Harol SL400 User manual

INSTALLATION &

OPERATION MANUAL

WIND AND SUN SCREEN

SL400

Art. no. 49013

SUN PROTECTIONSHUTTERSDOORS

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 2

TABLE OF CONTENTS

1. INTRODUCTION 3

2. GENERAL WARNINGS 3

3. LIST OF TOOLS REQUIRED 4

4. INSTALLATION STEPS 5

4.1. Checking and opening the packaging 5

4.2. Checking the contents 5

4.3. Checking the dimensions 5

4.4. Fabric opening left or right 5

4.5. Mounting height of the wall brackets 6

4.6. Alignment of the wall brackets 7

4.7. Optional mounting of the box (A2638) 7

4.8. Hooking up the box 7

4.9. Installation of the supporting system 7

4.10. Optional installation of a supporting system for wall or railing assembly (A2639) 8

4.11. Fine-tuning of the handgrip height and the supporting system 8

5. DISMANTLING 9

6. PUTTING INTO OPERATION AND HANDOVER 9

6.1. Opening the screen 9

6.2. Closing the screen 9

6.3. Handover to the customer 9

7. USER INFO 10

7.1. Basic information 10

7.2. Safety instructions 10

7.3. Terms of use 11

7.4. Maintenance 11

8. TROUBLESHOOTING 12

9. GENERAL INFO ON FABRICS 12

Appendices: CE certificate of conformity

Service log

Handover form installer

Handover form customer

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 3

1. INTRODUCTION

The SL400 is a wind and sun screen. The screen consists of a box with roll-up system, a

fabric, a pull rod and a supporting system mounted at drop distance from the box. At the

top, the fabric can be either straight or oblique with a maximum angle of 15° and depending

on the length of the drop reinforced with boning. This drop can vary from a minimum of 1

metre up to a maximum of 4 metres.

This manual starts with a step-by-step description of the installation instructions of the

SL400 for installers. This is followed by information concerning the use and maintenance

of the screen for the end user. The last pages consist of the handover forms which the

installer can use to handover the SL400 to the end user.

2. GENERAL WARNINGS

A number of precautions must be taken for the safe installation, operation and maintenance

of the SL400. Please take note of the following warnings for the safety of everyone

concerned!

!Please read these instructions carefully before starting with the installation.

!The screen must be fitted or mounted in accordance with local requirements and

standards. All work must be carried out by a trained and experienced member of

sta from recognized companies, and never by “do-it-yourself” fitters or apprentices.

!Always proceed with caution. Ensure that you have a robust footing.

!Make sure there is adequate lighting in the assembly space. Remove obstacles and

dirt. Ensure that no other persons except the installers are present. Unauthorized

persons can get in the way or be at risk during the installation.

!There is a lot of tension on the fabric of the wind and sun screen, due to the

integrated coiled spring located in the fabric roll. Always take the necessary care

when assembling or dismantling the screen.

!The screen must be kept clearly in view at all times during installation and operation.

Persons in the vicinity may be at risk of injury.

!Our products must be installed in such a way that all parts remain accessible at

all times for maintenance and repairs. If this is not the case, Harol cannot be held

responsible for any additional costs (e.g. demolition work, repairs to exterior or

interior walls) which may result from this.

The SL400 has been designed for use as a wind and sun screen and as such

must not be used for all-weather protection. During heavy rain or wind the

screen must be retracted immediately.

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 4

Guarantee, terms and conditions

• Harol has endeavoured to design and manufacture the SL400 in compliance with

the current CE standards. Always check that our version complies with your own

national standards.

• No rights can be derived from these instructions whatsoever. Technical modifications

are reserved without written notification.

• All parts supplied are intended for this specific screen. Adding dierent parts may

have a negative impact on the safety of your awning. The warranty is void if parts are

added or changed without first consulting the supplier.

• For large projects we strongly advise you to first fit 1 complete awning before fitting

the remaining awnings. This will help detect any potential faults early on and enable

these to be remedied at the lowest possible cost.

• For our general terms and conditions of sale: see price list.

• Make sure the box can always be opened so the mechanical parts inside can be

reached easily. If this requirement is not respected, Harol cannot be held responsible

for the cost of demolition work or any paint work or wallpapering.

Harol NV

Industriepark 3 – 3290 Diest

Belgium

+32 (0)13 38 01 11

+32 (0)13 31 48 03

info@harol.be

www.harol.com

3. LIST OF TOOLS REQUIRED

• Ladder(s)

• Box cutter

• Tape measure

• Pencil or felt pen

• Spirit level, plumb line or hose level

• Cord

• Drill and set of stone drills

• Cross-head and flat-head screwdrivers

• Set of open-ended and ring spanners

• Set of Allen keys

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 5

4. INSTALLATION STEPS

4.1. Checking and opening the packaging

First check the packaging for any external damage. Next open the cardboard packaging.

Be careful when cutting the straps with a knife. Careless opening of the box may result in

damage to the paint. It is recommended to remove the plastic film only from the ends. The

plastic provides good protection during installation.

4.2. Checking the contents

The SL400 is delivered ready for installation and includes the required screws. Check the

contents of the package and check that the box has been painted in the requested colour.

Check also that the supporting system is present, together with the guarantee card and

the table with tensile forces on screws. Screws for installation on the existing mounting

surface are not included.

4.3. Checking the dimensions

Measure the length of the box of the SL400. This should be 50 mm smaller than the specified

ordered length! The drop can only be checked after the screen has been mounted.

