation. Care should be taken to avoid damage

to the system and surroundings.

This is not a safety symbol. This symbol indicates important information.

Warning of a general hazard. The type of hazard is determined by the

specific warning text.

Warning of dangerous electrical voltage and its eects.

Beware of hot surfaces.

Beware of suspended loads.

Precautions when handling electrostatic sensitive components.

1.2 Disclaimer and Copyright

The contents, images and graphics contained in this document are protected by copyright. In addition to the copyright, logos,

fonts, company and product names can also be protected by brand law or trademark law. The use of text, extracts or graphics

requires the permission of the publisher or rights holder.

We have checked the contents of this document. Since errors cannot be ruled out entirely, we do not accept liability for mis-

takes which may have occurred. Notification of any mistake or suggestions for improvements will be gratefully received and

any necessary correction will be included in subsequent editions.

DANGER

WARNING

ATTENTION

INFORMATION

ADVICE

51019659 11/2014

2. Safety and Installation Instructions

Please take note of the information and instructions in this document. Specialy designed models may dier in technical

detail. If in doubt, we strong recommend that you contact the manufacturer, giving the type designation and serial number

for clarification.

2.1 Hazards

Electric products have dangerous live and redating parts. All work during connection, operation, repair and disposal must

be carried out by qualified personnel as described in the standards EN50110-1 and IEC 60364! Before starting any work, and

especially before opening covers, the actuator must be properly isolated. In addition to the main circuits, the user also has to

pay attention to any auxilliary circuits.

Observing the five safety rules:

• Disconnect mains

• Prevent reconnection

• Test for absence of harmful voltages

• Ground and short circuit

• Cover or close o nearby live parts

The measures taken above must only be withdrawn when the work has been completed and the device is fully assembled.

Improper handling can cause damage to persons and property. The respective national, local and factory specific regulations

must be adhered to.

Electric, magnetic and electromagnetic fields are dangerous, in particular for persons with pacemakers, implants or similiar.

Vulnerable groups must not be in the immediate vicinity of the products themselves.

Built-in holding brakes alone are not functional safe. Particularly with unsupported vertical axes, the functional safety and

security can only be achieved with additional, external mechanical brakes.

The successful and safe operation of gears, products requires proper transport, storage and assembly as well as correct

operation and maintenance.

The surface temperature of gears, motors and actuators can exceed 55 degrees Celsius. The hot surfaces should not be touched.

DANGER

DANGER

DANGER

ATTENTION

WARNING

61019659 11/2014

2.2 Intended Purpose

The Harmonic Drive® products are intended for industrial or commercial applications. They comply with the relevant parts of

the harmonised EN 60034 standards series.

Typical areas of application are robotics and handling, machine tools, packaging and food machines and similar machines.

The products may only be operated within the operating ranges and environmental conditions shown in the documentation

(altitude, degree of predection, temperature range etc).

Before plant and machinery which have Harmonic Drive® products built into them are commissioned, the compliance must be

established with the Machinery Directive, Low Voltage Directive and EMC guidelines.

Plant and machinery with inverter driven motors must satisfy the predection requirements in the EMC guidelines. It is the

responsibility of the installer to ensure that installation is undertaken correctly.

Signal and power lines must be shielded. The EMC instructions from the inverter manufacturer must be observed in order

that installation meets the EMC regulations.

2.3 Non Intended Purpose

The use of products outside the areas of application mentioned above or, inter alia, other than in the operating areas

or environmental conditions described in the documentation is considered as non-intended purpose.

The following areas of application are, inter alia, those considered as non-intended purpose:

• Aerospace

• Areas at risk of explosion

• Machines specially constructed or used for a nuclear purpose whose breakdown might lead to the emission of radio-activity

• Vacuum

• Machines for domestic use

• Medical equipment which comes into direct contact with the human body

• Machines or equipment for transporting or lifting people

• Special devices for use in annual markets or leisure parks

Movement and lifting of products with a mass > 20 Kg should only be carried out with suitable lifting gear.

Cables must not come into direct contact with hot surfaces.

Special versions of drive systems and motors may have diering specifications. Please consider all data sheet, catalogues and

oers etc. sent concerning these special versions.

