Harwin Z80-255 User manual

IS-46

Hand Crimp Tool Z80-255

2

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

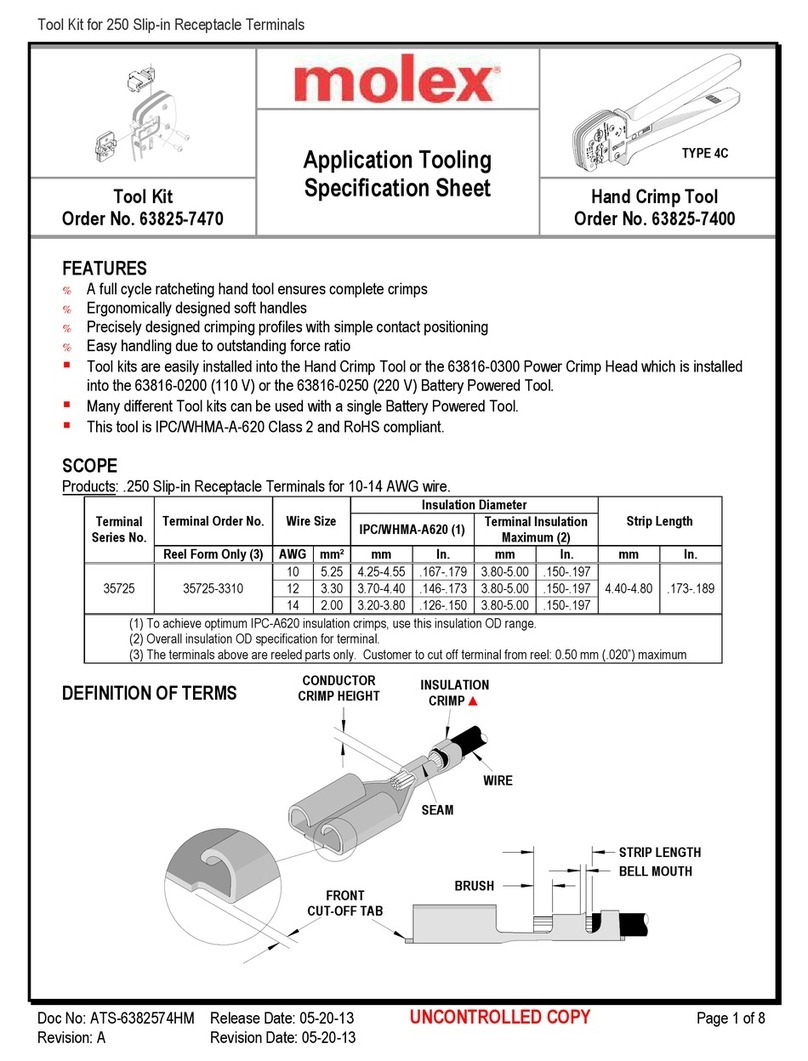

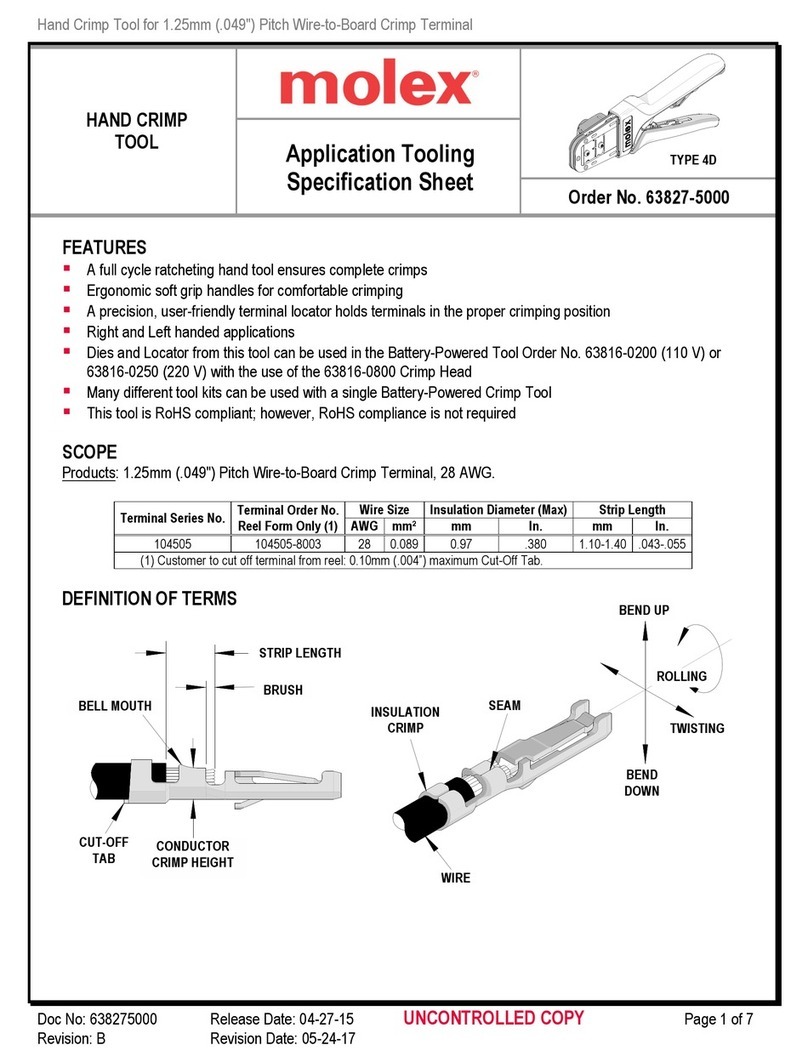

CRIMP CONTACT INFORMATION

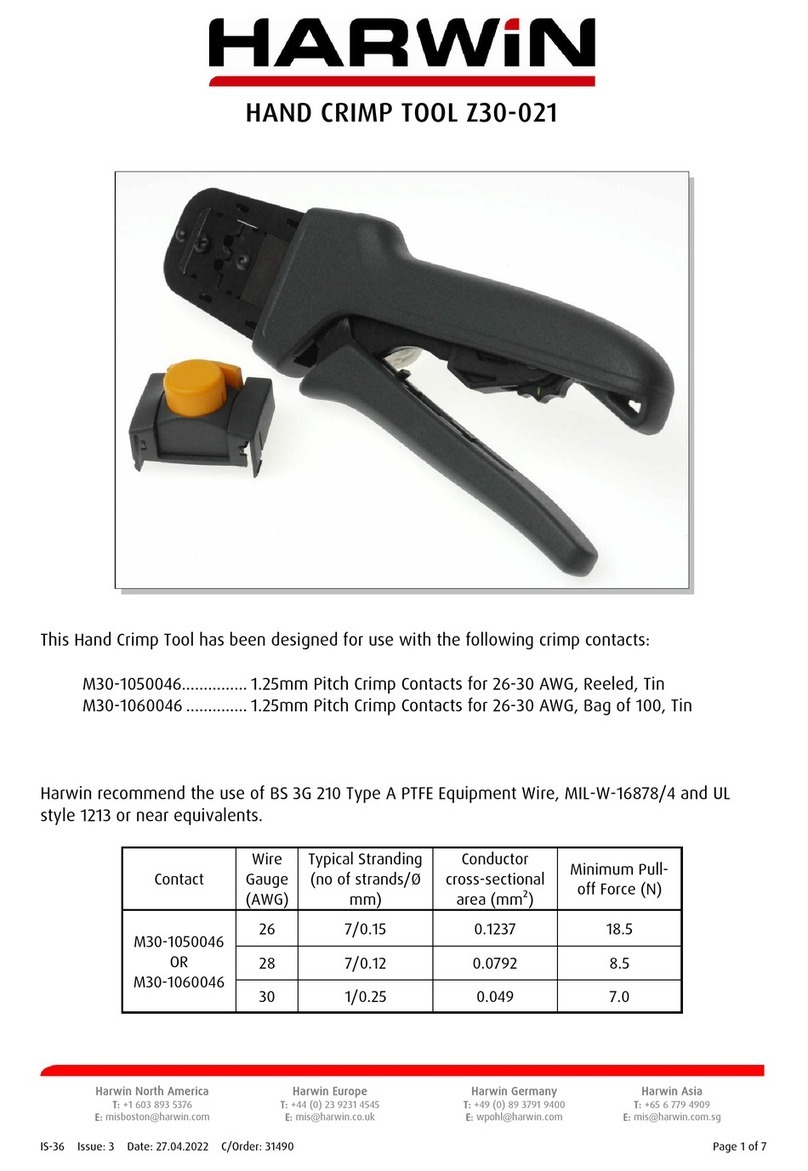

This Hand Crim Tool has been designed for use with the following M225 series Crim Contacts:

M225-2830046 ............. Female crim contact for 22-24 AWG wire, su lied loose

M225-2840046 ............. Female crim contact for 26-28 AWG wire, su lied loose

M225-2530046 ............. Female crim contact for 22-24 AWG wire, su lied reeled

M225-2540046 ............. Female crim contact for 26-28 AWG wire, su lied reeled

Harwin recommends the use of BS 3G 210 Ty e A PTFE Equi ment Wire, see Com onent

S ecification C049XX for suggested alternatives.

