Di-Acro 4 Bender User manual

REV. H 10/12

1

DI-ACRO

#4 HAND BENDER

INSTRUCTION MANUAL

REV. H 10/12

2

TABLE OF CONTENTS

A. SAFETY INFORMATION PG. 3

B. MAINTENANCE PG. 3

C. #4 HAND BENDER BREAKDOWN AND PARTS LIST PG. 4-6

D. QUIK-LOK BREAKDOWN AND PARTS LIST PG. 7-8

E. SPECIFICATIONS & THE ART OF BENDING PG.9

F. RATCHET AND DIRECT OPERATION PG. 10

G. QUIK-LOK INSTALLATION & OPERATION PG. 11

H. OPTIONAL STAND PG. 12

WARRANTY PG. 13

REV. H 10/12

3

A. SAFETY INFORMATION

Before bender is set up for operation, mount on work bench or stand*

with stand or work bench bolted in place.

*IF BRAKE IS MOUNTED ON ITS OWN STAND, SECURE STAND TO

FLOOR

B. MAINTENANCE

Lubricate chain as needed. Add grease in grease zerk periodically.

REV. H 10/12

4

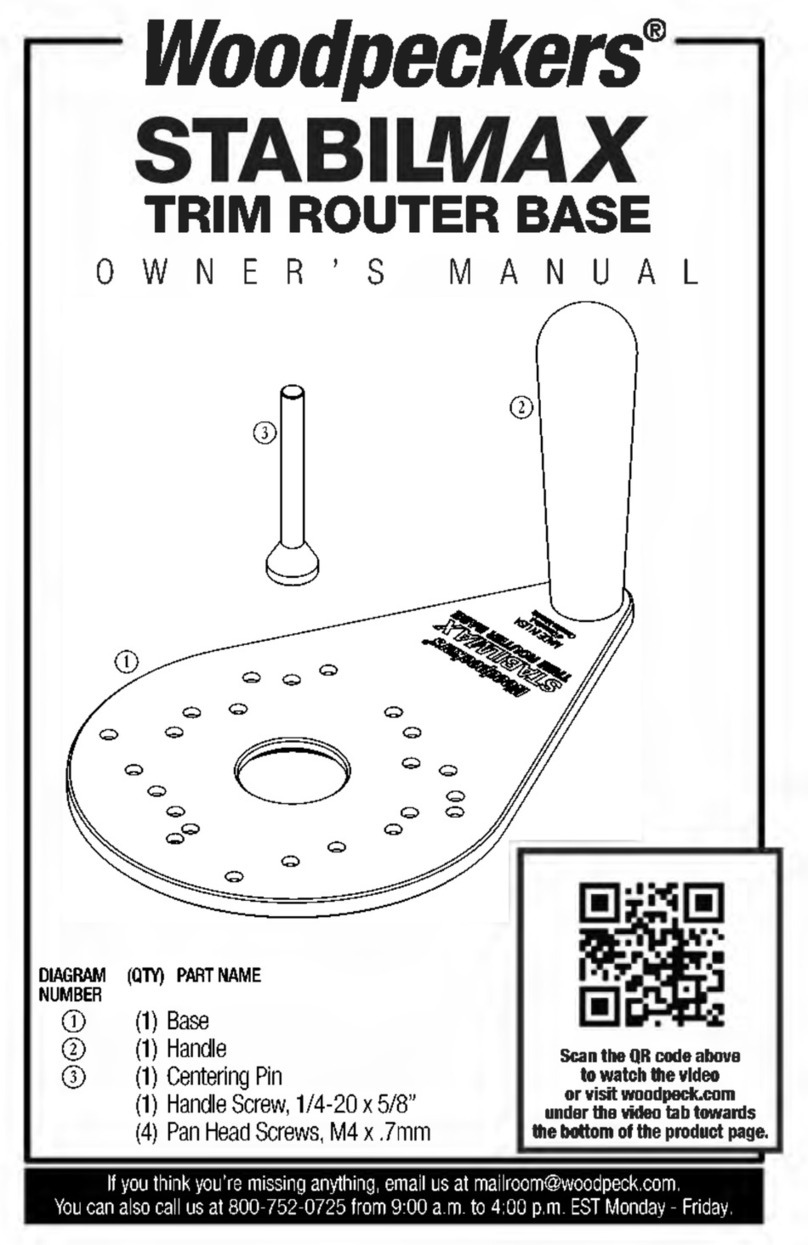

#4 HAND BENDER PARTS BREAKDOWN

8140800-080

REV. H 10/12

5

Parts List

8140800-080

ITEM PART NUMBER DESCRIPTION QTY

1

8140110-100

BASE-#4 BENDER

1

2

8430200-200

PIN LINK ATTACHMENT

3

4

100-0089-P

60 ROLLER CHAIN

74”

5

8150650-110

SERIAL TAG

1

7

8140120-800

HANDLE ARM WELDMENT

1

8

120-0191-P

GREASE FITTING

1

9

8130120-801

EXTENSION ARM WELDMENT

1

10

23A0516C1000

SCREW-SSS 5/16-18X1

1

11

8140110-501

MOUNTING PLATE

1

12

8140120-301

MOUNTING PLATE PIN

2

13

8310300-200

NEEDLE BEARING

109

14

8130570-203

SHIM

6

15

20A0308C1102

SCREW-SHCS 3/8-16X1-1/2

3

16

8130016-970

RADIUS PIN

1

17

8158120-302

HOLDING PIN

1

18

22D0104C0308

SCREW-THMS 1/4-20X3/8

1

19

8158111-370

LCKG PIN ASSY “A” (13/16”)

1

20

8000111-370

LCKG PIN ASSY “B” (15/16”)

1

21

8100111-370

LCKG PIN ASSY “C” (1-1/16”)

1

22

8200121-701

NOSE HOLDER

1

23

8000120-301

NOSE PIN

1

24

23A0308C0102

SCREW-SSS 3/8-16X1/2

1

25

8130121-701

FORMING NOSE

1

26

8120510-401

NOSE SPRING

2

27

21A0516C0102

SCREW-HHCS 5/16-18X1/2

2

28

0102WILLIAMS

WASHER

1/2 WILLIAMS WASHER

4

29

21A0102F3000

SCREW-HHCS 1/2-20X3

2

30

8158121-702

TRIGGER

1

31

18A0104X3000

PIN-SPRING 1/4X3

1

32

8310301-200

NEEDLE ROLLER

2

33

8010461-000

1/4” DIA STEEL BALL

1

34

8210510-204

SPRING

1

35

8158121-701

NOSE HOLDER SUPPORT

1

36

8300121-701

NOSE HOLDER SUPPORT SCR

1

37

21A0102F2102

SCREW-HHCS 1/2-20X2-1/2

2

38

23A0104C0102

SCREW-SSS 1/4-20X1/2

1

39

BEND LOCATING GAUGE (SEE

BELOW)

