HAWEKA RPV1300 User manual

Operating Instructions

Runout Measurement Device

HAWEKA AG • Kokenhorststraße 4 • D-30938 Burgwedel • Phone +49 5139 8996-0 •

Technical modifications reserved. Text and layout protected. Reprinting and copies, including extracts, are only permitted with written authorisation.

GEB 001 128

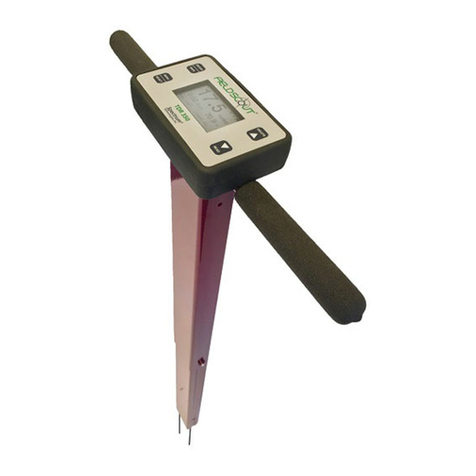

Runout measurement device for heavy vehicle tyres

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

3

Table of Contents

1General Safety Instructions ...............................................................................5

1.1 Operator’s duty of care ................................................................................................5

1.2 Basic safety precautions..............................................................................................6

2Product Description............................................................................................7

2.1 Authorised intended use..............................................................................................8

2.2 Description of the area of application:..........................................................................8

2.3 Technical Data.............................................................................................................9

2.4 PC system requirements for RPV1300 ........................................................................9

3Equipment provided .........................................................................................10

3.1 Parts list for standard version RPV1300 ....................................................................10

4Commissioning.................................................................................................11

4.1 Mounting the laser tripods..........................................................................................11

4.2 Installing the software in Windows.............................................................................12

4.3 Installing the laser driver............................................................................................12

5The RPV1300 Program......................................................................................13

5.1 Setting up the software..............................................................................................13

5.1.1 Customer data:........................................................................................................................14

5.1.2 Language: ...............................................................................................................................14

5.1.3 Interface for laser sensor: .......................................................................................................15

5.1.4 Laser symbol information:.......................................................................................................16

5.1.5 Instructions..............................................................................................................................16

5.1.6 Data directory..........................................................................................................................17

5.1.7 Password ................................................................................................................................17

5.1.8 Saving program settings .........................................................................................................17

5.1.9 Advanced settings...................................................................................................................17

5.1.10 System overview.....................................................................................................................17

6Preparing for measurement recording............................................................18

6.1 Preparatory measures ...............................................................................................18

6.1.1 Setup of measuring device on vehicle wheel..........................................................................19

7Measurement recording ...................................................................................20

7.1 Entering vehicle, wheel and rim data in the program..................................................20

7.2 Selecting the wheel to be measured..........................................................................21

7.3 Assigning the laser sensors.......................................................................................22

7.4 Markings on the wheel...............................................................................................24

7.5 Rotational speed during measurement recording......................................................24

7.6 Start wheel measurement..........................................................................................25

7.7 Error during wheel measurement...............................................................................26

8Control measurement after matching .............................................................27

8.1 Control measurement ................................................................................................27

9Show log............................................................................................................28

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

4

10 Servicing............................................................................................................30

11 Error description...............................................................................................30

12 Appendix............................................................................................................31

12.1 Measurement log for individual wheel........................................................................31

12.2 Measurement log for overview...................................................................................32

13 EC Declaration of Conformity..........................................................................33

HAWEKA AG

Kokenhorststr. 4 Burgwedel 11.12.17

30938 Burgwedel Release notes page 7

Phone +49 (0)5139 8996 - 0

Fax: +49 (0)5139 8996 222

info@haweka.com

www.haweka.com

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

5

1 General Safety Instructions

1.1Operator’s duty of care

The runout measurement device RPV1300 has been designed

and built after thorough selection of applicable harmonised

standards. It therefore corresponds to the current state of the art

and offers the highest degree of safety during operation.

The device may only be structurally modified with written

authorisation by the manufacturer!

Device safety can only be implemented during practical operation

if all required applicable measures have been taken. The

operator’s duty of care includes planning such measures and

checking their implementation.

