HAWK-I Security 8630B User manual

HAWK-I

USER MANUAL

™

Model 8630B

Hardware Manual

AMOT

CONTROLS

HAWK-I

USER MANUAL

™

Model 8630B

Hardware Manual

AMOT

CONTROLS

HAWK-I

USER MANUAL

i

© 1998 AMOT Controls Corp.

All Rights Reserved

Printed in USA

Trademarks used in this text:

Hawk-I and HawkWin are trademarks of AMOT Controls Corp. Windows and

Windows␣ 95 are registered trademarks of Microsoft Corporation. Modbus is a

registered trademark of Modicon Ltd. Other trademarks and trade names may be

used in this document to refer to either the entities claiming the marks and

names or their products. AMOT Controls Corp. disclaims any proprietary

interest in trademarks and trade names other than its own.

This document is based on information available at the time of its publication.

While efforts have been made to be accurate, the information contained herein

does not purport to cover all details or variations in hardware or software, nor to

provide for every possible contingency in connection with installation, operation,

or maintenance. Features may be described herein which are not present in all

hardware and software systems. AMOT Controls Corp. assumes no obligation of

notice to holders of this document with respect to changes subsequently made.

AMOT Controls Corp. makes no representation or warranty, expressed, implied,

or statutory with respect to, and assumes no responsibility for the accuracy,

completeness, sufficiency, or usefulness of the information contained herein. No

warranties of merchantability or fitness for purpose shall apply.

Use of DANGER, WARNING, CAUTION, and NOTE:

This publication includes DANGER, WARNING, CAUTION, and NOTE

information where appropriate to point out safety related or other impor-

tant information.

DANGER: Hazards which could result in severe personal injury or death.

WARNING: Hazards which could result in personal injury.

CAUTION: Hazards which could result in equipment or property damage.

NOTE: Alerts user to pertinent facts and conditions.

Although DANGER and WARNING hazards are related to personal injury,

and CAUTION hazards are associated with equipment or property damage,

it should be understood that the operation of damaged equipment could,

under certain conditions, result in degraded system performance leading to

personal injury or death. Therefore, comply fully with all DANGER,

WARNING, AND CAUTION NOTICES.