8130142-003

BEND LOCATING GAUGE ROD

1

8470510-900

RETAINING RING

2

8200142-003

BENDING LOCATING GAUGE ARM

1

8300142-003

BEND LOCATING GAUGE BTN

1

43

8140121-803

RATCHET HANDLE HOLDER

1

44

8140120-303

RATCHET HANDLE PIN

1

45

8140470-605

PIN CLIP

1

REV. H 10/12

6

Parts List –Continued

8140800-080

ITEM PART NUMBER DESCRIPTION QTY

46

8140120-304

RATCHET HANDLE PIN STOP

2

47

20B0104C0308

SCREW-BHCS 1/4-20X3/8

2

48

8000121-803

COLLAR

1

49

20A0104C1104

SCREW-SHCS 1/4-20X1-1/4

1

50

8000121-804

CHECK PAWL R

1

51

8100121-804

CHECK PAWL L

1

52

8510100-100

CHECK PAWL SPRING

1

53

8200121-804

CHECK PAWL COLLAR

2

54

23A0104C0104

SCREW-SSS 1/4-20X1/4

2

55

19A0308X2104

PIN-DOWEL 3/8X2-1/4

2

56

19A0308X1304

PIN-DOWEL 3/8X1-3/4

2

57

8500121-804

CHECK PAWL SPACER

2

58

8300121-804

CHECK PAWL SPRING STOP

2

59

8400121-804

CHECK PAWL HANDLE

2

60

8000120-304

RATCHET PAWL PIN

1

61

8140510-405

RATCHET PAWL SPRING

1

62

8140121-804

RATCHET PAWL

1

63

23A0104C0104

SCREW-SSS 1/4-20X1/2

1

64

8200120-800

EXTENSION ARM

1

65

100-0142-M

HANDLE GRIP

1

66

21A0308C2104

SCREW-HHCS 3/8-16X2-1/4

2

67

61X0308

WASHER-FLAT 3/8

2

68

8120142-001

ANGLE GAUGE

1

69

21A0308C2104

SCREW-HHCS 3/8-16X2-1/4

1

70

8100142-001

RETURN STOP

1

71

20A0308C

NUT-FULL 3/8-16

3

8030650-301

PINCH POINT LABEL(NOT SHOWN)

1

030-6503001

CAUTION LABEL (NOT SHOWN)