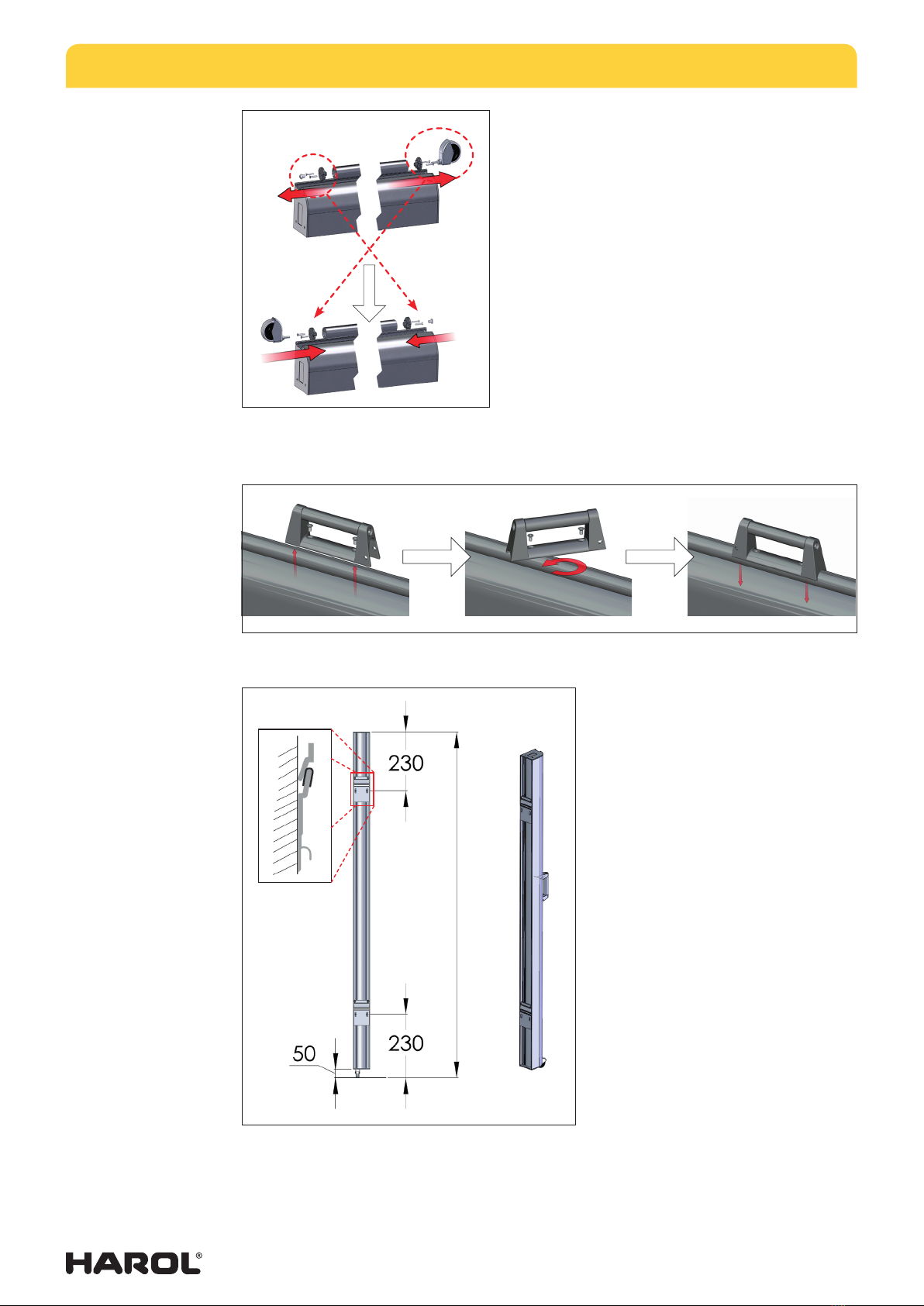

4.4. Fabric opening left or right

left right

Before starting with the installation, check that the fabric

opening is facing the correct side as specified in the order. If

upon closer inspection you decide that you want the other

fabric opening, then this can only be done on-site with the

straight fabric configuration.

Changing the fabric opening must always be carried out with the

screen closed, and the 3 steps below must be closely followed.

1. Unscrew the suspension bracket from the housing or box, rotate the suspension

bracket 180° and then reinstall it in the same place using the nut and bolt.

