Hartmann CML00 User manual

CML00

Control, Measurement and

Data Logging System

www.hartmann-electronic.com 09.04.2021 Rev. 1.5

Rev:

R 1.0

29.08.2011

R 1.1

30.08.2011

R 1.2

30.08.2011

R 1.3

05.12.2011

R 1.4

02.09.2016

R 1.5

09.04.2021

Impressum:

Hartmann Electronic GmbH

Motorstraße 43, D-70499 Stuttgart (Weilimdorf)

Telefon + 49 711 1 39 89-0

Telefax + 49 711 8 66 11 91

E-mail info @ hartmann-electronic.com

Internet www.hartmann-electronic.com

Hartmann Electronic is a longstanding partner of the

embedded industry and has a variety of different backplanes.

With our wide selection of backplanes and enclosure you can

build your perfect system platform

Copyright © 2016

All rights and technical modifications reserved.

www.hartmann-electronic.de II Rev. 1.5

Table of Contents

1Applicability..................................................................................................................................... 5

1.1 Background Information......................................................................................................... 5

2Safety.............................................................................................................................................. 6

2.1 Intended Application............................................................................................................... 6

2.2 Safety Symbols ...................................................................................................................... 6

2.3 General Safety Precautions................................................................................................... 6

2.4 Safety Instructions.................................................................................................................. 7

2.4.1 Protection Against Electromagnetic Interference (EMI) ................................................ 7

2.4.2 Electrostatic Discharge Precautions.............................................................................. 7

2.4.3 Location......................................................................................................................... 7

2.4.4 Voltage Hazards............................................................................................................ 7

2.4.5 Mounting Considerations............................................................................................... 7

2.4.6 Electrical Hazards.......................................................................................................... 7

3Product Description......................................................................................................................... 9

3.1 General Information ............................................................................................................... 9

3.1.1 System Overview........................................................................................................... 9

3.1.2 Features ........................................................................................................................ 9

3.1.3Optional Features........................................................................................................ 10

3.2 Front Panel Elements........................................................................................................... 11

3.2.1 CML00 3U / 8HP ......................................................................................................... 11

3.2.2 Power entry module and fuse...................................................................................... 11

3.2.3 Main Power switch....................................................................................................... 11

3.2.4 Ethernet connector...................................................................................................... 12

3.2.5 USB connector ............................................................................................................ 12

3.2.6 Status LED .................................................................................................................. 12

3.2.7 ON / OFF Soft Switch.................................................................................................. 12

3.2.8 Interface overview ....................................................................................................... 13

3.2.9 Grounding/Protective Earthing .................................................................................... 15

3.3 Fans ..................................................................................................................................... 16

3.3.1 Fan Speed Measurement............................................................................................ 16

3.3.2 Fan Speed Regulation................................................................................................. 16

3.4 Temperature Sensor Inputs ................................................................................................. 17

3.5 Basic Control & Meassurement Signals............................................................................... 20

3.5.1 Digital Inputs................................................................................................................ 21

3.5.2 Digital Outputs............................................................................................................. 21

3.6 Additional Control & Meassurement Signals........................................................................ 21

3.6.1 Analog Inputs............................................................................................................... 21

4CML Setup via USB...................................................................................................................... 22

4.1 Installation MUSEcontrol...................................................................................................... 22

4.2 The Main Window MUSEcontrol.......................................................................................... 22

5CML setup via Ethernet ................................................................................................................ 23

5.1 Installation SYScontrol......................................................................................................... 23

5.2 The Main Window “SYScontrol” ........................................................................................... 24

5.2.1 SYScontrol window “Outputs” ..................................................................................... 25

5.2.2 SYScontrol window “Networks” ................................................................................... 26

5.2.3 Connect devises in your network ................................................................................ 26

6CML setup via “snmp”................................................................................................................... 27

7Set the default settings ................................................................................................................. 28

8Service.......................................................................................................................................... 28

8.1 Technical support and Return for Service Assistance......................................................... 28

Rev. 1.5 III www.hartmann-electronic.com

List of Figures

Figure 3-1: CML00................................................................................................................................. 11

Figure 3-2: Ethernet Connector Pin Assignment................................................................................... 12

Figure 3-3: USB Connector Pin Assignment......................................................................................... 12

Figure 3-4: interface connector ............................................................................................................. 13

Figure 3-5: Protective Earth and Grounding.......................................................................................... 15

Figure 3-6: Window “Fans” in SYScontrol ............................................................................................. 16