Table of Contents

ii

1. INTRODUCTION

1.1 Easy and Flexible Programming............................. 1-1

1.2 Other Key Features................................................. 1-1

1.3 Scaling and Signal Processing................................. 1-2

1.4 RS–232C Communications Port ............................ 1-2

2. SPECIFICATIONS

2.1 Inputs..................................................................... 2-1

2.2 Outputs .................................................................. 2-1

2.3 Communications.................................................... 2-2

2.4 Display ................................................................... 2-2

2.5 Environment .......................................................... 2-2

2.6 Power Supply.......................................................... 2-3

2.7 Hawk-I Specification Sheet .................................... 2-4

3. INSTALLATION

3.1 Installation Overview ............................................. 3-1

3.2 Recommended Environment .................................. 3-1

3.3 Mechanical Installation .......................................... 3-1

3.4 Wiring Requirements ............................................. 3-4

3.5 Grounding Requirements ....................................... 3-4

3.6 Digital Inputs......................................................... 3-6

3.6.1 Selecting Fault Sensing Switches ........................ 3-6

3.6.2 Dry Contacts ..................................................... 3-6

3.6.3 Sealed and Precious Metal Contacts ................... 3-6

3.6.4 Normally Open and Normally Closed ............... 3-6

3.6.5 Using Relay Contacts as Sensor Switches............ 3-7

3.6.6 Connecting The Digital Inputs .......................... 3-7

3.7 The Thermocouple Inputs...................................... 3-8

3.7.1 Connecting the Thermocouple Inputs ............... 3-8

3.8 The 4-20 mA Sensor Inputs.................................... 3-9

3.8.1 Connecting the 4-20 mA Sensor Inputs ............. 3-9

3.9 The Tachometer Input............................................ 3-9

3.9.1 Connecting the Tachometer Input ................... 3-10

3.10 The Start and Stop Inputs .................................. 3-10

3.10.1 Connecting the Start and Stop Inputs ............ 3-10

3.11 The Power Supply .............................................. 3-10

3.11.1 Connecting the Power Supply ........................ 3-10

3.12 The RS232C Communications Port................... 3-11

3.12.1 Connecting the RS232C Port for Programming 3-11

3.12.2 Connecting the RS232C Port for Monitoring 3-12

3.13 The Configuration Link Input ........................... 3-12

3.13.1 Connecting the Configuration Link Input ..... 3-13

3.14 The Pulse Input.................................................. 3-13

3.14.1 Connecting the Pulse Input ........................... 3-13

3.15 The Standard Relay Outputs .............................. 3-13

3.15.1 Connecting the Standard Relay Outputs ........ 3-13

3.16 The Optional Digital Outputs............................ 3-13

3.16.1 Connecting the Optional Digital Outputs ..... 3-13

3.17 The 4-20 mA Analog Outputs ............................ 3-14

3.17.1 Connecting the 4-20 mA Analog Outputs ..... 3-14

4. TEST AND OPERATION

4.1 Pre-Operation Test Procedure ............................... 4-1

4.2 Initial Check of Hawk-I Operation........................ 4-2

4.2.1 Configure Mode and Run Mode ........................ 4-2

4.3 Troubleshooting the Installation ............................ 4-3

4.3.1 LED Status Indicator ......................................... 4-3

4.4 Hawk-I Does Not Operate ..................................... 4-3

4.5 Digital Input Channel Does Not Function............. 4-3

4.5.1 Common Wiring Problems ................................ 4-4

4.5.2 Intermittent Wiring Problems............................ 4-5

4.5.3 Swapping Channels............................................ 4-6

4.6 Electromagnetic Interference (EMI)....................... 4-6

4.6.1 Symptoms of EMI ............................................. 4-6

4.6.2 Grounding ......................................................... 4-7

4,6,3 Ground Loops ................................................... 4-7

4.7 Before Contacting AMOT ...................................... 4-7

iii

Table of Contents

ii

1. INTRODUCTION

1.1 Easy and Flexible Programming............................. 1-1

1.2 Other Key Features................................................. 1-1

1.3 Scaling and Signal Processing................................. 1-2

1.4 RS–232C Communications Port ............................ 1-2

2. SPECIFICATIONS

2.1 Inputs..................................................................... 2-1

2.2 Outputs .................................................................. 2-1

2.3 Communications.................................................... 2-2

2.4 Display ................................................................... 2-2

2.5 Environment .......................................................... 2-2

2.6 Power Supply.......................................................... 2-3

2.7 Hawk-I Specification Sheet .................................... 2-4

3. INSTALLATION

3.1 Installation Overview ............................................. 3-1

3.2 Recommended Environment .................................. 3-1

3.3 Mechanical Installation .......................................... 3-1

3.4 Wiring Requirements ............................................. 3-4

3.5 Grounding Requirements ....................................... 3-4

3.6 Digital Inputs......................................................... 3-6

3.6.1 Selecting Fault Sensing Switches ........................ 3-6

3.6.2 Dry Contacts ..................................................... 3-6

3.6.3 Sealed and Precious Metal Contacts ................... 3-6

3.6.4 Normally Open and Normally Closed ............... 3-6

3.6.5 Using Relay Contacts as Sensor Switches............ 3-7

3.6.6 Connecting The Digital Inputs .......................... 3-7

3.7 The Thermocouple Inputs...................................... 3-8

3.7.1 Connecting the Thermocouple Inputs ............... 3-8

3.8 The 4-20 mA Sensor Inputs.................................... 3-9

3.8.1 Connecting the 4-20 mA Sensor Inputs ............. 3-9

3.9 The Tachometer Input............................................ 3-9

3.9.1 Connecting the Tachometer Input ................... 3-10

3.10 The Start and Stop Inputs .................................. 3-10

3.10.1 Connecting the Start and Stop Inputs ............ 3-10

3.11 The Power Supply .............................................. 3-10

3.11.1 Connecting the Power Supply ........................ 3-10

3.12 The RS232C Communications Port................... 3-11

3.12.1 Connecting the RS232C Port for Programming 3-11

3.12.2 Connecting the RS232C Port for Monitoring 3-12

3.13 The Configuration Link Input ........................... 3-12

3.13.1 Connecting the Configuration Link Input ..... 3-13

3.14 The Pulse Input.................................................. 3-13

3.14.1 Connecting the Pulse Input ........................... 3-13

3.15 The Standard Relay Outputs .............................. 3-13

3.15.1 Connecting the Standard Relay Outputs ........ 3-13

3.16 The Optional Digital Outputs............................ 3-13

3.16.1 Connecting the Optional Digital Outputs ..... 3-13

3.17 The 4-20 mA Analog Outputs ............................ 3-14

3.17.1 Connecting the 4-20 mA Analog Outputs ..... 3-14

4. TEST AND OPERATION

4.1 Pre-Operation Test Procedure ............................... 4-1

4.2 Initial Check of Hawk-I Operation........................ 4-2

4.2.1 Configure Mode and Run Mode ........................ 4-2

4.3 Troubleshooting the Installation ............................ 4-3

4.3.1 LED Status Indicator ......................................... 4-3

4.4 Hawk-I Does Not Operate ..................................... 4-3

4.5 Digital Input Channel Does Not Function............. 4-3

4.5.1 Common Wiring Problems ................................ 4-4

4.5.2 Intermittent Wiring Problems............................ 4-5

4.5.3 Swapping Channels............................................ 4-6

4.6 Electromagnetic Interference (EMI)....................... 4-6

4.6.1 Symptoms of EMI ............................................. 4-6

4.6.2 Grounding ......................................................... 4-7

4,6,3 Ground Loops ................................................... 4-7

4.7 Before Contacting AMOT ...................................... 4-7

iii

5. MAINTENANCE AND REPAIR

vi

5.1 Maintenance........................................................... 5-1

5.1.1 Cleaning ............................................................ 5-1

5.1.2 Battery Replacement .......................................... 5-1

5.1.3 Fuse replacement ............................................... 5-2

5.2 Repair..................................................................... 5-3

5.2.1 Returning Equipment for Repairs ...................... 5-3

6. CHANGING THE HAWK-I’S CONFIGURATION

6.1 The Hawk-I Keypad ............................................... 6-1

6.2 Gaining Access to the Configuration Menus .......... 6-1

6.3 Moving Up and Down Between Menus.................. 6-2

6.4 Moving From Side to Side in a Menu..................... 6-2

6.5 Revising Data Within a Menu Box......................... 6-2

6.6 Exiting Configuration Mode .................................. 6-3

6.7 Precautions............................................................. 6-3

6.8 Descriptions of Individual Menu Boxes ................. 6-4

6.8.1 Controllers...................................................... 6-4

6.8.2 Analog User Input .......................................... 6-4

6.8.3 Hours Run/Power Down ................................ 6-4

6.8.4 Fault Logging .................................................. 6-4

6.8.5 Digital Inputs ................................................. 6-4

6.8.6 Analog Inputs ................................................. 6-4

6.8.7 Digital Outputs .............................................. 6-4

6.8.8 Analog Outputs .............................................. 6-5

6.8.9 Timers ............................................................ 6-5

6.8.10 Tachometer ..................................................... 6-5

6.8.11 Time of day .................................................... 6-5

6.8.12 User Switches .................................................. 6-5

6.8.13 Average Groups ............................................... 6-5

6.8.14 Split Ranges .................................................... 6-5

6.8.15 User Setpoints ................................................. 6-5

6.8.16 Communications ............................................ 6-5

6.8.17 Test Mode Timer ............................................ 6-6

6.8.18 Diagnostics ..................................................... 6-7

6.8.19 Lock/Unlock ................................................... 6-8

7.VIEW MODE

7.1 Descriptions of Individual Menu Boxes ................. 7-1

7.1.1 Controllers...................................................... 7-1

7.1.2 Analog User Input .......................................... 7-1

7.1.3 Unhealthy Channels ....................................... 7-1

7.1.4 Hours Run/Power Down ................................ 7-1

7.1.5 Fault Logging .................................................. 7-1

7.1.6 Digital Inputs ................................................. 7-1

7.1.7 Analog Inputs ................................................. 7-2

7.1.8 Digital Outputs .............................................. 7-2

7.1.9 Analog Outputs .............................................. 7-2

7.1.10 Timers ............................................................ 7-2

7.1.11 Tachometer ..................................................... 7-2

7.1.12 Time of day .................................................... 7-2

7.1.13 User Switches .................................................. 7-2

7.1.14 Average Groups ............................................... 7-2

7.1.15 Split Ranges .................................................... 7-2

7.1.16 User Setpoints ................................................. 7-2

7.1.17 Run Diagnostics.............................................. 7-3

7.1.18 Lock/Unlock ................................................... 7-4

7.1.19 Test Mode ....................................................... 7-4

vii

5. MAINTENANCE AND REPAIR

vi

5.1 Maintenance........................................................... 5-1

5.1.1 Cleaning ............................................................ 5-1

5.1.2 Battery Replacement .......................................... 5-1

5.1.3 Fuse replacement ............................................... 5-2

5.2 Repair..................................................................... 5-3

5.2.1 Returning Equipment for Repairs ...................... 5-3

6. CHANGING THE HAWK-I’S CONFIGURATION

6.1 The Hawk-I Keypad ............................................... 6-1

6.2 Gaining Access to the Configuration Menus .......... 6-1

6.3 Moving Up and Down Between Menus.................. 6-2

6.4 Moving From Side to Side in a Menu..................... 6-2

6.5 Revising Data Within a Menu Box......................... 6-2

6.6 Exiting Configuration Mode .................................. 6-3

6.7 Precautions............................................................. 6-3

6.8 Descriptions of Individual Menu Boxes ................. 6-4

6.8.1 Controllers...................................................... 6-4

6.8.2 Analog User Input .......................................... 6-4

6.8.3 Hours Run/Power Down ................................ 6-4

6.8.4 Fault Logging .................................................. 6-4

6.8.5 Digital Inputs ................................................. 6-4

6.8.6 Analog Inputs ................................................. 6-4

6.8.7 Digital Outputs .............................................. 6-4

6.8.8 Analog Outputs .............................................. 6-5

6.8.9 Timers ............................................................ 6-5

6.8.10 Tachometer ..................................................... 6-5

6.8.11 Time of day .................................................... 6-5

6.8.12 User Switches .................................................. 6-5

6.8.13 Average Groups ............................................... 6-5

6.8.14 Split Ranges .................................................... 6-5

6.8.15 User Setpoints ................................................. 6-5

6.8.16 Communications ............................................ 6-5

6.8.17 Test Mode Timer ............................................ 6-6

6.8.18 Diagnostics ..................................................... 6-7

6.8.19 Lock/Unlock ................................................... 6-8

7.VIEW MODE

7.1 Descriptions of Individual Menu Boxes ................. 7-1

7.1.1 Controllers...................................................... 7-1

7.1.2 Analog User Input .......................................... 7-1

7.1.3 Unhealthy Channels ....................................... 7-1

7.1.4 Hours Run/Power Down ................................ 7-1

7.1.5 Fault Logging .................................................. 7-1

7.1.6 Digital Inputs ................................................. 7-1

7.1.7 Analog Inputs ................................................. 7-2

7.1.8 Digital Outputs .............................................. 7-2

7.1.9 Analog Outputs .............................................. 7-2

7.1.10 Timers ............................................................ 7-2

7.1.11 Tachometer ..................................................... 7-2

7.1.12 Time of day .................................................... 7-2

7.1.13 User Switches .................................................. 7-2

7.1.14 Average Groups ............................................... 7-2

7.1.15 Split Ranges .................................................... 7-2

7.1.16 User Setpoints ................................................. 7-2

7.1.17 Run Diagnostics.............................................. 7-3

7.1.18 Lock/Unlock ................................................... 7-4

7.1.19 Test Mode ....................................................... 7-4

vii

1-1

1.INTRODUCTION

The Hawk-I system is a unique, highly advanced, programmable

controller combining the power of a PLC with the easy to use functional-

ity of an embedded control system. This system allows safe, localized

scanning of digital inputs, temperatures, pressures, flows, electrical

currents and voltages, and fluid levels in machinery and industrial

processes. Built-in communications make the Hawk-I a powerful and safe

front end for hazardous-area data acquisition and alarm annunciation.

1.1 Easy and Flexible Programming

The graphical programming interface to the Hawk-I system allows the

user to overcome the rigid constraints of conventional EPROM-based

equipment. AMOT’s innovative Ladder Logic lets even the novice

programmer set up new system functions easily and quickly.

