Harmonic Drive SHG Series User manual

21021387 12/2018 V02

Contents

1. General .................................................................................................................................................. 4

1.1 Description of Safety Alert Symbols....................................................................................................................................5

1.2 Disclaimer and Copyright ......................................................................................................................................................5

2. Safety and Installation Instructions.................................................................................................... 6

2.1 Hazards ..................................................................................................................................................................................6

2.2 Intended Purpose ..................................................................................................................................................................7

2.3 Non Intended Purpose ..........................................................................................................................................................7

2.4 Use in Special Application Areas ......................................................................................................................................... 8

2.5 Declaration of Conformity.................................................................................................................................................... 8

2.5.1 Gears.......................................................................................................................................................................... 8

2.5.2 Servo Actuators and Motors.................................................................................................................................... 8

3. Technical Description............................................................................................................................ 9

3.1 Product Description...............................................................................................................................................................9

3.2 Ordering Code ...................................................................................................................................................................... 10

3.3 Technical Data.......................................................................................................................................................................11

3.3.1 General Technical Data .............................................................................................................................................11

3.3.2 Dimensions .............................................................................................................................................................. 12

3.3.3 Minimum Housing Dimensions SHG-2SO and SHG-2SH....................................................................................... 21

3.3.4 Accuracy ................................................................................................................................................................... 21

3.3.5 Torsional Stiness...................................................................................................................................................22

3.3.6 Bearings....................................................................................................................................................................23

3.3.7. Housing Materials and Surfaces.............................................................................................................................26

4. Actuator Selection...............................................................................................................................27

4.1 Selecting Harmonic Drive® Gears........................................................................................................................................29

4.1.1 Torque Based Dimensioning................................................................................................................................... 30

4.1.2 Life of the Wave Generator Bearing .......................................................................................................................32

4.1.3 Stiness Based Dimensioning................................................................................................................................33

4.2 Calculation of the Torsion Angle.........................................................................................................................................35

4.3 Accuracy of the Oldham Coupling SHG-2SO ......................................................................................................................35

4.4 Eciency Calculation SHG-2UH .........................................................................................................................................36

4.4.1 Eciency Calculation Scheme ................................................................................................................................36

4.4.2 Eciency Correction factor .....................................................................................................................................37

4.4.3 Eciency Correction Value......................................................................................................................................37

4.4.4 Eciency Tables ..................................................................................................................................................... 38

4.5 No Load Torque values SHG-2UH ...................................................................................................................................... 38

4.5.1 No Load Running Torque.........................................................................................................................................39

4.5.2 No Load Starting Torque ........................................................................................................................................ 40

4.5.3 No Load Back Driving Torque.................................................................................................................................. 40

4.6 Continuous Operation SHG-2UH......................................................................................................................................... 41

4.7 Output Bearing Operating Life ...........................................................................................................................................42

4.7.1 Output Bearing at Oscillating Motion.................................................................................................................... 44

4.8 Permissible Static Tilting Moment.................................................................................................................................... 45

4.9 Angle of Inclination ............................................................................................................................................................ 45

4.10 Lubrication.......................................................................................................................................................................... 46

4.10.1 Grease Lubrication.................................................................................................................................................. 46

4.10.2 Oil Lubrication......................................................................................................................................................... 48

4.11 Axial Forces at the Wave Generator SHG-2SO and SHG-2SH .......................................................................................... 49

31021387 12/2018 V02

5. Installation and Operation.................................................................................................................50

5.1 Transport and Storage........................................................................................................................................................ 50

5.2 Gear Condition at Delivery.................................................................................................................................................. 50

5.3 Assembly Information........................................................................................................................................................ 50

5.4 Recommended Tolerances for Assembly SHG-2SO and SHG-2SH ................................................................................... 51

5.5 Lubrication...........................................................................................................................................................................52

5.5.1 Grease lubrication SHG-2UH ..................................................................................................................................52

5.5.2 Grease Lubrication SHG-2SO and SHG-2SH ...........................................................................................................52

5.5.3 Additional Grease Package......................................................................................................................................53

5.5.4 Grease Change .........................................................................................................................................................53

5.5.5 Oil Lubrication......................................................................................................................................................... 54

5.6 Assembly Preparation........................................................................................................................................................ 54

5.7 Assembly of SHG-2SO and SHG-2SH Units .......................................................................................................................55

5.7.1 Motor Assembly SHG-2SO ......................................................................................................................................56

5.7.2 Wave Generator Components SHG-2SO.................................................................................................................57

5.7.3 Mounting the Wave Generator (WG) to the Motor Shaft ....................................................................................57

5.7.4 Check before Assembly of the Wave Generator (WG).......................................................................................... 58

5.7.5 Assembly of the Wave Generator (WG) into the Flexspline (FS) ........................................................................ 58

5.7.6 Assembly Control.................................................................................................................................................... 58

5.7.7 Assembly of the Output Flange..............................................................................................................................59

5.7.8 Assembly of the Housing Flange............................................................................................................................59

5.7.9 Installation of the Input Shaft SHG-2UH and SHG-2SH........................................................................................59

6. Decommissioning and Disposal.........................................................................................................60

7. Glossary................................................................................................................................................61

7.1 Technical Data ..................................................................................................................................................................... 61

7.2 Labelling, Guidelines and Regulations .............................................................................................................................. 68

41021387 12/2018 V02

1. General

About this documentation

This document contains safety instructions, technical data and operation rules for servo actuators and servo motors of

Harmonic Drive AG.

The documentation is aimed at planners, project engineers, commissioning engineers and machine manufacturers, oering

support during selection and calculation of the servo actuators, servo motors and accessories.

