molex 63827-5000 User manual

Other molex Crimping Tools manuals

molex

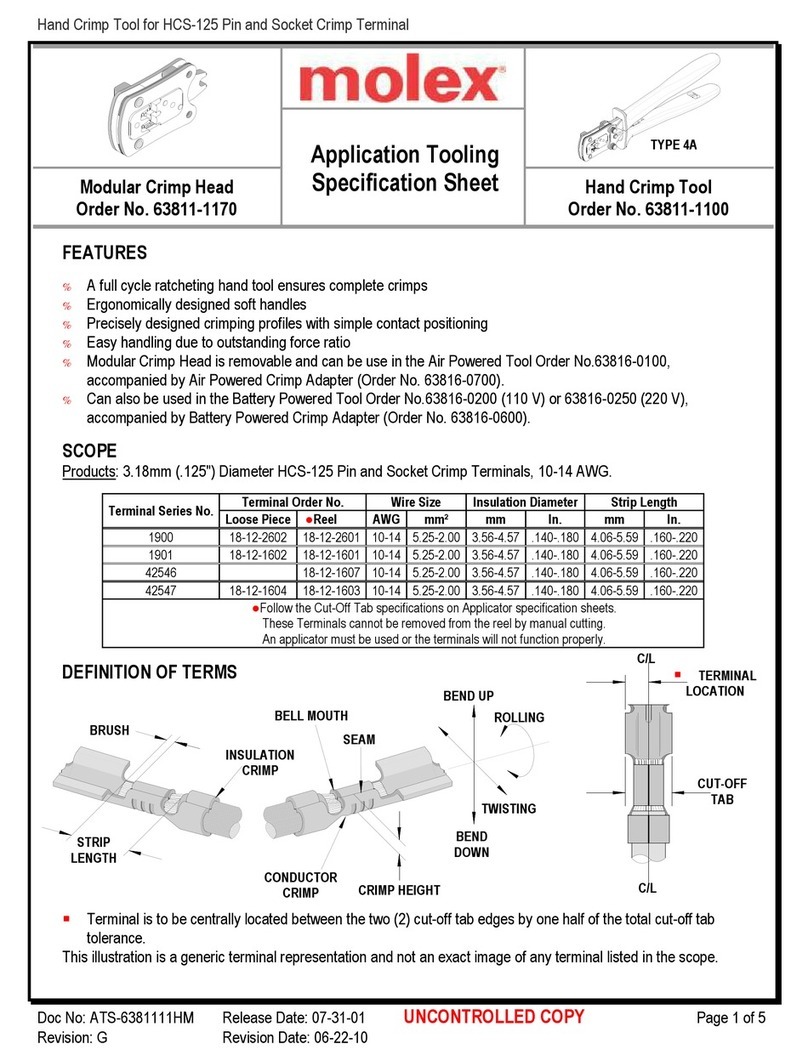

molex 63811-7100 User manual

molex

molex 207129 Series User manual

molex

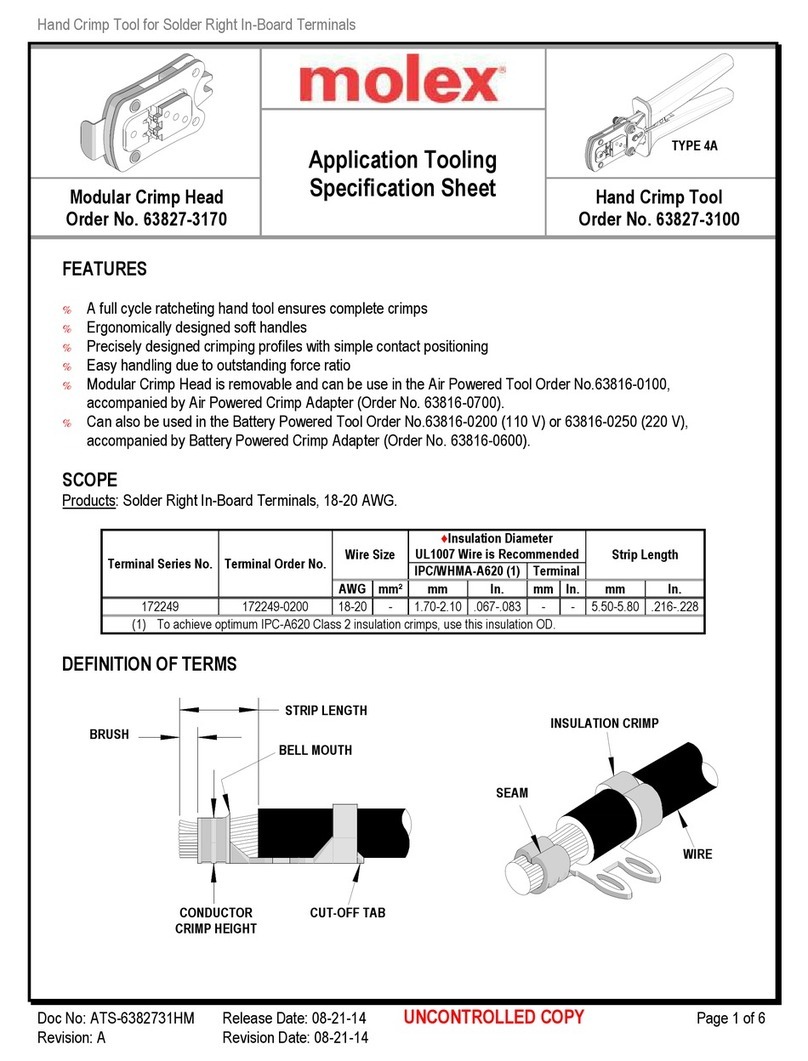

