Harrington Hoists ER Series Configuration guide

Owner's Manual Supplement

ELECTRIC

CHAIN HOIST

ER and NER

SERIES

CYLINDER

CONTROL MODEL

1/8 and 1/4 Ton Capacities

Code, Lot and Serial Number

WARNING

This equipment should not be installed, operated or

maintained by any person who has not read and understood

all the contents of this manual. Failure to read and comply

with the contents of this manual can result in serious bodily

injury or death, and/or property damage.

EFFECTIVE: February 18, 2002

2

IMPORTANT INFORMATION ON HOW TO USE THIS MANUAL

This OWNER’S MANUAL SUPPLEMENT is intended for use in combination with the “Owner’s Manual for

Electric Chain Hoist ER and NER Series 1/8 through 5 Ton Capacity”. Refer to the Table of Contents below to

determine the location(s) of information pertaining to your hoist. References to the “Owner’s Manual for Electric Chain

Hoist ER and NER Series 1/8 through 5 Ton Capacity” will be designated by the use of the acronym “EROM”.

Table of Contents

Section Page Number

1.0 Important Information and Warnings ……………………………………………………………….. EROM

1.1 Terms and Summary EROM

1.2 Warning Tags and Labels EROM

2.0 Technical Information…………………………………………………………………………….…………. 4

2.1 Specifications 4

2.2 Dimensions 5

3.0 Preoperational Procedures ……………………………………………………….………. 6 and EROM12

3.1 Fill Gear Box with Oil EROM

3.2 Chain 6

3.3 Mounting Location 7

3.4 Mounting the Hoist 7

3.5 Electrical Connections 7

3.6 Preoperational Checks and Trial Operation EROM

4.0 Operation ……………………………………………………………………………………… 9 and EROM

4.1 Introduction EROM

4.2 Shall’s and Shall Not’s for Operation EROM

4.3 Hoist Controls 9

3

Section Page Number

5.0 Inspection ……………………………………………………………………………………………...EROM

5.1 General EROM

5.2 Inspection Classification EROM

5.3 Frequent Inspection EROM

5.4 Periodic Inspection EROM

5.5 Occasionally Used Hoists EROM

5.6 Inspection Records EROM

5.7 Inspection Methods and Criteria EROM

6.0 Maintenance & Handling ……………………………………………………………………………. EROM

6.1 Count/Hour Meter EROM

6.2 Lubrication EROM

6.3 Motor Brake EROM

6.4 Load Chain EROM

6.5 Friction Clutch and Mechanical Load Brake with Friction Clutch EROM

6.6 Storage EROM

6.7 Outdoor Installation EROM

7.0 Troubleshooting ……………………………………………………………………………………… EROM

8.0 Material Safety Data Sheets ………………………………………………………………………… EROM

8.1 ER Model Gear Box Oil EROM

8.2 NER Model Gear Box Oil EROM

9.0 Warranty ……………………………………………………………………………………………… EROM

10.0 Parts List ……………………………………………………………………………………... 10 and EROM

4

2.0 Technical Information

2.1 Specifications

2.1.1 Product Code

2.1.2 ER and NER Models - Harrington ER series hoist are available in two versions, the ER and NER.

These two versions are equipped with different options as standard equipment. The NER has a friction

clutch mechanism that provides over winding protection. The ER has a mechanical load brake/friction

clutch combination and an electronic count/hour meter in the control circuit. Refer to Figure 2-1 for the

visual differences between the ER and NER.

Figure 2-1 Identifying ER verses NER Models

2.1.3 Operating Conditions and Environment

Temperature range: -4° to +104°F (-20° to +40°C)

Humidity: 85% or less

Enclosure Rating: Hoist Meets IP 55, Cylinder Meets IP44

Supply Voltage: Standard 208-230/460V-3-60, Optional 575V-3-60, Special Voltages Available

Single Speed Dual Speed

ASME Duty Classification: H4 H4

Intermittent Duty Rating: 60% ED

360 starts per hour

40/20% ED

120/240 starts per hour

Short Time Duty Rating: 60 min. 30/10 min.

5

Table 2-1 Hoist Specifications

Lifting Motor 3 Phase 60 Hz

Rated Current

(amps)

Cap.

