Harwin Z55-020 User manual

Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 T: +44 (0) 23 9231 4545 T: +65 6 779 4909

E: [email protected]m W: www.harwin.com E: mis@harwin.co.uk W: www.harwin.com E: [email protected] W: www.harwin.com

IS-51 Issue: 1Date: 26-Apr-22 C/Order: 31534 Page 1 of 5

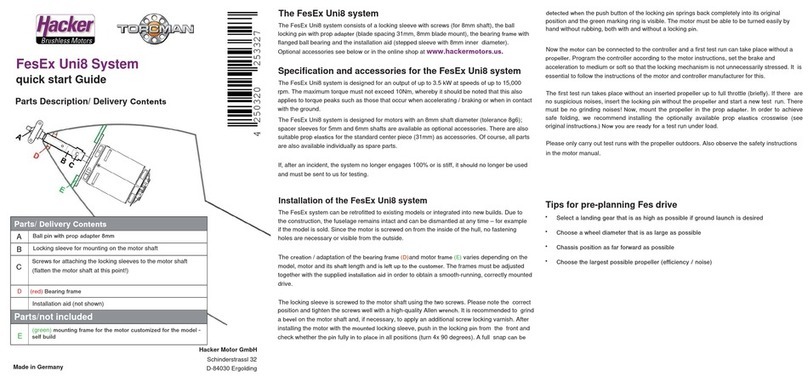

Z55-020 – Archer Kontrol IDC Termination Hand Tool

This IDC Termination Hand Tool is intended for use with the following Archer Kontrol 1.27mm

pitch cable connectors:

M55-820XX42..............Female IDC Cable Connector for 30 AWG ribbon cable

(XX = up to 80 contacts)

GENERAL INFORMATION

The Z55-020 IDC Termination Hand Tool ensures the complete and secure assembly of Archer

Kontrol IDC connectors. The tool uses a ratchet mechanism and press plate to assemble the

connector onto the ribbon cable. The tool is also supplied with a desk clamp, for secure fastening

during operation.

The connector is fully assembled once the tool is free to open fully to its original position, i.e.

when the ratchet releases. The ratchet will release once the handles have been compressed to

the fully closed position and should not be forced open before reaching fully closed.

Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 T: +44 (0) 23 9231 4545 T: +65 6 779 4909

E: [email protected]m W: www.harwin.com E: mis@harwin.co.uk W: www.harwin.com E: [email protected] W: www.harwin.com

IS-51 Issue: 1Date: 26-Apr-22 C/Order: 31534 Page 2 of 5

TOOL PARTS

ASSEMBLY PROCEDURE

1. Ensure that the crimp tool is on the correct tool setting at number 5 (see figure A). The

settings start from 1 and go round the dial clockwise.

Figure A: Tool set at 5

Table Clamp

Ratchet Tool

with clamp

jaws fitted

Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 T: +44 (0) 23 9231 4545 T: +65 6 779 4909

E: [email protected]m W: www.harwin.com E: mis@harwin.co.uk W: www.harwin.com E: [email protected] W: www.harwin.com

IS-51 Issue: 1Date: 26-Apr-22 C/Order: 31534 Page 3 of 5

2. Decide whether you will clamp the tool to the desk or use the tool freehand. If clamping the

tool to a desk, make sure the tool is securely fastened before use (see figures B and C).

Figure B: Locate clamp into tool Figure C: Tighten the clamp to the

undercarriage work surface

3. Make certain that the hand tool is in the fully open position, and that the jaws are free from

dirt and debris.

4. Select a suitable ribbon cable for the connector. Harwin recommends:

Wire Type............................UL2678

Wire Pitch ...........................0.635mm

Wire Thickness....................30AWG

5. Make sure the ribbon is the correct width for the applicable connector, and that the ends are

cut clean and straight at the desired length.

6. Feed the cable into the connector, with the Contact 1 wire (normally marked red) positioned

correctly to the Contact 1 ident on the connector.

7. Securely place the connector in the tool recess and align it approximately in the center, using

the center mark on the tool as a guide (see figures D & E). Exact positioning is not critical.

Figure D: Align connector central to tool Figure E: Rest connector on outer ledge

(ribbon not shown in both images for clarity)

Center mark

Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 T: +44 (0) 23 9231 4545 T: +65 6 779 4909

E: [email protected]m W: www.harwin.com E: mis@harwin.co.uk W: www.harwin.com E: [email protected] W: www.harwin.com

IS-51 Issue: 1Date: 26-Apr-22 C/Order: 31534 Page 4 of 5

8. Once the connector is secure in the correct position, slowly compress the handle (see figures

F and G) until the tool and the connector are fully shut and the ratchet within the tool has

released.

Figure F: Tool jaw in contact with connector Figure G: Mid-compression of handles

9. If assembling a second connector to the cable, take care to ensure the Contact 1 wire is

positioned correctly to the Contact 1 ident on this second connector, and the required

orientation is used – see figure H for the two orientations. Repeat steps 5 to 8 to assemble

the second connector.

Figure H: Choice of orientation for second connector assembly

Harwin North America Harwin Europe Harwin Asia

T: +1 603 893 5376 T: +44 (0) 23 9231 4545 T: +65 6 779 4909

E: [email protected]m W: www.harwin.com E: mis@harwin.co.uk W: www.harwin.com E: [email protected] W: www.harwin.com

IS-51 Issue: 1Date: 26-Apr-22 C/Order: 31534 Page 5 of 5

TOOL MAINTENANCE

1. Keep the tool clean and free from dirt and foreign matter. Ensure that all pins and clips are in

place before use, and that signs of wear are not visible. If the pivots are worn, the tool must

be replaced, or integrity of assembly will be compromised.

2. Oil at all pivots and bearings using light cycle oil.

3. At regular intervals, check the assembly tool jaws for wear or damage, and inspect sample

connector assemblies for form and function.

If you have any questions about this instruction sheet, or the Archer Kontrol range of connectors,

please contact technical@harwin.com.

Table of contents

Popular Tools manuals by other brands

Goodyear

Goodyear 46731 Operation manual

Weaver

Weaver MASTER TOOL MIGHTY WONDER quick start guide

Liberty Garden

Liberty Garden NAVIGATOR 714 owner's manual

Teryair

Teryair TEFD 75-110V Operation and maintenance guide

9circle

9circle 9CL-30501 instruction manual

Bosch

Bosch GTA 60 W Professional Original instructions