1

REV. H 10/12

7

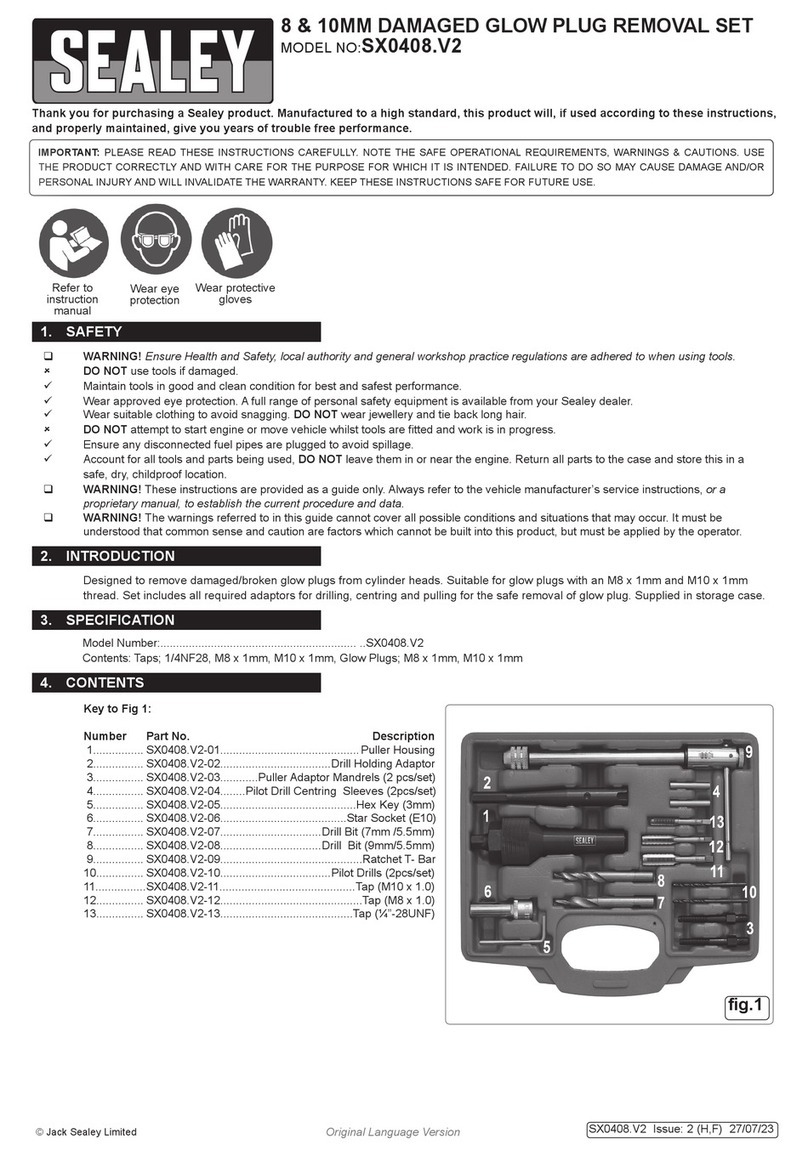

C. QUIK-LOK BREAKDOWN AND PARTS LIST - 8146111-373

ITEM PART NUMBER DESCRIPTION QTY

1

8146111-300

BASE

1

2

8700111-300

SLIDE WELDMENT

1

3

19A0104X1000

PIN-DOWEL 1/4X1

1

4

20A0308C0304

SCREW-SHCS 3/8-16X3/4

1

5

8146110-700

HANDLE ARM

1

6

8310410-900

BEARING

1

7

19A0102X1304

PIN-DOWEL 1/2X1-3/4

1

8

8100470-102

STUD BOLT

1

9

8120810-600

PLASTIC KNOB

1

10

8800111-300

LINK

1

11

19A0102X1104

PIN-DOWEL 1/2X1-1/4

1

12

8146111-301

CLAMP

1

13

21A0102F2102

SCREW-HHCS 1/2-20X2-1/2

1

14

8100111-301

SPACER A

1

15

8146111-370

HANGER ASSEMBLY OUTER

1

16

19A0516X1000

PIN-DOWEL 5/16X1

4

17

21A0308C1102

SCREW-HHCS 3/8X16X1-1/2

1

18