Rules for storage

Please keep this document for the entire life of the product, up to its disposal. Please hand over the documentation when

re-selling the product.

Additional documentation

For the configuration of drive systems using the products of Harmonic Drive AG, you may require additional documents.

Documentation is provided for all products oered by Harmonic Drive AG and can be found in pdf format on the website.

www.harmonicdrive.de

Third-party systems

Documentation for parts supplied by third party suppliers, associated with Harmonic Drive® Components, is not included in

our standard documentation and should be requested directly from the manufacturers.

Before commissioning servo actuators and servo motors from Harmonic Drive AG with servo drives, we advise you to obtain

the relevant documents for each device.

Your feedback

Your experiences are important to us. Please send suggestions and comments about the products and documentation to:

Harmonic Drive AG

Marketing and Communications

Hoenbergstraße 14

65555 Limburg / Lahn

Germany

E-Mail: info@harmonicdrive.de

51021387 12/2018 V02

1.1 Description of Safety Alert Symbols

Symbol Meaning

Indicates an imminent hazardous situation. If this is not avoided, death or

serious injury could occur.

Indicates a possible hazard. Care should be taken or death or serious injury may

result.

Indicates a possible hazard. Care should be taken or slight or minor injury

may result.

Describes a possibly harmful situation. Care should be taken to avoid damage

to the system and surroundings.

This is not a safety symbol. This symbol indicates important information.

Warning of a general hazard. The type of hazard is determined by the

specific warning text.

Warning of dangerous electrical voltage and its eects.

Beware of hot surfaces.

Beware of suspended loads.

Precautions when handling electrostatic sensitive components.

Beware of electromagnetic environmental compatibility.

1.2 Disclaimer and Copyright

The contents, images and graphics contained in this document are predected by copyright. In addition to the copyright, logos,

fonts, company and product names can also be predected by brand law or trademark law. The use of text, extracts or graphics

requires the permission of the publisher or rights holder.

We have checked the contents of this document. Since errors cannot be ruled out entirely, we do not accept liability for mis-

takes which may have occurred. Notification of any mistake or suggestions for improvements will be gratefully received and any

necessary correction will be included in subsequent editions.

DANGER

WARNING

ATTENTION

INFORMATION

ADVICE

61021387 12/2018 V02

2. Safety and Installation Instructions

Please take note of the information and instructions in this document. Specially designed models may dier in technical

detail. If in doubt, we recommend to contact the manufacturer, giving the type designation and serial number for

clarification.

2.1 Hazards

DANGER

Electric servo actuators and motors have dangerous live and rotating parts. All work during connection, operation, repair and

disposal must be carried out by qualified personnel as described in the standards EN 50110-1 and IEC 60364! Before starting

any work, and especially before opening covers, the actuator must be properly isolated. In addition to the main circuits, the

user also has to pay attention to any auxilliary circuits.

Observing the five safety rules:

• Disconnect mains

• Prevent reconnection

• Test for absence of harmful voltages

• Ground and short circuit

• Cover or close o nearby live parts

The measures taken above must only be withdrawn when the work has been completed and the device is fully assembled.

Improper handling can cause damage to persons and property. The respective national, local and factory specific regulations

must be adhered to.

ATTENTION

The surface temperature of products exceed 55 degrees Celsius. The hot surfaces should not be touched.

ADVICE

Cables must not come into direct contact with hot surfaces.

DANGER

Electric, magnetic and electromagnetic fields are dangerous, in particular for persons with heart pacemaker, implants or

similiar. Vulnerable individuals must not be in the close proximity of the product.

DANGER

Built-in holding brakes are not functional safe by themselves. Particularly with unsupported vertical axes, functional safety

can only be achieved with additional, external mechanical brakes.

71021387 12/2018 V02

DANGER

Danger of injury due to improper handling of batteries.

Observing of the battery safety rules:

• do not insert batteries in reverse. Observe the + and - marks on the battery and on the electrical device

• do not short circuit

• do not recharge

• do not open or deform

• do not expose to fire, water or high temperature

• do not leave discharged batteries in the electrical device

• keep batteries out of reach of children. In case of ingestion of a battery, seek medical assistance promptly.

WARNING

The successful and safe operation of products requires proper transport, storage and assembly as well as correct operation

and maintenance.

ATTENTION

Use suitable lifting equipment to move and lift products with a weight > 20 kg.

INFORMATION

Special versions of products may dier in the specification from the standard. Further applicable data from data sheets,

catalogues and oers of the special version have to be considered.

2.2 Intended Purpose

Harmonic Drive® Products are intended for industrial or commercial applications.

Typical areas of application are robotics and handling, machine tools, packaging and food machines and similar machines.

The products may only be operated within the operating ranges and environmental conditions shown in the documentation

(altitude, degree of predection, temperature range, etc).

Before commissioning of plants and machinery including Harmonic Drive® Products, the compliance with the Machinery

Directive must be established.

2.3 Non Intended Purpose

The use of products outside the areas of application mentioned above or beyond the operating areas or environmental

conditions described in the documentation is considered as non-intended purpose.

81021387 12/2018 V02

2.4 Use in Special Application Areas

The use of the products in one of the following application areas requires a risk assessment and approval by

Harmonic Drive AG.

• Aerospace

• Areas at risk of explosion

• Machines specially constructed or used for a nuclear purpose whose breakdown might lead to the emission of radio-activity

• Vacuum

• Household devices

• Medical equipment

• Devices which interact directly with the human body

• Machines or equipment for transporting or lifting people

• Special devices for use in annual markets or leisure parks

2.5 Declaration of Conformity

2.5.1 Gears

Harmonic Drive® Gears are components for installation in machines as defined by the Machinery Directive.