In particular, the operator has to ensure that

•the device is only used for its intended purpose

•the device is only used in a fully functioning state and free

from defects

•the complete operating instructions are permanently

available in a readable condition at the operating location of

the device

•only accordingly qualified and authorised personnel operate

the device

•personnel are regularly instructed in all relevant health and

safety issues and are familiar with the operating instructions,

in particular with the safety instructions contained therein

•all safety and warning notices attached to the machine are

not removed and are legible.

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

6

1.2Basic safety precautions

The runout measurement device may only be used by accordingly

qualified and authorised personnel who are familiar with these

operating instructions and can work in accordance with these

instructions!

Prior to each use of the device it has to be checked for visible damage

and it must be ensured that the device is only operated when free from

defects! Any defects that are identified must be reported to a superior

immediately!

Laser product

CLASS 2

TYPE 1

Warning - laser radiation

This symbol indicates potential danger to persons. (risk of injury)

Some basic instructions must be followed for all lasers:

- Never look directly into the beam!

- Define beam paths precisely!

- Avoid dangerous reflections. Pay particular attention to reflective or

shiny surfaces as these can cause reflections.

- Turn off the laser after work has finished!

The lasers used are Class 2 laser products. The laser radiation

generated is not hazardous to the eyes for short periods of exposure

(up to 0.25 s). If you accidentally look into the laser beam for a short

period, the eye is protected by the blink reflex.

NEVER INTENTIONALLY LOOK INTO THE LASER BEAM!

If you have reason to believe that your eyes has been damaged by the laser beam,

seek the advice of an eye specialist immediately.

Please refer to the accident prevention regulation (VGB 93 Laser

radiation) for further safety instructions for working with lasers.

The user is independently responsible for proper operation and

compliance with safety regulations.

The system must be protected against moisture at all times.

This applies in particular during transport and storage of the entire

device case.

Ensure that the storage location is dry and free from dust and that the

storage temperature does not fall below 0 °C.

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

7

2 Product Description

Runout Measurement Device RPV1300

Item No. 900 008 214 (standard)

Technical modifications reserved.

Version 1.3

Images: HAWEKA AG / D-30938 Burgwedel

Reproduction in any form is not permitted.

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

8

2.1 Authorised intended use

•The runout measurement device RPV1300 has been developed to allow optimisation of

runout of large tractor wheels and other heavy vehicle wheels for agricultural and

earthmoving machinery.

•It is exclusively intended for quickly measuring runout of the vehicle rim while simultaneously

measuring runout of the vehicle tyre.

•Using the runout measurement device allows determination of the ideal positioning of the

tyre on the rim through measuring.

•The wheel for testing has to be clamped well centred to the vehicle (tractor) or another

suitable rotation device, e.g. a mounting machine (see page 18).

•The wheel for testing has to have a clear, countable number of tread lugs and be new or as

new.

The operator of the runout measurement device rather than the

manufacturer shall be liable for all personal injury and property damage

caused by incorrect use!

2.2 Description of the area of application:

Tolerances caused by production often cause deviations in runout of rim and tyre. These deviations

can have a negative effect on the runout of the wheel through accumulation of the tolerances,

causing the vehicle to vibrate and even “bob”.

(Vehicle vibrations)

The runout of the individual wheel is also tested and – if necessary – optimised to be able to make a

statement about this value. The laser sensors of the runout measurement device RPV1300 measure

the rim on both sides, in the area of the hump (tyre seating on the rim) and the tyre over the tread

lugs and evaluates it using the program.

The RPV1300 program uses the recorded measurement values to determine the best possible

position of the tyre in relation to the rim.

Afterwards, the smallest runout between the two components can be achieved through targeted

rotation of the tyre on the rim (matching).

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

9

2.3 Technical Data

Functions of distance measuring

Distance measuring range 80 - 120 mm

Measuring tolerance +/- 0.01 mm

Power supply for laser sensors through USB slot of computer

Laser class 2 -> DIN EN 60825-1

Sampling rate 130 Hz

Protection rating IP 54

Temperature range 0 °C - +50 °C

2.4 PC system requirements for RPV1300

Required operating system: Windows XP, Windows 7, 8.1, 10

Minimum hardware requirements:

Processor: Pentium IV – AMD Athlon 1 GHz

RAM: 512 MB (Windows XP) / 1024 MB (Windows 7, 8.1, 10)