HawkWin, the Windows 95, 98, NT based configuration software used to

program the Hawk-I system, was developed from AMOT’s long experience

in embedded controllers. The most critical problem with embedded control-

lers is the inability to make fast, on-site software changes, because the

programming of a typical embedded controller is contained in an EPROM

chip that cannot be altered. Software changes in such a system must be made

at the factory, not in the field, taking up to several weeks to implement.

Hawk-I and HawkWin were created to overcome this limitation. Almost

any safety shutdown, data monitoring, or alarm function can be rapidly

programmed on-site using HawkWin. Then the function sequence is

downloaded into Hawk-I through a standard RS232 Null Modem cable

from the PC.

1.2 Other Key Features

The Hawk-I is based on an expandable platform. The basic system

supports 16 discrete inputs, 4 power relay outputs, and a speed input to

sense RPM. It can be expanded to include 8 or 16 thermocouples, 8 or

16 4-20 mA loop inputs, 2 PID 4-20 mA loop outputs, and 8 low power

relays. (NOTE: Unit may be configured with no more than 24 analog

inputs total and no more than 16 of one specific type).

A communications option allows connection to a modem or Distributed

Control System (DCS) via Modbus/RTU protocol.

The Hawk-I module features a tactile keyboard (NEMA 4) and a large,

high-contrast, 32-character display with backlight.

1-2

1.3 Scaling and Signal Processing

The Hawk-I contains scaling and linearizing circuits that provide

individual channel readouts in software selectable units such as Centi-

grade and Fahrenheit temperatures, psig, psia, psid, feet and inches,

meters and centimeters, inches of water, etc. Individually set alarm and

shutdown setpoints are available for each channel, as well as multiple

user-defined setpoints. Any channel can be configured to trip when the

channel input is less than or greater than the setpoint. Timer class logic

can also be associated with channels on an individual basis.

Input channels can be grouped together for signal averaging. The Hawk-I

can generate an alarm or shutdown based on the deviation of any single

channel from the average. Each input channel setpoint or averaging

group setpoint can be assigned to any selected digital output.

1.4 RS-232C Communications Port

The RS232C serial data port and Modbus/RTU protocol allow easy

interfacing to many types of PLCs and distributed control systems,

including Modicon, Allen-Bradley, and Fisher Provox. Modbus supports

one master and multiple slave units. Baud rate and Modbus ID number

can be set from the Hawk-I keypad.

1-1

1.INTRODUCTION

The Hawk-I system is a unique, highly advanced, programmable

controller combining the power of a PLC with the easy to use functional-

ity of an embedded control system. This system allows safe, localized

scanning of digital inputs, temperatures, pressures, flows, electrical

currents and voltages, and fluid levels in machinery and industrial

processes. Built-in communications make the Hawk-I a powerful and safe

front end for hazardous-area data acquisition and alarm annunciation.

1.1 Easy and Flexible Programming

The graphical programming interface to the Hawk-I system allows the

user to overcome the rigid constraints of conventional EPROM-based

equipment. AMOT’s innovative Ladder Logic lets even the novice

programmer set up new system functions easily and quickly.

HawkWin, the Windows 95, 98, NT based configuration software used to

program the Hawk-I system, was developed from AMOT’s long experience

in embedded controllers. The most critical problem with embedded control-

lers is the inability to make fast, on-site software changes, because the

programming of a typical embedded controller is contained in an EPROM

chip that cannot be altered. Software changes in such a system must be made

at the factory, not in the field, taking up to several weeks to implement.

Hawk-I and HawkWin were created to overcome this limitation. Almost

any safety shutdown, data monitoring, or alarm function can be rapidly

programmed on-site using HawkWin. Then the function sequence is

downloaded into Hawk-I through a standard RS232 Null Modem cable

from the PC.

1.2 Other Key Features

The Hawk-I is based on an expandable platform. The basic system

supports 16 discrete inputs, 4 power relay outputs, and a speed input to

sense RPM. It can be expanded to include 8 or 16 thermocouples, 8 or

16 4-20 mA loop inputs, 2 PID 4-20 mA loop outputs, and 8 low power

relays. (NOTE: Unit may be configured with no more than 24 analog

inputs total and no more than 16 of one specific type).

A communications option allows connection to a modem or Distributed

Control System (DCS) via Modbus/RTU protocol.

The Hawk-I module features a tactile keyboard (NEMA 4) and a large,

high-contrast, 32-character display with backlight.

1-2

1.3 Scaling and Signal Processing

The Hawk-I contains scaling and linearizing circuits that provide

individual channel readouts in software selectable units such as Centi-

grade and Fahrenheit temperatures, psig, psia, psid, feet and inches,

meters and centimeters, inches of water, etc. Individually set alarm and

shutdown setpoints are available for each channel, as well as multiple

user-defined setpoints. Any channel can be configured to trip when the

channel input is less than or greater than the setpoint. Timer class logic

can also be associated with channels on an individual basis.

Input channels can be grouped together for signal averaging. The Hawk-I

can generate an alarm or shutdown based on the deviation of any single

channel from the average. Each input channel setpoint or averaging

group setpoint can be assigned to any selected digital output.

1.4 RS-232C Communications Port

The RS232C serial data port and Modbus/RTU protocol allow easy

interfacing to many types of PLCs and distributed control systems,

including Modicon, Allen-Bradley, and Fisher Provox. Modbus supports

one master and multiple slave units. Baud rate and Modbus ID number

can be set from the Hawk-I keypad.

2-1

2.SPECIFICATIONS

The Hawk-I is an expandable-platform digital controller with many

available options that allow the user to select a powerful yet economical

control system.

2.1 Inputs

The sixteen discrete digital inputs used in the Hawk-I have volt-free contacts

and are non-incendive; any kind of input switching device can be used. There

is not enough energy in the circuit to ignite any gas mixture that may be

present. The minimum loop resistance for an ‘off’ state is 15kΩ, the scan rate

is 100 msec, and the response time is 100 msec.

The Hawk-I provides a speed input designed for use with an AMOT

magnetic pickup, which senses gear teeth to determine RPM.

The optional J and/or K-type thermocouple inputs may be used with an

expanded Hawk-I system. The available temperature range is -346º to 1940º

F, or -210º to 1060º C. Accuracy is better than 1% of FSD with a 100 ms

scan rate. The thermocouple input field connections are classified as non-

incendive, since a thermocouple is a simple device that cannot store energy.

The field wiring is 37-Way D Type through a DB-37 connector.

The Hawk-I can provide optional 4-20 mA/two-wire analog inputs. These

inputs have an accuracy of ±0.5% of indicated parameter value with a scan

rate of 100 ms. Loop power of 15 Vdc (open circuit) is provided. These

analog inputs are designed for use with transmitters that are approved for use

in a Class I, Division 2 area and are non-incendive. The field wiring is 25-

Way D Type through a DB-25 connector. For hazardous area installations, if

non-approved end devices are used, wiring must pass through an approved

barrier.

2.2 Outputs

The basic Hawk-I system has four relay outputs. The outputs are solid-

state (non-sparking) relays rated at 36Vdc, 1.75A. An external snubber

network is required when switching inductive loads. These outputs are

accessed through two-part Phoenix connectors on the back of the Hawk-I

module. The connectors can accept wire as large as 12 AWG, allowing

long wire runs without excessive signal loss.

2-2

WARNING

SINCE THESE RELAYCIRCUITSTRANSMIT POWER FROM

AUXILIARYEQUIPMENT, THEYARE CLASSED

INCENDIVE. ALL ASSOCIATED WIRING MUST BE

SEPARATED FROM NON-INCENDIVE WIRING BYAN

APPROPRIATE DISTANCE.

A further option allows for eight low power, solid state relays. These

outputs are rated at 100 mA/36 V. Connections are made through a 9-

way, D type connector. One side of the relays is bussed common.

Two optional analog outputs can also be provided. These 4-20 mA

outputs can be used to transmit selected data to a remote receiver. The

accuracy is better than 0.75% of FSD with an update rate of 100 msec.

These analog outputs are designed to be attached to a 4-20mA receiver

that has been approved or recognized for use in a Class I, Division 2 area.

If a non-approved receiver is used, the analog output wiring must pass

through an approved barrier, when used in a hazardous area.

