Hawksmoor TOOLSTATION M1L-5ET-200 User manual

SKU: 26290

750W Pole Saw

Original User’s Instructions

READ BEFORE USE

PLEASE KEEP THESE INSTRUCTIONS FOR FURTHER REFERENCE

2

CONTENT

∫WHAT’S IN THE BOX ---------------------------------------------------------- 3

∫SPECIFICATIONS -------------------------------------------------------------- 4

∫EXPLANATIONS AND SYMBOLS, CAUTIONS AND WARNINGS ---------- 5

∫IMPORTANT SAFETY WARNINGS -------------------------------------------- 8

∫PRODUCT DESCRIPTION AND IDENTIFICATIONS ------------------------ 19

∫ASSEMBLY AND OPERATING INSTRUCTIONS -----------------------------20

∫CARE AND CLEANING ------------------------------------------------------- 29

∫TROUBLE SHOOTING -------------------------------------------------------- 34

∫DECLARATION OF CONFORMITY / PERFORMANCE -------------------- 35

∫ENVIRONMENTAL INFORMATION ------------------------------------------36

∫GUARANTEE -------------------------------------------------------------------37

∫CUSTOMER SUPPORT ------------------------------------------------------- 37

3

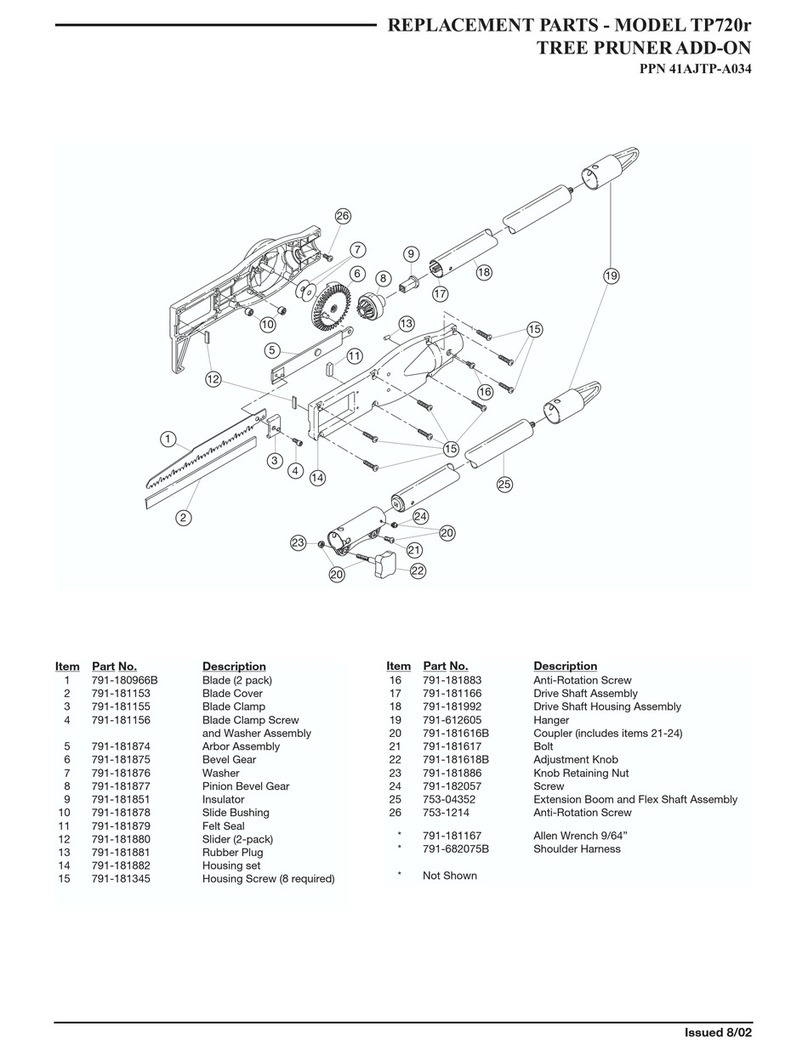

WHAT'S IN THE BOX

If you do not have all these items, please contact:

www.coreservice.co.uk

Hotline: +44 01904 947568

Email [email protected]