ADVICE

ADVICE

ADVICE

INFORMATION

71019659 11/2014

2.4 Declaration of Conformity

Harmonic Drive® gears are components for installation in machines as defined by the machine directive 89/392/EWG.

Commissioning is prohibited until such time as the end product has been proved to conform to the provisions of this directive.

Essential health and safety requirements were considered in the design and manufacture of these gear component sets.

This simplifies the implementation of the machinery directive by the end user for the machinery or the partly completed

machinery. Commissioning of the machine or partly completed machine is prohibited until the final product conforms to

the EC Machinery Directive.

81019659 11/2014

CSD-2A Series Component Sets are available in seven sizes with gear ratios of 50, 100 and 160:1 oering repeatable peak

torques from 12 to 823 Nm and a power density of up to 512 Nm/kg.

If required, the Component Sets are available as specific configurations tailoredto your application. Consisting of just three

individual components, they are very lightweight and the series with the shortest axial length. The hollow shaft can be used

to feed through supply lines, shafts or cables for further axes. Due to their positioning accuracy, stable machine properties

with short cycle times are guaranteed.

3. Technical Description

3.1 Product Description

The short series

91019659 11/2014

3.2 Ordering Code

Explanation of the technical data can be found in the Glossary.

Table 9.1

Table 9.2 Table 9.3

Series Size Ratio 1) Version Flexsplinetype Special design

CSD

14 50 100

2A-R

According to

customer requirements

17 50 100

20 50 100 160

2A-GR

-

BB

25 50 100 160

32 50 100 160

40 50 100 160

50 50 100 160

Ordering code

CSD 25 100 2A-GR BB SP

- --- -

Flexsplinetype

Ordering code Description

- Standard

BB Flexspline with enlarged bore

Version

Ordering code Description

2A-R Component Set

2A-GR

1) The ratios shown here are for a standard driving configuration with the circular spline fixed, the Wave Generator used for the input and the Flexspline attached to the output.

Other configurations are possible. Please consult the chapter 4 “Ratio”.