Commissioning is prohibited until the end product conforms to the provisions of this directive.

Essential health and safety requirements were considered in the design and manufacture of these gear component sets.

This simplifies the implementation of the Machinery Directive by the end user for the machinery or the partly completed

machinery. Commissioning of the machine or partly completed machine is prohibited until the end product conforms to the

Machinery Directive.

2.5.2 Servo Actuators and Motors

The Harmonic Drive® Servo Actuators and Motors described in the engineering data comply with the Low Voltage Directive.

In accordance with the Machinery Directive, Harmonic Drive® Servo Actuators and Motors are electrical equipment

for the use within certain voltage limits as covered by the Low Voltage Directive and thus excluded from the scope of the

Machinery Directive. Commissioning is prohibited until the final product conforms to the Machinery Directive.

According to the EMC directive Harmonic Drive® Servo Actuators and Motors are inherently benign equipment, unable to

generate electromagnetic disturbance or to be aected by such disturbance.

The conformity to the EU directives of equipment, plant and machinery in which Harmonic Drive® Servo Actuators and Motors

are installed must be provided by the user before taking the device into operation.

Equipment, plant and machinery with inverter driven motors must satisfy the protection requirements of the EMC directive.

It is the responsibility of the user to ensure that the installation is carried out correctly.

91021387 12/2018 V02

3. Technical Description

3.1 Product Description

The SHG-2UH Series Units are available in ten sizes with gear ratios of 50, 80, 100, 120 and 160:1 oering repeated peak

torques from 23 to 3419 Nm.

The integrated output bearing with high tilting capacity enables the direct attachment of heavy payloads without the need

for further support, ensuring a simple and space-saving design.

The SHG-2UH Unit is fully sealed with a large hollow shaft diameter to feed through supply lines, shafts or cables for further

drive systems. The gears cover a wide torque range and feature a long service life, confirmed by many years of successful

service.

The SHG-2SH and -2SO Simplicity Units are very short and lightweight. The absence of input and output flanges means ma-

ximum flexibility in design integration. The -2SH version comes with a large hollow shaft and the -2SO versions is delivered

with a standard Wave Generator.

Maximum torque capacity with largest hollow shaft

10 1021387 12/2018 V02

3.2 Ordering Code

- - -- -

Series Size Ratio1) Version Special design

SHG

14 50 80 100

2UH

2SO

2SH

According

to customer

requirements

17 50 80 100 120

20 50 80 100 120 160

25 50 80 100 120 160

32 50 80 100 120 160

40 50 80 100 120 160

45 50 80 100 120 160

50 50 80 100 120 160

58 50 80 100 120 160

65 80 100 120 160

Ordering code

SHG 25 100 2UH SP

Table 10.1

Table 10.2

- -- -

Version

Ordering code Description

2UH Unit with hollow shaft

2SO Simplicity Unit for motor assembly

2SH Simplicity Unit with hollow shaft

Clarification of the technical data can be found in the Glossary

1) The ratios shown here are for a standard driving configuration with the circular spline fixed, the Wave Generator used for the input and the Flexspline

attached to the output. Other configurations are possible. Please consult chapter 4 “Ratio”.