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 6

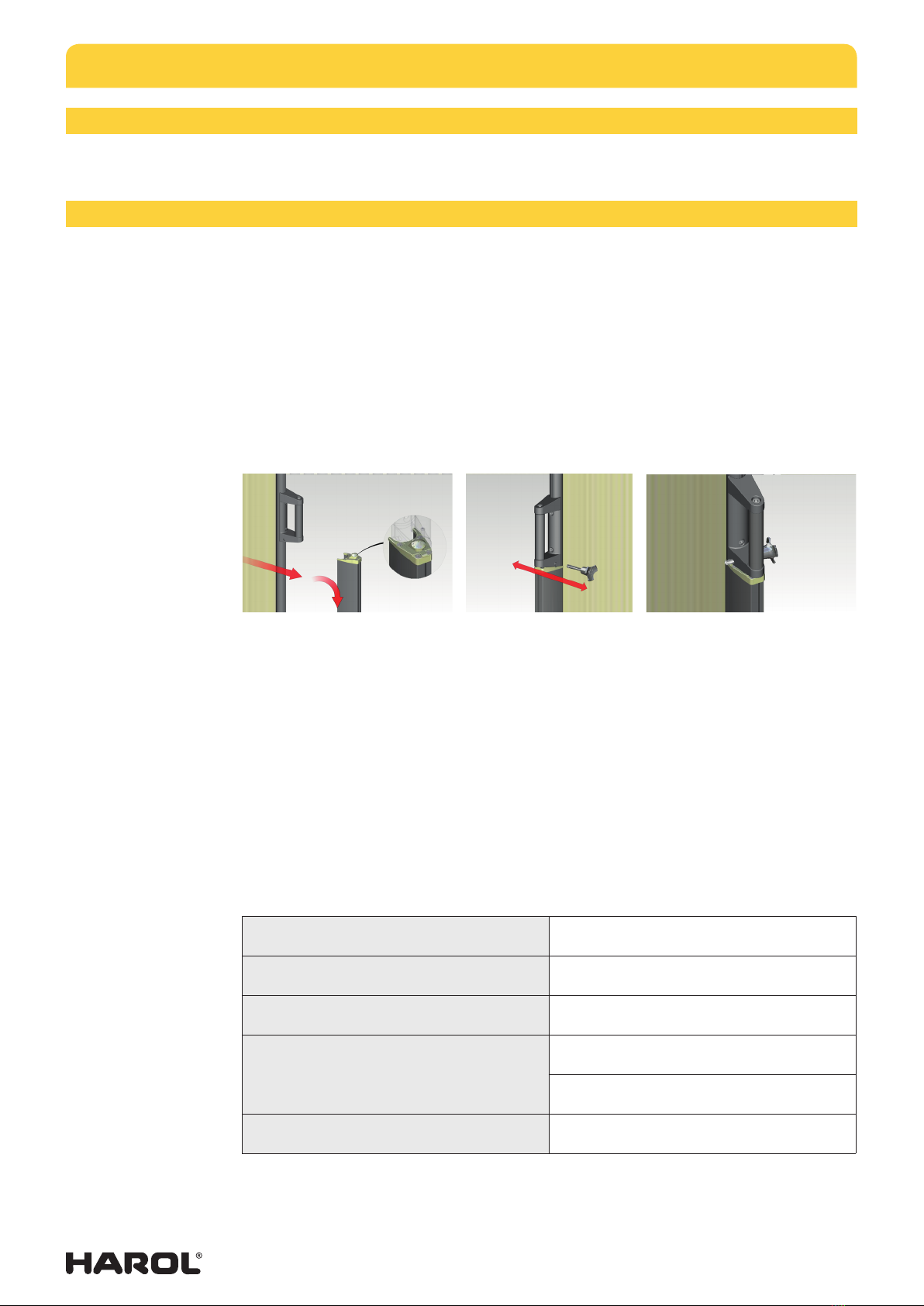

2. Detach the wheel from the pull rod; this is done

by unscrewing the pin with an SW12 spanner.

Unscrew the cover on the other side of the pull rod

with an SW5 Allen key. Switch around the wheel

and cover and tighten the screws again.

3. Loosen the handgrip by unscrewing two flush mount screws with an SW4 Allen

key, rotate the handgrip 180° and refasten it at the correct height. This height is

determined by the support pin or supporting system.