molex 63827-3170 User manual

molex

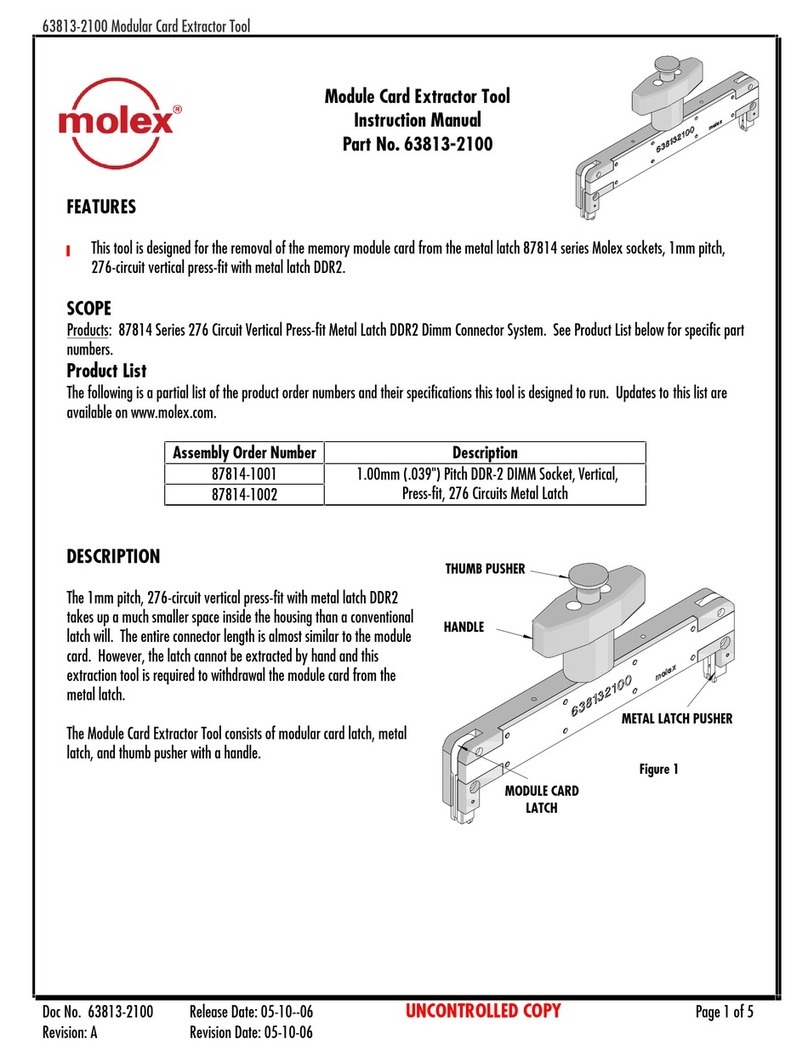

molex 63813-2100 User manual

molex

molex MTA-100 Manual

molex

molex 63816-1000 User manual

molex

molex 63827-1600 User manual

molex