Upper part

Lower part

Shoulder strap

Guide bar Chain Oil bottle

Bar & chain cover

4

SPECIFICATION

Technical Data

Model M1L-5ET-200

Rated Voltage 230-240V~ 50Hz

Rated Power Rate (W) 750

Guide bar length/Cutting length(mm) 240/190

Chain speed (m/s) 10

Oil tank capacity (cm3) 100

Protection class II

Net Weight (kg) approx. 3.9

Cabel/Plug H05VV-F 2x0.75mm2, 6m, BS plug

Aluminium telescopic pole 220cm-280cm

3-position adjustable angle 0°/15 °/30 °

Oregon Bar & Chain 080SDEA041(547980) & 91PJ033X

Adjustable shoulder strap Yes

The sound values have been determined according to noise test code given in BS EN ISO

11680-1, using the basic standards BS EN ISO 3744 and ISO 9207.

The sound intensity level for the operator may exceed 80 dB(A) and ear protection measures

are necessary.

The declared vibration value has been measured in accordance with a standard test method

(according to BS EN 62841-1, BS EN ISO 11680-1) and may be used for comparing one product

with another. The declared vibration value may also be used in a preliminary assessment of

exposure.

WARNING! Depending on the actual use of the product the vibration values can differ

from the declared total. Adopt proper measures to protect yourself against vibration

exposures. Take the whole work process including times the product is running

under no load or switched off into consideration.

Proper measures include among others regular maintenance and care of the product

and accessories, keeping hands warm, periodical breaks and proper planning of

work processes.

Chain pitch

Chain gauge

3/8''

.050''