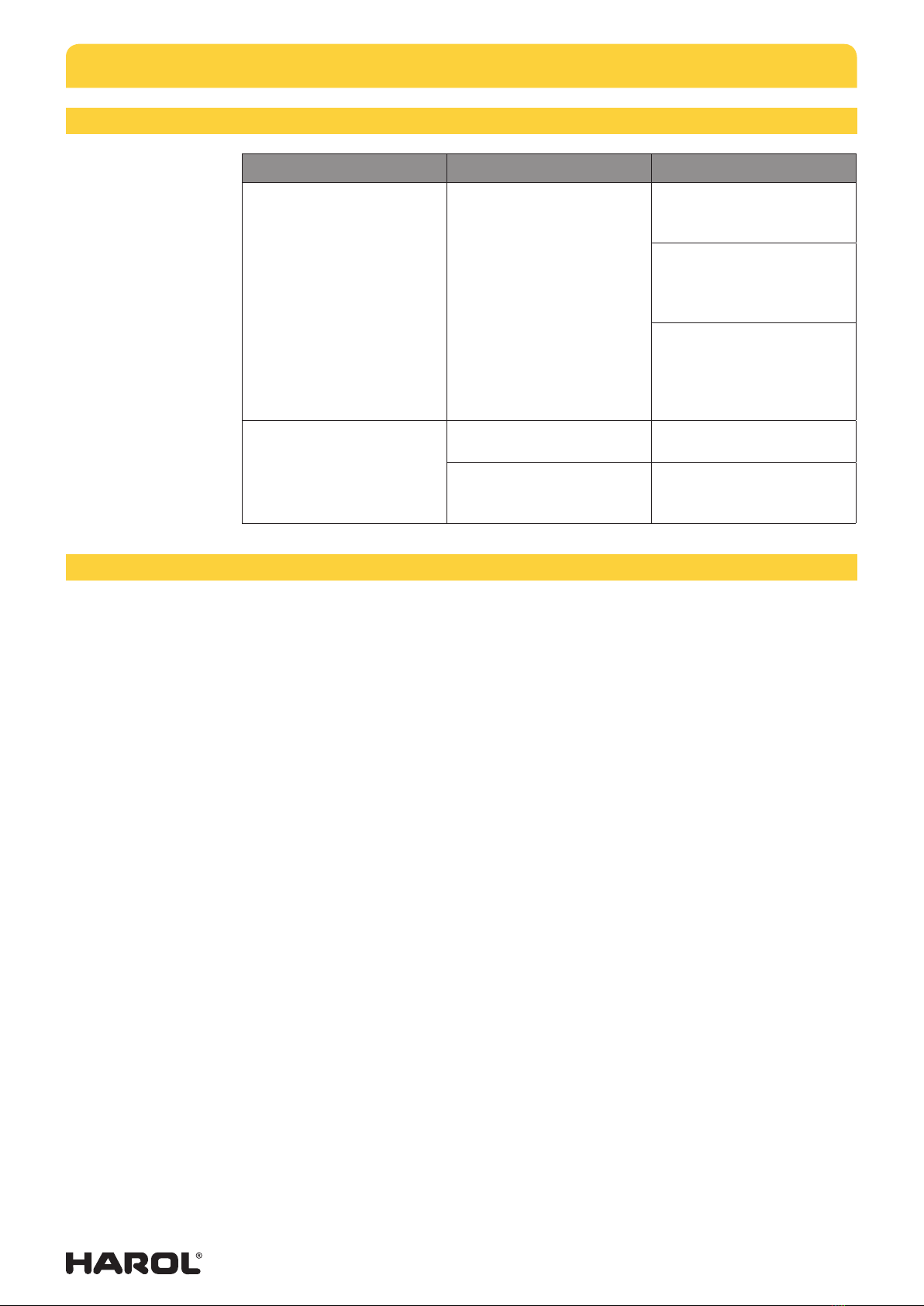

4.5. Mounting height of the wall brackets

The height of the mounting brackets

on the wall must match the distance

between the brackets on the box

of the SL400. The housing of the

wind and sun screen must be placed

vertically at 50 mm above the

ground, to accommodate the wheel

at the bottom of the pull rod.

The choice of fastening materials

for the attachment of the brackets

depends greatly on the mounting

surface. For walls made of cellular

concrete blocks or soft/hollow bricks

it is necessary to use appropriate

fastening materials such as expansion

bolts, chemical anchors etc. The

installer is responsible for selecting

the best method. Harol accepts no

responsibility for fasteners that do

not hold securely.

HEIGHT

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 7

4.6. Alignment of the wall brackets

The two wall brackets must be plumb and level. Any irregularities in the mounting surface

must be compensated. Take the time to make sure the screen is positioned perfectly vertically.

If the mounting surface is of poor quality, we recommend ordering additional brackets. Also

check the distance between the brackets and then tighten all the screws. The mounted

screen is now ready for further adjustment and alignment of the supporting system.

4.7. Optional mounting of the box (A2638)

Instead of mounting the wall brackets directly on to the wall,

it is also an option to use a wall console for each wall bracket.

Here too the choice of fastening materials depends largely

on the mounting surface and must be assessed by the fitter.

The mounting height of the wall consoles must match the

distance between the brackets on the box of the SL400.

Once again, it is very important that the wall consoles are

aligned correctly.

4.8. Hooking up the box

A damping rubber is placed over each wall bracket. Next, the

SL400 can be hoisted over the brackets and pressed down

so the screen is suciently protected and secure.

Two people are required to attach heavier screens.

4.9. Installation of the supporting system

A supporting system should be installed at drop distance from the box in order to keep the

screen in the open position. This supporting system is for hooking up the pull rod.

There are various ways to do this:

• Floor assembly (A2642): A support pin with ground support plate are anchored on

to the floor, optionally either a concrete anchor (option A2640) or a ground anchor

(A2641) can be used.

• Wall assembly (A2644): A wall mounting block must first be mounted to the wall

using the appropriate fastening materials. Next a short support is fastened to the

mounting block.

• Railing assembly (A2643): A wall mounting block must first be mounted to the

railing using the appropriate fastening materials. Next a support pin is fastened to

the mounting block.

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 8

Always make sure that the supporting system is mounted perfectly vertically and is correctly

anchored. The height of the pull rod depends on the height of the screen. For the locking

system the rule of thumb is to have it positioned at half the height.

4.10. Optional installation of a supporting system for wall or railing assembly (A2639)

Instead of mounting the supporting system directly

with wall or railing mounted systems, it can also be

mounted to the wall using a wall console for columns

(option A2639). In this case the wall mounting block

must be removed, so the supporting system can

be secured to the wall console with the three bolts

supplied. Depending on the mounting surface, the

fitter must choose a particular option for securing

the console to the wall.

The mounting height of the wall console needs to

be such that the top of the cover & lock plate of the

supporting system are at the same height as the bottom

of the handgrip of the pull rod. Correct alignment of

the wall console is also very important here.

4.11. Fine-tuning of the handgrip height and the supporting system

If the bottom of the handgrip of the pull rod does not grip into the cover & lock plate, then

this can be resolved by lowering or raising the handgrip. This is done by gently unscrewing

two countersunk screws, repositioning the handgrip and then tightening the screws again.

(A2641)

(A2640)

Floor assembly

(A2642)

Wall assembly

(A2644)

Railing assembly

(A2643)

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 9

5. DISMANTLING

Always close the screen before lifting it and removing it from the brackets.