111021387 12/2018 V02

3.3 Technical Data

3.3.1 General Technical Data

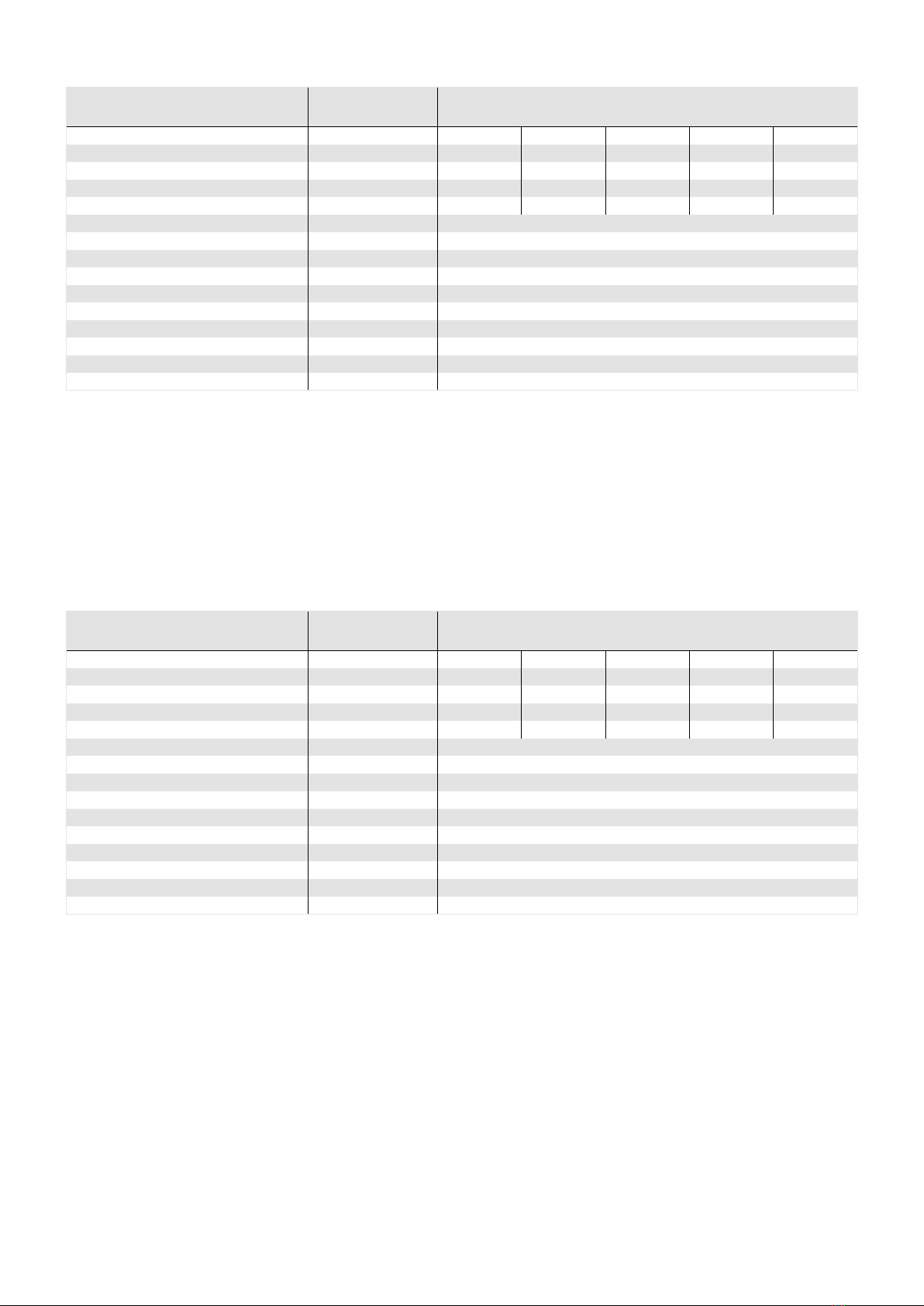

Table 11.1

Symbol

[Unit] SHG-14

Ratio i [ ] 50 80 100

Repeated peak toque TR[Nm] 23 30 36

Average torque TA[Nm] 9.0 14 14

Rated torque TN[Nm] 7.0 10 10

Momentary peak torque TM[Nm] 46 67 70

Maximum input speed (oil lubrication) nin (max) [rpm] 14000

Maximum input speed (grease lubrication) nin (max) [rpm] 8500

Average input speed (oil lubrication) nav (max) [rpm] 6500 / 11001)

Average input speed (grease lubrication) nav (max) [rpm] 3500 / 11001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 0.091

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 0.033

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 0.091

Weight SHG-2UH m [kg] 0.71

Weight SHG-2SO m [kg] 0.41

Weight SHG-2SH m [kg] 0.45

1)) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

Symbol

[Unit] SHG-17

Ratio i [ ] 50 80 100 120

Repeated peak toque TR[Nm] 44 56 70 70

Average torque TA[Nm] 34 35 51 51

Rated torque TN[Nm] 21 29 31 31

Momentary peak torque TM[Nm] 91 113 143 112

Maximum input speed (oil lubrication) nin (max) [rpm] 10000

Maximum input speed (grease lubrication) nin (max) [rpm] 7300

Average input speed (oil lubrication) nav (max) [rpm] 6500 / 11001)

Average input speed (grease lubrication) nav (max) [rpm] 3500 / 11001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 0.193

