Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 T: +44 (0) 23 9231 4545 T: +65 6 779 4909

IS-34 Issue: 6Date: 26.04.2022 C/Order: 31490 Page 4 of 4

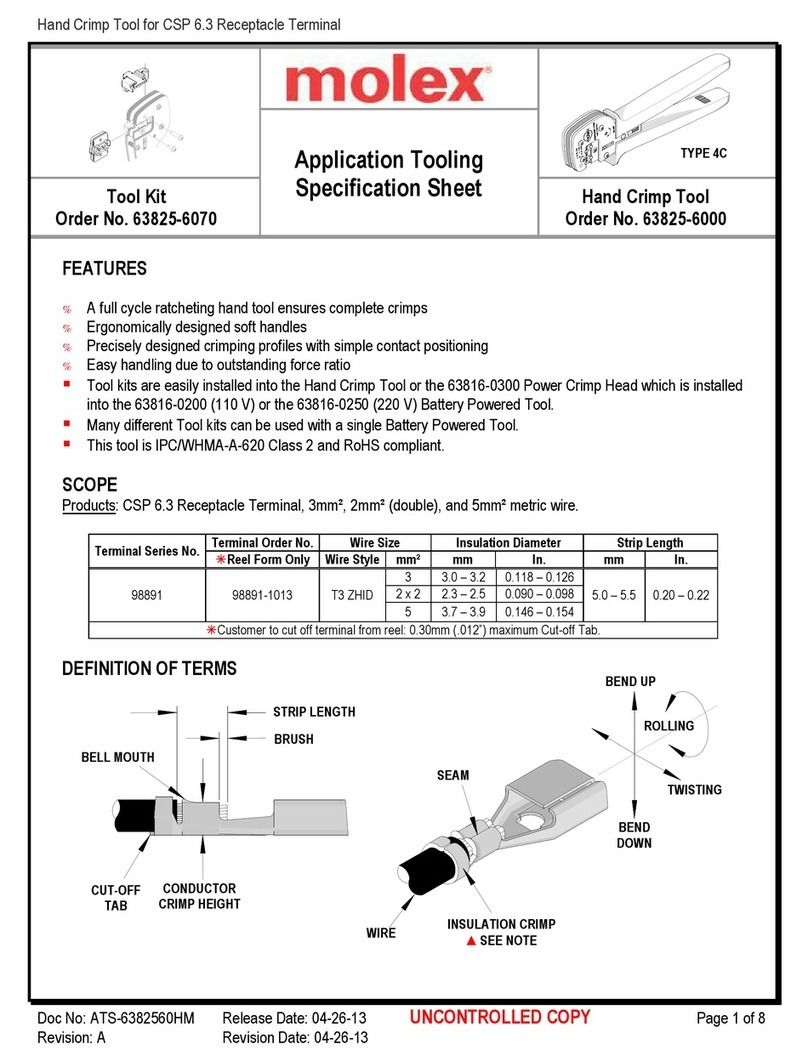

CRIMPING PROCEDURE Z80-293

1. Ensure that the wire to be crimped is within the specified range of sizes for the contact

and the crimp tool (see table 1). Failure to use the specified wire size will result in poor

quality crimps and possible tool damage.

2. See Figs. A & B for correct wire stripping dimensions for the appropriate contact. The

straight coax contact (Fig A) will need to be crimped to the wire before insertion into

outer contact. For the 90° coax contact (Fig B) the wire is inserted into the coax body and

soldered before assembly, see component specification C005XX for further details of coax

assembly methods. We recommend that when the wire is stripped, it is clamped or

supported close to the stripping area - this will prevent insulation slippage. Suitable wire

strippers (such as a PTFE wire stripper) must be used.