2.3 Communications

In addition to the I/O options, the Hawk-I has a 9-pin RS232C connec-

tor that can be used to connect the Hawk-I system with a modem, DCS,

or a PC for programming and configuration changes. The protocol is

Modbus/RTU. This additional programming capability is further

discussed in a separate AMOT manual that describes the HawkWin

computer program.

Signal levels on the RS232C port may be incendive. Any attached device

within a hazardous area must be approved or recognized for use within

that area.

2.4 Display

The Hawk-I controller has a large, high-contrast, backlit, 32-character

display on a NEMA 4 faceplate. This LCD is 16 character by 2-line.

System faults are identified in plain English, and display messages can be

configured into the Hawk-I unit by the user.

2.5 Environment

The Hawk-I is suitable for use only in Class I, Division 2, Groups A, B,

C and D, or non-hazardous locations. Wiring should be installed by

qualified personnel in compliance with local electrical codes.

2-1

2.SPECIFICATIONS

The Hawk-I is an expandable-platform digital controller with many

available options that allow the user to select a powerful yet economical

control system.

2.1 Inputs

The sixteen discrete digital inputs used in the Hawk-I have volt-free contacts

and are non-incendive; any kind of input switching device can be used. There

is not enough energy in the circuit to ignite any gas mixture that may be

present. The minimum loop resistance for an ‘off’ state is 15kΩ, the scan rate

is 100 msec, and the response time is 100 msec.

The Hawk-I provides a speed input designed for use with an AMOT

magnetic pickup, which senses gear teeth to determine RPM.

The optional J and/or K-type thermocouple inputs may be used with an

expanded Hawk-I system. The available temperature range is -346º to 1940º

F, or -210º to 1060º C. Accuracy is better than 1% of FSD with a 100 ms

scan rate. The thermocouple input field connections are classified as non-

incendive, since a thermocouple is a simple device that cannot store energy.

The field wiring is 37-Way D Type through a DB-37 connector.

The Hawk-I can provide optional 4-20 mA/two-wire analog inputs. These

inputs have an accuracy of ±0.5% of indicated parameter value with a scan

rate of 100 ms. Loop power of 15 Vdc (open circuit) is provided. These

analog inputs are designed for use with transmitters that are approved for use

in a Class I, Division 2 area and are non-incendive. The field wiring is 25-

Way D Type through a DB-25 connector. For hazardous area installations, if

non-approved end devices are used, wiring must pass through an approved

barrier.

2.2 Outputs

The basic Hawk-I system has four relay outputs. The outputs are solid-

state (non-sparking) relays rated at 36Vdc, 1.75A. An external snubber

network is required when switching inductive loads. These outputs are

accessed through two-part Phoenix connectors on the back of the Hawk-I

module. The connectors can accept wire as large as 12 AWG, allowing

long wire runs without excessive signal loss.

2-2

WARNING

SINCE THESE RELAYCIRCUITSTRANSMIT POWER FROM

AUXILIARYEQUIPMENT, THEYARE CLASSED

INCENDIVE. ALL ASSOCIATED WIRING MUST BE

SEPARATED FROM NON-INCENDIVE WIRING BYAN

APPROPRIATE DISTANCE.

A further option allows for eight low power, solid state relays. These

outputs are rated at 100 mA/36 V. Connections are made through a 9-

way, D type connector. One side of the relays is bussed common.

Two optional analog outputs can also be provided. These 4-20 mA

outputs can be used to transmit selected data to a remote receiver. The

accuracy is better than 0.75% of FSD with an update rate of 100 msec.

These analog outputs are designed to be attached to a 4-20mA receiver

that has been approved or recognized for use in a Class I, Division 2 area.

If a non-approved receiver is used, the analog output wiring must pass

through an approved barrier, when used in a hazardous area.

2.3 Communications

In addition to the I/O options, the Hawk-I has a 9-pin RS232C connec-

tor that can be used to connect the Hawk-I system with a modem, DCS,

or a PC for programming and configuration changes. The protocol is

Modbus/RTU. This additional programming capability is further

discussed in a separate AMOT manual that describes the HawkWin

computer program.

Signal levels on the RS232C port may be incendive. Any attached device

within a hazardous area must be approved or recognized for use within

that area.

2.4 Display

The Hawk-I controller has a large, high-contrast, backlit, 32-character

display on a NEMA 4 faceplate. This LCD is 16 character by 2-line.

System faults are identified in plain English, and display messages can be

configured into the Hawk-I unit by the user.

2.5 Environment

The Hawk-I is suitable for use only in Class I, Division 2, Groups A, B,

C and D, or non-hazardous locations. Wiring should be installed by

qualified personnel in compliance with local electrical codes.

Electrical and RF interference immunity is designed into the Hawk-I,

with RFI screening in the case. The unit has a high reliability due to

conservative derating of electronic components. The internal printed

circuit boards are conformally coated for extra environmental protection.

The Hawk-I can operate in temperatures between -20º and 65º Centigrade.

The humidity limits are 5% to 95% non-condensing. The controller is

weather and UV protected, and will withstand vibration up to 10G at 100

Hz. The protective case is sealed to NEMA 4 (IP65, dust tight and protected

from water jets) from the front panel when properly installed.

2.6 Power Supply

The Hawk-I can be powered by either 12Vdc or 24Vdc. The 12-V input

can accept DC ranging from 9V to 18V. The 24-V input can accept DC

ranging from 18V to 36V. The supply should be capable of delivering 1A.

Maximum ripple should be 1V P-P. Power is supplied through a terminal

block on the rear of the Hawk-I.

2-3 2-4

Hazardous Approvals:

ETL:Class 1, Division 2

Groups A, B, C, & D

ETLFM 3810 CETL

FM 3611

CAN/CSA C22.2 No. 142

CAN/CSA C22.2 No. 2B

B.A.S.E.E.F.A.: Ex N II C

Power Requirements: Table A

Voltage: 24 Vdc (18-36 Vdc)

12 Vdc (9-18 Vdc)

Current: 500 mA max.(24V)

800 mA max. (12V)

Ripple: <1V pk-pk

Environment:

ETL B.A.S.E.E.F.A.

Temperature: 0°to 150°F 0°to 122°F

(-18°to 65°C) (-18°to 50°C)

Vibration: 0-10g @ 100 Hz

Sealing: NEMA4 from Front Panel

EMC: IEC 801-2(ESD), 801-3(RF Immunity)

Display:Table E

Type:Backlit LCD

Characters: 16 Chars X 2 Lines

Char Size: 8.05 X 5.5mm

Digital Inputs (Non-Incendive):

Type:Volt-Free Contacts

Number:16

Open Circuit: > 15 k ohms

Hawk-I™Hardware Specifications

2-4

Hazardous Approvals:

ETL: Class 1, Division 2

Groups A, B, C, & D

ETL FM 3810 CETL

FM 3611

CAN/CSA C22.2 No. 142

CAN/CSA C22.2 No. 2B

B.A.S.E.E.F.A.: Ex N II C

Power Requirements: Table A

Voltage: 24 Vdc (18-36 Vdc)

12 Vdc (9-18 Vdc)

Current: 500 mA max.(24V)

800 mA max. (12V)

Ripple: <1V pk-pk

Environment:

ETL B.A.S.E.E.F.A.

Temperature: 0°to 150°F 0°to 122°F

(-18°to 65°C) (-18°to 50°C)

Vibration: 0-10g @ 100 Hz

Sealing: NEMA4 from Front Panel

EMC: IEC 801-2(ESD), 801-3(RF Immunity)

Display: Table E

Type: Backlit LCD

Characters: 16 Chars X 2 Lines

Char Size: 8.05 X 5.5mm

Digital Inputs (Non-Incendive):

Type: Volt-Free Contacts

Number:16

Open Circuit: > 15 k ohms

Hawk-I™Hardware Specifications

2-5

Speed Input (Non-Incendive):

Type: Magnetic Pickup

Number: 1

Signal: Zero Crossing >2V pk-pk

Analog Inputs (Optional): Table C

Type: 4-20mA, 2-wire Transmitter,

(Non Incendive)

Number: 8 or 16

Accuracy: Better than 1% of FSD

Loop Power: 15 Vdc provided by the Hawk-I™

Thermocouple Inputs (Optional): Table C

Type: J and/or K, (Non Incendive)

Number: 8 or 16

Accuracy: Better than 1% of FSD

Relay Outputs: Table B

Type: DC Solid State Relay

Number: 4

Rating: 3-36 V at 1.75 A (Continuous)

Isolation: 4 kV

Digital Outputs (Optional): Table B

Type: Solid State Relay, Common Ground

Number: 8

Rating: 36 V at 100 mA

Isolation: 1.5 kV (min)

Analog Outputs (Optional): Table D

Type: 4-20 mA (2-wire)

Number: 1 or 2

Accuracy: Better than 0.75% of FSD

Communications: Table F

Standard: RS232C

Protocol: MODBUS-RTU

Baud Rates: 300-19,200 Baud

Hawk-I™Hardware Specifications

2-4

Hazardous Approvals:

ETL: Class 1, Division 2

Groups A, B, C, & D

ETL FM 3810 CETL

FM 3611

CAN/CSA C22.2 No. 142

CAN/CSA C22.2 No. 2B

B.A.S.E.E.F.A.: Ex N II C

Power Requirements: Table A

Voltage: 24 Vdc (18-36 Vdc)

12 Vdc (9-18 Vdc)

Current: 500 mA max.(24V)

800 mA max. (12V)

Ripple: <1V pk-pk

Environment:

ETL B.A.S.E.E.F.A.