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 0.079

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 0.193

Weight SHG-2UH m [kg] 1.0

Weight SHG-2SO m [kg] 0.57

Weight SHG-2SH m [kg] 0.63

Table 11.2

1)) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

12 1021387 12/2018 V02

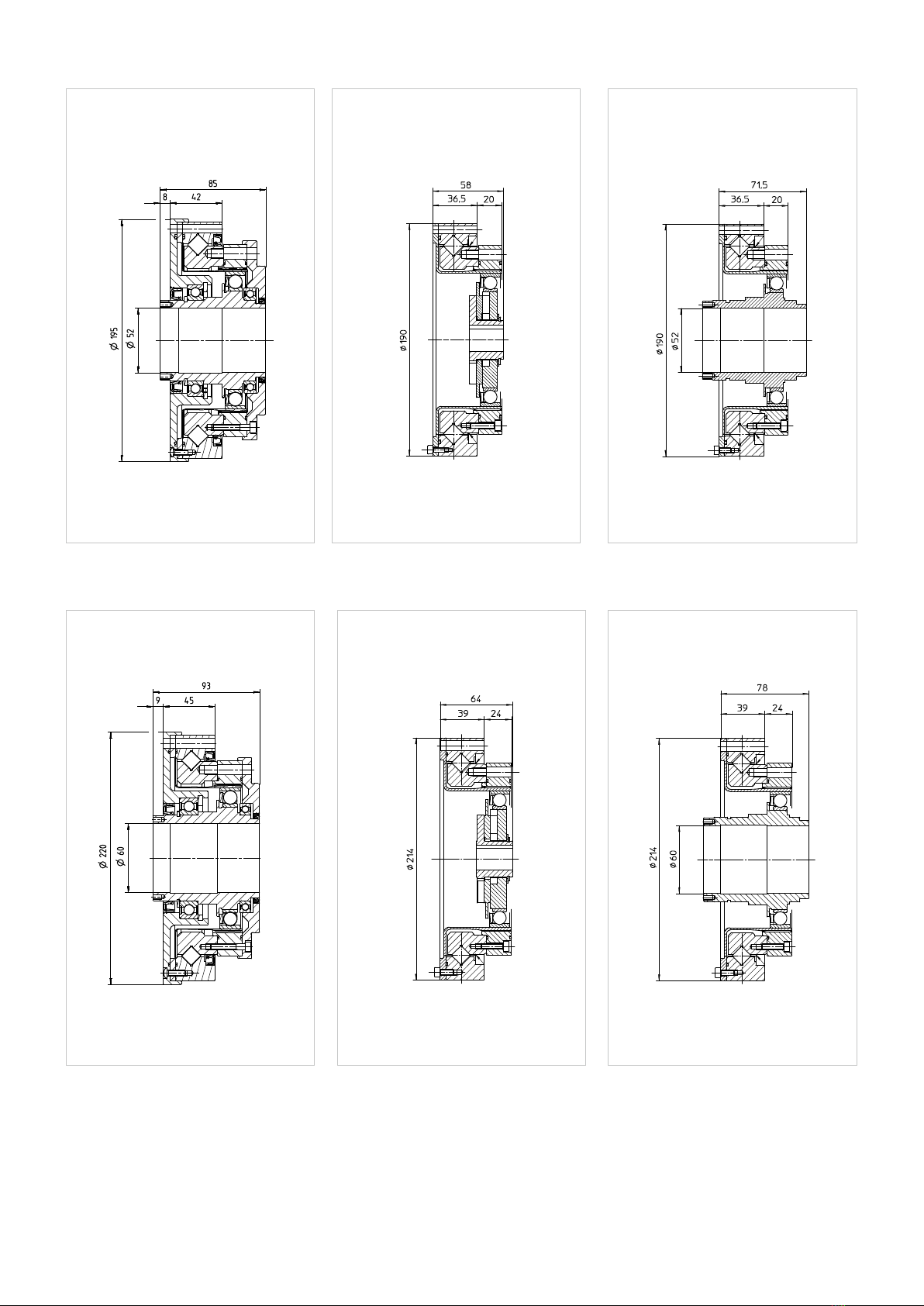

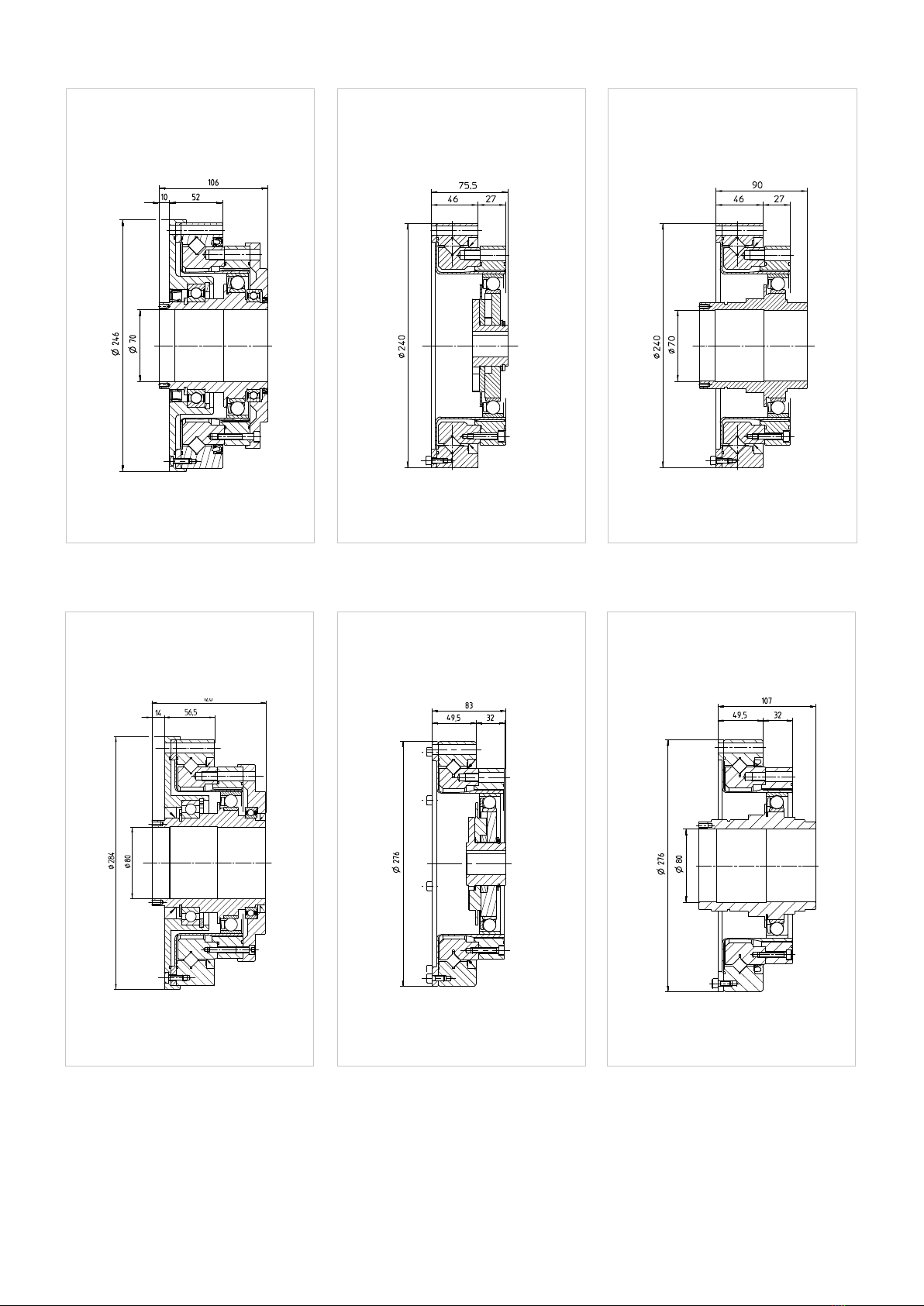

3.3.2 Dimensions

Illustration 12.1

Illustration 12.4

Illustration 12.2

Illustration 12.5

Illustration 12.3

Illustration 12.6

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

SHG-14-2UH

SHG-17-2UH

SHG-14-2SO

SHG-17-2SO

SHG-14-2SH

SHG-17-2SH

131021387 12/2018 V02

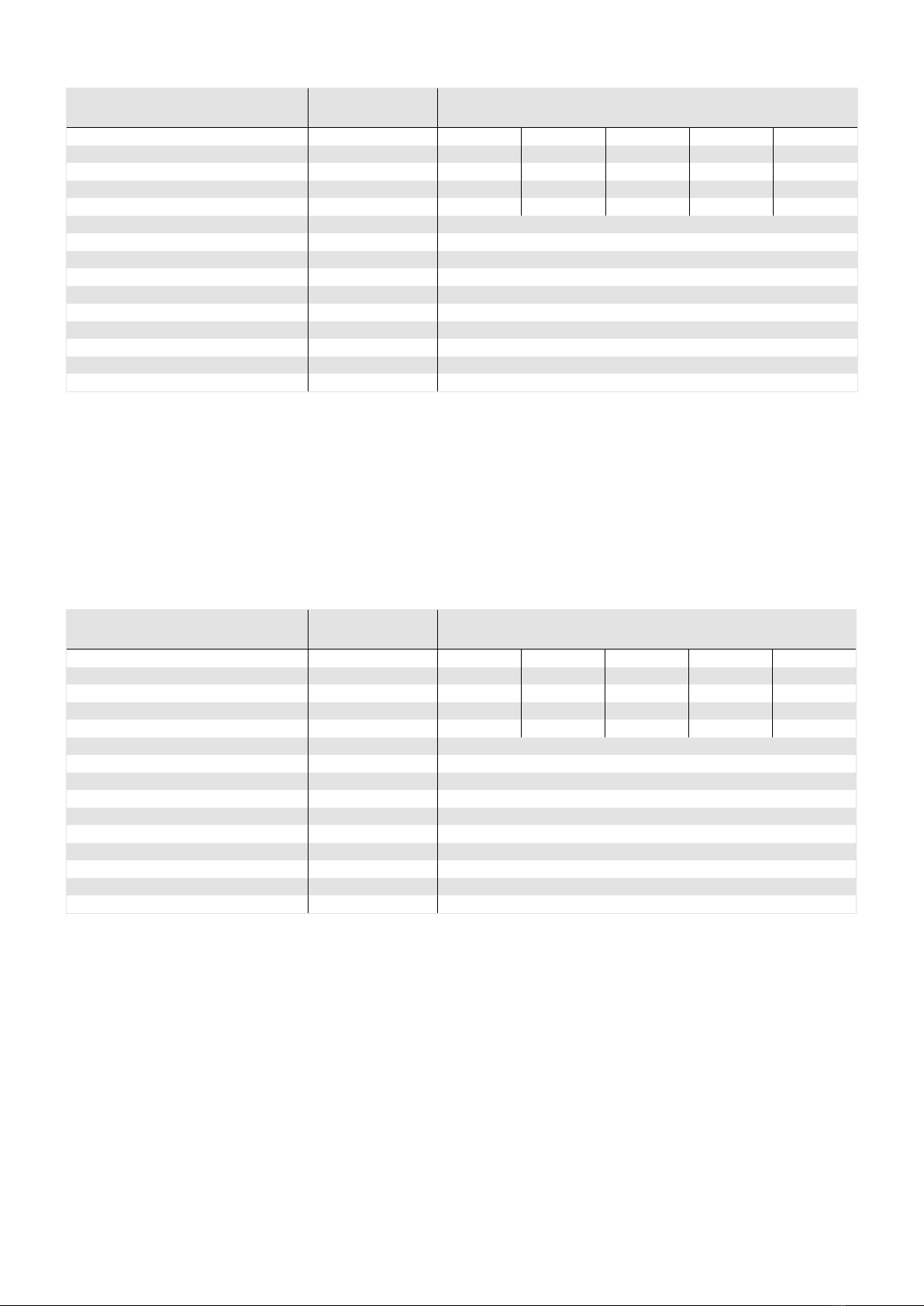

Table 13.2

Symbol

[Unit] SHG-25

Ratio i [ ] 50 80 100 120 160

Repeated peak toque TR[Nm] 127 178 204 217 229

Average torque TA[Nm] 72 113 140 140 140

Rated torque TN[Nm] 51 82 87 87 87

Momentary peak torque TM[Nm] 242 332 369 395 408

Maximum input speed (oil lubrication) nin (max) [rpm] 7500

Maximum input speed (grease lubrication) nin (max) [rpm] 5600

Average input speed (oil lubrication) nav (max) [rpm] 5600 / 10001)

Average input speed (grease lubrication) nav (max) [rpm] 3500 / 10001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 1.07

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 0.413

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 1.07

Weight SHG-2UH m [kg] 2.1

Weight SHG-2SO m [kg] 1.31

Weight SHG-2SH m [kg] 1.44

1)) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

Table 13.1

Symbol

[Unit] SHG-20

Ratio i [ ] 50 80 100 120 160

Repeated peak toque TR[Nm] 73 96 107 113 120

Average torque TA[Nm] 44 61 64 64 64

Rated torque TN[Nm] 33 44 52 52 52

Momentary peak torque TM[Nm] 127 165 191 191 191

Maximum input speed (oil lubrication) nin (max) [rpm] 10000

Maximum input speed (grease lubrication) nin (max) [rpm] 6500

Average input speed (oil lubrication) nav (max) [rpm] 6500 / 11001)

Average input speed (grease lubrication) nav (max) [rpm] 3500 / 11001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 0.404