100 MB available hard disk space

Graphics: 1024 x 768 pixel resolution / High Colour

Sound card

Port: USB 1.1

CD-ROM drive

Recommended:

Processor: Intel or AMD with 1.6 Ghz or better

RAM: 1024 MB

Graphic card with 16 MB AMD (ATI) or NVIDIA chipset or better

1280 x 1024 pixel resolution / True Colour

Printer

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

10

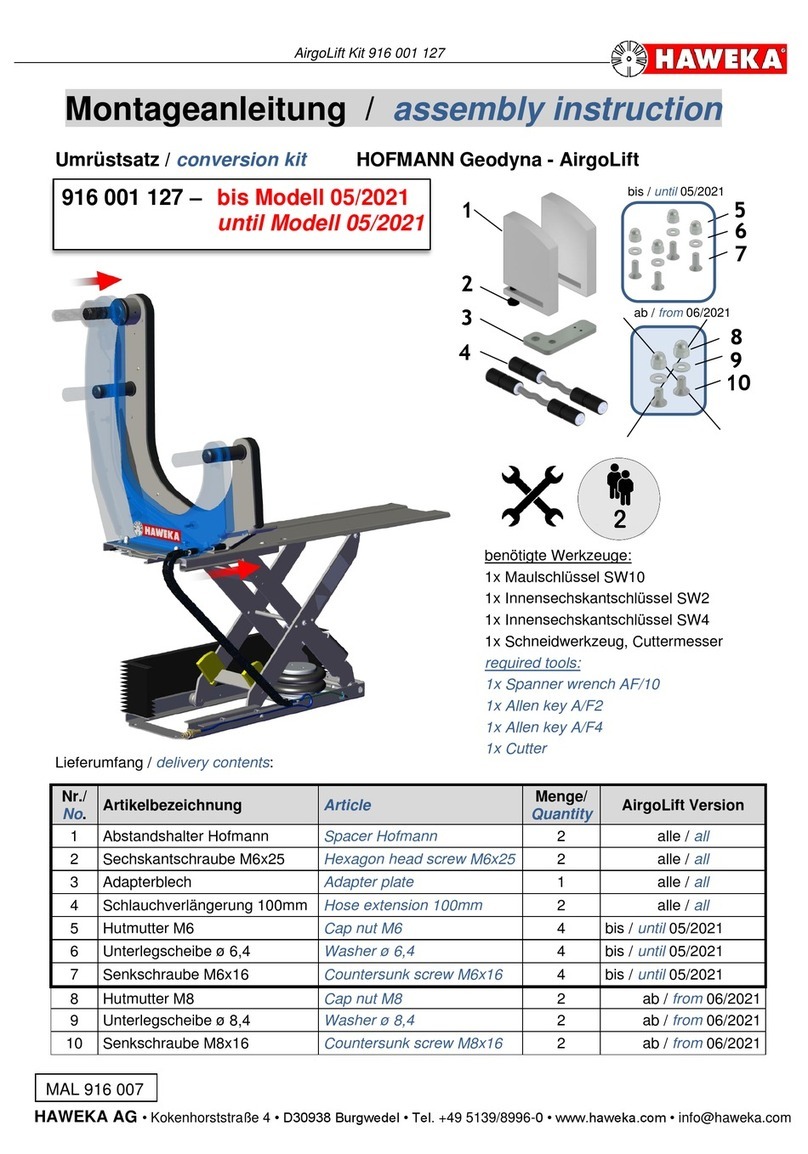

3 Equipment provided

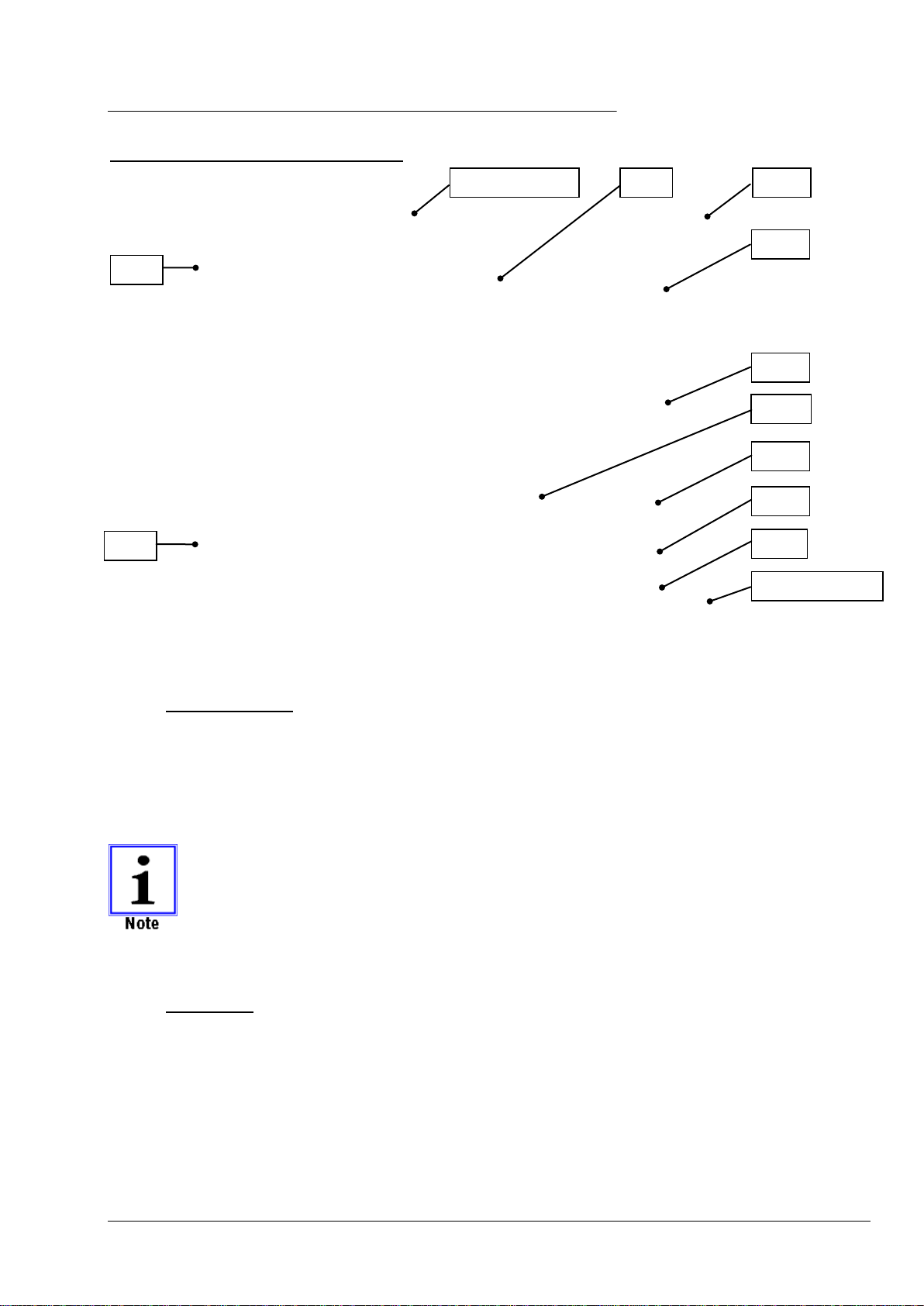

3.1 Parts list for standard version RPV1300

2 Laser sensors including telescopic tube

Item no. 900e008 334

1 Laser sensor including support tube

Item no. 900e008 335

3 Tripods

Item no. 900e008 340

2 Tripod heads including tube 1 4-port USB hub 2.0 hub

Item no. 900e008 332 Item no. Du-US75012034

1x USB-Stick 1 operating manual 1 transport case

Program

RPV1300 Item no. GEB 001 127 Item no. 900e008 336

Please contact your sales representative for additional accessories.

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

11

4 Commissioning

The following tasks are required for first use of the runout measurement device:

Mounting the laser tripods

Installing the software in Windows

Setting up the RPV1300 software.