(Tons)

Product

Code

Standard

Lift

(ft)

Lifting

Speed

(ft/min) Output

(Hp) @208V

– 230V @460V

Load

Sheave

Pockets

Load

Chain

Diameter

(mm)

X

Chain

Fall

Lines

Net

Weight

(lbs)

1/8 ER001HCC 6 57 0.75 4.2 2.1 5 5.0 x 1 68

Single

Speed 1/4 ER003SCC 6 39 0.75 4.2 2.1 5 5.0 x 1 68

1/8 ER001HDCC 6 58/19 0.6/0.2 2.9/2.4 1.5/1.2 5 5.0 X 1 79

Dual

Speed 1/4 ER003SDCC 6 29/10 0.6/0.2 2.9/2.4 1.5/1.2 5 5.0 X 1 79

2.2 Dimensions

Table 2-2 Hoist Dimensions

Cap.

(Tons)

Product

Code

Headroom

C

D

(in)

a

(in)

b

(in)

d

(in)

e

(in)

f

(in)

g

(in)

h

(in)

i

(in)

1/8 ER001HCC 40.6 17.7 21.1 13.0 10.4 10.7 10.4 1.0 4.0 3.9

Single

Speed 1/4 ER003SCC 40.6 17.7 21.1 13.0 10.4 10.7 10.4 1.0 4.0 3.9

1/8 ER001HDCC 40.6 17.7 22.2 13.0 10.4 11.9 10.4 1.0 4.0 3.9

Dual

Speed 1/4 ER003SDCC 40.6 17.7 22.2 13.0 10.4 11.9 10.4 1.0 4.0 3.9

Table 2-3 Hook Dimensions

Capacity

Code Hook** a

(in)

b

(in)

c

(in)

d

(in)

e

(in)

g

(in)

T 1.1 0.7 0.9 0.7 1.4 1.1

001H, 003S

B 0.8 0.5 0.7 0.5 1.4 1.0

6

3.0 Preoperational Procedures

3.2 Chain

3.2.1 Chain Components – Refer Figure 3-1 and ensure that stoppers and cushion rubbers are in the

correct location and properly installed. Never operate the hoist with incorrect, missing or

damaged chain components.

Figure 3-1 Chain Component Location

3.2.2 Chain Container – Install the chain container on the hoist body as shown in Figure 3-2. To place the

chain into the chain container, feed the chain into the chain container beginning with the free end. Take

care to avoid twisting or tangling the chain. NEVER put all the chain into the container at once. Lumped

or twisted chain may jam against the hoist body activating the friction clutch and potentially damaging

the chain.

7

Figure 3-2 Chain Container Installation

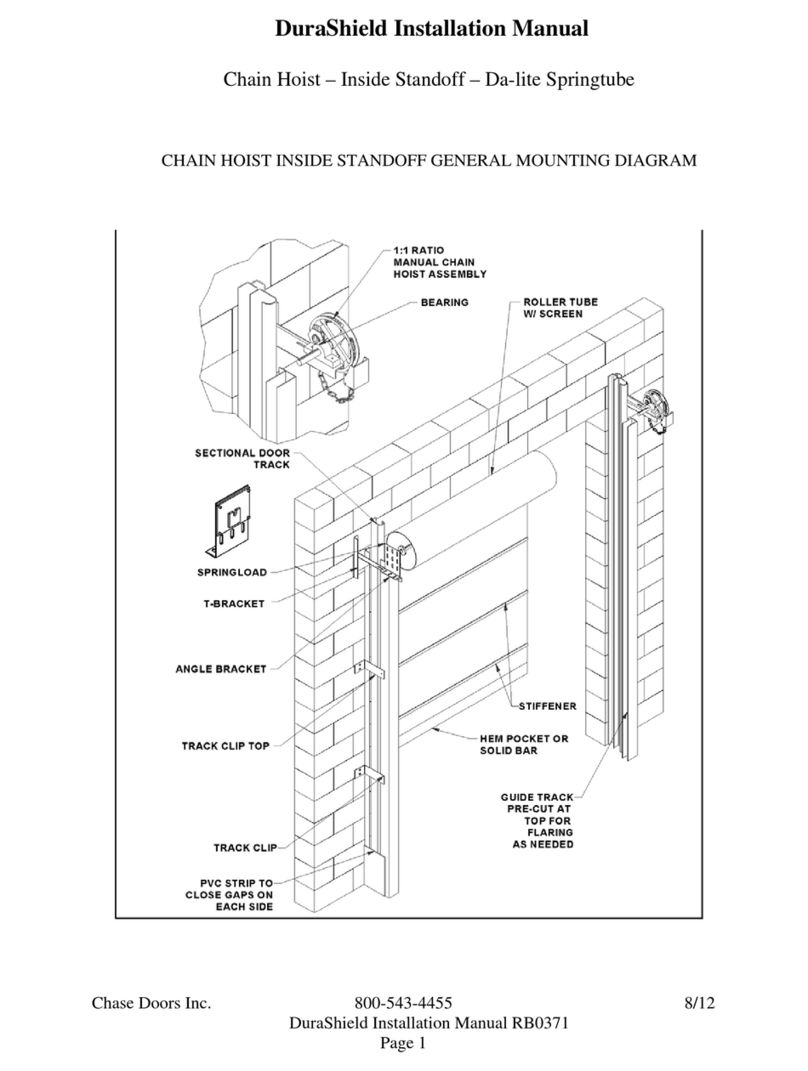

3.3 Mounting Location

3.3.1 WARNING Prior to mounting the hoist ensure that the suspension and it supporting

structure are adequate to support the hoist and its loads. If necessary consult a professional that

is qualified to evaluate the adequacy of the suspension location and its supporting structure.

3.3.2 NOTICE See Section 6.7 of the EROM for outdoor installation considerations.

3.4 Mounting the Hoist

3.4.1 Manual Trolley - Follow instructions in Owner’s Manual provided with the trolley.

3.4.2 Motorized Trolley – Cylinder control model hoists are NOT intented to be used with motorized trolleys.

3.4.3 Hook Mounted to a Fixed Location - Attach the hoist’s top hook to the fixed suspension point.

3.4.4 CAUTION Mount the hoist at a height that will allow the operator to maintain a clearance of at

least 4 inches between the Cushion Rubber and the hoist body during operation.

3.4.5 WARNING Ensure that the fixed suspension point rests on the center of the hook’s saddle and

that the hook’s latch is engaged.

3.5 Electrical Connections

3.5.1 CAUTION Ensure that the voltage of the electric power supply is proper for the hoist.

3.5.2 DANGER Before proceeding, ensure that the electrical supply for the hoist has been de-

energized (disconnected). Lock out and tag out in accordance with ANSI Z244.1 “Personnel Protection

-Lockout/Tagout of Energy Sources”.

3.5.3 Coiled Control Cable - The Coiled Control Cable connects to the hoist via a 5-pin (5P) or 8-pin (8P)

Plug and Socket. Make this connection as follows:

§Refer to Figure 3-3.

§Insert the 5P/8P Plug into the 5P/8P Socket on the hoist and hand tighten the Screw Coupling.

8

3.5.4 Power Supply Cable Hoist Connection – The Power Supply Cable connects to the hoist via a 4-pin

(4P) plug and socket. Make this connection as follows:

§Refer to Figure 3-3.

§Insert the 4P plug of the Power Supply Cable into the 4P Socket on the hoist and hand tighten the

screw coupling.

§Install the Cable Support Arm (pre-installed on the Power Supply Cable) on to the Socket Holder

using the pre-installed Machine Screws and Lock Washers.

Use care to avoid twisting or kinking the Power Supply Cable.

3.5.5 Power Supply Cable Installation – If the hoist is hook mounted to a fixed support ensure that the

Power Supply Cable is properly installed and supported between the hoist and the electrical

power supply.

If the host is installed on a manual trolley, then the Power Supply Cable must be installed along the

beam that the trolley runs on. For curved beams a special cable suspension system will be

needed, and this instruction does not apply. For straight beams install the Power Supply Cable as

follows:

§Install a guide wire system parallel to the beam.

§For a manual trolley the guide wire should be positioned slightly outside the hoist's Cable

Support as shown in Figure 3-3.

§Use the Cable Trolleys supplied with the hoist to suspend the Power Supply Cable from the

guide wire. Space the Cable Trolleys every 5 feet.