Temperature: 0°to 150°F 0°to 122°F

(-18°to 65°C) (-18°to 50°C)

Vibration: 0-10g @ 100 Hz

Sealing: NEMA4 from Front Panel

EMC: IEC 801-2(ESD), 801-3(RF Immunity)

Display: Table E

Type: Backlit LCD

Characters: 16 Chars X 2 Lines

Char Size: 8.05 X 5.5mm

Digital Inputs (Non-Incendive):

Type: Volt-Free Contacts

Number:16

Open Circuit: > 15 k ohms

Hawk-I™Hardware Specifications

2-5

Speed Input (Non-Incendive):

Type: Magnetic Pickup

Number: 1

Signal: Zero Crossing >2V pk-pk

Analog Inputs (Optional): Table C

Type: 4-20mA, 2-wire Transmitter,

(Non Incendive)

Number: 8 or 16

Accuracy: Better than 1% of FSD

Loop Power: 15 Vdc provided by the Hawk-I™

Thermocouple Inputs (Optional): Table C

Type: J and/or K, (Non Incendive)

Number: 8 or 16

Accuracy: Better than 1% of FSD

Relay Outputs: Table B

Type: DC Solid State Relay

Number: 4

Rating: 3-36 V at 1.75 A (Continuous)

Isolation: 4 kV

Digital Outputs (Optional): Table B

Type: Solid State Relay, Common Ground

Number: 8

Rating: 36 V at 100 mA

Isolation: 1.5 kV (min)

Analog Outputs (Optional): Table D

Type: 4-20 mA (2-wire)

Number: 1 or 2

Accuracy: Better than 0.75% of FSD

Communications: Table F

Standard: RS232C

Protocol: MODBUS-RTU

Baud Rates: 300-19,200 Baud

Hawk-I™Hardware Specifications

2-6

8630B 1 1 0000

Basic

Model

Number

Model Code

Table C

Table D

Table E

Table F

Table A

Power Source

Code Input Power Options

1 24 VDC (18-36)

5 12 VDC (9-18)

Table B

Relays

Code Relay Options

1 4 DC Relays

3 4 DC Relays + 8 Aux. Outputs

Table C

Extended Board

Code Extended Input Options

0 Extended Board not Fitted

1 16TC Inputs

2 8 (4-20mA) Inputs

3 16TC Inputs + 8 (4-20mA) Inputs

4 8TC Inputs

5 16 (4-20mA) Inputs

6 8TC + 16 (4-20mA) Inputs

Table D

Analog Output

Code PID Options

0 PID Board not Fitted

1 Qty. 1 - PID for Grounded Load

2 Qty. 2 - PID for Grounded Load

Note: Extended Input Board must be

Fitted for use with PID Options 1 & 2

Table E

LCD

Code LCD Options

0 without Backlight

1 with Backlight

Table F

Communications

Code Options

0 HawkWin

1 HawkWin + Data Out

2 HawkWin + MODBUS

Basic Unit

3.INSTALLATION

This chapter covers only the physical installation of the Hawk-I. The

Hawk-I digital controller must be programmed with a set of user-selected

functions before it can be put into service. The user first creates a

customized program for the Hawk-I with AMOT’s HawkWin software,

which is installed in an IBM-type host computer. Then the customized

program is downloaded from the PC into the Hawk-I. Once the Hawk-I

is in service, the program can be updated using the built-in keypad.

For further information about programming your Hawk-I with HawkWin

software, please consult AMOT’s HawkWin Programming Manual.

3.1 Installation Overview

The Hawk-I is often installed in a conventional equipment cabinet of the

enclosed type that can be used to hold a variety of electronic and

pneumatic control equipment. Mounting brackets are provided to hold

the unit in place. The environmental limitations listed on the Specifica-

tions Sheet should be observed. The Hawk-I is designed to be non-

incendive for hazardous atmospheres, but retaining the non-incendive

characteristics of the equipment depends critically on proper installation,

good wiring practices, and the use of certified (or listed) end devices.

3.2 Recommended Environment

The Hawk-I is designed for continuous use (100% duty cycle) in an

ambient temperature ranging from 0º F to 150º F (-18º C to 65º C)

with a humidity of 5% to 95% (non-condensing). Site vibration must

not exceed 10G at 100 Hz.

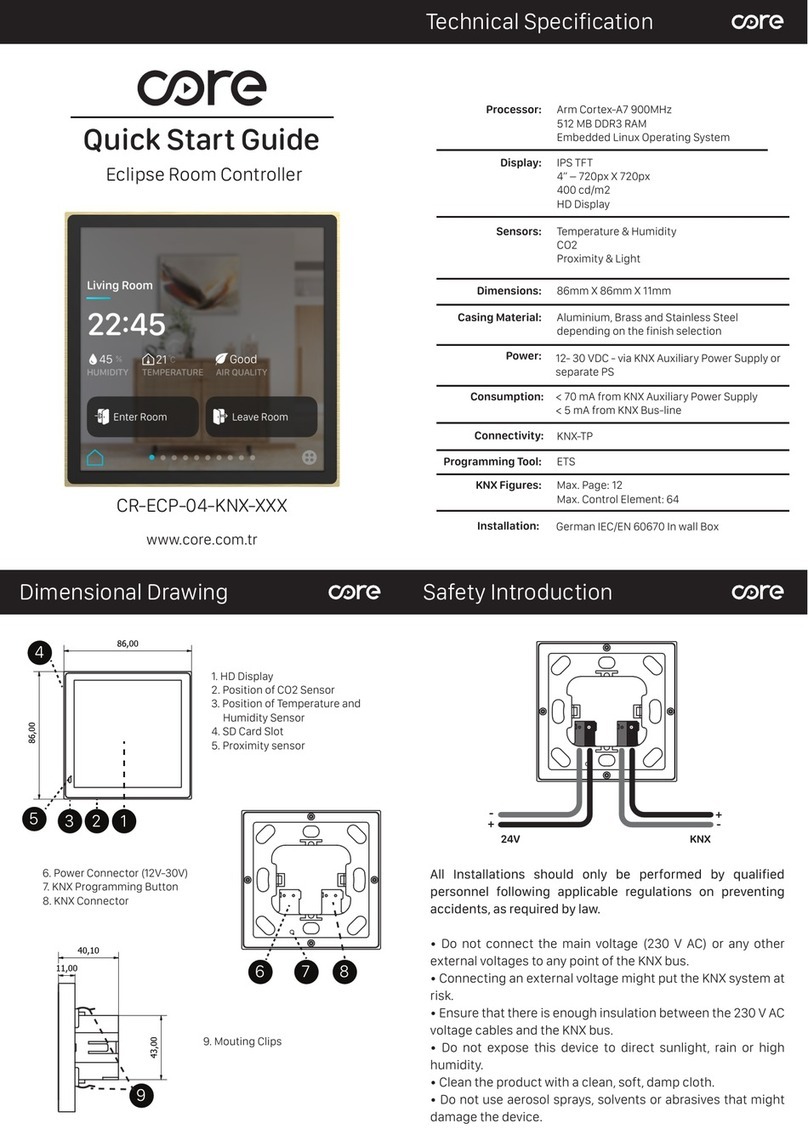

3.3 Mechanical Installation

The Hawk-I enclosure requires a 1⁄2 DIN cutout of 3.7 ±0.1” by

7.3 ±0.1”, as dimensioned in Fig. 3-1.