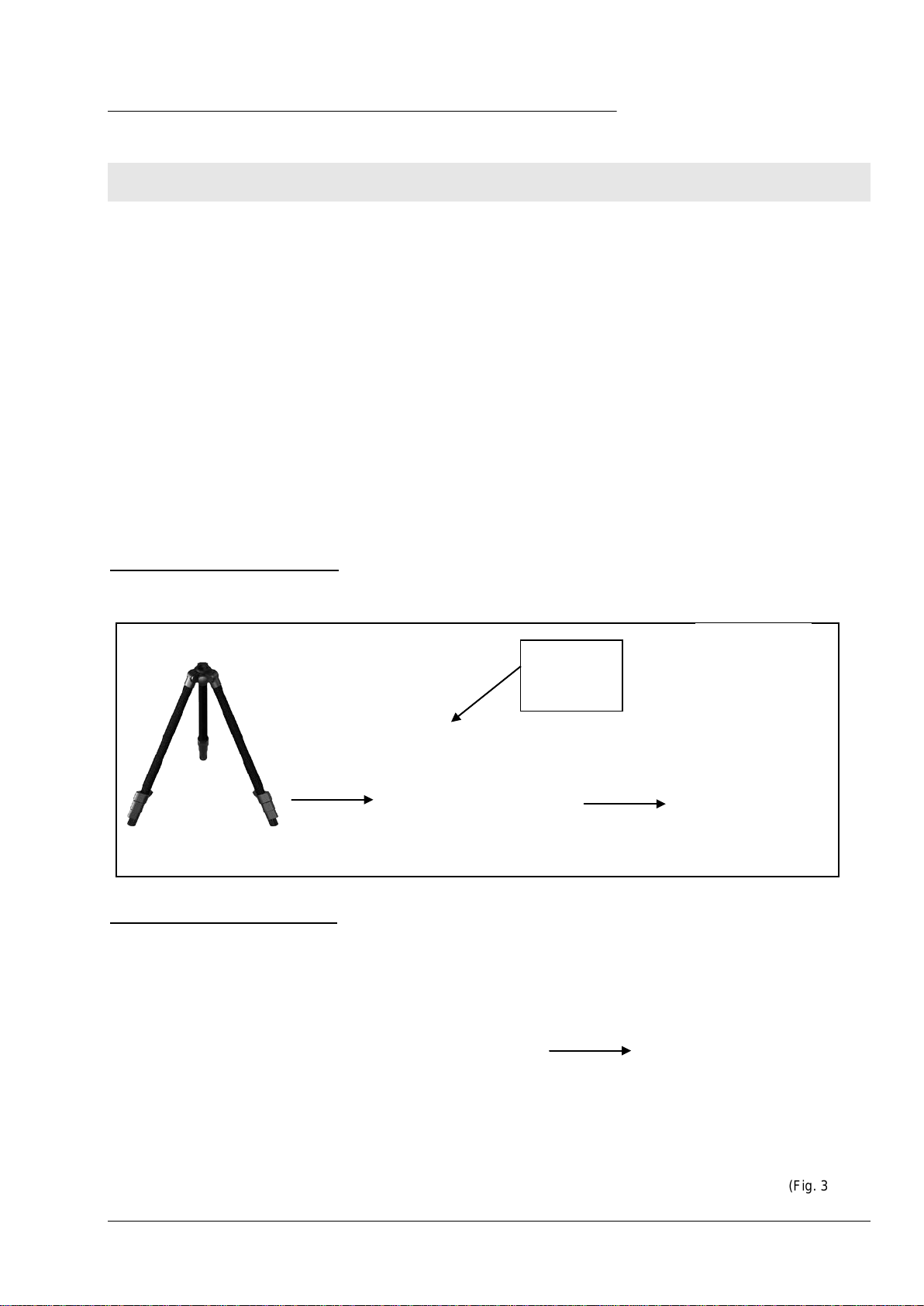

4.1Mounting the laser tripods

1 tripod for tyre measurement:

Insert the laser sensor incl. support tube into the tripod and screw in. (Fig. 1)

2 tripods for rim measurement

Insert tripod head including tube into the tripod and

screw in. (Fig. 2)

Insert the laser sensor including the telescopic tube into

the snap-in fixture on the tripod head. (Fig. 3)

(Fig. 1)

(Fig. 2)

(Fig. 3)

Check for

the

groove!

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

12

4.2 Installing the software in Windows

•Close all open applications on the computer.

•Insert the USB-Stick (Fig. 4) into the PC.

If the installation wizard does not start automatically, click

Start on the Windows task bar and then click Run.

Enter D:\rpv1300setup_1.04.004.exe, where D is the drive

letter of the USB-Stick.

•Confirm the Windows security warning if necessary and

click Run.