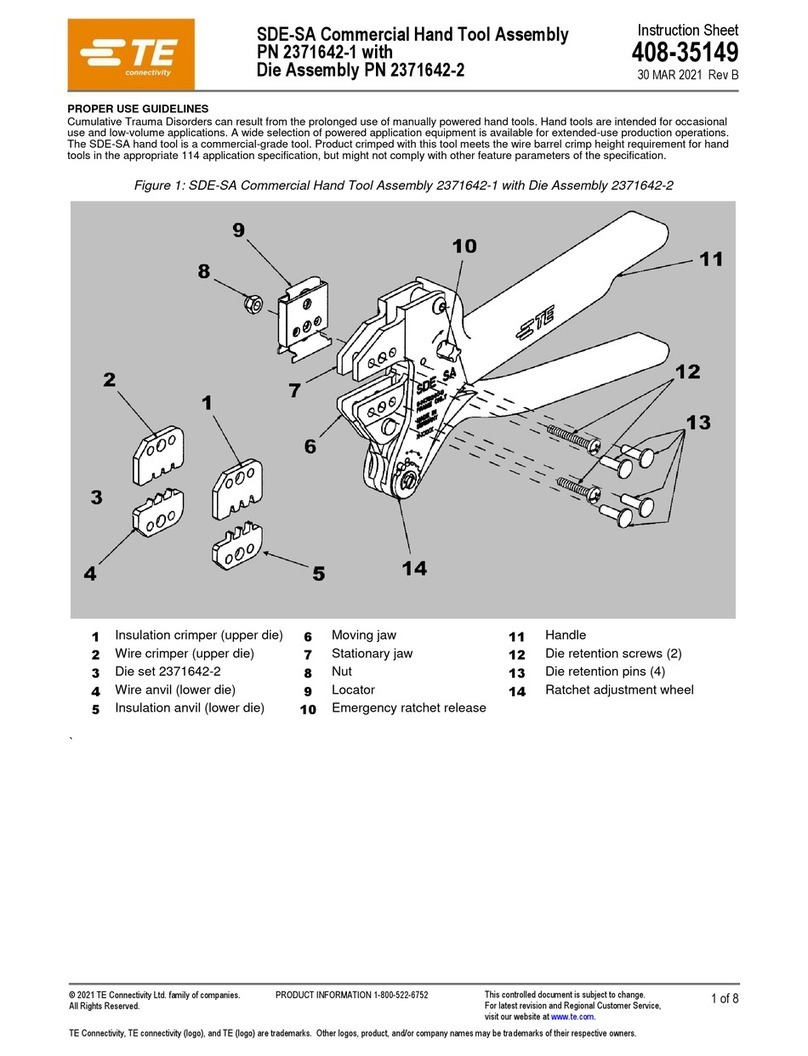

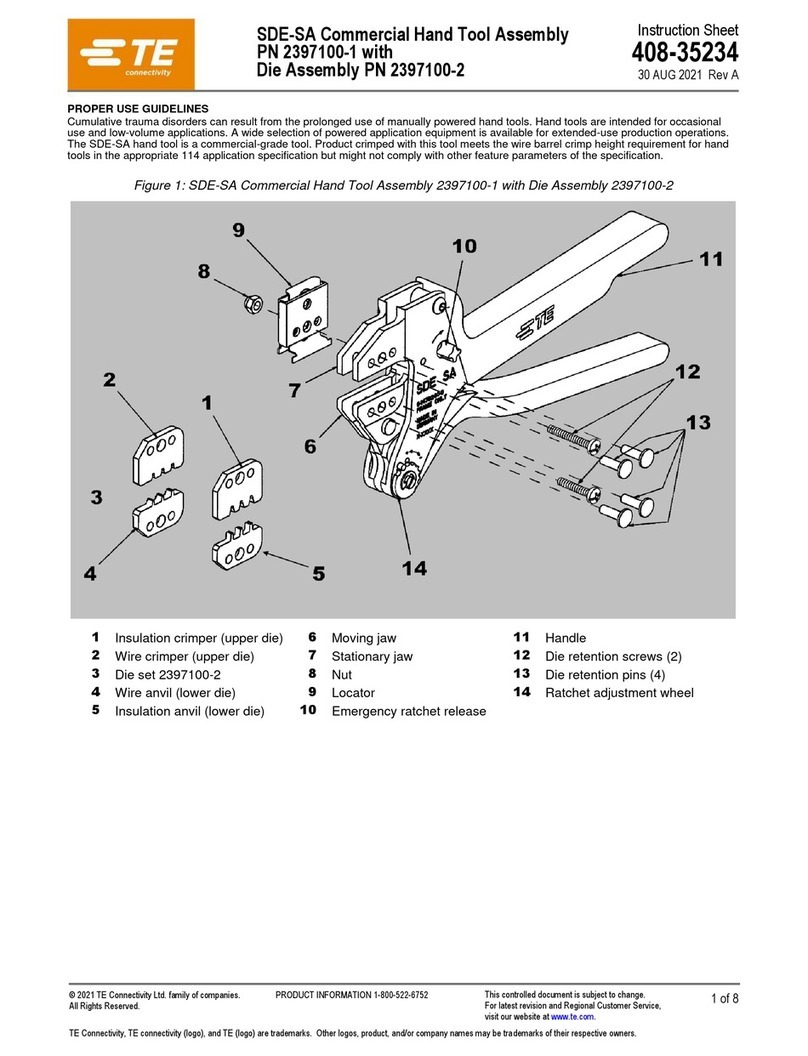

3. Check below table 3 to select which of the two hexagon sizes is correct to crimp contact

with. Place contact with crimp sleeve in position into the above selected hexagon with the

flat against the surface (the side with the manufacturers ID plate on), gently squeeze the

handle until it will go no further the crimp is now complete, squeeze handle again to

release completed crimp.

4. A correctly crimped contact & sleeve will achieve a pull off force of 30N minimum.

Table 3

Cable

Type

Max.

Insulation

Compatible Contacts Crimp Sleeve

Hexagon Size

RG 178 Ø2.0mm

M80-305, M80-308,

M80-315, M80-318

Small

0.105” (2.67mm) A/F

RG 174 Ø2.7mm

M80-307, M80-309,

M80-317, M80-319

Large

0.128” (3.25mm) A/F

RG 179 Ø2.7mm

M80-307, M80-309,

M80-317, M80-319

Large

0.128” (3.25mm) A/F

RG 316 Ø2.7mm M80-307, M80-309,

Large

CARE OF TOOL

There is virtually no maintenance required for the Z80-292 & Z80-293. However, it is good

practice to keep the indenter tips free of residual colour band deposits and other debris. A small

wire brush may be used for this purpose.

We strongly recommend that you:

1. DO NOT immerse tools in any cleaning solution.

2. DO NOT spray oil into tool to lubricate.

3. DO NOT attempt to disassemble tool or make repairs

This is a precision crimp tool and should be handled as such.