8200111-370

HANGER ASSEMBLY INNER

1

19

8000111-301

SUPPORT BAR

1

20

21A0308C3102

SCREW-HHCS 3/8-16X3-1/2

1

21

21A0308C1000

SCREW-HHCS 3/8-16X1

1

22

19A0308X2000

PIN-DOWEL 3/8X2

2

23

21A0102C1304

SCREW-HHCS 1/2-13X1-3/4

2

24

8200111-301

CLAMP BLOCK (Available upon request)

1

25

19A0102X1102

PIN-DOWEL 1/2X1-1/2

1

REV. H 10/12

9

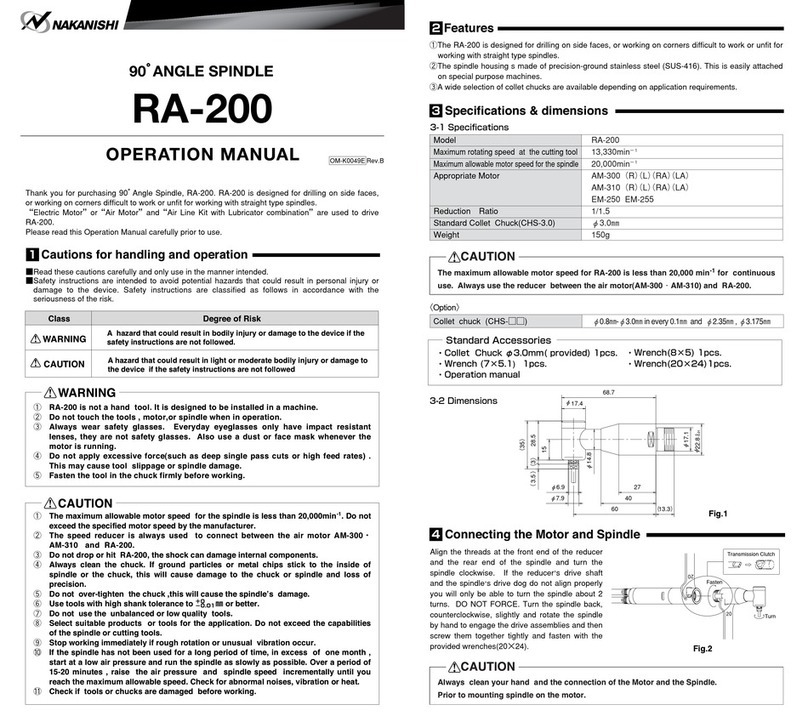

E. RATCHET AND DIRECT OPERATION

RATCHET OPERATION

For clockwise operation of the Di-Acro No. 4 Bender, engage check

pawl (B) and disengage check pawl (C). Remove stop pin (F) from hole

(D) and place in hole (E). For counter-clockwise operation, engage

check pawl (C) and disengage check pawl (B). Remove stop pin (F)

from hole (E) and place in hole (D).