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 0.193

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 0.404

Weight SHG-2UH m [kg] 1.38

Weight SHG-2SO m [kg] 0.81

Weight SHG-2SH m [kg] 0.89

1)) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

14 1021387 12/2018 V02

Illustration 14.1

Illustration 14.4

Illustration 14.2

Illustration 14.5

Illustration 14.3

Illustration 14.6

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

SHG-20-2UH

SHG-25-2UH

SHG-20-2SO

SHG-25-2SO

SHG-20-2SH

SHG-25-2SH

151021387 12/2018 V02

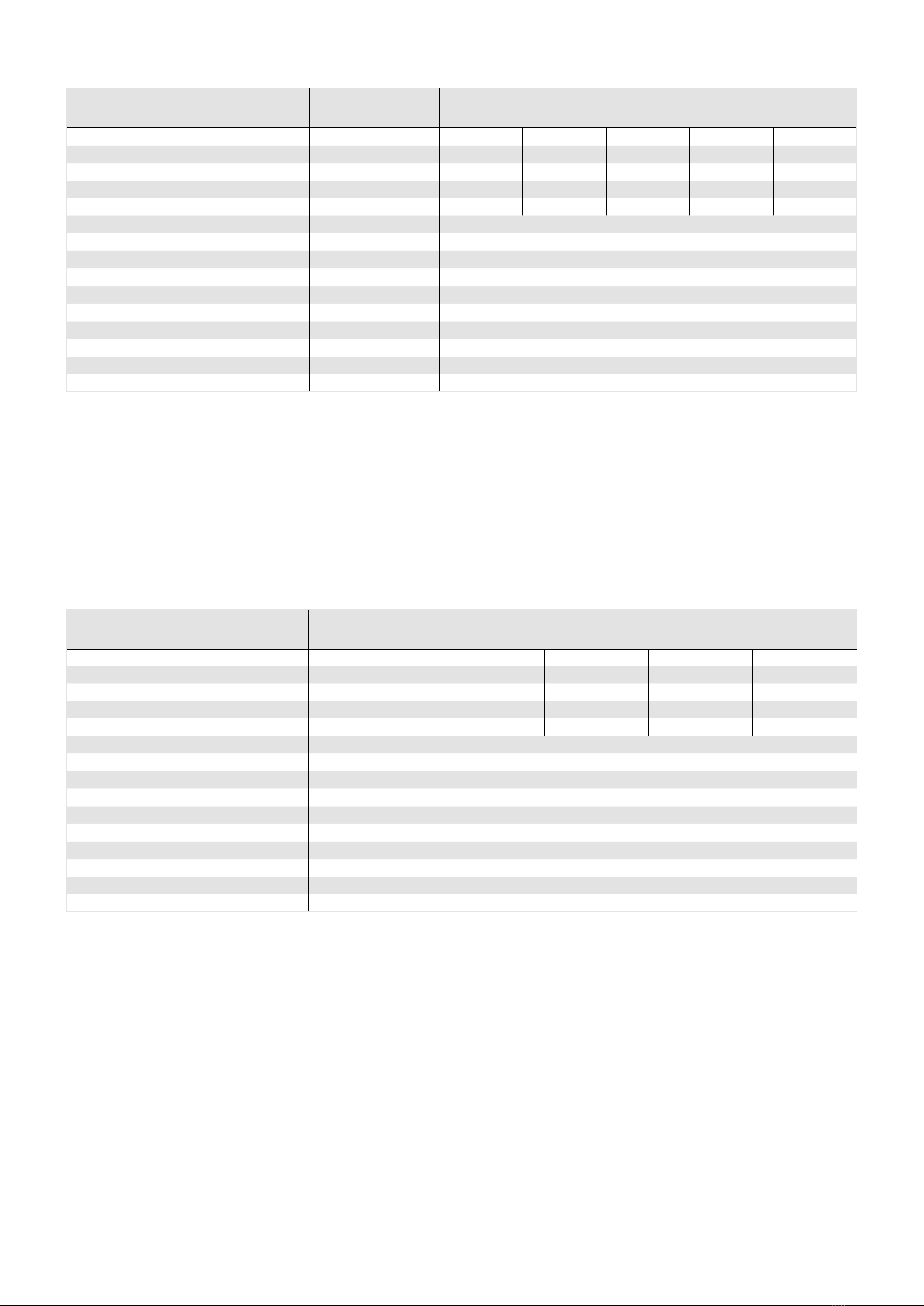

Table 15.1

Symbol

[Unit] SHG-32

Ratio i [ ] 50 80 100 120 160

Repeated peak toque TR[Nm] 281 395 433 459 484

Average torque TA[Nm] 140 217 281 281 281

Rated torque TN[Nm] 99 153 178 178 178

Momentary peak torque TM[Nm] 497 738 841 892 892

Maximum input speed (oil lubrication) nin (max) [rpm] 7000

Maximum input speed (grease lubrication) nin (max) [rpm] 4800

Average input speed (oil lubrication) nav (max) [rpm] 4600 / 10001)

Average input speed (grease lubrication) nav (max) [rpm] 3500 / 10001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 2.85

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 1.69

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 2.85

Weight SHG-2UH m [kg] 4.2

Weight SHG-2SO m [kg] 2.9

Weight SHG-2SH m [kg] 3.1

1) ) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

Symbol

[Unit] SHG-40

Ratio i [ ] 50 80 100 120 160

Repeated peak toque TR[Nm] 523 675 738 802 841

Average torque TA[Nm] 255 369 484 586 586

Rated torque TN[Nm] 178 268 345 382 382

Momentary peak torque TM[Nm] 892 1270 1400 1530 1530

Maximum input speed (oil lubrication) nin (max) [rpm] 5600

Maximum input speed (grease lubrication) nin (max) [rpm] 4000

Average input speed (oil lubrication) nav (max) [rpm] 3600 / 9501)