molex 63816-0200 User manual

molex

molex 98897 User manual

molex

molex 207129 Series User manual

molex

molex RHT-5771 User manual

molex

molex 63825-5000 User manual

molex

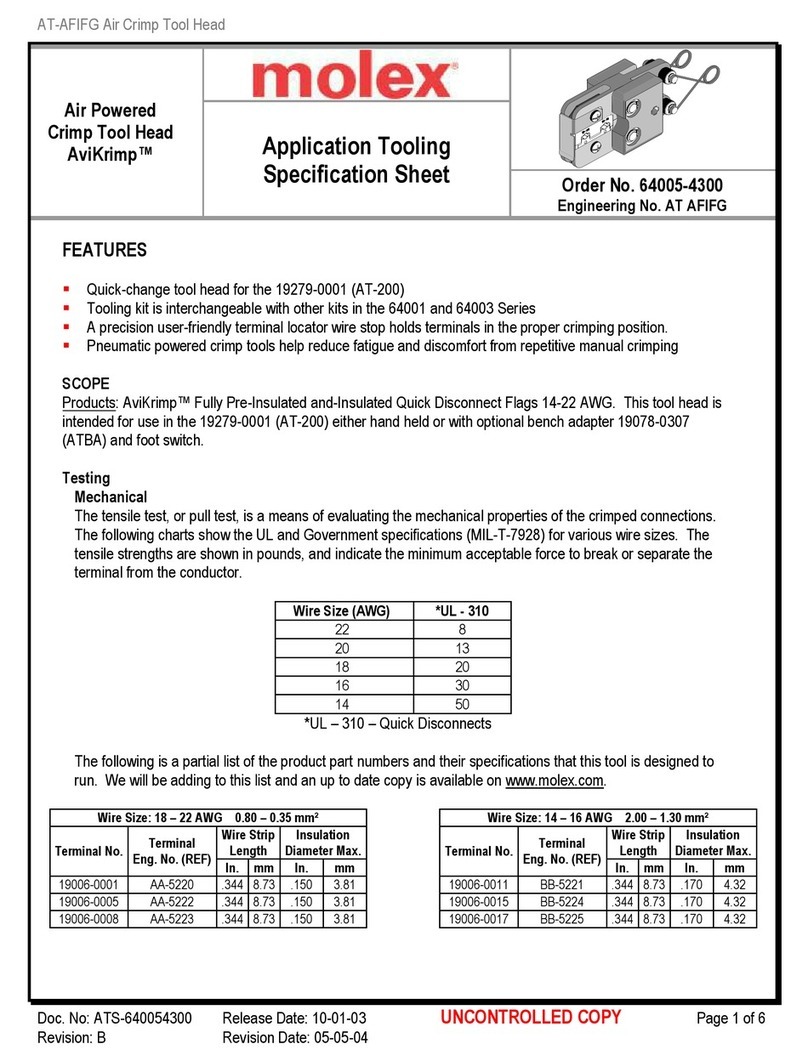

molex AT AFIFG User manual