*CAUTION*

STOP PINS MUST BE USED AS DESCRIBED ABOVE WHEN USING

THE RATCHET MECHANISM. FAILURE TO DO SO CAN RESULT IN

SERIOUS BODILY INJURY.

DIRECT OPERATION

For direct drive operation without the ratchet, disengage both check

pawls (B) and (C). Remove handle (H), place handle holder (I) in

neutral position between holes (D) and (E). Insert stop pins into both

holes.

E-F C

H I D B

REV. H 10/12

10

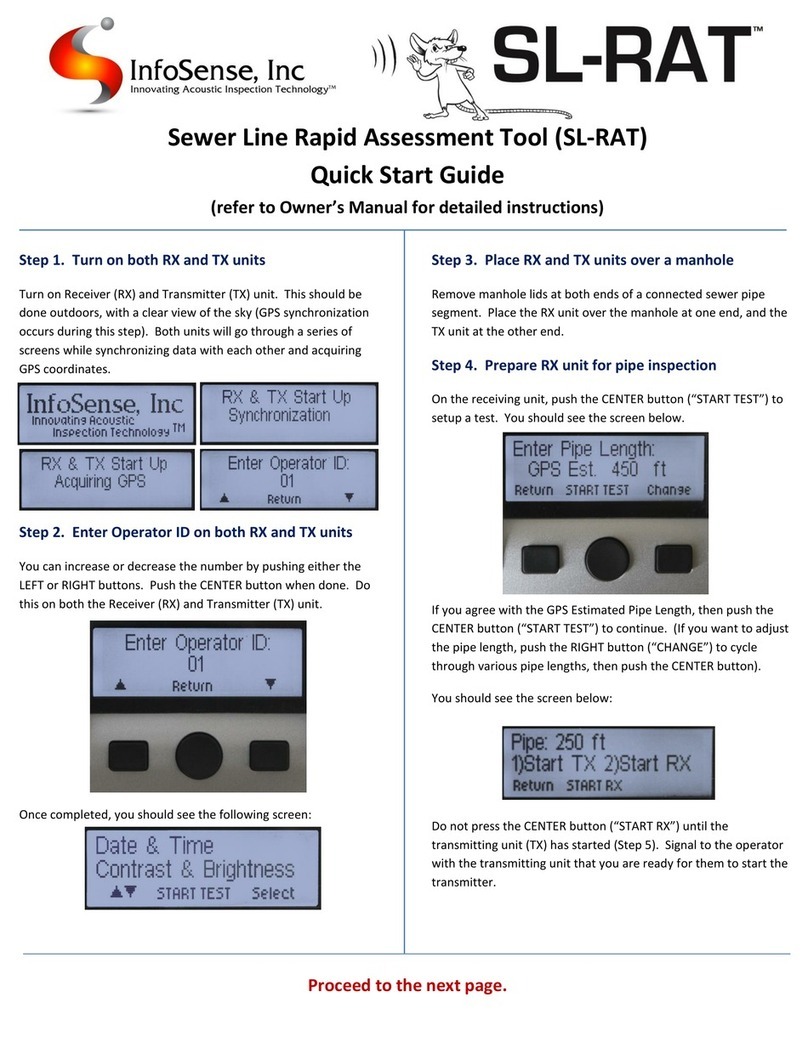

F. QUIK-LOK INSTALLATION AND OPERATION

To mount Quik-Lok Clamp on Di-Acro No. 4 Bender for clockwise

forming, insert 3/8” dowel pins (K) and (K-1) in holes to bender base

casting. Bolt in position with 1/2-20 hex screws (L) and (L-1) inserted

from the bottom side of base.