•Read the licence agreement and follow the instructions of

the installation wizard on screen. (Fig. 5)

•When the installation procedure has completed, the

RPV1300 software and the driver for the laser sensors

have been installed on the computer.

•Remove the USB-Stick from the PC after installation.

4.3Installing the laser driver

The driver for the laser sensor is automatically added to the

PC system during installation of the RPV1300 program

•A Windows security information is displayed during

installation of the driver.

In this window, select “Install this driver software anyway”

(Fig. 7)

•When one or more laser sensors are connected to the free

USB ports on the USB hub of the PC after installation, the

new hardware is recognised and added to the system.

(Fig. 8)

(Fig. 4)

(Fig. 5)

(Fig. 7)

(Fig. 8)

(Fig. 6)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

13

5 The RPV1300 Program

We have taken great care to ensure that the entire program is straightforward and clear so that

the user can monitor and operate the device at all times with ease.

You will learn how to use this program to determine the rim and tyre geometry of a vehicle

wheel in a very short time.

In just a few steps, help texts and graphical illustrations guide you through the different parts of

the program and provide sufficient information about the program at all times.

Before you begin with your first measurement, however. the most important program

parameters have to be set up for individual use.

5.1Setting up the software

•Start the program.

Click on the RPV1300 icon on the desktop or in Windows select:

START - ALL PROGRAMS - HAWEKA – RPV1300 / RPV1300.

After program start select the option “Settings” for the first basic setting.

The “Start measurement” button only becomes active when at least 2 laser sensors are

connected to the PC.

(Fig. 9)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

14

Overview of the program settings page

5.1.1 Customer data:

Enter your company name on the applicable lines so that the name can be included and printed on

the measurement protocol. (Fig. 10)

Select image button:

A company logo can be saved to be displayed on the log.

Supported file types: BMP, JPG, GIF, PNG

The image size is scaled.

Image files that are too small are enlarged, reducing their quality. The smallest format

should be 400 x 200 pixels at 72 dpi.

5.1.2 Language:

Click on the Select Language button to display

menus and all instructions in a different language.

(Fig. 11)

5.1.1

5.1.2

5.1.3

Information bar

5.1.4

5.1.5

5.1.6

5.1.8

5.1.9

Cancel/Back

5.1.7

5.1.10

(Fig. 10)

(Fig. 11)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

15

5.1.3 Interface for laser sensor:

After successful installation, new virtual COM interfaces are added to the system, depending on

the number of connected laser sensors.

The entry with the new COM interface can be verified in Windows device manager.

Each laser sensor requires one free USB port.

The supplied USB hub (Fig. 12) is connected to a

USB port on the PC, allowing connection of the

individual laser sensors.

The program can control up to three laser sensors.

(Fig. 13)

When the program has detected a laser sensor it will

display the corresponding serial number.

Description of symbols:

Display is grey. No laser sensor detected.

Display is green. Laser sensor was connected and

detected.

Display is red: Flash test on the laser sensor.

(Fig. 13)

(Fig. 12)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

16

5.1.4 Laser symbol information:

During the entire program execution the connection to

the laser sensors and the measurement procedures is

verified and displayed at the top right.

(Fig. 14)

Description of symbols:

Display is grey. The laser sensor is not connected to the

system. Unknown state. (Fig. 15)

The display flashes yellow and red alternately. The program is

attempting to establish a connection with the lasers. (Fig. 16)

Display is green. Connection to laser established. (Fig. 17)

Display is green with a red centre: The connection is

established but no measuring points were found, or flashing

during setup of laser sensor (Fig. 18)

Display is green with a yellow centre: Connection is established

and wheel was detected. Ready to for measurement recording

(Fig. 19)

Display is striped grey/yellow. Laser was removed from the

interface.

(Fig. 20)

Display is red. Error in of measurement recording.

(Fig. 21)

5.1.5 Instructions

Specifying the default for displaying/hiding operating

instructions during measurements. (Fig. 22)

The instructions window can be

displayed/hidden at any point in the

program. Click on the Instructions button

on the program page.

(Fig. 15)

(Fig. 16)

(Fig. 17)

(Fig. 18)

(Fig. 19)

(Fig. 21)

(Fig. 22)

(Fig. 20)

(Fig. 14)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

17

5.1.6 Data directory

All vehicle measurements are saved in a log file. The

preset file path is:

My_Documents\UserName\AppData\Haweka\

RPV1300\Database\(Fig. 23)

To change the file location, click on “Folder”:

To reset the default path, click on “Reset”:

5.1.7 Password

This function is used only by our service personnel

to carry out system diagnostics.