molex

molex 63819-2900 User manual

molex

molex 207129 Series User manual

molex

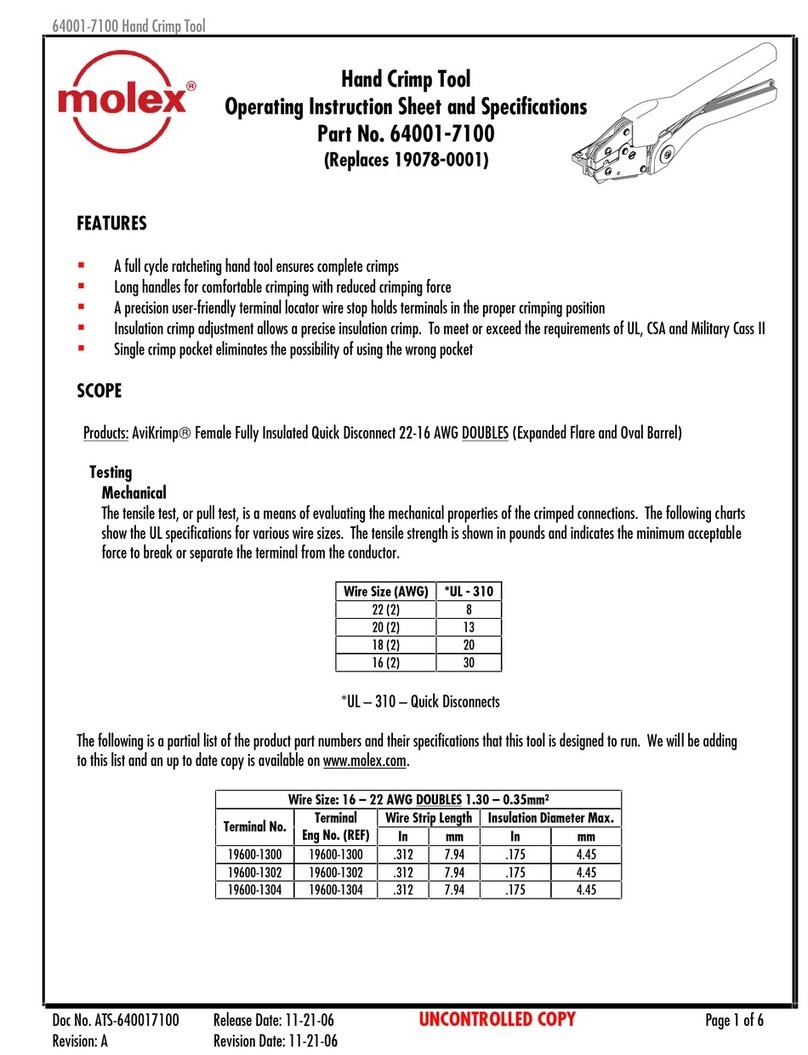

molex AT 1610 User manual

molex

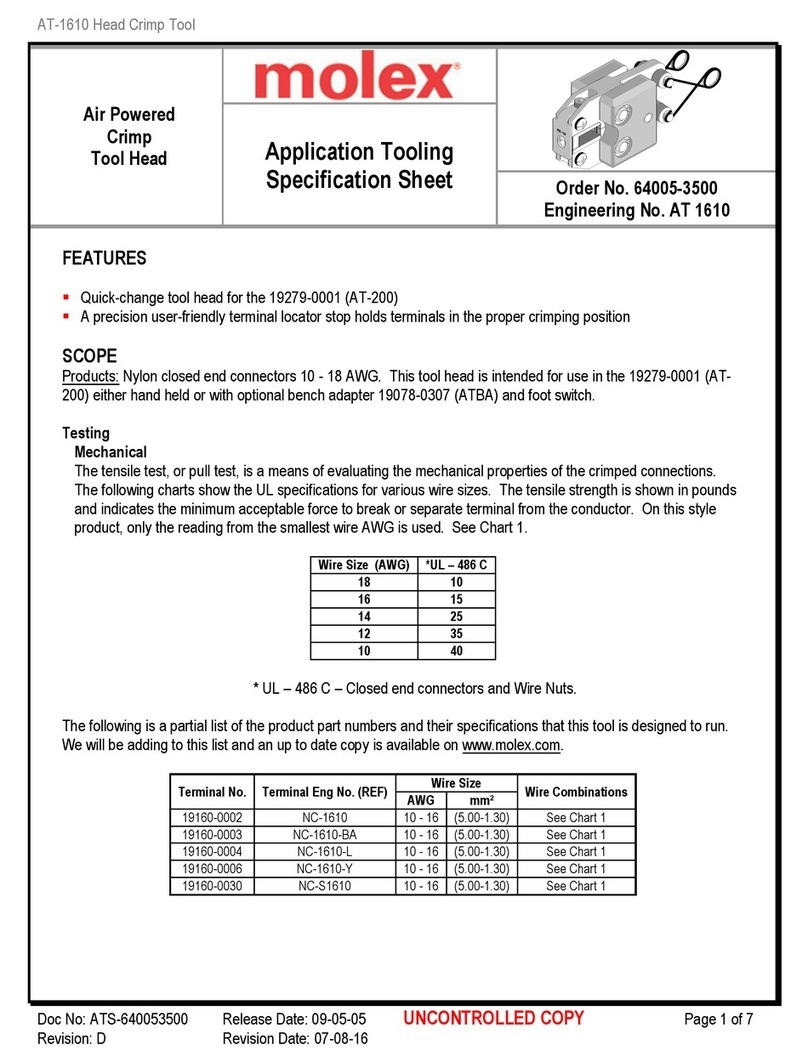

molex 64003-0800 User manual