Figure 3-3 Coiled Control Cable and Power Supply Cable Connections

3.5.6 Connection to Electrical Power Source - The red, white, and black wires of the Power Supply Cable

should be connected to an Electric Power Disconnect Switch or Circuit Breaker. This connection

should be made so that the hoist is phased properly. Refer to Section 3.6.11 of the EROM for

instructions on how to check for correct power supply phase connection.

3.5.7 Fuse/Breaker Capacity -The hoist's power supply should be equipped with overcurrent protection such

as fuses, which should be selected for 110% to 120% of total listed full load amperage, and should be

dual element time-delay fuses. Refer to the motor nameplate for the full load amperage draw.

3.5.8 DANGER Grounding - An improper or insufficient ground connection creates an electrical

shock hazard when touching any part of the hoist or trolley. In the Power Supply Cable the ground wire

will be either Green with Yellow stripe or solid Green. It should always be connected to a suitable

ground connection. Do not paint the trolley wheel running surfaces of the beam as this can affect

grounding.

9

4.0 Operation

4.3 Hoist Controls

4.3.1 Single Speed Hoists – Firmly hold the black Grip on the cylinder control. Slide the Up/Down Switch

Operator up to raise the load or down to lower the load as shown in Figure 4-1. To stop the hoist slide

the Up/Down Switch Operator back to the middle position.

4.3.2 Dual Speed Hoists – Select high or low speed using the Speed Selector Switch. Lights ajacecnt to the

Speed Selector Switch indicate if low or high speed is selected. Slide the Up/Down Switch Operator up

to raise the load or down to lower the load Figure 4-1. To stop the hoist slide the Up/Down Switch

Operator back to the middle position.

4.3.3 CAUTION Make sure the motor completely stops before reversing direction.

Single Speed Dual Speed

Figure 4-1 Cylinder Control Operation

10

10.0 Parts List

Figure 10-1 Cylinder Control Parts

11

Figure

No. Part Name Parts per

Hoist Part Number

1Detachable Hook Assy 1CD1BI1011

2Latch Assembly 1CF071005

3Detachable Fitting E 1E2D5041125

4Flat Head Screw 19096528

5Chain Pin 1M3041005

6Slotted Nut 1M3049005

7Split Pin 19009402

8Cushion Rubber 2E5FE003S9046

9Stopper Assembly 2ES1045003

S 1 C10013H1020

10 Cylinder Switch Set D 1 C20013H1020

11 Truss-Head Screw 1TRUSSM4X10

5P Plug S 1 ES613003

12 8P Plug D 1 ESM538010

13 Warning Tag 1WTAG7

14 Cable Holder A 1CD1BS9750

15 Cable Holder B 1CD1BS9751

16 Cable Tie 29006602

17 Machine Screw w/Spring

Washer 4MS554010

18 Socket Bolt 19091259

19 Lever Nut 1ES855003

20 Limit Lever Pin Assembly 1CD1BS2757

21 Spacer 1CD1BS9758

5P Socket S 1 CD1BS1564

22 8P Socket D 1 CD1BB1564

23 Chain Container Kit 1PBK-B

24 Chain Container Spring 1ER1BS9416

25 Socket Bolt 1J1BE10816513

26 Lever Nut 1ES857005S

www.harringtonhoists.com

Harrington Hoists, Inc. Harrington Hoists – Western Division

401 West End Avenue 2341 Pomona Rincon Rd. #103

Manheim, PA 17545-1703 Corona, CA 92880-6973

Phone: 717-665-2000 Phone: 909-279-7100

Toll Free: 800-233-3010 Toll Free: 800-317-7111

Fax: 717-665-2861 Fax: 909-279-7500

ERCYLSup

This manual suits for next models

5

Table of contents

Other Harrington Hoists Chain Hoist manuals

Popular Chain Hoist manuals by other brands

OZ Lifting Products

OZ Lifting Products OZ500EC Operator's manual

Parkside

Parkside PSZ 250 A1 Operation and safety notes

Ingersol Rand

Ingersol Rand LC2A Series Product information

Silverline

Silverline 442463 manual

Austlift

Austlift 915303 Service manual

ACI Hoist & Crane

ACI Hoist & Crane MH Operation manual