6. PUTTING INTO OPERATION AND HANDOVER

6.1. Opening the screen

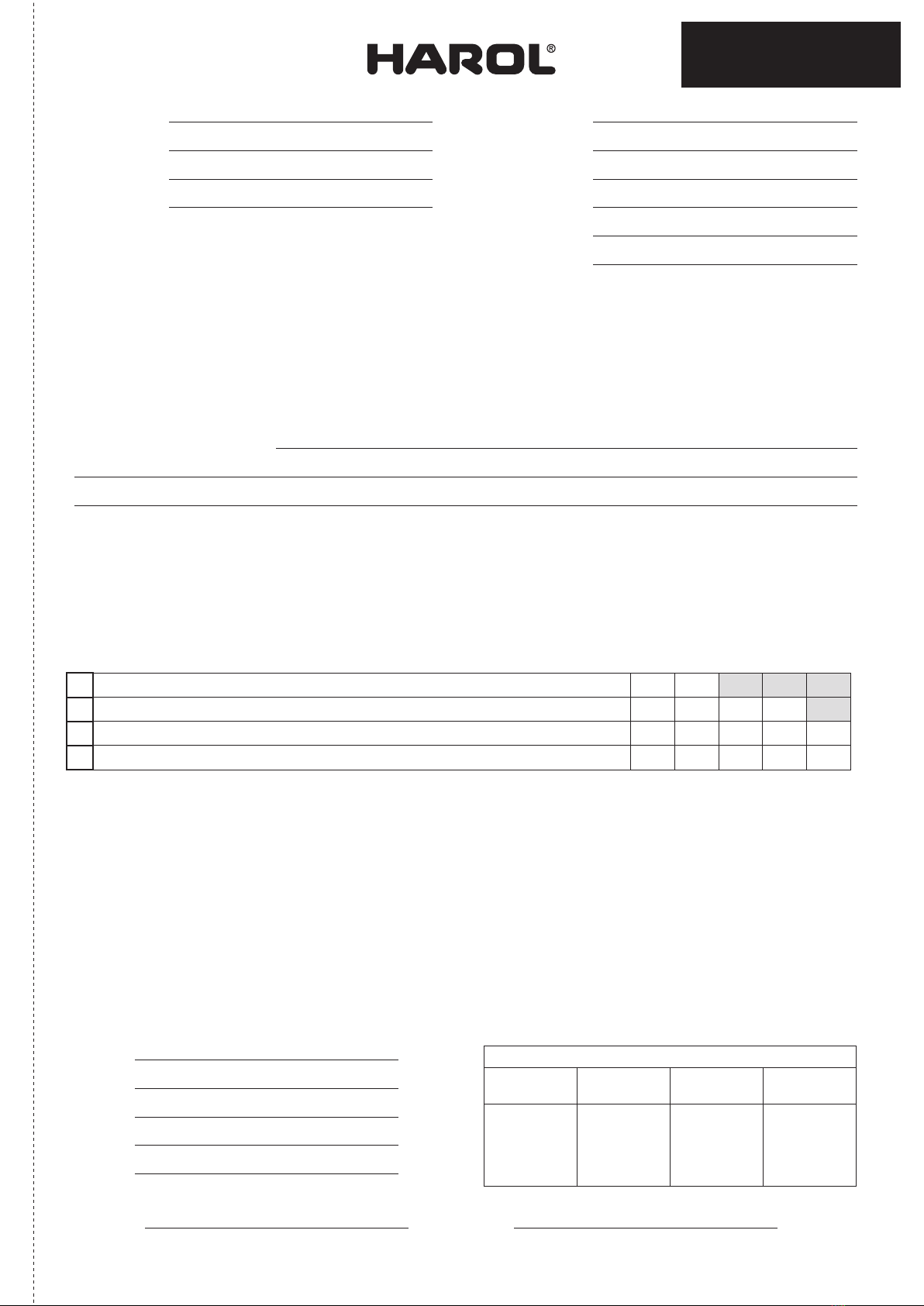

• To open the screen use the pull rod and handgrip. Always make sure that the wheel

at the bottom of the pull rod rolls over the floor! This ensures a smooth and even

extension of the screen.

• Once the screen has reached the support, lift the handgrip slightly upwards and on

to the locking system.

• Then press the handgrip downwards and give it a brief tug to ensure it has properly

engaged with the locking system.

• Finally, to prevent the screen from suddenly disengaging, a safety lock is pushed

through the hole in the handgrip. In order to be able to carry out this action, you

must first press down the pin on the button.

6.2. Closing the screen

To close the screen, follow the reverse procedure for opening the screen (see F.1.).

Never suddenly let go of the fabric and the pull rod! Closing the SL400 in an uncontrolled

manner can damage the fabric and result in personal injuries!

6.3. Handover to the customer

After assembling and testing the screen, clean up the workplace, take the packaging away

with you and hand this installation and operating manual to the user. Do not forget to

complete the handover forms on the last pages.

To make it easier for us to respond to any questions or to provide you with information

regarding this SL400 in the future, please make sure the installation details below are

completed by the installer.

Product name: Wind and sun screen SL400

HAROL order number:

Installation date:

Handover:

from:

to:

Installer’s signature:

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 10

7. USER INFO

7.1. Basic information

Before operating the SL400, you need to have sucient knowledge of the product. The

contents of this manual is a sound basis for a smooth, continuous operation and a long

service life of this product.