!"#

$

%

$&''

$

#

''(

)#

$'

''

'"

''

''

"##%%

%

**+

*+,--

**+*.,--

22

19/0.15

0.3358

1.10

0.76–0.82

45

24

7/0.20

0.2199

0.95

29

**+

*+--

**+*.--

26

7/0.15

0.1237

0.80

0.50–0.56

18

28

7/0.12

0.0792

0.71

9.8

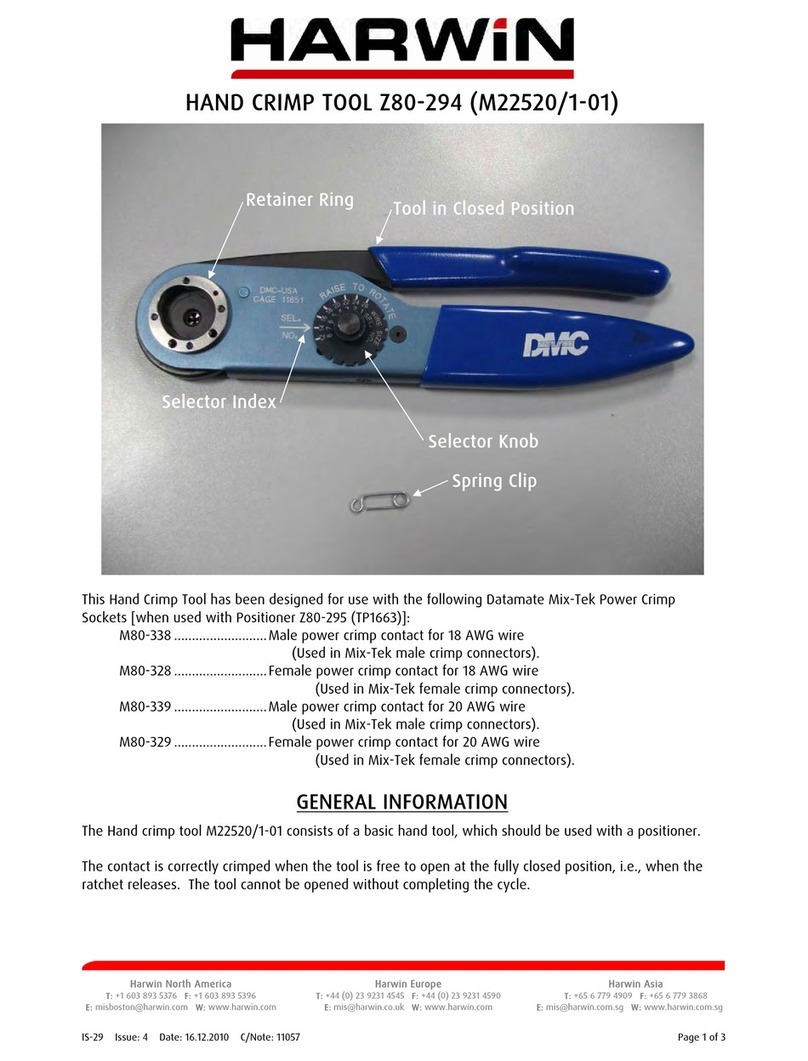

GENERAL INFORMATION

The Hand crim tool Z80-255 consists of a Rigidus Hand Crim Tool with a die-set (Z80-244)

designed for M225 series crim contacts. The tool is su lied with a locator (Z80-259), fitted to

the rear of the tool, to ensure correct and consistent location of the crim contacts within the

tool.

The Rigidus Hand Crim Tool includes the following features:

Parallel action stroke for accurate and consistent crim erformance

Unique locator design for full visibility of contact and wire insertion

Symmetric crim dies and locator allow assembly to suit right-handed

or left-handed users

Lightweight and com act design for easy access

Ergonomic handles sha ed for low effort crim ing

Ratchet control to ensure com letion of crim cycles

Die closure adjustment function for tool calibration

Lifetime tests exceeding 50,000 cycles

The contact is correctly crim ed when the tool is free to o en at the fully closed osition, i.e., when

the ratchet releases. The tool cannot be o ened without com leting the cycle – if the handles have

not o ened, squeeze the handles together to com lete the cycle.

3

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

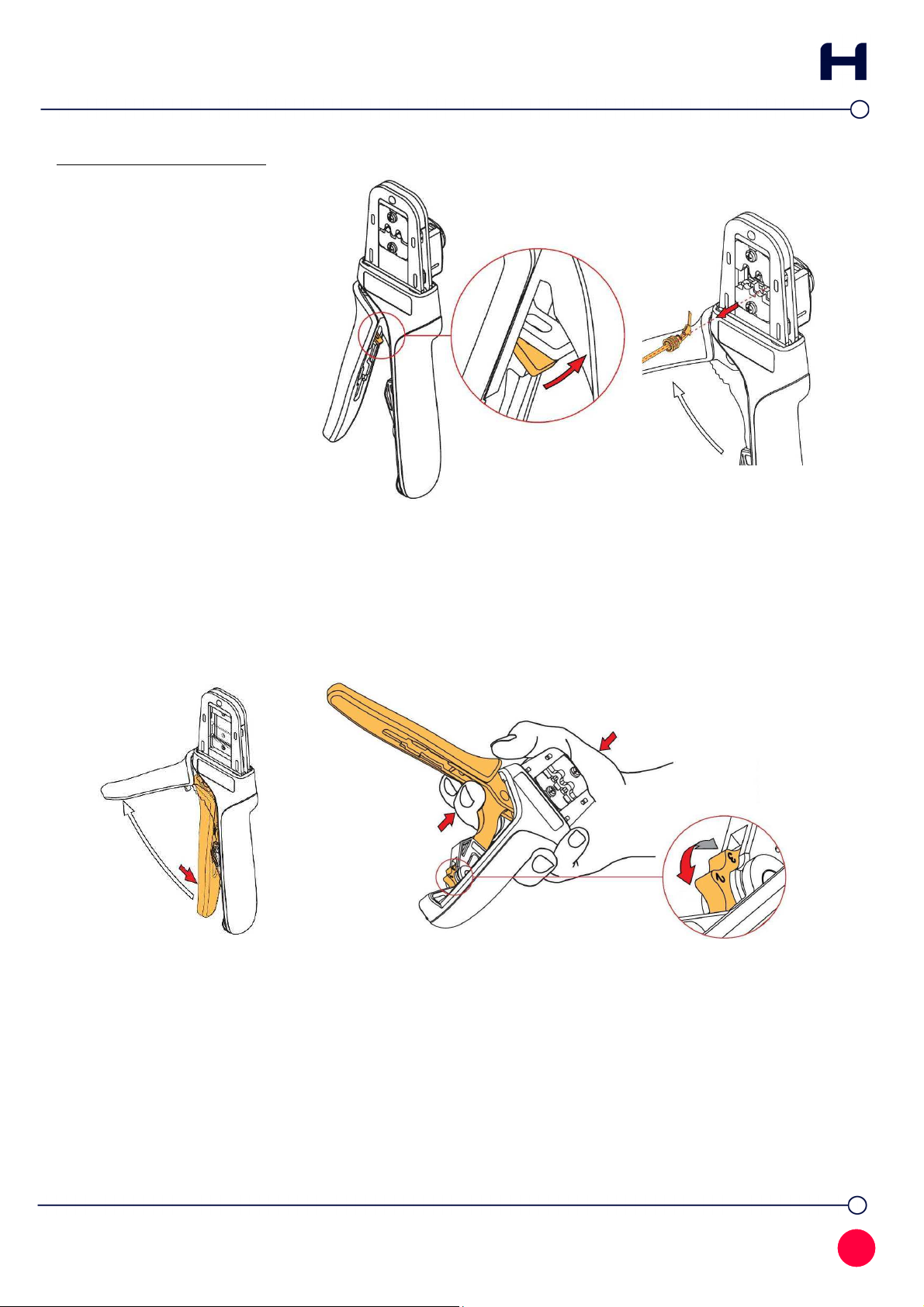

TOOL PREPARATION

%'#%$"