10 1019659 11/2014

3.3 Technical Data

3.3.1 General Technical Data

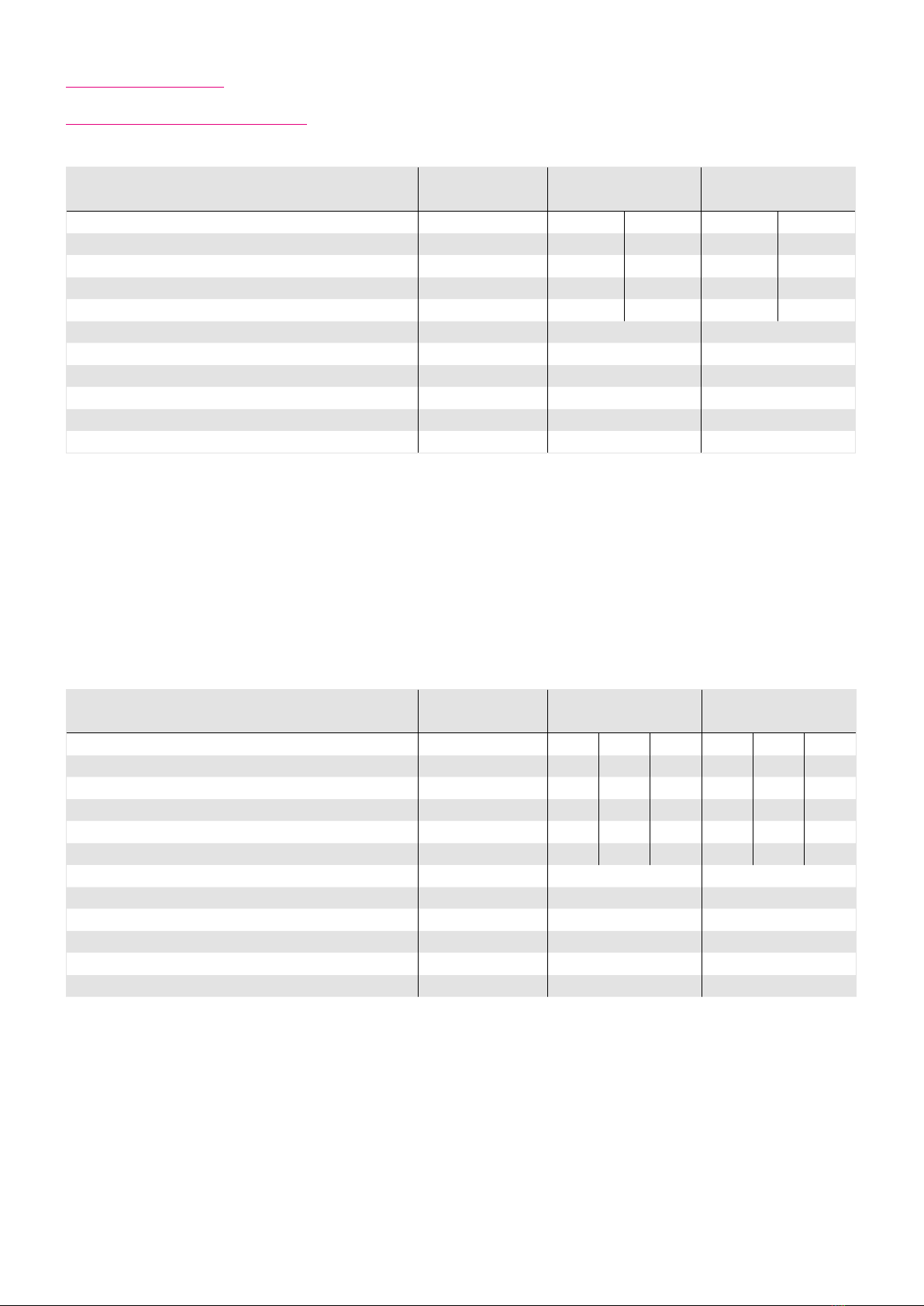

Table 10.1

Unit CSD-14-2A CSD-17-2A

Ratio i [ ] 50 100 50 100

Repeatable peak torque TR[Nm] 12 19 23 37

Average torque TA [Nm] 4.8 7.7 18 27

Rated torque TN[Nm] 3.7 5.4 11 16

Momentary peak torque TM[Nm] 24 31 48 55

Maximum input speed (oil lubrication) nin (max) [rpm] 14000 10000

Maximum input speed (grease lubrication) nin (max) [rpm] 8500 7300

Average input speed (oil lubrication) nav (max) [rpm] 6500 6500

Average input speed (grease lubrication) nav (max) [rpm] 3500 3500

Moment of inertia Jin [x10-4 kgm²] 0.021 0.054

Weight m [kg] 0.06 0.1

Table 10.2

Unit CSD-20-2A CSD-25-2A

Ratio i [ ] 50 100 160 50 100 160

Repeatable peak torque TR[Nm] 39 57 64 69 110 123

Average torque TA [Nm] 24 34 34 38 75 75

Rated torque TN[Nm] 17 28 28 27 47 47

Momentary peak torque standard TM[Nm] 69 76 76 127 152 152

Momentary peak torque with enlarged Flexspline bore (BB) TM[Nm] 64 64 64 127 135 135