Also, for the sake of personal safety, it is important to follow these instructions. Failure to

follow these instructions relieves the manufacturer of all liability.

Keep this installation and operation manual handy for future reference. Should the SL400

be handed over to a third party, then this manual must also be supplied to the new owner.

7.2. Safety instructions

A number of precautions must be taken for the safe operation and maintenance of the

SL400. Installation, maintenance or repair of the wind and sun screen by anyone other

than a recognized fitter can be a safety hazard or cause injury. For the safety of everyone

concerned, please take note of the instructions, warnings and directions below! If in doubt,

always contact your supplier. Always take care when using the sun screen!

!Please read this manual carefully before operation or maintenance.

!Installation, maintenance and repairs must only be carried out by a qualified and

experienced technician!

!Malfunctions, which can impair the safety, must be reported and repaired

immediately.

!The product may only be operated by persons who have been instructed by the

installer about the correct mode of operation. It is strictly forbidden to allow children

to operate the SL400! They may put themselves at risk while operating the screen.

!When opening and closing the screen, always keep the SL400 in sight and make

sure that there are no persons (children!) or obstacles within its range of movement.

!The safety lock must always be engaged when the screen is open, to prevent it from

unexpectedly retracting.

!Watch out for hands/fingers when hooking up the pull rod to the system, as well as

when closing the screen. Danger of pinching!

!If work is being carried out in the vicinity of the screen, then make sure it is always

closed.

!Ensure that the sun screen is regularly inspected and maintained..

DANGER! BECAUSE OF THE INTEGRATED SPRING SYSTEM, THERE IS ALWAYS

TENSION ON THE SL400. FOR THIS REASON ALL REPAIRS OR DISMANTLING

MUST BE CARRIED OUT BY PROFESSIONALLY TRAINED AND QUALIFIED

STAFF. ALWAYS TAKE CARE WHEN USING THIS SUN SCREEN!

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 11

7.3. Terms of use

• The SL400 serves mainly as a protection against wind and sun or for additional

privacy. It must never be used for all-weather-protection.

• The sun screen should never be exposed to wind loads that are greater than 27

km/h or greater than 20 km/h if a ground anchor is being used. Also the fastening

materials used for the mounting surface play an important part. The manufacturer

accepts no responsibility for damage caused by excessive wind.

• Never unroll the screen in rain, snow or freezing weather conditions. This may cause

damage.

• If the fabric of the wind and sun screen becomes damp or wet, then it must be dried

as quickly as possible while unrolled. Otherwise there is a risk of stains and mould

appearing or damage to the fabric or the seams.

• The screen must be rolled up during the night and when no one is present.

• Always avoid any accidental loads on the SL400. This can lead to damage or

defects.

• A screen that is not in perfect condition must be repaired immediately.

• Only OEM replacement parts may be used for repairs.

• The manufacturer is not responsible for damage resulting from improper use.

7.4. Maintenance

To guarantee trouble-free use of the SL400 it is prudent to regularly maintain and inspect

the screen, at least once a year. Check for signs of wear or damage to the fabric or frame.

In the case of wear or damage, your installer is the designated person to carry out these

repairs.

You can carry out small maintenance and inspection jobs as described below. Never use

a high-pressure cleaner!

Maintaining the fabric:

• The screen fabric has been treated with a special dirt-repellent product, which slows

down the process of dirt build-up.

• Use a soft brush to clean dust from the dry sun screen fabric.

• For watery stains first moisten the fabric and then rub with a clean cloth. Only use

detergents such as soap or other chemical products in very exceptional situations.

• For finger or oil stains, use a clean cloth with a drop of soft neutral washing-up liquid

and subsequently use plenty of water to rinse. Always avoid using trichloretane.

• After cleaning the fabric always allow it to dry thoroughly.

Maintaining the frame:

• The supporting system, the pull rod and the external box must be cleaned regularly

with tepid water and a neutral soap such as car shampoo, and rinsed thoroughly with

tap water (at least 2x a year).

• It is emphatically not recommended to use corrosive or aggressive products,

scouring pads or other abrasives.

InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12 | 12

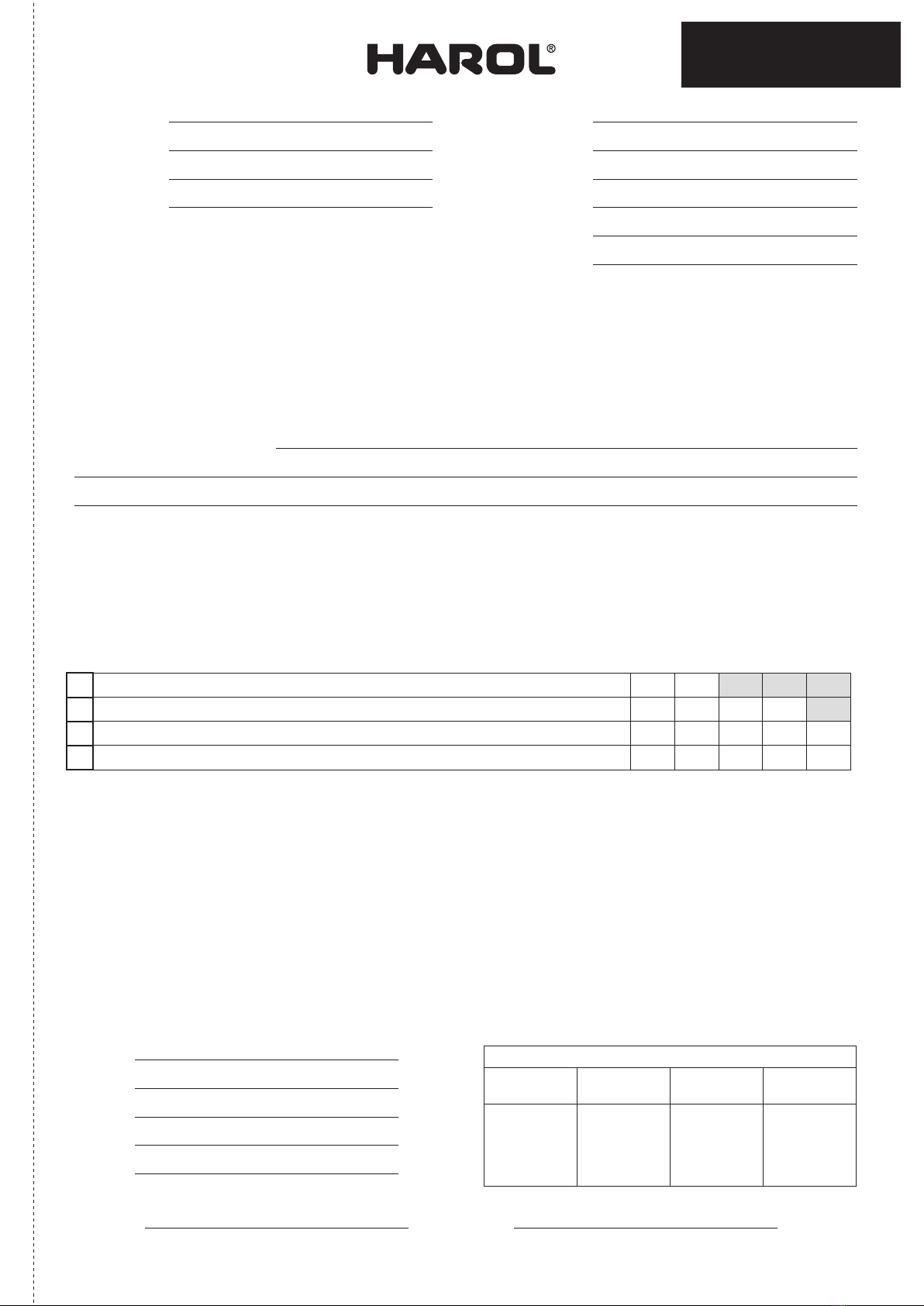

8. TROUBLESHOOTING

NATURE OF THE FAULT CAUSE SOLUTION

Pull rod does not fit tightly

against the box in the

closed position.

The fabric does not roll up

evenly.

Pull out the pull rod to fully

extend the fabric and then

roll it up again.

Keep more tension on the

pull rod and fabric whilst

extending it and rolling it

up.

The wheel no longer turns

freely, making it necessary

to hold the pull rod higher

above the ground whilst

rolling up the screen.

Fabric does not roll up

evenly or one end is rolled

loosely.

The height of the handgrip

is incorrect.

Adjust the position of the

handgrip.

The height of the housing

is incorrect.

Slightly adjust the height of

the assembly brackets for

the box.

9. GENERAL INFO ON FABRICS

The fabric collection consists of acrylic fabrics and the Soltis range (86, 92 or 96), which

can be selected from the collection folders.

The same fabric may have a dierent surface and slight variations in colour or design cannot

be completely eliminated.

When working with a much larger drop, rows of fabric are needed and consequently creasing

may occur. There is also a greater risk of the fabric becoming slack because of the weight

of the fabric, however, this will not aect the functioning of the screen in any way.

Where the fabric is attached to the fabric roll, stripes may appear for each rotation around

the roll.

The above-mentioned cases are not errors, but phenomena which are the result of technical

factors. These can never give rise to complaints, or be a reason for demanding another

fabric or for obtaining a discount!

09/12 | 13

CE-Gelijkvormigheidsverklaring

Machinerichtlijn 2006/42/EC

Wij, Harol NV, verklaren geheel onder eigen verantwoordelijkheid dat de producten

waarop deze verklaring betrekking heeft, in overeenstemming zijn met de volgende norm of

ander(e) normatie(f)(ve) document(en)

Deze verklaring is enkel geldig indien de installateur de installatie heeft uitgevoerd

geheel volgens de voorschriften van de fabricant en

volgens de normen die van kracht zijn op de installatie.

België, Diest, 1 maart 2011

Screens, type SC700, SC800 en

uitvalschermen, type US701, US702 en wind-zonnescherm SL400

EN 13561

Gelezen en goedgekeurd,

de installateur,

Stempel:

Datum plaatsing:

Industrieterrein 1/3 - I.Z. Webbekom 1025| 3290 Diest | België

tel. +32 13 38 01 11 | fax +32 13 31 48 03

de fabrikant,

Harol NV

vertegenwoordigd door

Dhr. Jan De Lobel

kwaliteitsmanager

CE-Conformity declaration

Relevant EC Directives pertaining to machines 2006/42/EC

We, Harol NV, declare fully on our own responsibility that the products

related to this declaration, are conform to the following agreed standard or

other normative document(s).

This declaration is only valid if the installer has executed the installation

fully conform the conditions of the manufacturer and

conform the agreed standards pertaining to the installation.