If the locator is fitted, lease see section “Troubleshooting – Re lacing the Dies” on age 6 for

instructions on removing the locator.

Ensure that the crim

tool is at the fully

o en osition.

Remove the TX

-

10 TORX head

screws holding the die sets in

lace.

Reverse the die sets,

ensuring

that the small locating marks

line u and are on the outside

of the tool.

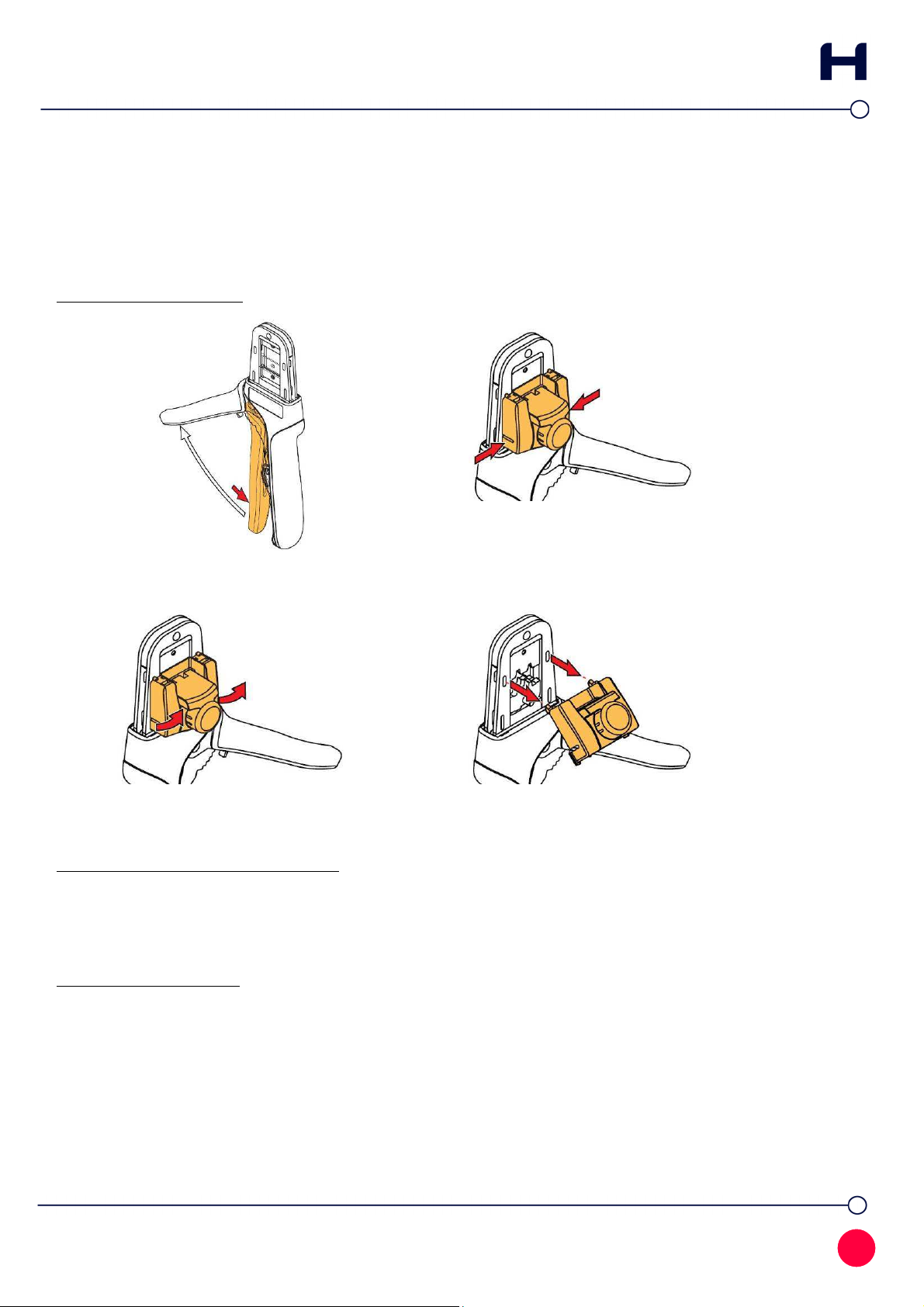

'/#0

Ensure that the crim

tool is at the fully o en

osition.

Push down the centre insert of the

locator, as far as it will go.

Insert the to

hooks of

the locator into to

slots of the tool frame.

Rotate the locator down, sna ing the lower tabs on the locator

into the bottom slots on the tool.

Correct osition for

the locator.