Figure 3-7: Window “Temperature Sensors” in SYScontrol.................................................................. 17

Figure 3-8: Hysteresis control mode ..................................................................................................... 18

Figure 3-9: Linear control mode ............................................................................................................ 19

Figure 3-10: Low noise control mode.................................................................................................... 20

Figure 3-11: High density SUB-D DIO connector 26 Pol ...................................................................... 20

Figure 4-1: Main Window MUSEcontrol................................................................................................ 22

Figure 5-1: Window “Clobal” in SYScontrol........................................................................................... 24

Figure 5-2: Window “Outputs” in SYScontrol ........................................................................................ 25

Figure 5-3: Window “Network” in SYScontrol........................................................................................ 26

Figure 5-4: Window “Preferences” in SYScontrol.................................................................................. 26

Figure 5-5: Window “Search” in SYScontrol.......................................................................................... 27

www.hartmann-electronic.com 5 Rev 1.5

1 Applicability

System name

Order number

CML00 Controlboard with TCP/IP and USB

1H00004147

230VAC Power supply with power entry for CML00

D575.00373

CML00 Kit. 1H00004146 + D575.00373 with 3U/8HP front panel

1H00004170

1.1 Background Information

•IEC 60297-3-101, -102, -103

•PICMG 2.0 R3.0 CPCI Core Specification

•PICMG 2.01 R2.0 Hot Swap

•PICMG 2.09 R1.0 System Management Bus

•PICMG 2.10 R1.0 Keying

•IEC 1000-4-4 Electromagnetic Compatibility, Part 4, Section 4, Electrical fast

transient/burst immunity test.

•EN60950-1

•Shock:

MIL-STD-810F 1 January 2000 Annex C, U.S highway truck

Figure 514.5C-1, vertical Shock test (Sawtooth) Figure 516.5-10

•Vibration:

DIN EN 61373:1999, Figure 2, Category 1, Class B

MIL-STD-810F 1 January 2000 Annex C, Shipboard: Figure 514.5C-15

Rev. 1.5 6 www.hartmann-electronic.com

2 Safety

2.1 Intended Application

CML00 are not end-products, so there is no valid approval for this unit. In Order to enable

stand-alone functionality, additional elements are required.

The completion and final testing of the units have been carried out, or at least supervised, by

qualified technicians. These instructions are directed exclusively to these qualified technicians

i.e.engineers, trained and qualified electricians etc.

Make sure that the finished system complies with the safety regulations currently applicable in

the country it is going to be used.

2.2 Safety Symbols

Hazardous voltage!

Familiarise yourself with the danger of electrical voltages and the safety

precautions before starting to work with parts that carry dangerous voltages

Caution!

This symbol indicates a condition where damage of the equipment or injury of

the service personnel could occur. To reduce the risk of damage or injury,

follow all steps or procedures as instructed.

Danger of electrostatic discharge!

Static electricity can damage sensitive components in a system. To avoid

damage, wear ESD wrist straps or at regular intervals touch blank enclosure

parts.

2.3 General Safety Precautions

Warning!

Voltages over 60 VDC can be present in this equipment. This equipment is

intended to be accessed, to be installed and maintained by qualified and trained

service personnel only.

This equipment is designed in accordance with protection class 1!

lt must therefore be operated only with protective GND/earth connection!

www.hartmann-electronic.com 7 Rev 1.5

2.4 Safety Instructions

The intended audience of this User's Manual is system Integrators and hardware/software

engineers.

The product has been designed to meet relevant standard industrial safety requirements. It

must not be used except in its specific area of office telecommunication industry and industrial

control. It shall not be used in safety-critical applications, life-sustaining appliances or in

aircraft.

Only trained personnel or persons qualified in electronics or electrical engineering are

authorized to install, operate or maintain the product.

This section provides safety information about:

•Protection Against Electromagnetic Interference (EMI)

•Electrostatic Discharge Precautions

•System Installation

2.4.1 Protection Against Electromagnetic Interference (EMI)

The product has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules, EN 55022 Class A.

To ensure proper EMC shielding, operate the subrack only with all free slots populated with

filler panels.

Ensure that all EMI gaskets make correct contact.

2.4.2 Electrostatic Discharge Precautions

Electronic components can easily be destroyed by electrostatic discharge which can occur

between subrack components and a person.

•Before working on the rack make sure that you are working in an ESD-safe

environment.