Maximum input speed (oil lubrication) nin (max) [rpm] 10000 7500

Maximum input speed (grease lubrication) nin (max) [rpm] 6500 5600

Average input speed (oil lubrication) nav (max) [rpm] 6500 5600

Average input speed (grease lubrication) nav (max) [rpm] 3500 3500

Moment of inertia Jin [x10-4 kgm²] 0.090 0.282

Weight m [kg] 0.13 0.24

111019659 11/2014

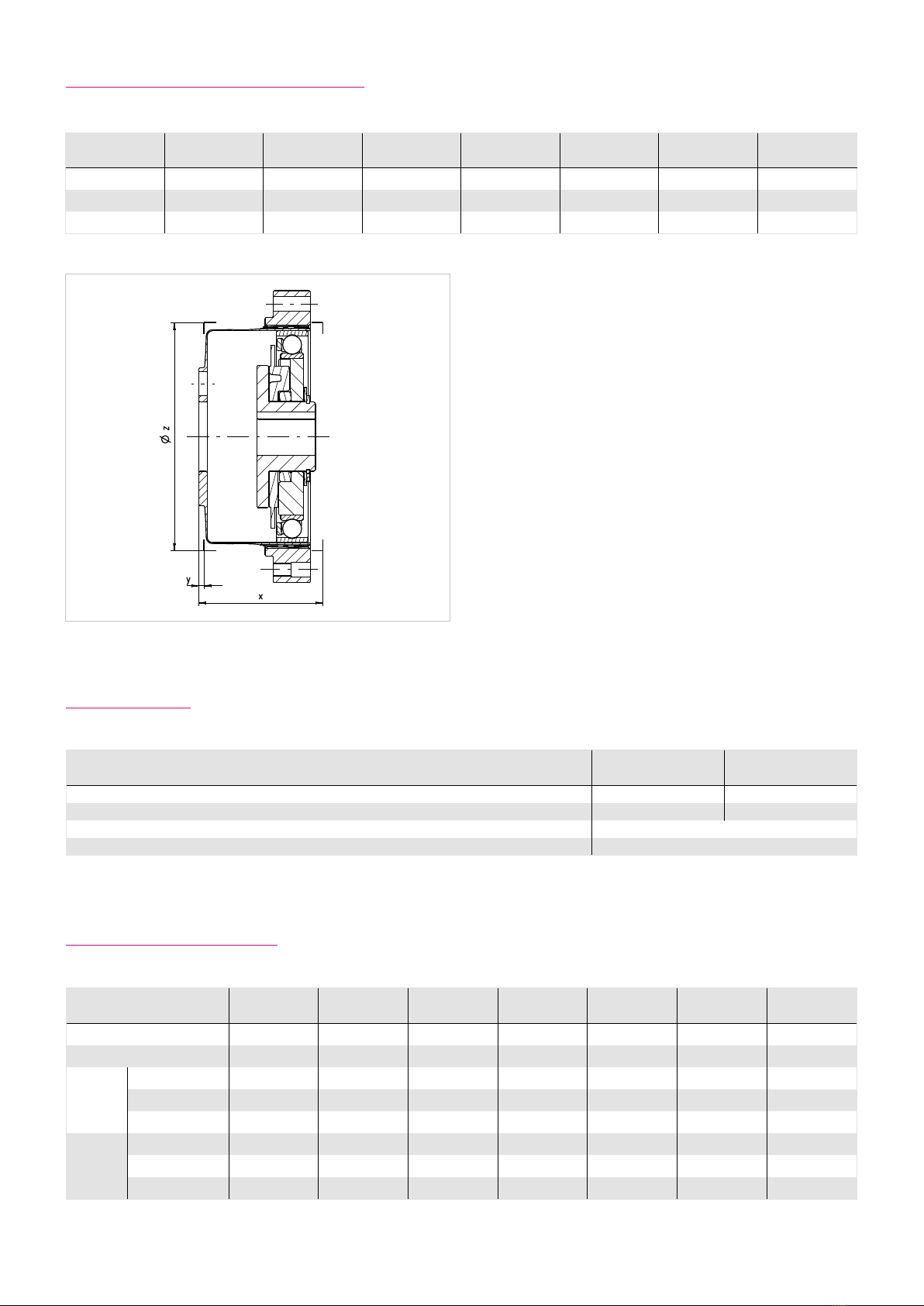

3.3.2 Dimensions

Illustration 11.1 Illustration 11.2[mm] [mm]

CSD-14-2A CSD-17-2A

Illustration 11.3 Illustration 11.4

[mm] [mm]

CSD-20-2A CSD-25-2A

QUICKLINK

www.harmonicdrive.de/CAD3060

12 1019659 11/2014

Table 12.1

Unit CSD-32-2A CSD-40-2A

Ratio i [ ] 50 100 160 50 100 160

Repeatable peak torque TR[Nm] 151 233 261 281 398 453

Average torque TA [Nm] 75 151 151 137 260 316

Rated torque TN[Nm] 53 96 96 96 185 206

Momentary peak torque standard TM[Nm] 268 359 359 480 696 696

Momentary peak torque with enlarged Flexspline bore (BB) TM[Nm] 268 331 331 480 578 578