4

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

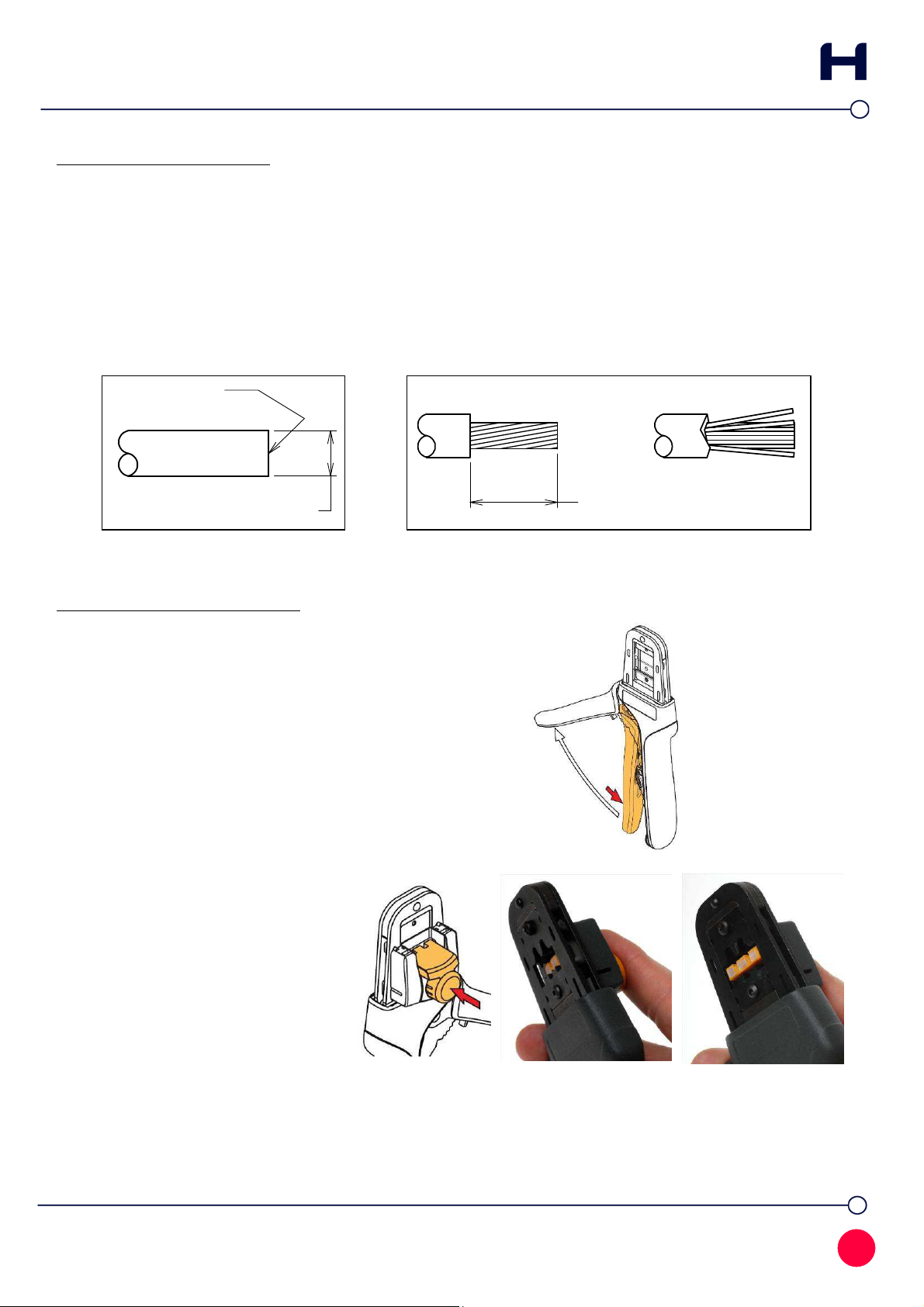

WIRE PREPARATION

1. Ensure that the wire to be crim ed is within the s ecified range of sizes for the contact and

the crim tool. Failure to use the s ecified wire size will result in oor quality crim s and

ossible tool damage.

2. Cut the end of the cable to be terminated so that there is a clean cut end (Figure A). Stri the

cable to the correct length (Figure B). We recommend that when the wire is stri ed, it is

clam ed or su orted close to the stri ing area - this will revent insulation sli age.

Suitable wire stri ers (such as a PTFE wire stri er) must be used. This should result in all

the strands laying together neatly. If the lay of the strands is disturbed, it may be re-im osed

with a slight twist.

Clean cut

Ø1.10

mm

max

2.

7

0

–

3.00

mm

1 12

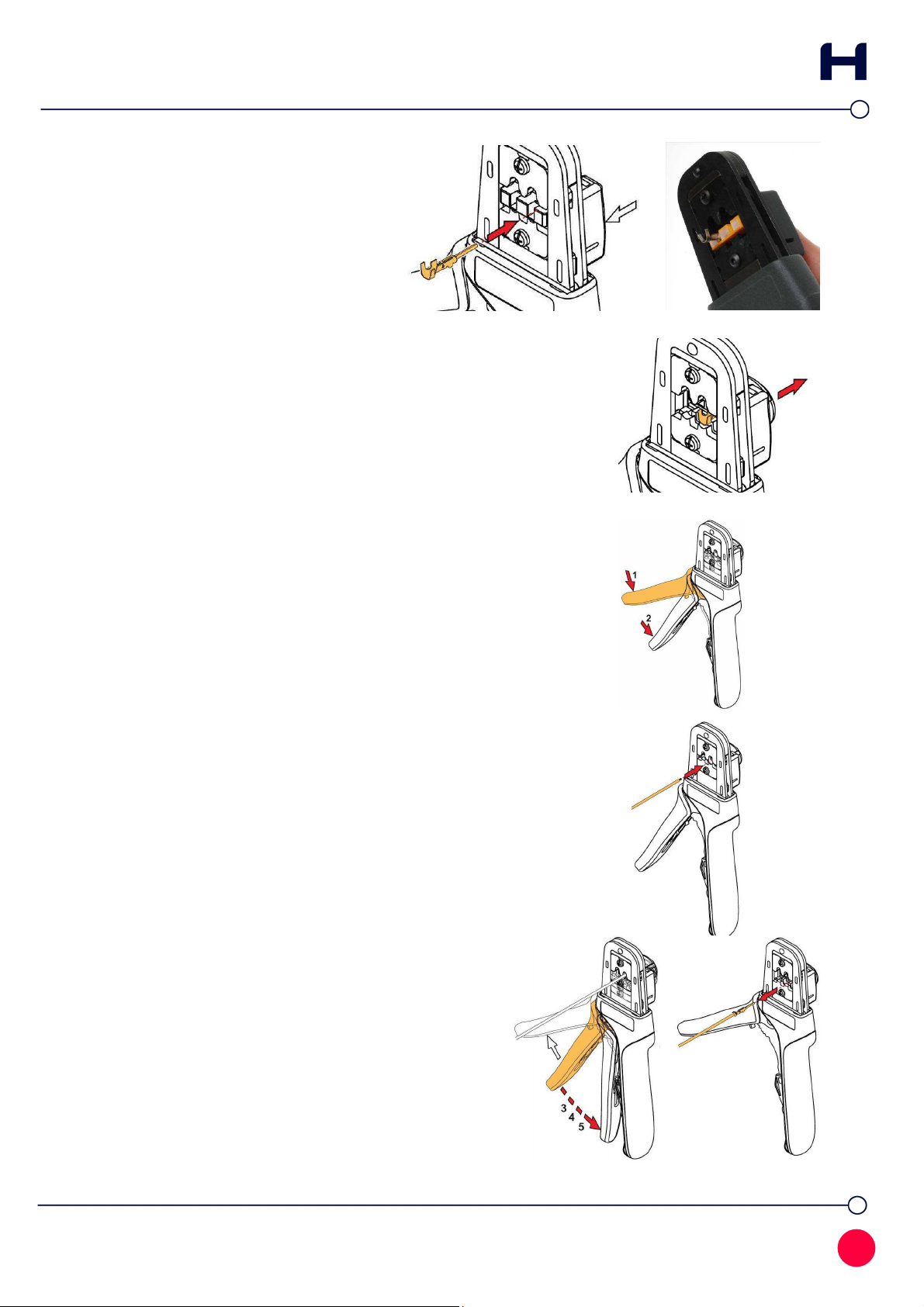

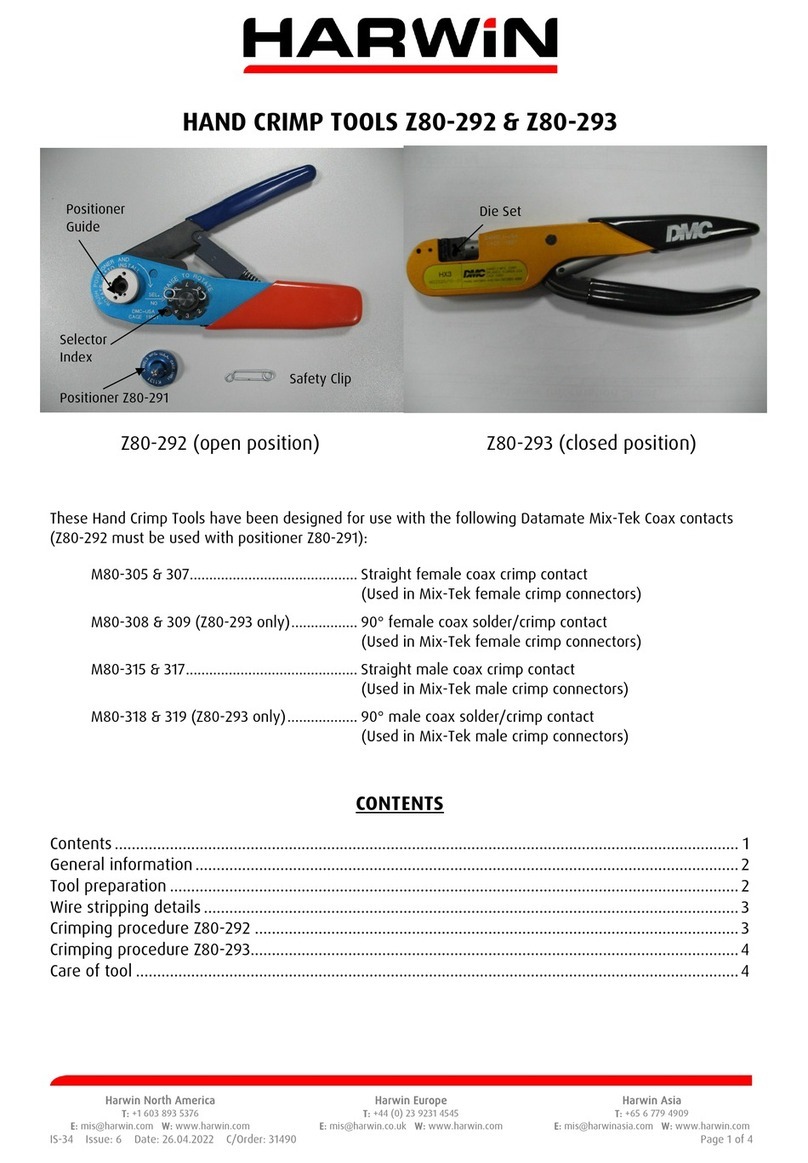

CRIMPING PROCEDURE

1. Ensure that the crim tool is at the fully o en osition.

2. Push the button on the back of

the locator, which will move the

locator forward between the

crim dies.