2.4.3 Location

Locate the system in a stable area free of excessive movement and jarring, dust, smoke, and

electrostatic discharge (ESD). Make sure that the temperature does not exceed the operating

temperature given in the environmental requirements in this guide and allow room for proper

air flow for cooling.

2.4.4 Voltage Hazards

The system is powered with a power supply the mains voltage is 115/230VAC.

(Voltage range 85VAC to 265VAC)

This voltage is considered hazardous.

2.4.5 Mounting Considerations

During the course of handling, shipping, and assembly, parts could become loose or

damaged.

Do not operate a shelf in this condition, as this may cause damage to other equipment.

2.4.6 Electrical Hazards

The caution label on the system's rear near the grounding studs shows that you have

to create an earth connection because there may be a high leakage current which is

considered hazardous.

Rev. 1.5 8 www.hartmann-electronic.com

High leakage current can cause injuries.

Ensure that the system is properly grounded at all times, the following conditions shall be met:

•This equipment shall be connected directly to the AC supply system earthing

www.hartmann-electronic.com 9 Rev 1.5

3 Product Description

3.1 General Information

3.1.1 System Overview

The Control, Measurement and Data Logging system (CML) is designed to add remote control

and monitoring functionality to electronic systems.

Analog measurement is done with a fast & high precision 12 bit AD converter. The 18 analog

input channels are configured to measure 8 voltages, 6 temperature probes and 4 general

purpose analog inputs.

The integrated supervision system compares all measured voltages with a minimum and

maximum value and temperatures with a maximum value.

Exceeding the supervision threshold can switch off the system.

Fan speed measurement and speed control of up to 6 fans is provided. The fan supply voltage

is generated on board, so no special fans with PWM input are required. Up to 3 fan groups

can be regulated individually.

If the CMLs supplied by an external power source, it is possible to switch the main system

power supply on or off with the on/off switch or via network.

All necessary functions are implemented on a small (86mm x 110mm) board. The system

connections are provided on a 2mm high density connector.

For standard backplanes (e.g. VME) specific adapters are available.

The CML/adapter combination can be inserted into Hartmann electronic standard VME, VPX,

cPCI systems, backplanes or power backplanes.

An optional alphanumeric display module can be connected to the CML. With this display all

measured values can be visualized.

3.1.2 Features

•Bus-Voltage measurement: 8 channels for 3.3V, 5V, 12V and -12V

•Temperature measurement: 1-wire-bus for up to 6 digital temperature sensors

•Fan Control: 6 Fans monitored, fan speed settable via fan supply voltage

•Fully controlled, programmable trip thresholds (min./max. Voltage & temperature)

•Generation of VME/CPCI RESET and ACFAIL

•Detection of VME/CPCI RESET and SYSFAIL

•Detection of Derating or Failure signal from CPCI Power Supplies

•Capable to switch CPCI Power Supplies (ON/OFF)

•Ethernet connection IEEE 802.3 10BASE-T and IEEE 802.3u 100BASE-TX

•WWW-Server integrated, full control via SNMP protocol

•Different security access level

•Multicolored status LED

•AC Main switch

Rev. 1.5 10 www.hartmann-electronic.com

•Remote or local switch ON/OFF

•PC-Control (connected to galvanic isolated USB or Ethernet) with free available

software

•IP address settable to a fix value or configurable via DHCP

•Firmware update possible via USB.

•Automatic data logging on Windows/Linux computer possible

•Digital Signal Processor (DSP) for real-time processing of all measured data

•Powered by 5V bus voltage and independent power supply

•Configuration permanently saved in EEPROM

•Digital inputs: 8 x TTL

•Digital outputs: 8 x TTL

3.1.3 Optional Features

•OPC server available

•CAN-bus (galvanic isolated)

•alphanumeric display (via I²C-Bus)

•6 additional analog measurement channels for current, temperature or voltages

•Different Fan types supported (PWM-pulsed Fan or Fan with tachometer signal)

•PWM-Signal for external use

The system is based on a fast DSP-controller with flexible interface hardware. So it is possible

to implement various custom-specific applications.