molex

molex 63811-6170 User manual

molex

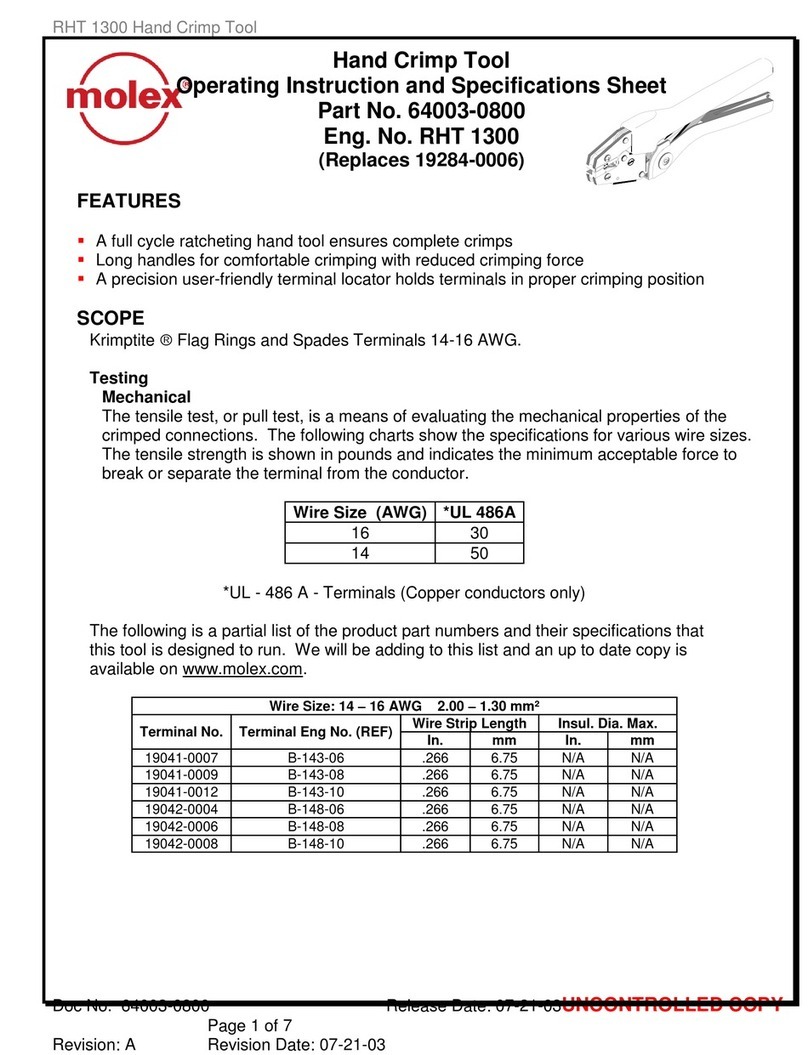

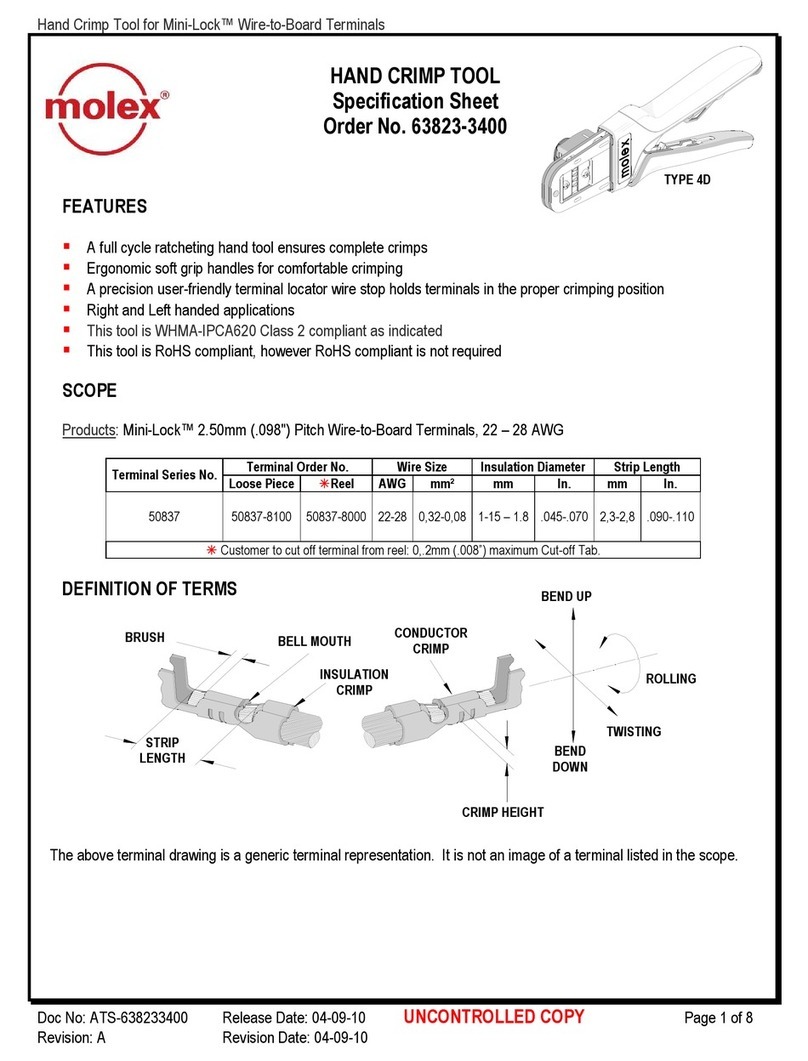

molex 4D User manual

molex

molex 50837 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet