Hilpress 17000 User manual

Other Hilpress Crimping Tools manuals

Popular Crimping Tools manuals by other brands

Cembre

Cembre B1350-C Operation and maintenance manual

JST

JST CS 10-WC-SF1002 instruction manual

Gates

Gates MobileCrimp 4-20 Safety and operating manual

Tyco Electronics

Tyco Electronics 408-10050 instruction sheet

KUDOS

KUDOS HD-BGD3 SAFETY OPERATING & MAINTENANCE INSTRUCTIONS

Cembre

Cembre B135-C Operation and maintenance manual

Tyco Electronics

Tyco Electronics 2063195-1 instruction sheet

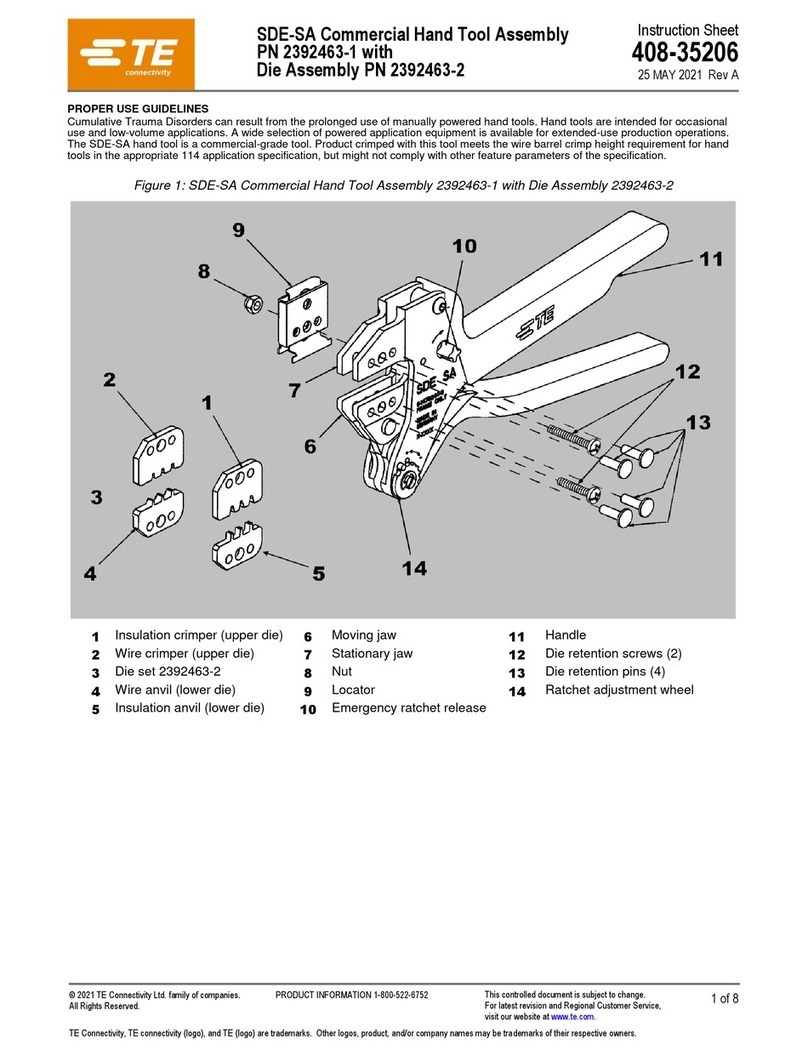

TE Connectivity

TE Connectivity SDE-SA instruction sheet

Conec

Conec 36-000530 operating instructions

TE Connectivity

TE Connectivity 2386892-1 instruction sheet

Greenlee

Greenlee EK1550FLX Operation manual

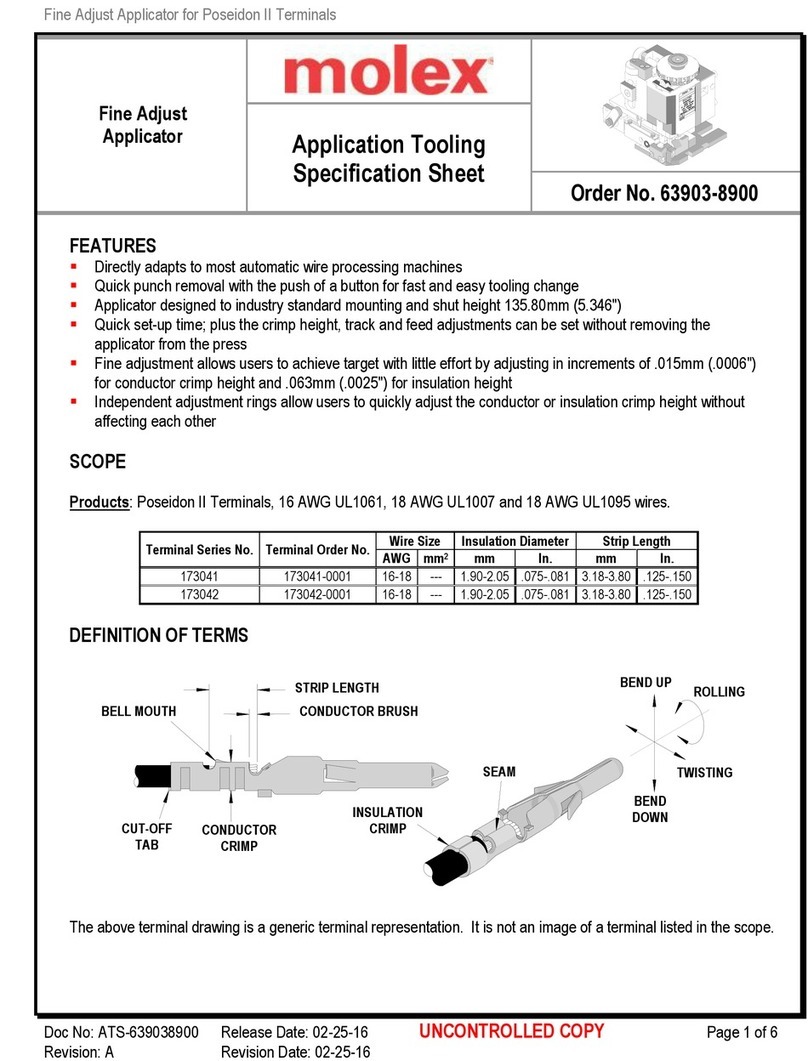

molex

molex 63825-8000 Specification sheet