Maximum input speed (oil lubrication) nin (max) [rpm] 7000 5600

Maximum input speed (grease lubrication) nin (max) [rpm] 4800 4000

Average input speed (oil lubrication) nav (max) [rpm] 4600 3600

Average input speed (grease lubrication) nav (max) [rpm] 3500 3000

Moment of inertia Jin [x10-4 kgm²] 1.09 2.85

Weight m [kg] 0.51 0.92

Table 12.2

Unit CSD-50-2A

Ratio i [ ] 50 100 160

Repeatable peak torque TR[Nm] 500 868 823

Average torque TA[Nm] 247 466 590

Rated torque TN[Nm] 172 329 370

Momentary peak torque standard TM[Nm] 1000 1440 1560

Momentary peak torque with enlarged Flexspline bore (BB) TM[Nm] 1000 1320 1320

Maximum input speed (oil lubrication) nin (max) [rpm] 4500

Maximum input speed (grease lubrication) nin (max) [rpm] 3500

Average input speed (oil lubrication) nav (max) [rpm] 3000

Average input speed (grease lubrication) nav (max) [rpm] 2500

Moment of inertia Jin [x10-4 kgm²] 8.61

Weight m [kg] 1.9

131019659 11/2014

Illustration 13.3 [mm]

CSD-50-2A

Illustration 13.1 Illustration 13.2[mm] [mm]

CSD-32-2A CSD-40-2A

QUICKLINK

www.harmonicdrive.de/CAD3060

14 1019659 11/2014

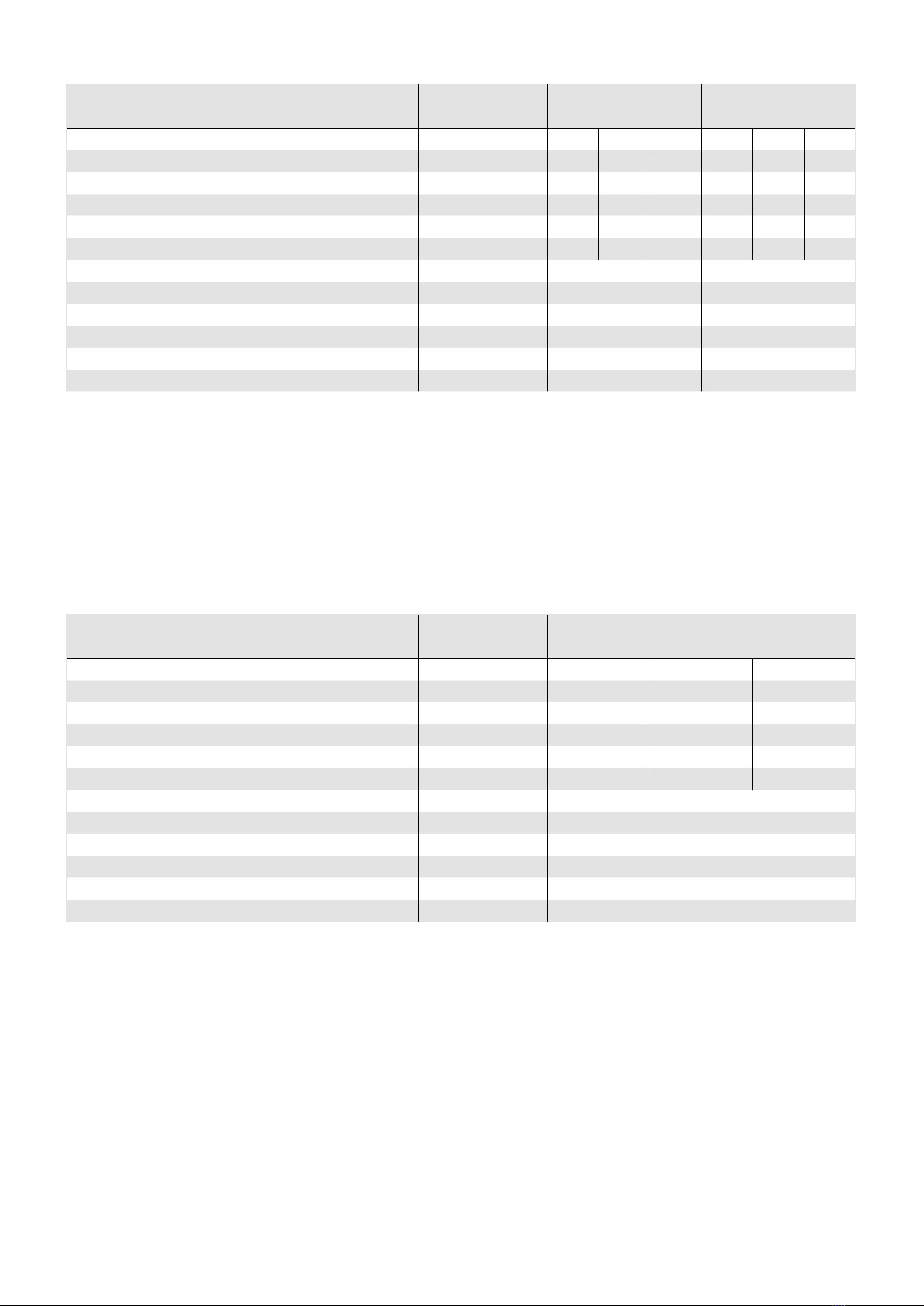

3.3.3 Minimum Housing Clearance

3.3.5 Torsional Stiness

3.3.4 Accuracy

Table 14.3

Table 14.1

Size 14. 17 ≥ 20

Transmission accuracy < 1.5 < 1

Hysteresis loss < 2 < 2

Lost Motion < 1

Repeatability < ±0.1

Table 14.4

Size 14 17 20 25 32 40 50

x 12 13.5 15.5 18.5 24 29.5 36.5

y 0000000

Øz 38 45 53 66 86 106 133

[mm]

Illustration 14.2

Size 14 17 20 25 32 40 50

T1[Nm] 2.0 3.9 7.0 14 29 54 108

T2[Nm] 6.9 12 25 48 108 196 196

i = 50

K3[x103Nm/rad] 5.7 13 23 44 98 180 540

K2[x103Nm/rad] 4.7 11 18 34 78 140 440

K1[x103Nm/rad] 3.4 8.1 13 25 54 100 310

i > 50

K3[x103Nm/rad] 7.1 16 29 57 12 230 710

K2[x103Nm/rad] 6.1 14 25 50 11 200 610

K1[x103Nm/rad] 4.7 10 16 31 67 130 400

151019659 11/2014

4. Actuator Selection Procedure

A variety of dierent driving arrangements is possible with Harmonic Drive® gears.

Overview Harmonic Drive® Products

The three main components of the Harmonic Drive® units, Circular Spline (CS), Flexspline (FS) and Wave Generator (WG) can

be seen in the illustration 15.2.

Ratio i = Input speed

Output speed

Equation 15.1

Illustration 15.2

The values for ratios of Harmonic Drive® gears refer to the standard input and output arrangement (example 1 in the

table below). Other arrangements are possible, and also shown in the table.

16 1019659 11/2014

FS WG

CS

Ratio = -

Reduction gearing

CS Fixed

WG Input

FS Output

Reduction gearing

FS Fixed

WG Input

CS Output

Reduction gearing

WG Fixed

FS Input

CS Output

Dierential gear

WG Control input

CS Main drive input

FS Main drive output

Numerous dierential functions can be obtained by combinations of the speed and rotational direction of the three basic elements.

Please refer to our broshure “Dierential Applications” available to download from our website.

Input and output rotate in opposite directions. Input and output rotate in same direction. Input and output rotate in same direction.

Equation 16.1

Equation 16.4

1) 2) 3)

Equation 16.2

Equation 16.5

Equation 16.3

Equation 16.6

Speed increaser gearing

WG Fixed

CS Input

FS Output

Speed increaser gearing

CS Fixed

FS Input

WG Output

Speed increaser gearing

FS Fixed

CS Input

WG Output

Input and output rotate in same direction. Input and output rotate in opposite directions. Input and output rotate in same direction.

4) 5) 6)

7)

Ratio

i

1Ratio = i+1

1Ratio= i +1

1

Ratio = i

i+1 Ratio = -1

i Ratio = 1

i+1

171019659 11/2014

4.1 Selecting Harmonic Drive® Gears

When choosing a gear, you should take into account both torque as well as stiness requirements. In robot applications, for

example, the necessary torque is the more crucial factor for the gear size, while the process related torsional stiness is often

decisive in machine tool manufacture. We therefore recommend that you always take both criteria into account according to the

following procedures.

Gear preselection

Application

Gear size sucient?

Gear size

sucient?