To install the unit in a panel:

1. Insert the Hawk-I unit from the front of the panel.

2. Slide the two mounting brackets into the grooves along the

sides of the enclosure.

3. Install the two socket-head screws into the grooves to clamp

the unit in place. Note that to avoid stripping the threads, the

screws must not be overtightened.

4. See Figs. 3-1 and 3-2 (AMOT Drawing No. 68630B-SD)

and the following text for wiring connections.

3-1

3-2

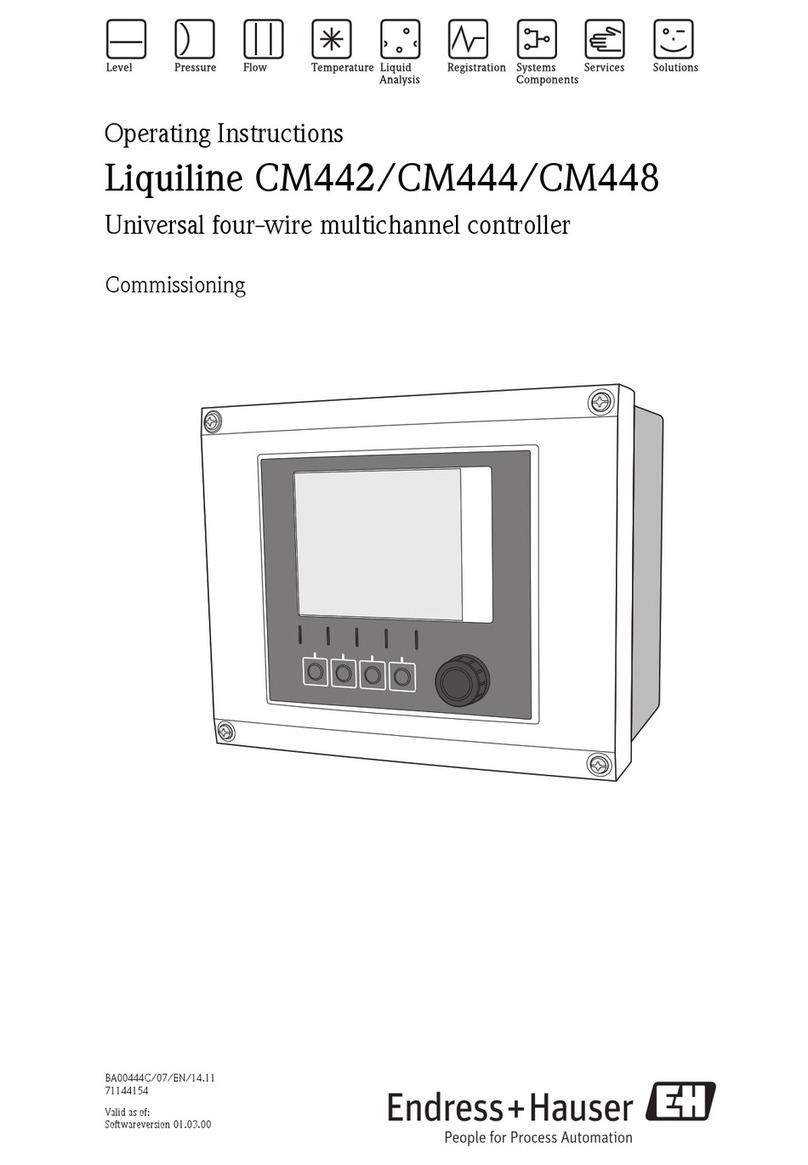

4–20mA INPUTS / OUTPUTSTHERMOCOUPLES

DISCRETE INPUTS–VOLT FREE CONTACTS

CONFIG

LINK

PLS

IN

N/O

START

N/C

STOP

MAGNETIC

PICK-UP

C

O

M

C

O

M

C

O

M

C

O

M

C

O

M

16151413121110987654321

NON–INCENDIVE FIELD WIRING CONNECTIONS FOR CLASS 1, DIVISION 2, GROUPS A, B, C & D

+–

36 VDC 1.75A MAX 36 VDC 100mA MAX

AUX.

OUTPUTSRS232C

DC POWER

18–36V

++

––+–+–+–

N/C N/C

RELAY 1 RELAY 2 RELAY 3 RELAY 4

WARNING AVERTISSEMENT

EXPLOSION HAZARD – DO NOT DISCONNECT WHILE CIRCUIT

IS LIVE UNLESS AREA IS KNOWN TO BE NON–HAZARDOUS

RISQUE D'EXPLOSION–NE PAS DEBRANCHER TANT QUE LE CIRCUIT EST SOUS

TENSION, A MOIN QU'IL NE S'AGISSE D'UN EMPLACEMENT NON DANGEREUX

Panel Cutout

7.3 + 0.1"

Panel Cutout

3.7 + 0.1"

–

–

Figure 3-1. Back view of the HAWK-I, showing connection points and panel cutout dimensions for mounting.

[

68630B–SD

DWG

NO. SHEET 1 OF 2

SHEET 1 OF 2

2

3

13

16

15

14

12

11

10

9

8

7

6

5

4

1+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

1TC

2TC

3TC

4TC

5TC

6TC

7TC

8TC

9TC

10TC

11TC

12TC

13TC

14TC

15TC

16TC

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

16

THERMO -

COUPLES

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

9

8

7

6

5

4

3

2

1

TACHO (ELECTROMAGNETIC

PICKUP HEAD) COMMON

STOP N/C

START N/O

+

–

S1

S1

PULSE INPUT (TTL LEVELS)

CONFIG. LINK

TO MODEM

RS232C PORT

4

CD

DSR

RXD

TXD

CTS

DTR

RI

COMMON

RTS

AUX 1

AUX 2

AUX 3

AUX 4

AUX 5

AUX 6

AUX 7

AUX 8

AUX _COM

3 5

24V

+

–

LOAD

8 AUXILLARY

OUTPUT S

MATL :

FINISH :

TITLE :

HAWK - I SYSTEM DIAGRAM

AMOT

CONTROLS

SIZE

B68630B - SD

DWG NO

RICHMOND, CA USA – BURY ST. EDMUNDS, SUFFOLK, ENGLAND

DWG CONTROL USA

DRAWN: EW

CHKD:

DATE:

FILE:

APPROVAL:

SCALE:

2 MAY 97

68630BSDS1r4.DWG

MODEL

8630B

REDRAWN/ADDED SHEET 2

REVISION RECORD

4

REV

09/09/98

DATE

DKH

BY REMOVE ALL BURRS AND SHARP EDGES

SURFACE

ROUGHNESS

DO NOT SCALE DRAWING

.XX

.XXX

.XXXX

+

–

+

–

+

–+

–

+

–

ANGLES

FRACTIONS

TOLERANCES UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES [MILLIMETERS]

AUX OUTPUTS RS232C

DB9 FEMALE DB9 MALE

5 9 4 23 1 1 7

82 3 4

6

6

6

78 9 5

POWER CHASSIS

GND

++

––+–+–+–

+

+–

–+–+–+–

RELAY

1 2 3 4

RELAY OUTPUTS

1 3 4 5 6 7 8

21 3 4 5 62

18–36V DC

1CHASSIS

GND

3 3 3 3 3 3 2 2 2 2 2 2 2 2 2 2

5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 0

123456789

1

0

1

1

1

2

1

3

1

4

1

5

1

6

16

53

489 76 5 3 2 2 2

90 0 0

00 8 7

1

66

53

442

99 8 7

15

34

2

9 8 8

77165

34

21

53 21 3 21

3333

333 2

2

2 2

2

222 1

1

11

1 1

1 1 2

2 1 1

1

222

11

2

0

0

4

44 4

9

9

6

66

8

8

7

7

5

55

3

33 3

1

1

11

11 1 1 1 11

12

22

2

04 96 87531 12 04 96 87531 12

111111 1

65 4 3 247

THERMOCOUPLES

DB37 FEMALE

4–20mA INPUTS/OUTPUTS

DB25 FEMALE

DISCRETE INPUTS

C CCC

C1, C2, C3, C4,

COMMON

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

CH16

16

DISCRETE

INPUTS

VOLT FREE

CONTACTS

14

1, 2, 3, 4, 5, 6, 7, 8

15

16

17

18

19

20

21

10

11

12, 13

1LP

2LP

3LP

4LP

5LP

6LP

7LP

8LP

LOOP POWER (15V MAX)

8 LOOP INPUTS

4–20mA

ANALOG OUT 1 (0–24mA)

ANALOG OUT 2 (0–24mA)

ANALOG OUTPUT RETURN

MA

–+

+

THIRD ANGLE PROJECTION

NOTES: UNLESS OTHERWISE SPECIFIED

DC INPUT POWER: 36V 500mA MAX

(18V 800mA MAX 12V INPUT)

SOLID STATE RELAY OUTPUTS RATED 5–36V 1.75A MAX

AUXILLARY OUTPUTS– 36V 100mA MAX

NULL–MODEM TYPE CONNECTION REQUIRED FOR

INTERFACE TO A COMPUTER

PIN 5 OF AUXILLARY OUTPUT CONNECTOR MUST BE

CONNECTED TO AUX POWER GROUND

SNUBBER DIODE REQUIRED FOR INDUCTIVE LOADS

UNDOCUMENTED PINS SHOULD REMAIN DISCONNECTED

1.

2.

3.

4.

5.

6.

7.

MODEL NO. SHEET NO.

8630B__3___

8630B__6___

1

2

AMOT CONTROLS CORPORATION RESERVES

PROPRIETARY RIGHTS TO THIS DRAWING

AND THE DATA SHOWN THEREON.

IT IS SUBMITTED IN CONFIDENCE FOR QUOTATION

OR ORDER OF THE PRODUCT SHOWN ONLY

SAID DRAWING AND/OR DATA ARE NOT

TO BE USED OR REPRODUCED FOR

ANY PURPOSE WITHOUT THE CONSENT OF

AMOT CONTROLS CORPORATION

Figure 3-2, Sheet 1

THIRD ANGLE PROJECTION

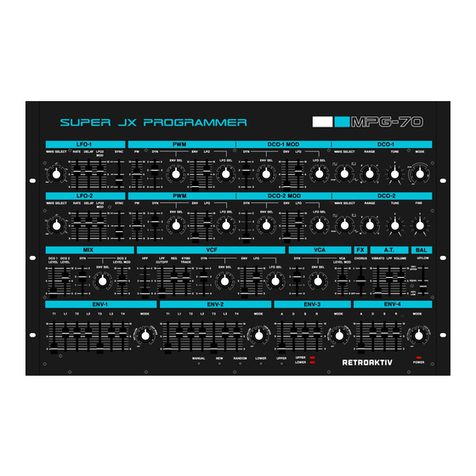

LOOP POWER #1 (15V MAX)

LOOP POWER #2 (15V MAX) 9,25

22, 23, 24

14

15

16

17

18

19

20

10

11

12.13

21

1

2

3

4

5

6

7

8

1LP

2LP

3LP

4LP

5LP

6LP

7LP

8LP

LP9

LP10

LP11

LP12

LP13

LP14

LP15

LP16

8 LOOP INPUTS

4–20mA

8 LOOP INPUTS

4–20mA

ANALOG OUT 1 (0–24mA)

ANALOG OUT 2 (0–24mA)

ANALOG OUTPUT RETURN

MA

–+

+ +

4–20mA INPUTS/OUTPUTS

DB25 FEMALE

3

15

22

14

21

13

20

1 2

2 9 2

180

266

5 4 49 8

77 5

3

1 1 2

11

1 1 1 16

389 76 5 3 2 2 2

90 0 08 7

1 3 29 8 7

15

34

21 65

34

21 3 21 3 21 33

33 2

2

2 2

2

1

1

11

1 1 1

65 4 3 247

THERMOCOUPLES

DB37 FEMALE

04 96 87531 1204 96 87531 12

0 4 4

9653 3

1

11 1 1 1 11 2CC

DISCRETE INPUTS

RELAY

4 6 8753 1

12

2CC

04 96 87531 12

C1, C2, C3, C4,

COMMON

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

CH16

16

DISCRETE

INPUTS

VOLT FREE

CONTACTS

+–

18–36V DC

1CHASSIS

GND

POWER CHASSIS

GND+ –

1 3 4 5 62

6

+–+–+–+–

+–+–+–+–

1 2 3 4

RELAY OUTPUTS

7 81 3 4 5 62

AUX OUTPUTS

DB9 FEMALE

RS232C

DB9 MALE

5 9 4 23 1 1 7

82 3 4

66

78 9 5

9

8

7

6

5

4

3

2

1

TO MODEM

RS232C PORT

4

CD

DSR

RXD

TXD

CTS

DTR

RI

COMMON

RTS

10

9

8

7

6

5

4

3

2

1

TACHO (ELECTROMAGNETIC

PICKUP HEAD) COMMON

STOP N/C

START N/O

+

–

S1

S1

PULSE INPUT (TTL LEVELS)

CONFIG. LINK

8

THERMO-

COUPLES

2

3

8

7

6

5

4

1+

+

+

+

+

+

+

+-

-

-

-

-

-

-

-

1TC

2TC

3TC

4TC

5TC

6TC

7TC

8TC

20

21

22

23

24

25

26

27

2 2 2 2 2 2 2 2

7 6 5 4 3 2 1 0

12345678

68630B–SD

DWG

NO. SHEET 2 OF 2

9

8

7

6

5

4

3

2

1AUX 1

AUX 2

AUX 3

AUX 4

AUX 5

AUX 6

AUX 7

AUX 8

AUX _COM

3 5

24V

+

–

LOAD

8 AUXILLARY

OUTPUT S

SHEET 2 OF 2

MATL :

FINISH :

TITLE :

HAWK - I SYSTEM DIAGRAM

AMOT

CONTROLS

SIZE

B68630B - SD

DWG NO

RICHMOND, CA USA – BURY ST. EDMUNDS, SUFFOLK, ENGLAND

DWG CONTROL USA

DRAWN: EW

CHKD:

DATE:

FILE:

APPROVAL:

SCALE:

2 MAY 97

68630BSDS2r4.DWG

MODEL

8630B

09/09/98

DATE

DKH

BY REMOVE ALL BURRS AND SHARP EDGES

SURFACE

ROUGHNESS

DO NOT SCALE DRAWING

.XX

.XXX

.XXXX +

–

+

–

+

–+

–

+

–

ANGLES

FRACTIONS

TOLERANCES UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES [MILLIMETERS]

REDRAWN/ADDED SHEET 2

REVISION RECORD

4

REV

AMOT CONTROLS CORPORATION RESERVES

PROPRIETARY RIGHTS TO THIS DRAWING

AND THE DATA SHOWN THEREON.

IT IS SUBMITTED IN CONFIDENCE FOR QUOTATION

OR ORDER OF THE PRODUCT SHOWN ONLY

SAID DRAWING AND/OR DATA ARE NOT

TO BE USED OR REPRODUCED FOR

ANY PURPOSE WITHOUT THE CONSENT OF

AMOT CONTROLS CORPORATIONFigure

Figure 3-2, Sheet 2

3.4 Wiring Requirements

The Hawk-I is Class I, Division 2 non-incendive equipment. The wiring

to the fault and sensing switches does not require explosion proof conduit

and housings. Such wiring cannot be the cause of a fire or an explosion.

The wiring must be kept separate from that of other electrical systems. If

the Hawk-I wiring is in the same enclosure as other wiring, keep a

minimum of two inches (2 in.) separation from the other wiring, and

securely hold the wiring in place by tie wraps or other means. Even

though explosion-proof conduit is unnecessary, give the wiring proper

mechanical protection. Use wire of good quality and of an insulation type

suitable for the environment.

WARNING

POWER AND HAZARDOUS AREA WIRING SHOULD BE

INSTALLED ONLY BY QUALIFIED PERSONNEL

Because of the small currents and voltages used, keep the sensor wiring

dry and keep splices to a minimum. If crimp-type wire terminations are

installed, use a crimping tool rated for use with the wire size and the lug.

Mismatch of a crimping tool to the wire and lug is a major source of poor

connections. Inspect each lug for correct compression of the crimp on the

cable conductor and the insulation.

Where conduit is used for protection of wiring, position it to avoid the

collection of moisture. In junction boxes or sensor enclosures where open

terminals are present, drain holes are recommended. The sensitivity of

the system to wiring practices is very low, but the value of good wiring

cannot be overestimated in the installation of electrical equipment.

