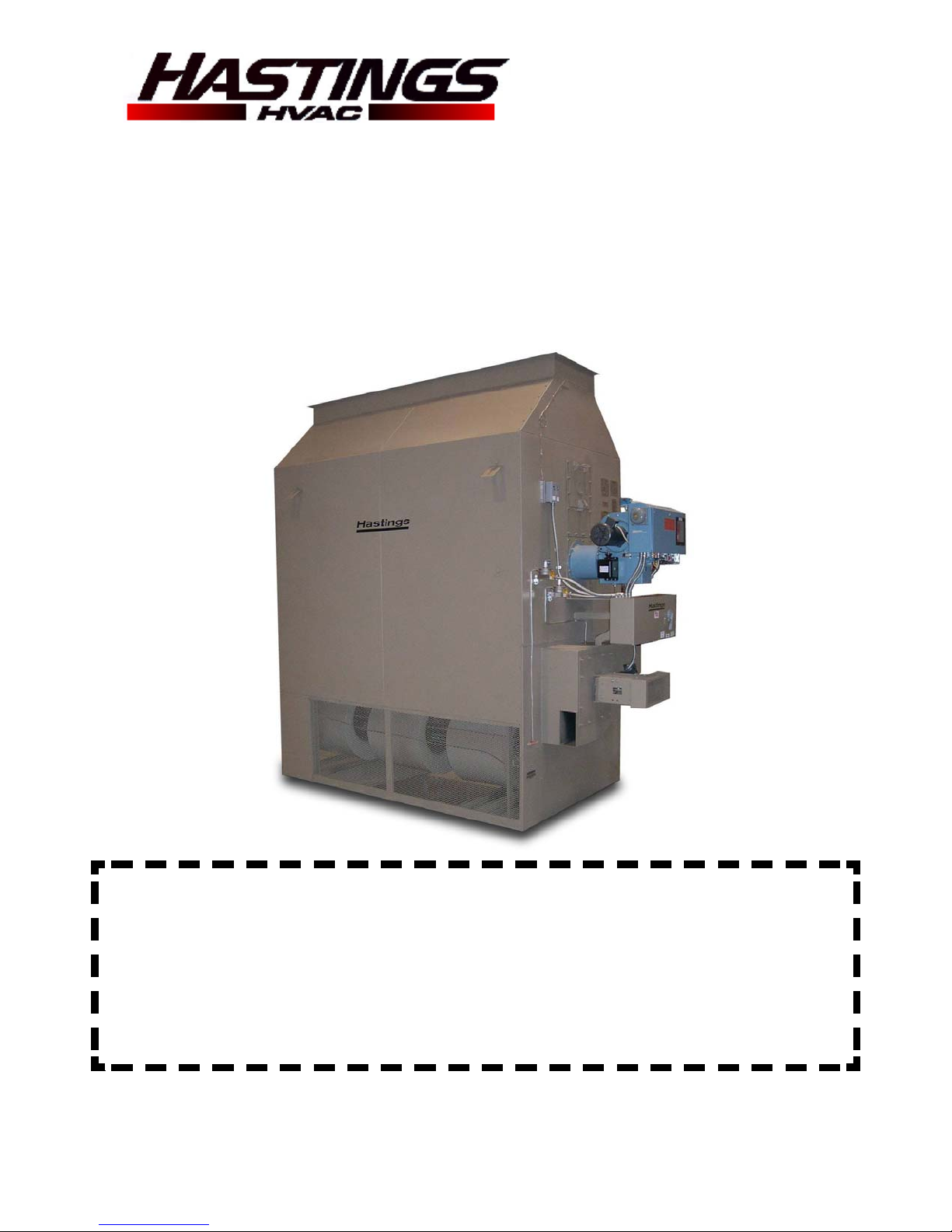

SECTION I. – GENERAL INFORMATION

A. PURPOSE

The purpose of this manual is to present a guide for proper installation, maintenance, and

operation of the Counterflo CF Series heaters, and to supplement, but not to replace, the

services of qualified field service personnel to supervise the initial start-up and adjustment of

the Counterflo unit. Persons without previous experience with large commercial and

industrial equipment should not attempt the initial adjustment and checkout procedure which

is essential before such installations may be considered as ready for operation. This manual

should be made readily available to operating personnel as an aid in trouble-shooting and

proper maintenance.

B. SHIPPING

Base Counterflo units are shipped with blower and burner sections assembled. Discharge air

nozzles and/or discharge hoods, optional filter and/or damper sections, or other large

optional accessories are assembled and shipped mounted and wired whenever possible

within limitations of shipping and handling. Optional accessories shipped separately are

shipped as assembled sections. Any wired accessories which have been disassembled for

separate shipment require no additional conduit or wire for field reassembly. All wire leads

will be tagged for ease of reconnection in the field.

Shipments are made F.O.B. Hastings, Nebraska, by rail or truck. In either case, the unit is

securely strapped, tied, and blocked to prevent shipping damage. All shipments are checked

by an inspector before they are accepted by the carrier. Parts that are shipped unmounted

are noted on the bill of material. These parts, where feasible, are packaged and shipped

with the units. Upon receipt of shipment, all units should be checked against the bill of

lading to insure all items have been received. The units should be checked carefully for

physical damage in the presence of the carrier’s representative. If parts are missing or

damage has occurred, a claim should be filed immediately with the carrier.

All Counterflo units are given a complete operations test and control circuit checkout before

shipment. A copy of the flame test report, wiring diagram, and bill of material is included

with each unit shipped. If correspondence with the factory is necessary, please provide the

unit model and serial number.

C. OPTIONAL FACTORY SERVICE

Periodic service on any piece of mechanical equipment is necessary for efficient operation.

Hastings HVAC, Inc. has a nationwide service organization available to make quick and

dependable servicing of make-up air, return air, heating, ventilating, or air handling types of

equipment. Hastings HVAC, Inc. also provides factory start-up service which includes the

presence of a service engineer to perform the initial start-up and adjustment of the

equipment, instruction of the owner’s maintenance personnel in proper operation and

maintenance, and return calls for any adjustments required to a particular unit within a

period of sixty (60) days after start-up is complete. Customer’s loss of power of fuel will

not constitute need for any return calls. Consult the factory for quotations on periodic or

start-up service. -1-