This option allows our service personnel to implement

program-specific changes. (Fig. 24)

5.1.8 Saving program settings

All settings must be confirmed by

clicking “Apply settings”.

5.1.9 Advanced settings

Under advanced settings, the user has the

option of personalising the program. (Fig. 25)

To customise settings, select the applicable

parameter in the table and change the value.

The modified entries must be confirmed by

clicking “Accept values” (Fig. 26).

5.1.10System overview

The system overview provides a list of the components

used, the PC, the sensor and the program versions.

This information is used by the service technician to

gain an overview of the system in the event of errors.

(Fig. 27)

(Fig. 23)

(Fig. 26)

(Fig. 24)

(Fig. 27)

(Fig. 25)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

18

6 Preparing for measurement recording

Different preconditions have to be met on the vehicle wheel for correct measurement.

•Drive the tyre for approx. 15 min. to warm it up and prevent flat spots

•Check that the vehicle has rims and tires of the same size

•Check that the tire pressure is correct

•Remove any dirt from wheel and tyre and clean these.

•Check wheel for sufficient tread depth (tread lugs have to be clearly visible)

6.1Preparatory measures

Variant 1

Jacking up the car

(Fig. 28)

•Secure vehicle against rolling away.

•Lift the vehicle at the axle to be measured

using a suitable lifting device until the wheel

can be rotated freely.

•Prevent vehicle from inadvertent lowering.

(e.g. support stands)

Variant 2

Vehicle wheel on tyre mounting machine

(Fig. 29)

•Clamp the vehicle wheel using a suitable* lorry

tyre mounting machine, following instructions

and ensuring exact centring.

•The wheel has to rotate freely.

∗

Observe the rotational speed of the

tyre mounting machine.

See table on page 24.

(Fig. 28)

(Fig. 29)