3.5 Grounding Requirements

The back of the Hawk-I has 5 circuit ground terminals (see Fig. 3-1) that

are labeled COM (common), and 2 equipment ground terminals that are

labeled with an earth ground symbol.

There is also a power supply return terminal labeled with a minus (-)

sign. These terminals are not interchangeable, and if they are improperly

connected, the Hawk-I may not function properly.

There are three basic purposes for a ground or common terminal. The first

purpose is to ensure safety for operating personnel by providing electrical

equipment with a direct connection or short circuit to the earth. The second

purpose is to provide a direct connection to a circuit return point in a signal

circuit, and the third purpose is to provide a return circuit for a power supply.

These three different types of grounds must not be carelessly connected

together, even though they are all referred to as grounds.

3-4

For example, on the back of the Hawk-I, the sixteen discrete digital

switching inputs have four interconnected circuit return points labeled

COM. The circuit returns for the digital inputs can be connected to any

of these COM points. The COM terminals are input circuit grounds,

and serve to complete the digital switching circuits. They are not power

supply grounds or equipment safety grounds, and they must not be

connected to the dc power supply or the protective or chassis earth

ground connection.

The protective or chassis ground connection should be kept completely

separate from the circuit ground. The protective ground is intended to

keep the metal chassis of the Hawk-I at the same voltage as its surround-

ings, thus protecting the user from accidental electrical shock. This

requires a separate grounding wire (minimum size 14 AWG) that is not

connected to any other grounds. This protective ground wire should be

connected to the earth-ground terminal bolt on the Hawk-I’s back panel

and then bonded to a good earth ground connection point.

The negative ground for the dc power supply connection is a power

supply ground, and should be connected to the terminal labeled with a

minus (-) sign just below the word POWER on the back panel.

If shielded cable is used to run input wires to the Hawk-I, the shields of

the cables should be connected to the protective ground, not COM. Note

also that cable shields should be grounded only at the Hawk-I and

nowhere else. If a cable shield is grounded at more than one point,

“ground loop” currents may flow through the shield, making it useless.

Under normal conditions, shielded cable is recommended for the

RS232C, thermocouple, and analog loop connections.

The user should follow these simple guidelines and avoid improper intercon-

nections between circuit ground, protective ground, power supply ground,

and cable shield ground. Many hard-to-diagnose equipment problems,

including intermittent problems caused by transient electrical interference,

can be prevented by careful and effective grounding.

If your installation has unusually high levels of electrical interference,

special grounding arrangements may be required. Consult your AMOT

service representative for further details.

3-5

3.4 Wiring Requirements

The Hawk-I is Class I, Division 2 non-incendive equipment. The wiring

to the fault and sensing switches does not require explosion proof conduit

and housings. Such wiring cannot be the cause of a fire or an explosion.

The wiring must be kept separate from that of other electrical systems. If

the Hawk-I wiring is in the same enclosure as other wiring, keep a

minimum of two inches (2 in.) separation from the other wiring, and

securely hold the wiring in place by tie wraps or other means. Even

though explosion-proof conduit is unnecessary, give the wiring proper

mechanical protection. Use wire of good quality and of an insulation type

suitable for the environment.

WARNING

POWER AND HAZARDOUS AREA WIRING SHOULD BE

INSTALLED ONLY BY QUALIFIED PERSONNEL

Because of the small currents and voltages used, keep the sensor wiring

dry and keep splices to a minimum. If crimp-type wire terminations are

installed, use a crimping tool rated for use with the wire size and the lug.

Mismatch of a crimping tool to the wire and lug is a major source of poor

connections. Inspect each lug for correct compression of the crimp on the

cable conductor and the insulation.

Where conduit is used for protection of wiring, position it to avoid the

collection of moisture. In junction boxes or sensor enclosures where open

terminals are present, drain holes are recommended. The sensitivity of

the system to wiring practices is very low, but the value of good wiring

cannot be overestimated in the installation of electrical equipment.

3.5 Grounding Requirements

The back of the Hawk-I has 5 circuit ground terminals (see Fig. 3-1) that

are labeled COM (common), and 2 equipment ground terminals that are

labeled with an earth ground symbol.

There is also a power supply return terminal labeled with a minus (-)

sign. These terminals are not interchangeable, and if they are improperly

connected, the Hawk-I may not function properly.

There are three basic purposes for a ground or common terminal. The first

purpose is to ensure safety for operating personnel by providing electrical

equipment with a direct connection or short circuit to the earth. The second

purpose is to provide a direct connection to a circuit return point in a signal

circuit, and the third purpose is to provide a return circuit for a power supply.

These three different types of grounds must not be carelessly connected

together, even though they are all referred to as grounds.

3-4

For example, on the back of the Hawk-I, the sixteen discrete digital

switching inputs have four interconnected circuit return points labeled

COM. The circuit returns for the digital inputs can be connected to any

of these COM points. The COM terminals are input circuit grounds,

and serve to complete the digital switching circuits. They are not power

supply grounds or equipment safety grounds, and they must not be

connected to the dc power supply or the protective or chassis earth

ground connection.

The protective or chassis ground connection should be kept completely

separate from the circuit ground. The protective ground is intended to

keep the metal chassis of the Hawk-I at the same voltage as its surround-

ings, thus protecting the user from accidental electrical shock. This

requires a separate grounding wire (minimum size 14 AWG) that is not

connected to any other grounds. This protective ground wire should be

connected to the earth-ground terminal bolt on the Hawk-I’s back panel

and then bonded to a good earth ground connection point.

The negative ground for the dc power supply connection is a power

supply ground, and should be connected to the terminal labeled with a

minus (-) sign just below the word POWER on the back panel.

If shielded cable is used to run input wires to the Hawk-I, the shields of

the cables should be connected to the protective ground, not COM. Note

also that cable shields should be grounded only at the Hawk-I and

nowhere else. If a cable shield is grounded at more than one point,

“ground loop” currents may flow through the shield, making it useless.

Under normal conditions, shielded cable is recommended for the

RS232C, thermocouple, and analog loop connections.

The user should follow these simple guidelines and avoid improper intercon-

nections between circuit ground, protective ground, power supply ground,

and cable shield ground. Many hard-to-diagnose equipment problems,

including intermittent problems caused by transient electrical interference,

can be prevented by careful and effective grounding.

If your installation has unusually high levels of electrical interference,

special grounding arrangements may be required. Consult your AMOT

service representative for further details.

3-5

Table of contents

Popular Controllers manuals by other brands

Superior Electric

Superior Electric STABILINE WHR34 S Series instructions

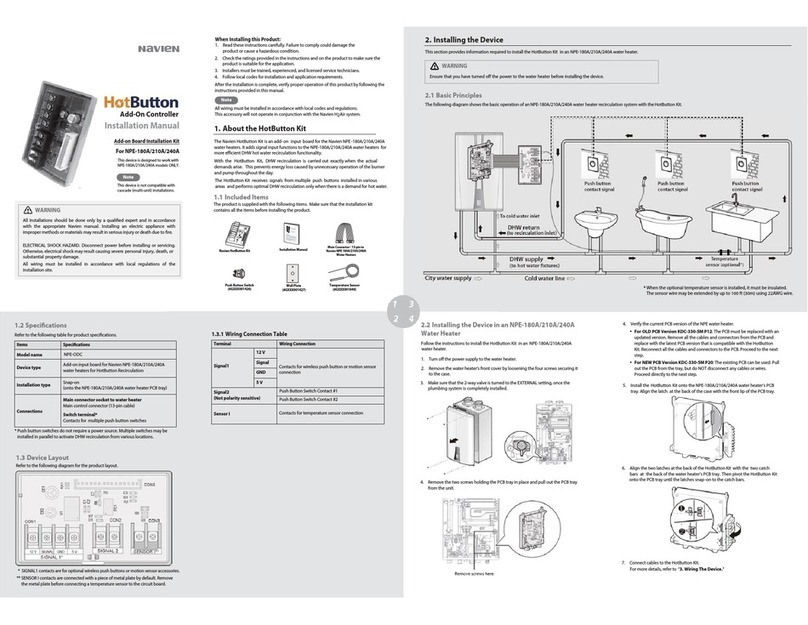

Navien

Navien HotButton NPE-ODC installation manual

Siemens

Siemens 7SR224 manual

Integra

Integra PIPETBOY acu 2 operating instructions

Norac

Norac UC4+ New Navigator 2007+ installation manual

Parker

Parker ER032 Maintenance Instructions & Parts List