Average input speed (grease lubrication) nav (max) [rpm] 3000 / 9501)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 9.28

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 4.50

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 9.28

Weight SHG-2UH m [kg] 7.7

Weight SHG-2SO m [kg] 5.1

Weight SHG-2SH m [kg] 5.4

Table 15.2

1) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

16 1021387 12/2018 V02

Illustration 16.1

Illustration 16.4

Illustration 16.2

Illustration 16.5

Illustration 16.3

Illustration 16.6

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

SHG-32-2UH

SHG-40-2UH

SHG-32-2SO

SHG-40-2SO

SHG-32-2SH

SHG-40-2SH

171021387 12/2018 V02

Table 17.1

Symbol

[Unit] SHG-45

Ratio i [ ] 50 80 100 120 160

Repeated peak toque TR[Nm] 650 918 982 1070 1147

Average torque TA[Nm] 345 507 650 806 819

Rated torque TN[Nm] 229 407 452 523 523

Momentary peak torque TM[Nm] 1235 1651 2041 2288 2483

Maximum input speed (oil lubrication) nin (max) [rpm] 5000

Maximum input speed (grease lubrication) nin (max) [rpm] 3800

Average input speed (oil lubrication) nav (max) [rpm] 3300 / 9001)

Average input speed (grease lubrication) nav (max) [rpm] 3000 / 9001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 13.8

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 8.68

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 13.8

Weight SHG-2UH m [kg] 10

Weight SHG-2SO m [kg] 6.5

Weight SHG-2SH m [kg] 6.9

1)) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

Table 17.2

Symbol

[Unit] SHG-50

Ratio i [ ] 80 100 120 160

Repeated peak toque TR[Nm] 1223 1274 1404 1534

Average torque TA[Nm] 675 866 1057 1096

Rated torque TN[Nm] 484 611 688 688

Momentary peak torque TM[Nm] 1860 2678 2678 3185

Maximum input speed (oil lubrication) nin (max) [rpm] 4500

Maximum input speed (grease lubrication) nin (max) [rpm] 3500

Average input speed (oil lubrication) nav (max) [rpm] 3000 / 8501)

Average input speed (grease lubrication) nav (max) [rpm] 2500 / 8501)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 25.2

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 12.5

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 25.2

Weight SHG-2UH m [kg] 14.5

Weight SHG-2SO m [kg] 9.6

Weight SHG-2SH m [kg] 10.2

1) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

18 1021387 12/2018 V02

Illustration 18.1

Illustration 18.4

Illustration 18.2

Illustration 18.5

Illustration 18.3

Illustration 18.6

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

SHG-45-2UH

SHG-50-2UH

SHG-45-2SO

SHG-50-2SO

SHG-45-2SH

SHG-50-2SH

191021387 12/2018 V02

Table 19.1

Table 19.2

Symbol

[Unit] SHG-58

Ratio i [ ] 80 100 120 160

Repeated peak toque TR[Nm] 1924 2067 2236 2392

Average torque TA[Nm] 1001 1378 1547 1573

Rated torque TN[Nm] 714 905 969 969

Momentary peak torque TM[Nm] 3185 4134 4329 4459

Maximum input speed (oil lubrication) nin (max) [rpm] 4000

Maximum input speed (grease lubrication) nin (max) [rpm] 3000

Average input speed (oil lubrication) nav (max) [rpm] 2700 / 8001)

Average input speed (grease lubrication) nav (max) [rpm] 2200 / 8001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 49.5

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 27.3

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 49.5

Weight SHG-2UH m [kg] 20

Weight SHG-2SO m [kg] 13.5

Weight SHG-2SH m [kg] 14.1

Symbol

[Unit] SHG-65

Ratio i [ ] 80 100 120 160

Repeated peak toque TR[Nm] 2743 2990 3263 3419

Average torque TA[Nm] 1352 1976 2041 2041

Rated torque TN[Nm] 969 1236 1236 1236

Momentary peak torque TM[Nm] 4836 6175 6175 6175

Maximum input speed (oil lubrication) nin (max) [rpm] 3500

Maximum input speed (grease lubrication) nin (max) [rpm] 2800

Average input speed (oil lubrication) nav (max) [rpm] 2400 / 8001)

Average input speed (grease lubrication) nav (max) [rpm] 1900 / 8001)

Moment of inertia SHG-2UH Jin [· 10-4 kgm²] 94.1

Moment of inertia SHG-2SO Jin [· 10-4 kgm²] 46.8

Moment of inertia SHG-2SH Jin [· 10-4 kgm²] 94.1

Weight SHG-2UH m [kg] 28.5

Weight SHG-2SO m [kg] 19.5

Weight SHG-2SH m [kg] 20.9

1 ) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

1) Valid for SHG-2UH and SHG-2SH when radial shaft seals are used on the hollow shaft.

20 1021387 12/2018 V02

Illustration 20.1

Illustration 20.4

Illustration 20.2

Illustration 20.5

Illustration 20.3

Illustration 20.6

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

SHG-58-2UH

SHG-65-2UH

SHG-58-2SO

SHG-65-2SO

SHG-58-2SH

SHG-65-2SH

This manual suits for next models

6

Table of contents

Other Harmonic Drive Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Daikin

Daikin EWWD 340 Installation, operation and maintenance manual

Rohloff

Rohloff SPEEDHUB 500/14 Mounting

Innotech

Innotech INNOTECH BEF 401-10 Instructions for installation and use

Jäger

Jäger F80-M530.05 K02S5R manual

THORLABS

THORLABS DTS25 user guide

Maschinenfabrik Reinhausen

Maschinenfabrik Reinhausen VACUTAP VM-Ex operating instructions