hawo HD 680 DEI-V Operating and installation instructions

hd 680 DEI-V 4.3 ValiDoc Pro 1.3

9.693.018

Version 1.06

Translation of the

original instruction for use

Sealing device hd 680 DEI-V

ValiDoc Prodocumentation and packaging system

hd 680 DEI-V

ValiDoc Pro

Page GB 2

9.693.018

Version 1.06

ENGLISH

1INTRODUCTION...............................................................................................................................................5

1.1 PREFACE ......................................................................................................................................................5

1.2 LEGEND ........................................................................................................................................................6

1.3 GENERAL SAFETY INSTRUCTIONS................................................................................................................7

1.4 ADVICE FOR OPERATING THE SEALING MACHINE.........................................................................................9

2BEFORE STARTING........................................................................................................................................9

2.1 DESIGNATED USE.........................................................................................................................................9

2.2 INSTALLING THE SEALING MACHINE............................................................................................................10

2.2.1 Configuring the interfaces...............................................................................................................10

2.3 COMMISSIONING THE SEALING MACHINE ...................................................................................................11

2.4 COMMISSIONING THE VALIDOC PRO®DOCUMENTATION SYSTEM.............................................................12

2.4.1 Printbox and printer.........................................................................................................................12

2.4.2 "IntelligentScan", connection of a barcode scanner ...................................................................14

3BASIC FUNCTIONS.......................................................................................................................................15

3.1 DESIGN AND FUNCTIONS............................................................................................................................15

3.2 OPERATION AND SEALING PROCESS..........................................................................................................15

3.2.1 Important note regarding the sealing process.............................................................................16

3.2.2 Control light functions......................................................................................................................17

3.2.3 Functions of the buttons .................................................................................................................18

3.3 MACHINE SETTINGS....................................................................................................................................19

3.3.1 Enter sealing temperature ..............................................................................................................19

3.3.2 Switching printer off and on............................................................................................................19

3.3.3 Entering personal number ..............................................................................................................20

3.3.4 Data input..........................................................................................................................................20

3.3.5 Print data selection..........................................................................................................................32

3.3.6 Sealing parameter view ..................................................................................................................33

3.4 SEALING AND PRINTING PROCESS .............................................................................................................34

3.4.1 Automatic printing after each seal.................................................................................................34

3.4.2 Automatic printing after every other seal......................................................................................34

3.5 PRINTING PROCESS WITHOUT SEALING .....................................................................................................35

3.6 LABEL INFORMATION -SEALING AND PRINTING..........................................................................................36

3.6.1 Nomenclature of the label data......................................................................................................36

3.7 CRITICAL PROCESS PARAMETERS..............................................................................................................38

3.7.1 Sealing temperature........................................................................................................................38

3.7.2 Contact pressure..............................................................................................................................38

3.7.3 Sealing time......................................................................................................................................38

3.8 MANUFACTURER RECOMMENDATION FOR ROUTINE CHECKS....................................................................39

3.8.1 Routine checking of sealing seam quality criteria.......................................................................39

3.8.2 Annual sealing seam strength checks..........................................................................................39

3.8.3 Routine checks of critical process parameters............................................................................39

3.8.4 Sealing seam test –“Seal Check” with label printer ...................................................................40

3.8.5 SealCheck label data ......................................................................................................................41

3.8.6 Sealing seam test –“Seal Check” without label printer .............................................................42

3.8.7 Sealing seam dye penetrant test (hawo InkTest)........................................................................42

4TROUBLESHOOTING ...................................................................................................................................43

4.1 TROUBLESHOOTING CHECKLIST.................................................................................................................43

4.2 CUSTOMER SERVICE ..................................................................................................................................44

4.3 ALARM FUNCTIONS AND ERROR DISPLAYS.................................................................................................45

4.3.1 Alarm functions.................................................................................................................................45

4.3.2 Error displays machine ...................................................................................................................46

4.3.3 Error displays on the Printbox........................................................................................................47

4.3.4 Error displays on the printer...........................................................................................................48

hd 680 DEI-V

ValiDoc Pro

Page GB 3

9.693.018

Version 1.06

5MAINTENANCE ..............................................................................................................................................49

5.1 PARTS SERVICE..........................................................................................................................................49

5.2 REPLACEMENT PARTS ORDERING –ALLOCATION OF ITEM NUMBERS .......................................................52

5.3 REPLACEMENT PARTS ORDERING -COMPREHENSIVE OVERVIEW.............................................................53

5.4 INFORMATION ABOUT REPLACING WORN AND SPARE PARTS.....................................................................54

5.5 ADJUSTING THE PROCESS PARAMETERS...................................................................................................56

5.5.1 Temperature control........................................................................................................................56

5.5.2 Contact pressure..............................................................................................................................58

5.5.3 Configuring motor monitoring.........................................................................................................60

5.6 SETTINGS ...................................................................................................................................................61

5.6.1 Activate default settings..................................................................................................................61

5.6.2 Setting the serial interface transmission rate (baud rate)..........................................................62