www.hartmann-electronic.com 11 Rev 1.5

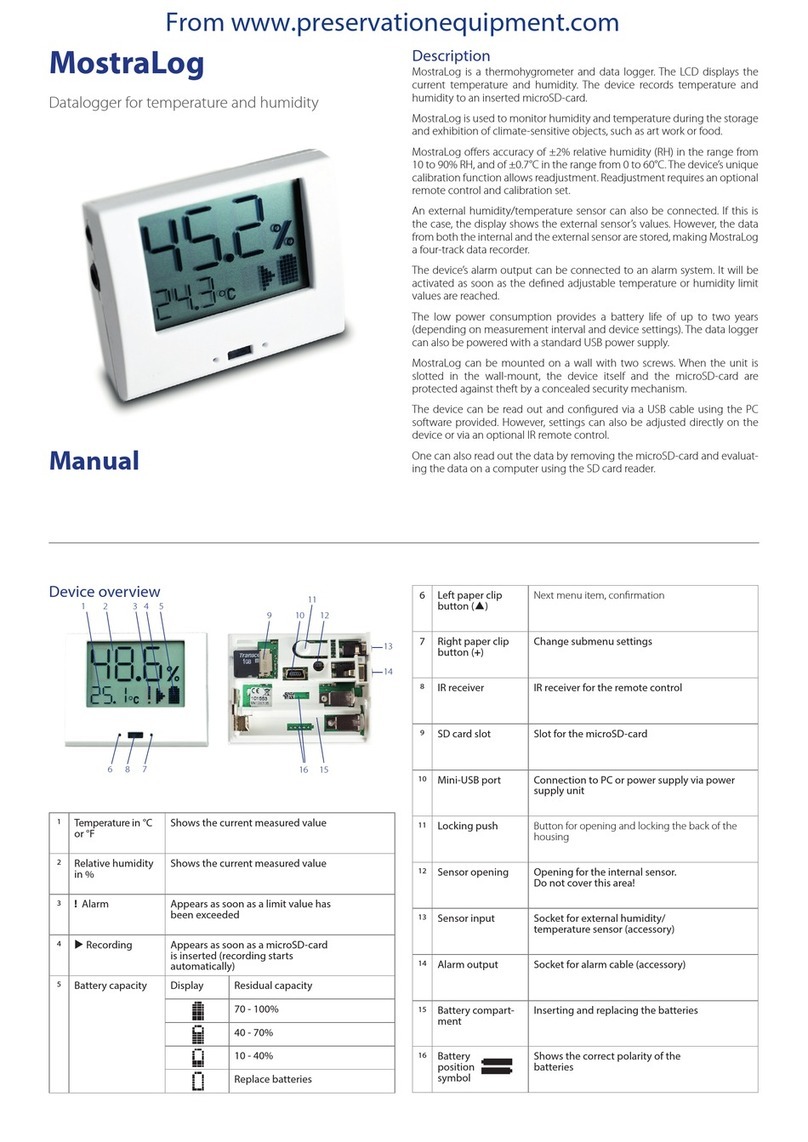

3.2 Front Panel Elements

3.2.1 CML00 3U / 8HP

1

Front panel 3U/8HP

5

USB connector

2

VAC Power entry module

6

Status LED

3

Main power switch

7

ON / OFF soft switch

4

Ethernet connector

8

Fuse

9

I / O Connector

3.2.2 Power entry module and fuse

The power entry module is provided with an IEC 320-C14 connector, contacted with fuse

holder 1 pole.

Caution!

The fuse values (6,3A T, 10A T) are only for incoming inspection.

The final value depends on the ready configuration of the completed system.

e.g. Number of power supplies.

3.2.3 Main Power switch.

Rocker switch 2-pole, non-illuminated, acc. to IEC 61058-1

If Power Switch “ON”, the CML and PSU are active in Standby mode, but the outputs on

Backplane are “OFF”

Figure 3-1: CML00

2

1

5

3

6

7

4

8

9

Rev. 1.5 12 www.hartmann-electronic.com

3.2.4 Ethernet connector

Figure 3-2: Ethernet Connector Pin Assignment

This is the standard NIC configuration. You need a 1:1-cable to connect a to a HUB, or a

cross-over cable to connect to another NIC (e.g. a computer).

There is no automatic signal crossing like with some routers.

3.2.5 USB connector

Pin 1: VCC

Pin 2: USB –

Pin 3: USB +

Pin 4: GND

Figure 3-3: USB Connector Pin Assignment

This is the standard USB connector type A.

The USB connection is galvanic isolated from the system to prevent ground loops.