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

19

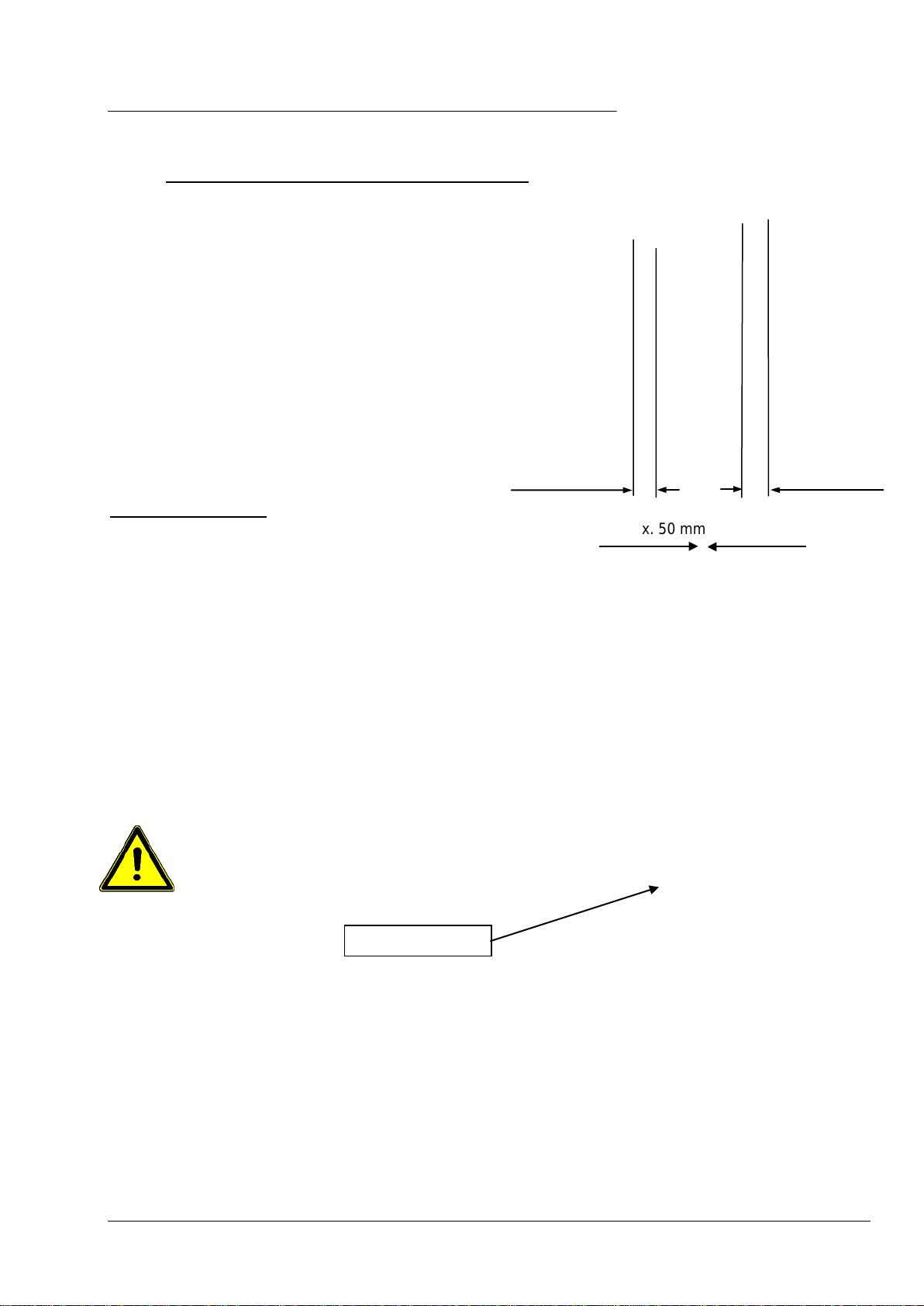

6.1.1 Setup of measuring device on vehicle wheel

Depending on the version, 2 or 3 sensors are

placed at the vehicle wheel.

The positions of the laser sensors on the wheel

are determined to create a distance (A) between

sensor and measuring point in the range of 80 to

120 mm.

(Fig. 30)

Laser sensor for tyre

The laser sensor is placed approx. 50 mm away

from the centre (to the left or right) of the tread so

that it faces a tread lug. (Fig. 31)

When setting up the laser sensors

ensure that all laser sensors are

aligned on a level passing through

the vehicle axle.

The measuring points have to be on a level with the

vehicle axle, with a tolerance of ±1 cm (Fig. 32).

(Fig. 31)

(Fig. 30)

(A)

(A)

Rim measurement

Tyre measurement

(Fig. 30)

approx. 50 mm

Measuring level

(Fig. 32)

Attention

RUNOUT MEASUREMENT DEVICE RPV1300

RPV1300 Operating Instructions

20

7 Measurement recording

7.1 Entering vehicle, wheel and rim data in the program

At least two laser sensors are connected to the PC and the PC is switched on. The program

rpv1300 is running and is set to the start page.

•Click on “Start measurement”.

•Enter vehicle data. (Fig. 33)

Entering the correct wheel geometry with

number of tread lugs and wheel diameter is

absolutely required for evaluation.

•Click “Next” to finish vehicle entry and continue to

the next program page. (Fig. 34)

•Select front or rear axle on the model on the right.

•Enter tyre and rim information in the corresponding

fields.

Information about centring:

How well is the wheel mounted on the hub? (Fig. 35)

GOOD: The distance between inside rim

opening and wheel hub is the same for

the entire circumference.

BAD: The wheel is not fixed centrally on the

wheel hub, the gap is not the same all

around.

NOT TESTED: No information about concentric fit

between wheel and hub.

GAP VALUE: You can enter a value (mm) for the gap measurement here. This information will

later appear as a note on the log.

The gap value has NO influence on the result of the evaluated measuring points!

SUSPENSION: This note field can be used for entering details about the actual situation of the

axle suspension on the vehicle. This information will be displayed on the log.

(Fig. 33)

(Fig. 34)

(Fig. 35)

Table of contents

Other HAWEKA Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Kaman

Kaman KDM-8206 Reference manual

GE

GE EPM6000 instruction manual

Johnson Controls

Johnson Controls FMS-1655M installation instructions

Concoa

Concoa Advantium 16 Installation and operating instructions

Renishaw

Renishaw RP1 Installation and user guide

KROHNE

KROHNE OPTIFLEX 2200 Supplementary instructions