5

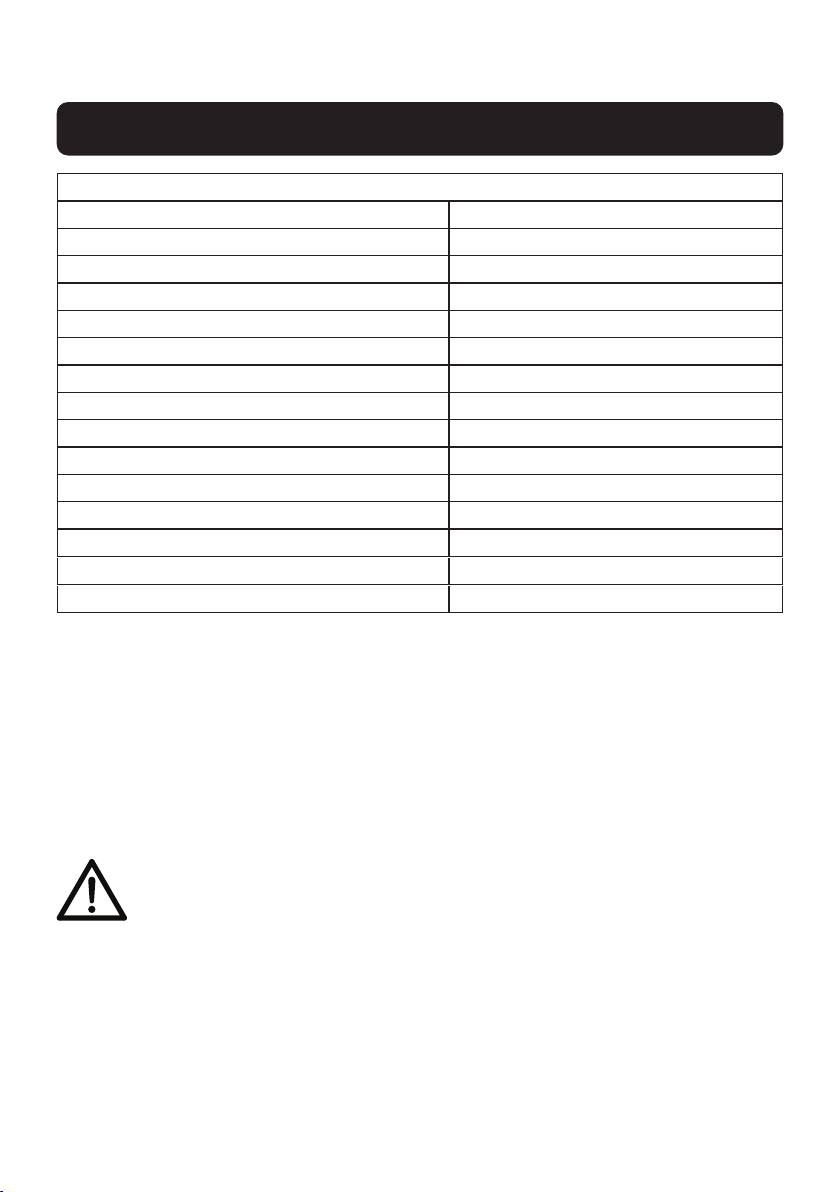

EXPLANATIONS AND SYMBOLS, CAUTIONS AND WARNINGS

Caution / Warning.

Read the instruction manual.

Wear hearing protection!

Wear eye protection!

Wear respiratory protection!

Wear protective gloves!

Wear slip-resistant, sturdy footwear!

Wear safety helmet!

10m

Warning! Danger from overhead electric-power lines! Keep at least 10 m distance.

Switch the product off and disconnect it from the power supply before assembly,

cleaning, adjustments, maintenance, storage and transportation.

Remove plug from the mains immediately if the power cord/extension cord is

damaged or cut.

Objects thrown by the product could hit the user or other bystanders. Always ensure

that other people and pets remain at a safe distance from the product when it is in

operation. In general, children must not come near the area where the product is.

Minimum distance 15m.

6

Kickback! Tip contact may cause the guide bar to move suddenly upward and

backwards what may cause serious injury to user.

Contact of the guide bar tip with any object should be avoided.

Always use the product with two hands. Do not use only one hand when operating

the product.

Do not use in rain or wet conditions.

104

Guaranteed sound power level value

Chain oil fill

Correct direction of cutting-teeth

Caution! Risk of injury due to running blades!

Danger of falling objects.

Double insulation. Protection class II

The product complies with the applicable European Directives and an evaluation

method of conformity for these Directives was done.

7

UK Comformity Assessed

This marking indicates that this product should not be disposed with other household

wastes. To prevent possible harm to the environment or human health from

uncontrolled waste disposal, recycle it responsibly to promote the sustainable reuse

of material resources.

8

IMPORTANT SAFETY WARNINGS

IMPORTANT

READ CAREFULLY BEFORE USE. KEEP FOR FUTURE

REFERENCE.

General power tool safety warnings

WARNING! Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury. Save

all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

Electrical safety

1. Power tool plugs must match the outlet. Never modify the plug

in any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching outlets will reduce

risk of electric shock.

9

2. Avoid body contact with earthed or grounded surfaces, such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or grounded.

3. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord for carrying, pulling

or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

5. When operating a power tool outdoors, use an extension cord

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

6. If operating a power tool in a damp location is unavoidable, use

a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

7. If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in

order to avoid a hazard.

Personal safety

1. Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result

in serious personal injury.

2. Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

10

3. Prevent unintentional starting. Ensure the switch is in the off-

position before connecting to power source and/or battery pack,

picking up or carrying the tool. Carrying power tools with your

finger on the switch or energising power tools that have the

switch on invites accidents.

4. Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the

power tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected

situations.

6. Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

7. If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards.

Power tool use and care

1. Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and

safer at the rate for which it was designed.

2. Do not use the power tool if the switch does not turn it on and

off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

3. Disconnect the plug from the power source and/ or the battery

pack from the power tool before making any adjustments,

changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool

accidentally.

This manual suits for next models

1

Table of contents

Other Hawksmoor Pole Saw manuals