3.2.6 Status LED

This multi-color LED shows the global status of the system:

•YELLOW Standby state (the system power supply is off)

•GREEN System power is on, all measurement values are in limit

•RED System switched off because of any failure

3.2.7 ON / OFF Soft Switch

The soft switch is used to switch the system power supply (push the switch to the “ON” or

position “OFF”).

www.hartmann-electronic.com 13 Rev 1.5

3.2.8 Interface overview

Figure 3-4: interface connector

Interface connector basic X2

Pin

Signal

Pin

Signal

X2:A

5V Standby from Backplane (n.c)

X2:R

COMPACT_PCI_FAL_2

X2:B

5V_SENSE

X2:S

SWITCH_PS_1_OUT

X2:C

5.0V_BUS

X2:T

SWITCH_PS_2_OUT

X2:D

3.3V_SENSE

X2:U

FANTACHO1_IN

X2:E

GND

X2:V

FANTACHO4_IN

X2:F

-12V_SENSE

X2:W

FANTACHO2_IN

X2:G

GND

X2:X

FANTACHO5_IN

X2:H

12V_SENSE

X2:Y

FANTACHO3_IN

X2:I

VME_SYS_RESET

X2:Z

FANTACHO6_IN

X2:J

GNDA

X2:AA

FAN_PWR_SPLY (Connect to 12V)

X2:K

FAN_PWM_EXTERN_OUT

X2:AB

FAN_PWR_SPLY (Connect to 12V)

X2:L

I2C_SCL_EXTERN

X2:AC

FAN+ (Connect to Fan)

X2:M

1-WIRE-BUS_DATA

X2:AD

FAN+ (Connect to Fan)

X2:N

I2C_SDA_EXTERN

X2:AE

FAN- (Connect to Gnd)

X2:O

COMPACT_PCI_DEG_1

X2:AF

FAN- (Connect to Gnd)

X2:P

COMPACT_PCI_DEG_2

X2:AG

FAN- (Connect to Gnd)

X2:Q

COMPACT_PCI_FAL_1

X2:AH

FAN- (Connect to Gnd)

X2 / 34 Pin basic

X1 /34 Pin extended

Rev. 1.5 14 www.hartmann-electronic.com

Interface connector X1

basic

extended

Pin

Signal

Pin

Signal

X1:A

DIGITAL_IN_7

X1:S

U8_SENSE

X1:B

DIGITAL_OUT_7

X1:T

U9_SENSE

X1:C

DIGITAL_IN_6

X1:U

U4+

X1:D

DIGITAL_OUT_6

X1:V

U4-

X1:E

DIGITAL_IN_5

X1:W

U5+

X1:F

DIGITAL_OUT_5

X1:X

U5-

X1:G

DIGITAL_IN_4

X1:Y

U6+

X1:H

DIGITAL_OUT_4

X1:Z

U6-

X1:I

DIGITAL_IN_3

X1:AA

U7+

X1:J

DIGITAL_OUT_3

X1:AB

U7-

X1:K

DIGITAL_IN_2

X1:AC

IO_LOAD

X1:L

DIGITAL_OUT_2

X1:AD

IO_CLOCK

X1:M

DIGITAL_IN_1

X1:AE

IO_SOM

X1:N

DIGITAL_OUT_1

X1:AF

IO_SIMO

X1:O

DIGITAL_IN_0

X1:AG

GND

X1:P

DIGITAL_OUT_0

X1:AH

GNDA

X1:Q

GND

X1:R

GNDA

www.hartmann-electronic.com 15 Rev 1.5

3.2.9 Grounding/Protective Earthing

The system contains gaskets at the subrack and board level to guard against electromagnetic

interference (EMI). Each of the subrack’s individual components make contact with the

gaskets and to the PE-flat plug inside the rear panel.

The guide rails are also fitted with electrostatic discharge (ESD) contacts for each blade and

RTM. These ESD contacts ensure that the boards are fully discharged to prevent static

caused by static as they are plugged into the subrack.

Caution!

The subrack is designed in accordance with protection class1l! lt must therefore

be operated with protective earth/GND connection. Use only a three conductor

AC power cable with a protective earth conductor that meets the IEC safety

standards!

There is a 6.3 x 0.8mm PE-flat plug at the auxiliary PSU. This flat plug is only for potential

equalization. Grounding is achieved through the protective earth conductor of the power cable!

Figure 3-5: Protective Earth and Grounding

Rev. 1.5 16 www.hartmann-electronic.com

3.3 Fans

3.3.1 Fan Speed Measurement

The CLM can measure the rotation speed of up to 6 fans simultaneously.

The standard fan speed signal is the open collector pulse output provided by many fans. If

such signal is not available, the fan current (measured at a small shunt resistor) can used and

the CML calculates the rotation speed by analyzing this current signal.