5

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

3. Whilst holding the locator in the forward

osition, insert the crim contact into

the correct locator nest. The wire size is

marked on the crim die, above each

location.

4. Release the locator button, allowing the crim contact to move

back between the crim ing jaws.

5. Close the handle, until the second ratchet osition engages.

6. Load the stri ed wire through the terminal, and against the wire

sto inside the tool.

7. Whilst holding the wire against the wire sto ,

com lete the crim by squeezing the tool handles

together through the rest of the ratchet clicks –

another 3, to make 5 in total. The handles should

then be free to o en. Remove the crim ed wire.

6

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

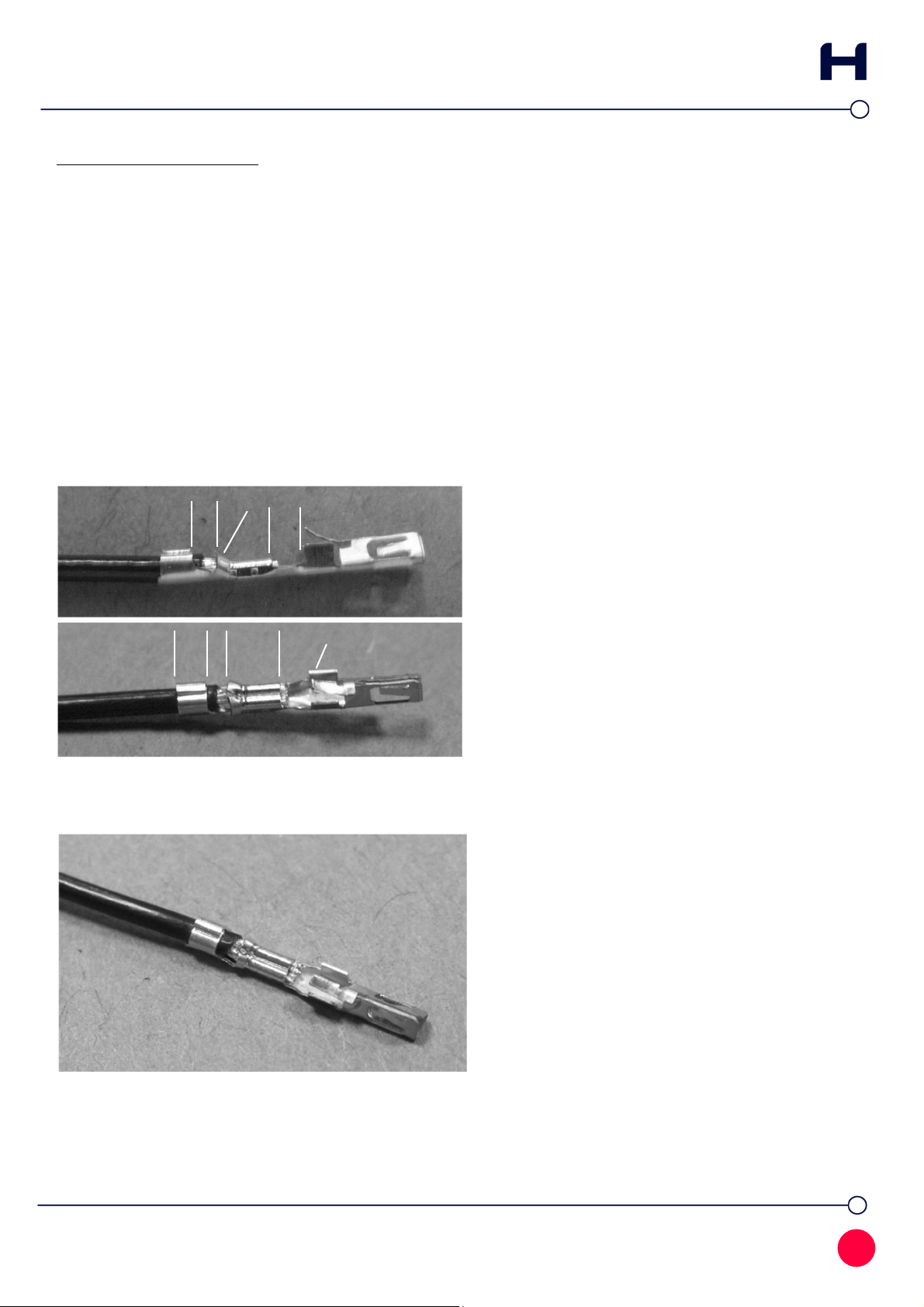

CRIMP INSPECTION

Crim joints should be checked for:

Correctness of form and location of crim .

Freedom of fracture and rough edges.

Adequate insertion of all conductor strands in the crim barrel.

Absence of damage to the conductor or the insulation.

Correct crim height, as er crim height values given on front age.

A destructive ull-off force test should also be erformed occasionally, to confirm the hand

crim tool is still o erating correctly. The correct values for this test are given on the front age

of this instruction sheet. Insulation should be stri ed back beyond insulation crim area before

re aring sam les for ull-off force test.

'""

1. Insulation Ins ection window

2. Bellmouth

3. Conductor Ins ection window

4. Insulation crim area

5. Conductor crim area

6. Contact sto ear

Insulation extends ast insulation crim

area, but does not enter Bellmouth.

Insulation crim does not cut or break

insulation.

Insulation crim is fully wra ed

around and su orting insulation.

Conductors extend ast conductor

crim area, but not ast contact sto

ear.

3

*

,

+

7

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

"/#

Insulation in-line with end of crim area.

Conductor in-line with end of crim area.

Insulation butted u to but not

entering bellmouth.

Conductor in-line with contact sto

ear, but not ast.

4%

Insulation crim incorrectly formed.

Conductor tra ed in Insulation crim .

Conductor outside of crim area.

8

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

Insulation not visible through

ins ection window.

Conductor not visible through

ins ection window.

Insulation enters bellmouth

Conductor extends ast sto ear

ASSEMBLY – CRIMP INTO HOUSING

The com leted crim can now be inserted into the a ro riate M225 series crim housing. For

larger wire sizes, no other tooling should be required for this o eration; the crim s can be

ushed in by hand. Crim s are assembled into the mould with the retaining tang towards the

outer edge of the housing. With thinner wires, it may be hel ful to ush onto the back of the

crim with the Extraction Tool Z80-258.

9

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

TROUBLESHOOTING

'"5'

Should the tool become stuck

or jammed in a artially

closed osition, DO NOT force

he handles open or closed.

There is a ratchet release

lever located inside the

movable handle. Pressing u

on this lever will release the

ratchet, and the handles

should then easily o en. The

jam or miscrim can then be

removed.