Selection of

a bigger size

Yes

Yes

No

No

Selection of

a bigger size

End of gear selection

Torque based dimensioning

according to selection procedure

on page 18

Stiness based dimensioning

according to selection procedure

on page

21

18 1019659 11/2014

4.1.1 Torque Based Dimensioning

Output Data

Time

n1

n2

t2

T2

t3

np

tpt1

T1

n1

n3

t1

T1

Torque Speed

T3

Time

Torques T1...Tn[Nm]

during the load phases t1...tn[s]

during the pause time tp[s]

and output speeds n1...nn[rpm]

Emergency stop/

momentary peak torque Tk[Nm]

at output speed nk[rpm]

and duration tk[s]

Equation 18.2

Illustration 18.1

Permissible maximum input speed

nin max = nout max · i ≤Maximum input speed (see Technical Data)

Load limit 2, TR

Tmax ≤ TR

Operating life

L50 = Ln*· Rated input speed ·(Rated torque TN)3

nin av Tav

nout av =

|n1|· t1+ |n2|· t2+ ... + |nn|· tn

t1+ t2+ ... + tn+ tp

Equation 18.4

Equation 18.6

Equation 18.8

Equation 18.11

Equation 18.9 Equation 18.10

Equation 18.5

Equation 18.7

Selection of a bigger size

No

Equation 18.3

Load limit 3, TM

Tk≤ TM

Allowable number of momentary peak torques

Nk max = 104

2· nk ·i·tk

60

Permissible average input speed

nin av ≤ Limit for average input speed

(see Technical Data)

Values for TA see Technical Data

Tav ≤ TA

Calculation of the average output speed

Load limit 1,

Calculation of the Average Output Torque Tav

3 |n1· T13| · t1+|n2· T23| · t2+ ... + |nn· Tn3 |· tn

|n1| · t1+|n2|·t2+ ... + |nn|· tn

Tav =

Average input speed

nin av = i · nout av

< 104

Values for Lnsee table 20.1

191019659 11/2014

Output Data

T1= 400 Nm t1= 0.3 s n1= 7 rpm

T2= 320 Nm t2= 3.0 s n2= 14 rpm

T3= 200 Nm t3= 0.4 s n3= 7 rpm

Tk=500 Nm tk= 0.15 s nk=14 rpm

tp= 0.2 s np=0 rpm

Ratio i = 120

Operating life L50 = 30000 h (required)

Load limit 1,

calculation of the average output torque Tav

Tav = 319 Nm ≤TA= 451 Nm Selected size

HFUC-40-120-2A-GR

Calculation of the average output speed

Average input speed

nin av = 120 · 12.0 rpm = 1440 rpm

nout av =7rpm · 0.3 s + 14 rpm · 3 s + 7 rpm · 0.4 s =12.0 rpm

0.3 s + 3 s + 0.4 s + 0.2 s

Permissible maximum input speed

nin max = 14 rpm · 120 = 1680 rpm ≤4000 rpm

Permissible average input speed

nin av = 1440 rpm ≤3000 rpm

Load limit 2, TRLoad limit 3, TM

Allowable number of

momentary peak torques

Tmax = 400 Nm ≤TR= 617 Nm Tk= 500 Nm ≤TM= 1180 Nm

104

14 · 120

2 · 60 · 0.15

Operating life

HFUC-40-120-2A-GR: L50 = 35000 h · 2000 rpm ·(294 Nm )3

1440 rpm 319 Nm L50 = 38054 h > 30000 h

3 7 rpm · (400 Nm)3 · 0.3 s + 14 rpm · (320 Nm)3 ·3 s + 7 rpm · (200 Nm)3 · 0.4 s

7 rpm · 0.3 s + 14 rpm · 3 s + 7 rpm · 0.4 s

Tav =

Nk max = = 1190 < 104

20 1019659 11/2014

Harmonic Drive® series Ln

CobaltLine, CSG, SHG 50000

HFUC, HFUS, CSD, CPU, CSF, SHD 35000

PMG gearbox 15000

[h]

L50 = Ln

nN

nin av

TN

Tav

( )3

L10 ≈1

–

5•L50

nN= Rated input speed [rpm]

nin av = Average input speed [rpm] (Equation 18.5)

TN= Rated output torque at rated speed [Nm]

Tav = Average output torque [Nm] (Equation 18.2)

Ln= See table 20.1

4.1.2 Life of the Wave Generator Bearing

Given that the Harmonic Drive® Gear is rated to provide infinite fatigue life for the Flexspline, the life expectancy is based on

the average life of the Wave Generator bearing. The rated torque at the rated speed given in the rating table is based on the

mean L50 bearing life.