To adjust for material size, radius of bend and clamping pressure;

loosen 1/2-20 hex screw (M) on clamp (O) and move slide assembly

(R) to the correct position and then tighten 1/2-20 hex screw (M).

To open Quik-Lok Clamp, move handle arm (W) to the right. To mount

Quik-Lok clamp for counter-clockwise forming, remove clamp

assembly from base by removing 3/8 hex screws (T-1) and (T-2).

Remove mounting plate from bender base by loosening 1/2-20 hex

screws (L) and (L-1). Press 3/8” dowel pins (K) and (K-1) through base

(U) and turn plate over so 3/8” dowel pins cab be inserted in holes (K)

and (K-2) then bolt in position with 1/2-20 hex screw (L). This will

place base (U) in a position 180° from its location in this photograph.

Bolt clamp assembly on base with 3/8” hex screws (T-1) and (T-2).

R M O U

W T-1 T-2 K-1 L-1 K L

REV. H 10/12

8

D. SPECIFICATIONS & THE ART OF BENDING

REV. H 10/12

11

G. OPTIONAL STAND

Part Number: 8230110-900

Stand Dimensions: 20” WIDE, 15” DEEP, 33-1/4” HIGH

CALL DI-ACRO FOR PRICE AND AVAILABILITY

Fasteners needed to attach Hand Bender to stand are the following:

Fasteners to attach stand to floor are not included

PART NUMBER

DESCRIPTION

QTY

21A0102C3000

SCREW-HHCS 1/2-13X3

3

61X0102

WASHER-FLAT 1/2

3

31X0102C

NUT-FULL 1/2-13

3

REV. H 10/12

12

Warranty & Limitation of Liability

Defective parts, of a product manufactured by DI-ACRO, will be replaced or repaired at

no charge for twelve (12) months following delivery to the original purchaser. Labor is

included for the first 90 days. This warranty becomes void when products have not

been used according to instructions furnished by DI-ACRO, nor does it cover any

altered parts or unauthorized repairs. We cannot be responsible for the cost of repairs

made or attempted outside of our factory. All other warranty claims are made FOB our

plant, providing such items(s) is returned freight prepaid to our plant for examination.

This warranty does not apply to parts, components or systems not manufactured by DI-

ACRO. These products are covered instead by the existing warranties, if any, of their

manufacturers. Normal service items with a reasonable life expectancy of less than one

year are warranted only to the extent of the reasonable life under normal use and

service.

Authorization must be obtained from DI-ACRO before returning parts or equipment to

the factory. DI-ACRO will satisfy this warranty by replacing the product or refunding the

purchase price upon receipt, inspection and defect identification.

DI-ACRO’s liability under this warranty shall not exceed the amount paid for the product.

THIS IS DI-ACRO’S SOLE WARRANTY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, WHICH ARE HEREBY EXCLUDED, INCLUDING IN

PARTICULAR ALL WARRANTIES OF MERCHANTABILITY, FITNESS OR ANY

LOSS, DAMAGE OR EXPENSES DIRECTLY OR INDIRECTLY RELATED TO THE

USE OF ITS PRODUCT OR FROM ANY OTHER CAUSE OR FOR CONSEQUENTIAL

DAMAGES INCLUDING, WITHOUT LIMITATION, LOSS OF TIME AND LOSS OF

PRODUCTION.

IT IS EXPRESSLY UNDERSTOOD THAT DI-ACRO IS NOT RESPONSIBLE FOR

DAMAGE OR INJURY CAUSED TO OTHER PRODUCTS, MACHINERY, PROPERTY

OR PERSONS BY REASON OF THE USE OF ITS PRODUCTS.

cCopyright 2012

Table of contents

Other Di-Acro Tools manuals