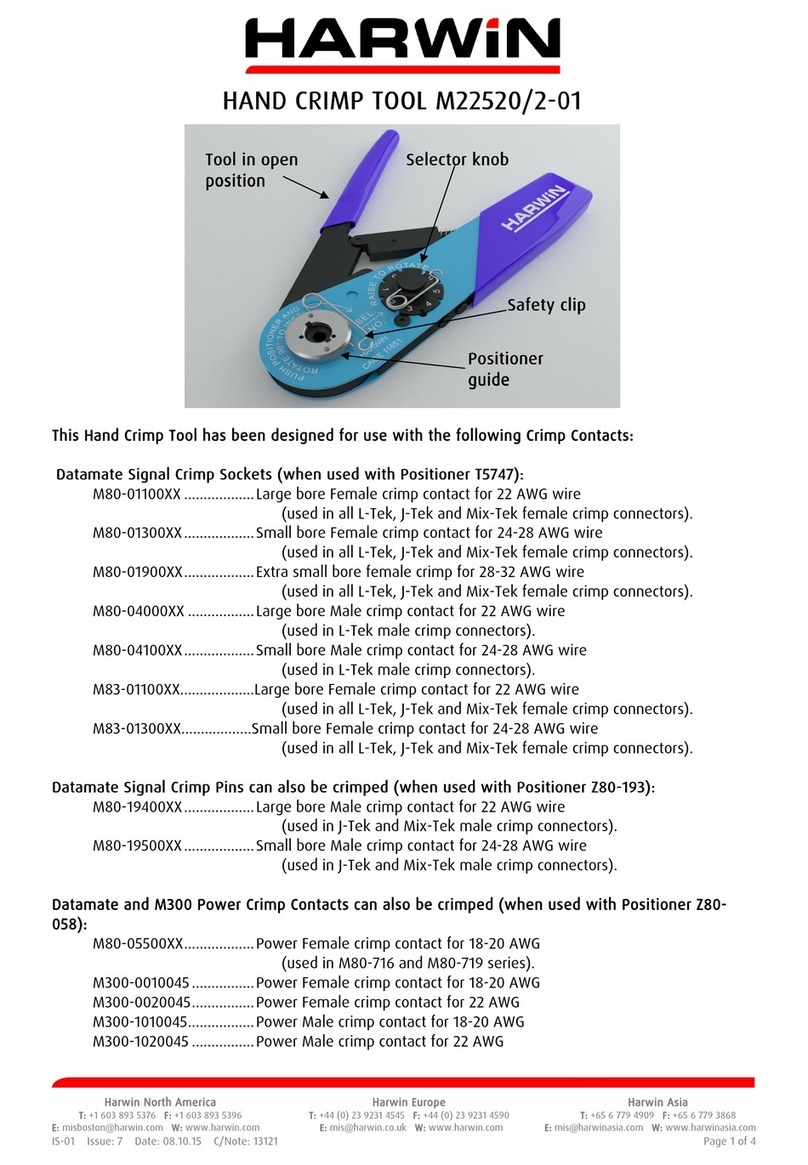

067##%%1

This tool is su lied as new, set to the right reload force necessary to crim the M225 series

contacts. However, over time, this force may fall off slightly. The tool can be adjusted to cater

for this wear and raise the reload force to give correct crim s.

If you need to carry out this rocedure, Harwin recommend that you crim a number of sam les

before and during adjustment, until the ull-off force achieved exceeds the minimum values

shown on the first age of this instruction sheet.

Ensure that the crim

tool is at the fully o en

osition.

Hold the hand tool as shown in the above figure and

squeeze the link bar in towards the to of the tool. This

releases the reload adjustment wheel.

Rotate the setting wheel to a different setting – the higher the number dis layed, the higher the

reload force.

Release the link to lock the wheel in lace.

If the wheel has been set to the maximum setting ossible, then the tool is no longer ca able of

achieving the minimum ull-off force and should be re laced.

10

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

"#4

If you need to remove the dies to clean the tool, or re lace the dies due to damage, then this

section will tell you how to first remove the locator and then the dies.

If you need to re lace the die-set, s are die-sets are available from Harwin. Please request Part

Number Z80-244.

A) Remove the Locator:

1. Ensure that the crim tool is at the

fully o en osition.

2. Squeeze gently on the lower area of

the locator shown in the above

icture, with your thumb and index

finger.

3. Lift the bottom of the locator and

swing it away from the tool.

4. The u er hooks should sli out of the

to slots easily.

B) Remove and Re lace the Die Set:

See the instructions under section “Tool Pre aration – Changing from Right to Left Hand

O eration”, on age 3.

C) Re lace the Locator:

See the instructions under section “Tool Pre aration – Assembling the Locator”, on age 3.

11

Issue:

3

Date:

01

/

02

/20

2

3

C/

Order

:

3210

2

Instruction Sheet for Z80-255 Hand Crim Tool

CARE OF TOOL

Although the Rigidus tool is engineered for durability, it is recommended that the following

maintenance oints are observed, to maximise the life of the tool.

1. Remove dust, moisture, and other contaminants

with a clean brush, or soft, lint-free cloth.

2. Do not use any abrasive materials that could

damage the tool.

3. All ins, ivot oints and bearing surfaces should

be covered with a thin coat of high-quality

machine oil – do not oil excessively. Light oil

(such as 30 weight automotive oil) used at the

oil oints shown in the diagram, is

recommended.

4. Wi e excess oil from hand tool, articularly from

the crim ing area. Oil transferred onto crim

contacts may affect the electrical characteristics

of the connector.

5. When tool is not in use, kee the handles closed to revent objects from becoming lodged in

the crim ing dies, and store the tool in a clean, dry area.

ADVICE ON USE

Wear eye rotection at all times.

Manual tools such as this Rigidus tools are intended for low volume use. Re etitive,

high-volume use is not recommended.

The insulated rubber handles are not designed or certified for rotection against

electrical shock.

Use with the M225 series crim contacts listed on the first age of this instruction sheet.

This tool is designed for hand use only, and must not be used with clam ing, fixturing or use of

handle extensions.

If you have any questions about this instruction sheet, or the M225 series range of connectors,

lease contact techni[email protected].