Belgium, Diest, 1 March 2012

Screens, type SC700, SC800, SC900 and drop arm awnings, type

US701, US702 and lateral screen SL400

EN 13561

Seen and approved,

the installer,

Stamp:

Date of installation:

Industrieterrein 1/3 - I.Z. Webbekom 1025 | 3290 Diest | Belgium

tel. +32 13 38 01 11 | fax +32 13 31 48 03

the manufacturer,

Harol NV

represented by

Mr Jan De Lobel

quality manager

09/12 | 14

Technical assistance:

(name, address, telephone number)

SERVICE-LOG BOOK

This proof book contains technical references and records of installation, maintenance, repairs and alterations carried out and must be made

available for any inspections by authorised bodies.

Customer: (name, address and reference persoon)

Description of the solar protection: (model, type)

Identification number: (clear reference of the solar protection)

Location: (address)

Fabric: (collection, quality)

Power supply: (voltage and input)

Type of operation: (hold-to-run, impulse, automatic)

Installer: (name, address, telephone number)

Date of installation: (day, month, year)

List of components installed (drive unit, control and safety devices)

The technical features and performances of the components listed below are documented in the relevant installation manuals and/or on the label

on the component itself.

Operation: (type, serial number)

Motor: (type, serial number)

Relay box: (type, serial number)

Wind-sun automatic: (type, serial number)

Switch: (type, serial number)

Remote control: (type, serial number)

Other domotics: (type, serial number)

Miscellany: (type, serial number)

Warning of residual risks and of foreseeable improper use

Inform with signs attached to the risk points of the product and/or with written instructions to be given and explained to the user of the solar

protection, or whoever is responsible, about the existing risks and the foreseeable improper use.

09/12 | 15

Date Description of work

(Installation, start-up, adjustments, check on

safety devices, repairs, alterations, ...)

Installer’s

signature

Customer’s

signature

✂

Order no :

Client :

Address :

Tel. :

Date :

Installer :

Address :

Tel. :

FORM OF TRANSFER

Confirmation of transfer

The solar protection has been mounted without visible defects, and according to

the agreements made with the seller and/or the installer*.

If not, what are the remarks :

* If the client is content with the formal control and bring the solar protection into use, he/she is supposed to have accepted it.

The client has been familiarized with the operation of the product, according to

the prescriptions by means of the manual for the consumer.

The solar protection may be used in following weather conditions:

Wind (*):

* Indicate the allowable wind resistance class in function of the location, mounting and mounting-surface.

Rain : ◊ not permitted ◊ permitted under the supervision of the user ◊ permitted

Danger of frost : ◊ not permitted

The following documents are transfered to the user :

Manual for the consumer :

Assembly instructions :

Manual of the manufacturer of motors, switches and electronical control :

Others :

◊ Yes ◊ No

◊ Yes ◊ No

◊ Yes ◊ No

◊ Yes ◊ No

◊ Yes ◊ No

Signature installer Signature client

Assembly made by :

Name : From time : Till time : Number of

hours

until a wind resistance class of 3 = wind-force 6 Bft. = 49 km/h max. permitted SC800 SC900

until a wind resistance class of 2 = wind-force 5 Bft. = 35 km/h max. permitted SC800 SC900 SC700 US701

/ US702

until a wind resistance class of 1 = wind-force 4 Bft. = 27 km/h max. permitted SC800 SC900 SC700 US701

/ US702 SL400

until a wind resistance class of 0 = wind-force ≤ 3 Bft. = ≤ 20 km/h max. permitted SC800 SC900 SC700 US701

/ US702 SL400

specimen installer

✂

Order no :

Client :

Address :

Tel. :

Date :

Installer :

Address :

Tel. :

FORM OF TRANSFER

Confirmation of transfer

The solar protection has been mounted without visible defects, and according to

the agreements made with the seller and/or the installer*.

If not, what are the remarks :

* If the client is content with the formal control and bring the solar protection into use, he/she is supposed to have accepted it.

The client has been familiarized with the operation of the product, according to

the prescriptions by means of the manual for the consumer.

The solar protection may be used in following weather conditions:

Wind (*):

* Indicate the allowable wind resistance class in function of the location, mounting and mounting-surface.

Rain : ◊ not permitted ◊ permitted under the supervision of the user ◊ permitted

Danger of frost : ◊ not permitted

The following documents are transfered to the user :

Manual for the consumer :

Assembly instructions :

Manual of the manufacturer of motors, switches and electronical control :

Others :

◊ Yes ◊ No

◊ Yes ◊ No

◊ Yes ◊ No

◊ Yes ◊ No

◊ Yes ◊ No

Signature installer Signature client

Assembly made by :

Name : From time : Till time : Number of

hours

until a wind resistance class of 3 = wind-force 6 Bft. = 49 km/h max. permitted SC800 SC900

until a wind resistance class of 2 = wind-force 5 Bft. = 35 km/h max. permitted SC800 SC900 SC700 US701

/ US702

until a wind resistance class of 1 = wind-force 4 Bft. = 27 km/h max. permitted SC800 SC900 SC700 US701

/ US702 SL400

until a wind resistance class of 0 = wind-force ≤ 3 Bft. = ≤ 20 km/h max. permitted SC800 SC900 SC700 US701

/ US702 SL400

specimen client

This manual suits for next models

1

Table of contents

Other Harol Accessories manuals