The life expectancy of a component set or an unit operating at an input speed n (rpm) and output torque T (Nm) may be

estimated from equation 20.2.

Table 20.1

Equation 20.2

Equation 20.3

This manual suits for next models

7

Table of contents

Other Harmonic Drive Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

schmersal

schmersal AZM300Z-ST-1P2P-N-DU instructions

Holmatro

Holmatro GRA4321 manual

MR

MR ECOTAP VPD I operating instructions

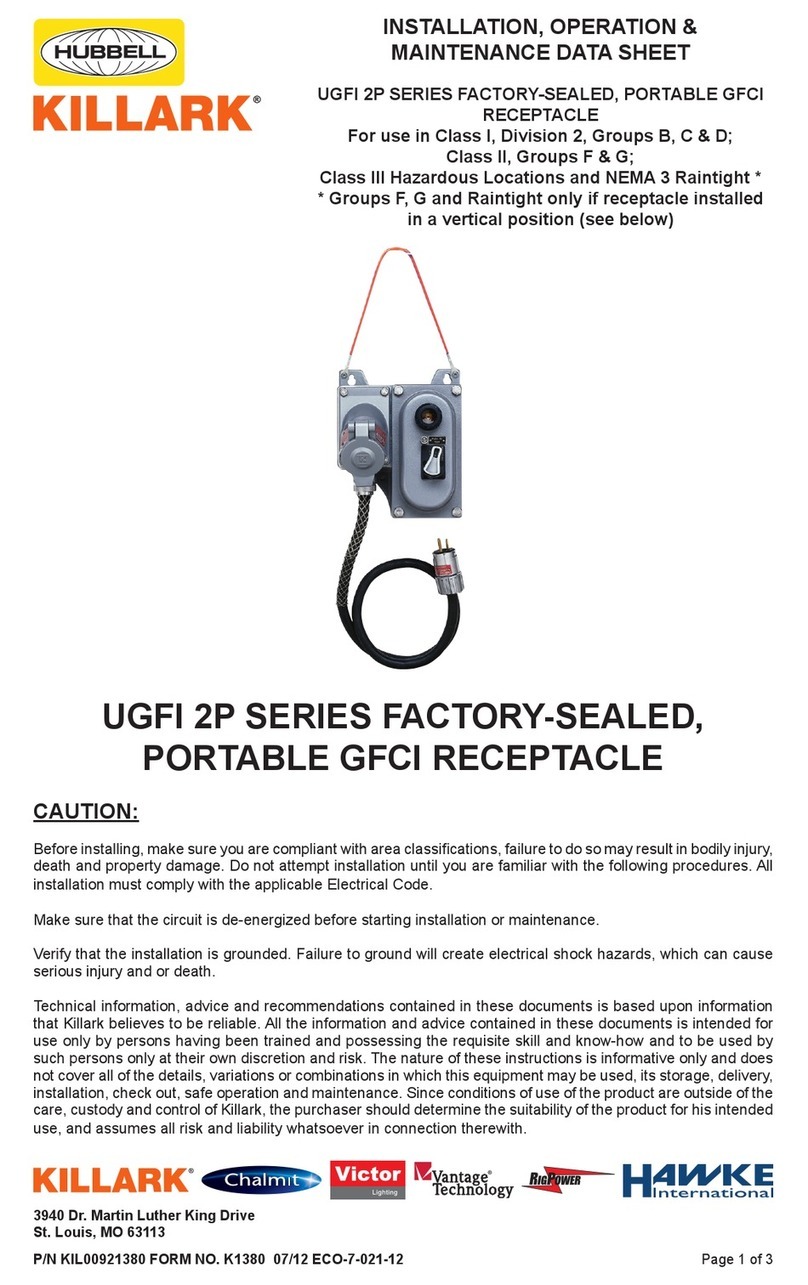

Hubbell

Hubbell KILLARK UGFI 2P Series INSTALLATION, OPERATION & MAINTENANCE DATA SHEET

Eaton

Eaton COOPER POWER SERIES installation instructions

Geovent

Geovent PRS instruction manual