Other manuals for Z80-255

1

Table of contents

Other Harwin Crimping Tools manuals

Harwin

Harwin Z80-293 User manual

Harwin

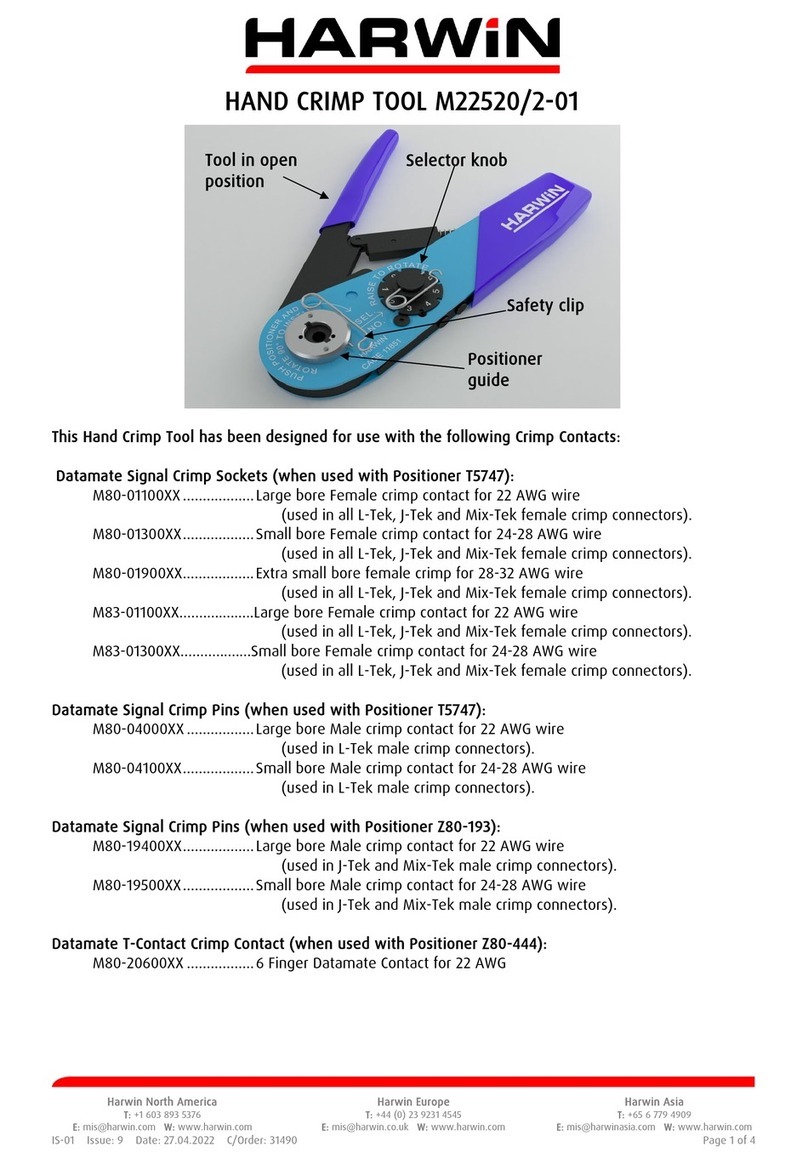

Harwin M22520/2-01 User manual

Harwin

Harwin Z22-020 User manual

Harwin

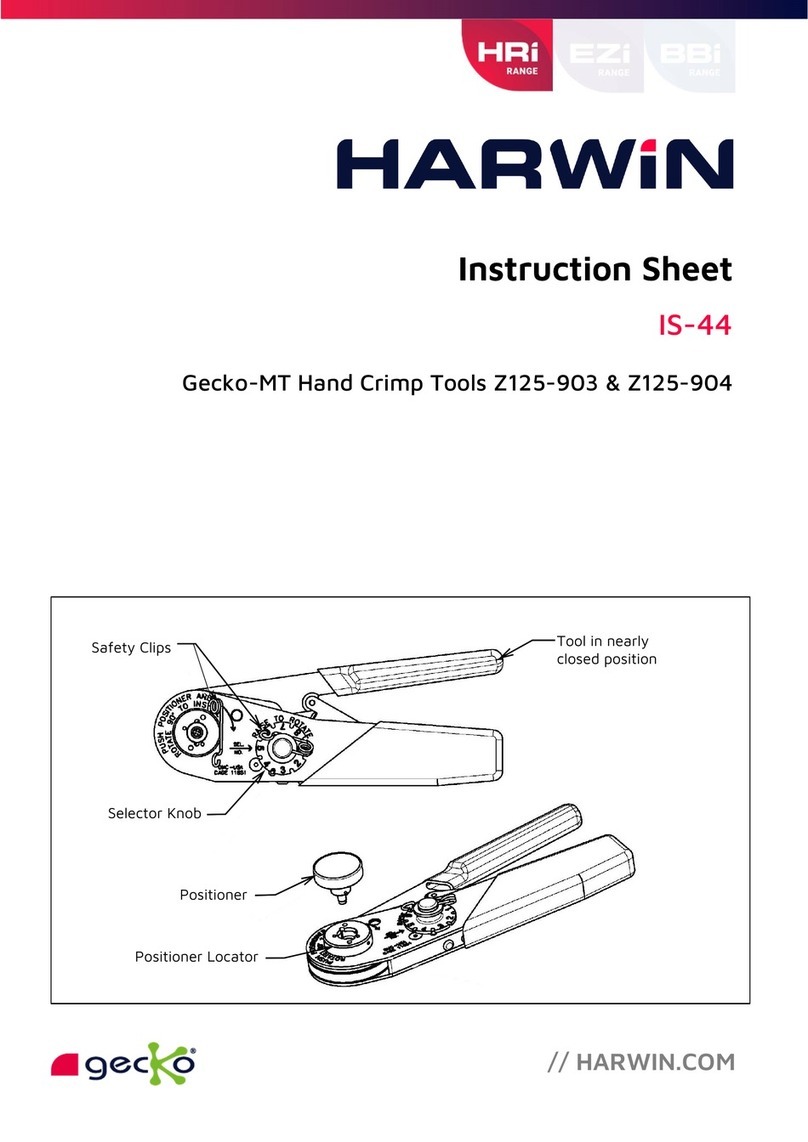

Harwin Gecko-MT Z125-903 User manual

Harwin

Harwin Z80-292 User manual

Harwin

Harwin M22520/2-01 User manual

Harwin

Harwin Z80-255 User manual

Harwin

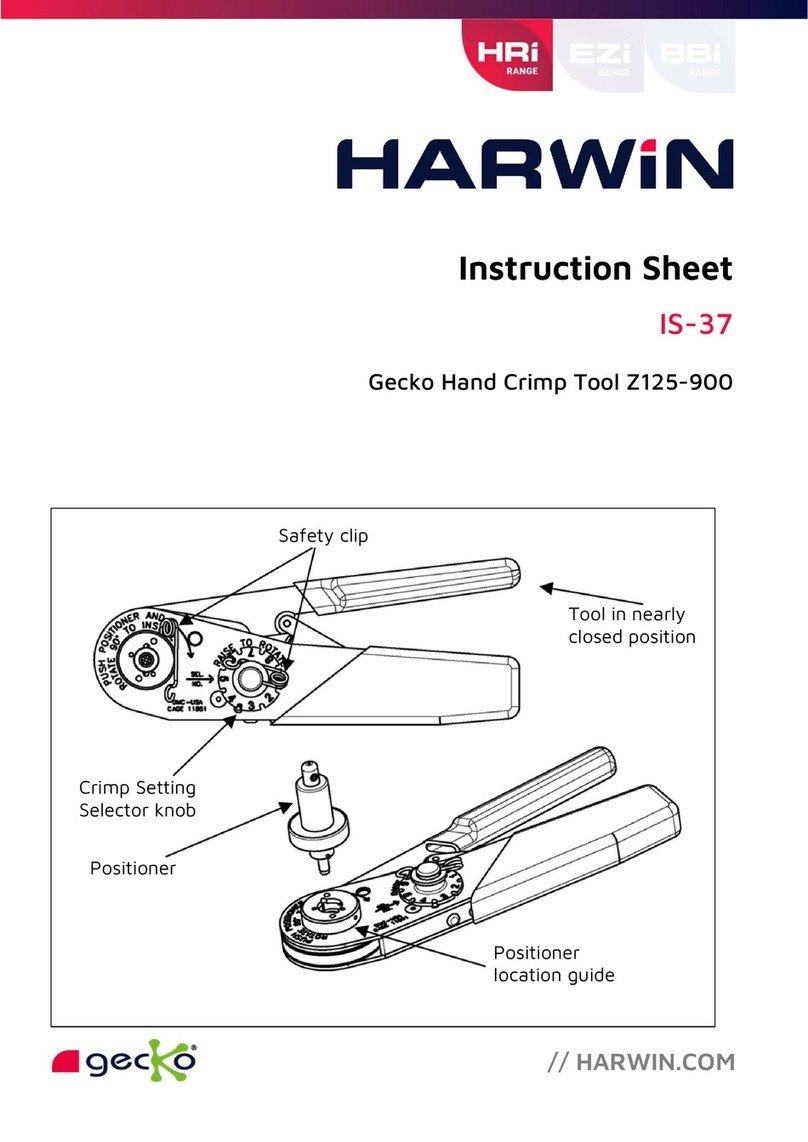

Harwin Gecko Z125-900 User manual

Harwin