The fan rotation speed is accessible with SNMP network commands (crate.fantray.fanSpeed

OID)

Figure 3-6: Window “Fans” in SYScontrol

3.3.2 Fan Speed Regulation

The CML provides 6 independent fan supply outputs. The output voltage is regulated by the

CML to achieve the requested rotation speed.

The nominal fan speed is changeable with the SNMP network commands

(crate.fantray.fanNominalSpeed OID) or in SYScontrol window “Global”

An automatic fan speed regulation depending on the temperature sensors is also possible.

www.hartmann-electronic.com 17 Rev 1.5

3.4 Temperature Sensor Inputs

The CML has 6 temperature sensor inputs (semiconductor sensors with 1 kOhm resistance at

25°C)

In the event of an error, the status LED on the front panel will turned red.

The temperatures can be read with the SNMP network command

(crate.sensor.sensorTemperature OID) or in SYScontrol window “Global”

Each temperature is compared with three threshold values.

(crate.sensor.sensorWarningThreshold, crate.sensor.sensorAlarmThreshold and

crate.sensor.sensorFailureThreshold OIDs).

The temperature threshold values can be read or write in SYScontrol window “Temperature

Sensors”.

Figure 3-7: Window “Temperature Sensors” in SYScontrol

Please set all group- thresholds to equal values.

Two different modes can be set. Please read more about the hysteresis control mode and the

linear control mode in the following paragraph.

To operate the device in the hysteresis control mode, it is necessary to swap the alarm with

the warning temperature value. The alarm temperature has to be less than the warning

temperature. The fan speed executes a hysteresis between the two temperature points of any

connected sensor between maximum speed and the nominal and minimal speed respectively.

If the “sensorFailureThreshold”of any connected sensor is reached, the main power supply of

the system is switched off.

The controlling result of fan speed is pictured in figure 3.8.

Rev. 1.5 18 www.hartmann-electronic.com

The second mode is the linear control mode. If the temperature of any connected sensor is

under the warning threshold the fans will operate in their nominal and minimum speed

respectively.

If the “sensorWarningThreshold”is reached, all fans will rotate in a calculated linear

temperature-sensitive speed.

Overstepping the “sensorAlarmThreshold”they will switch to their maximum speed.

After exceeding the “sensorFailureThrehold”of any connected sensor, the main power supply

of the system is switched off.

The controlling result of fan speed is pictured in figure 3.9.

Speed of Fan [rpm]

Operation

temperature

[°C]

Fan max

Fan nom

Device

switch off

Hysteresis

Talarm Twarn Tfail

Figure 3-8: Hysteresis control mode

www.hartmann-electronic.com 19 Rev 1.5

I

If using the linear control mode it is important to know that there exists a sub mode called low

noise mode. When the nominal speed set by user is under the allowed minimal speed, the

device will switch off all fans.

Linear control mode is the default setting at delivery.

If is it not necessary to cool down the device the fans stand still. After reaching of

“sensorWarningThreshold”the behavior of fan control is equal to the linear control mode.

The controlling result of fan speed is pictured in figure 3.10.

Speed of Fan [rpm]

Operation

temperature

[°C]

Fan max

Fan nom

Device

switch off

Linear fan

control

Twarn Talarm Tfail

Figure 3-9: Linear control mode

Rev. 1.5 20 www.hartmann-electronic.com

Speed of Fan [rpm]

Operation

temperature

[°C]

Fan max

Fan min

Device

switch off

Linear fan

control

Twarn Talarm Tfail

Fan nom

<

Fan min

Figure 3-10: Low noise control mode

The default setting at threshold is:

“sensorWarningThreshold” 30°C

“sensorAlarmThreshold” 45°C

“sensorFailureThrehold” 55°C

3.5 Basic Control & Meassurement Signals

8 digital inputs and 8 digital outputs are on the HD-SUB-D26 connector on the front plate.

Figure 3-11: High density SUB-D DIO connector 26 Pol

SUB-D

1

2

3

4

5

6

7

8

9

DI

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

GND

Table of contents

Popular Data Logger manuals by other brands

NOVAK

NOVAK DATA LOGGER instruction manual

Hydro International

Hydro International Hydro-Logic Flexi Logger 105 user manual

sauermann

sauermann KNT 320 user manual

Racelogic

Racelogic Performance Box Touch V1 user guide

Onset

Onset Hobo MicroRX RX2105 manual

EP Solar

EP Solar EPEVER westech eLOG01 Product introduction