Harwin M22520/2-01 User manual

Harwin

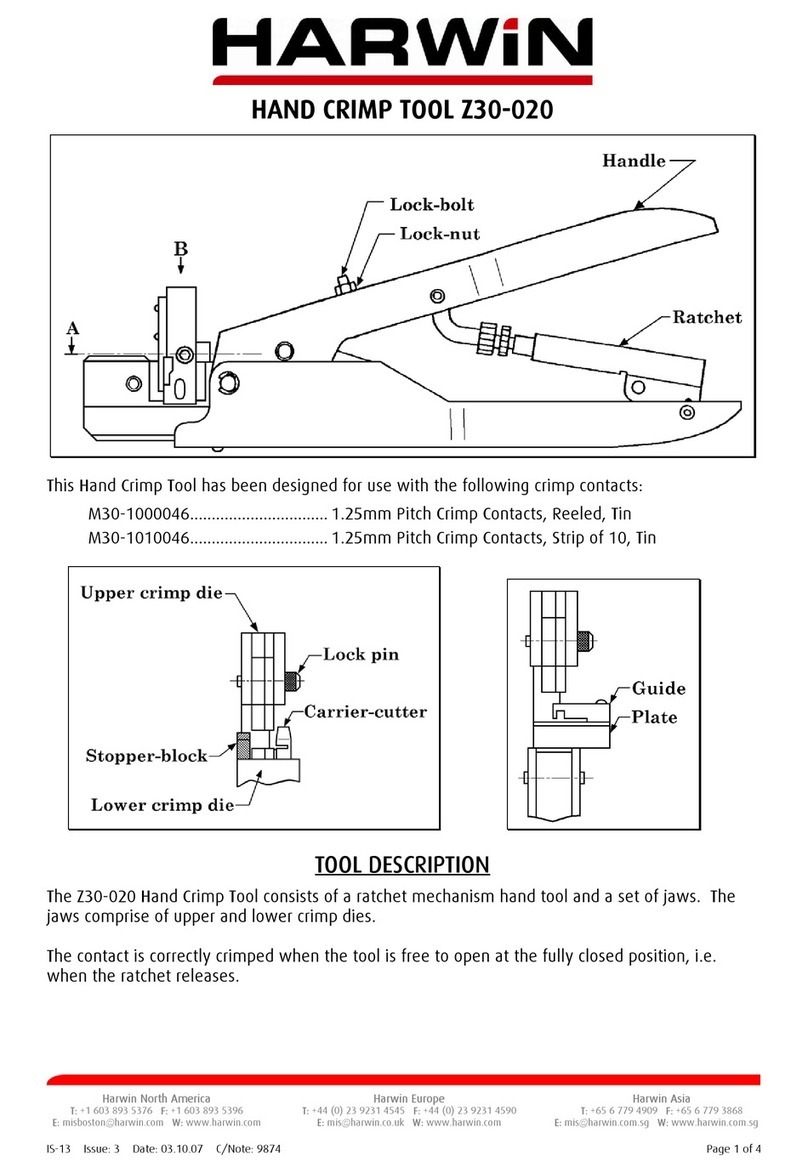

Harwin Z30-020 User manual

Popular Crimping Tools manuals by other brands

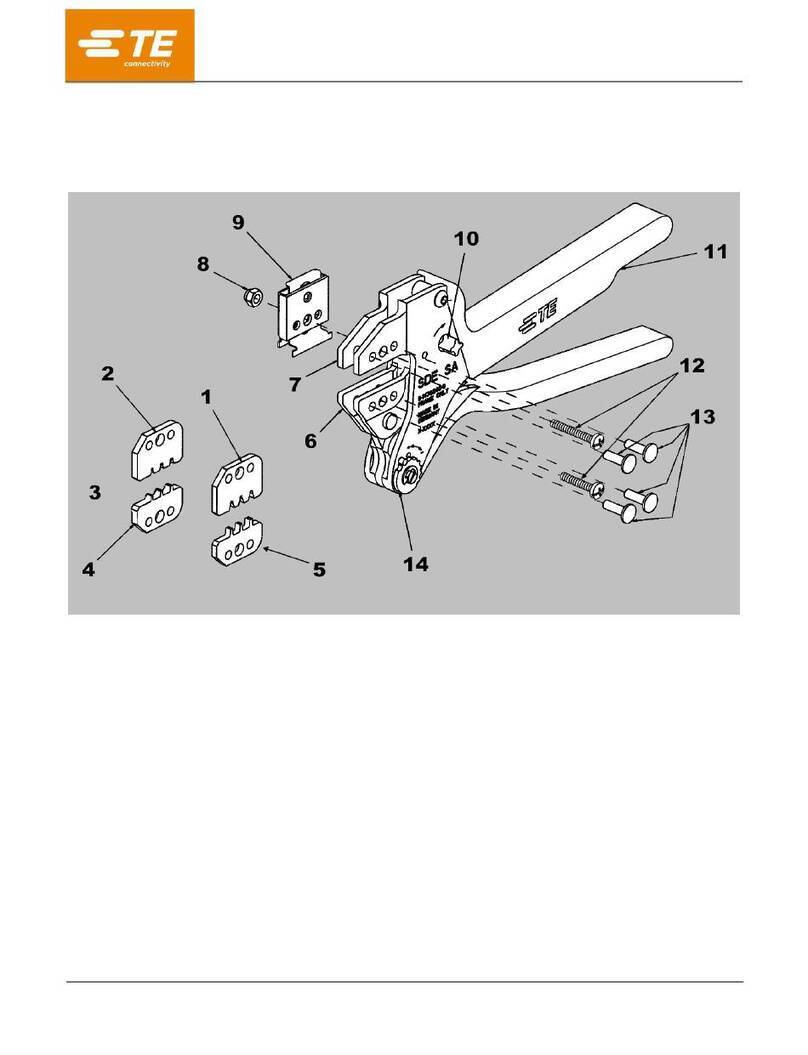

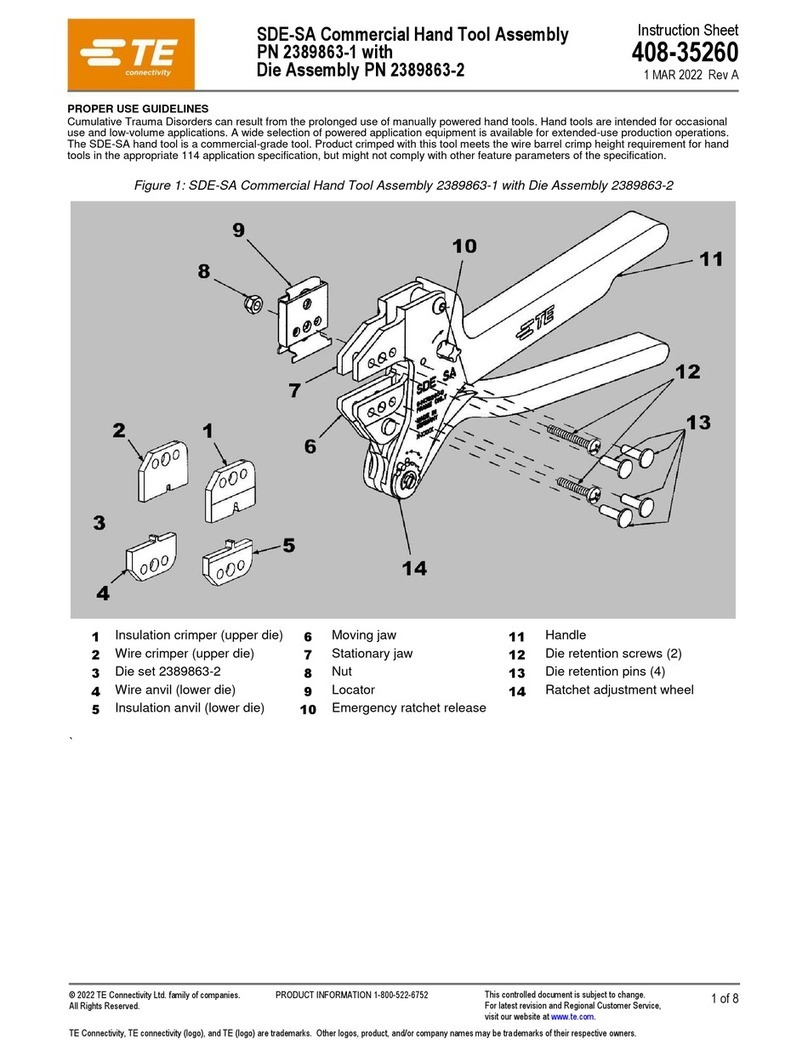

TE Connectivity

TE Connectivity SDE-SA instruction sheet

TE Connectivity

TE Connectivity SDE-SA instruction sheet

Staubli

Staubli M-PZ-T2600 operating instructions

TE Connectivity

TE Connectivity 2386892-1 instruction sheet

Textron

Textron EK1240CL Operation manual

CIMCO

CIMCO GENiUS 2.0 operating instructions