5.7 REPLACING THE PRINTER LABEL REEL.......................................................................................................63

5.8 REPLACING THE PRINTER INK RIBBON........................................................................................................66

6TECHNICAL DATA.........................................................................................................................................69

6.1 CIRCUIT DIAGRAM AND WIRING DIAGRAM...................................................................................................69

6.2 SPECIFICATIONS.........................................................................................................................................70

7DECLARATIONS OF CONFORMITY..........................................................................................................71

7.1 CE DECLARATION OF CONFORMITY ...........................................................................................................71

7.2 CE DECLARATION OF CONFORMITY PRINTER............................................................................................72

7.3 CE DECLARATION OF CONFORMITY VALIPRINPRINT BOX .........................................................................73

hd 680 DEI-V

ValiDoc Pro

Page GB 5

9.693.018

Version 1.06

1 Introduction

1.1 Preface

First of all we would like to thank you for your purchase.

In these instructions, you will find information regarding the operation, maintenance and care of

the hd 680 DEI-V sealing machine, the ValiDoc Pro documentation and packaging system and

information regarding the process validation.

The hd 680 DEI-V machine is a microprocessor-controlled, permanently heated sealing

machine for closing heat-sealable pouches and reels (SBS

1

).

The ValiDoc documentation system includes the hd 680 DEI-V sealing machine, the ValiPrint

with ValiPrint Box and the ValiScan®barcode scanner

The ValiPrint document printer is a thermal transfer label printer which prints sandwich labels

when connected to the sealing device.

The labels have an indicator for steam sterilisation.

The ValiScan barcode scanner is a scanner with which printed data can be read and print

functions triggered by means of specially created barcode lists, when connected to the sealing

device.

Always keep these instructions in close proximity to the machine.

Sterile Barrier System

Please read these operating instructions carefully before commissioning so that you

are familiar with the capabilities of the machine and the documentation system, and

you can make optimum use of all functions.

hd 680 DEI-V

ValiDoc Pro

Page GB 6

9.693.018

Version 1.06

1.2 Legend

The exclamation mark in the triangle draws your attention to important notes in

the operating instructions, which must absolutely be observed.

This warning sign refers to measures that could result in danger to human health

if they are not observed. It is compulsory to observe it.

Tips with a hand symbol next to them, which relate to daily practice.

Settings and functions which are only possible if the label printer is connected

and switched on.

Settings and functions which can be activated via the device.

Functions which can be activated with a barcode scanner connected.

Functions which can be activated via the serial interface.

Important notice

In accordance with the intended use, the CE marking is displayed based on

the following EU directives:

2006/42/CE, 2011/65/CE and 2004/108/CE.

The European Medical Device Directive 93/42/EEC and the German Medical

Products Act (MPG) are not applicable to the sealing device and printer.

The limit values of IEC 60601-1 must not be applied in repeated electrical

inspections.

The manufacturer accepts no liability whatsoever for damage caused by tests

in accordance with standards not listed in the declaration of conformity.

Note

Because we are constantly improving our products, we

reserve the right to modify these operating instructions

and the functions described in them.

These operating instructions apply to products from

software version A04 onwards

hd 680 DEI-V

ValiDoc Pro

Page GB 7

9.693.018

Version 1.06

1.3 General safety instructions

Our products are in a flawless condition in terms of safety technology when

they leave the plant.

To maintain this condition, the contents of these safety instructions as well as

type plates, labelling and safety instructions attached to the machine must be

observed while handling the machine (transport, storage, installation,

commissioning, operation and maintenance).

This machine is suitable for processing laminated films in the heat-sealing

process. See also chapter 2.1 "Designated use".

Please check the packaging and lodge a complaint for any damage with the

carrier or parcel service promptly before installing the machine.

Before commissioning, ensure that the machine does not show any evidence

of damage. In case of doubt, contact the manufacturer or a service partner

authorised by the manufacturer.

Do not operate the machine if the power cable or the power plug is

damaged. Do not use the machine if it does not operate correctly or it is

damaged in any way. If the mains cable or the machine have been damaged,

the machine must be repaired by the manufacturer or by one of the

manufacturer's authorised service partners.

The machine must be connected using the mains cable included in shipment

to a protective contact socket with a stable voltage. Operation on IT networks

is not permitted.

Place the machine on a stable base.

The machine must not be installed and operated in potentially explosive

areas.

If the sealing machine is brought directly from a cold environment into a

warm environment, condensation may form. Wait until temperature

equalisation has taken place.

Starting up the device when it contains condensation causes danger to

life!

Fuse changes and repairs must only be performed by the manufacturer or by

one of the manufacturer's authorised service partners.

But before switch off the machine and remove the power plug from the

socket.

Switch off the machine when it is not in use or remove the power plug from

the socket.

hd 680 DEI-V

ValiDoc Pro

Page GB 8

9.693.018

Version 1.06

Before cleaning: Switch off the machine and remove the power plug from

the socket.

Clean the machine only with a dry or damp soft cloth and a mild cleaning

agent. Do not allow any water to find its way into the machine. Caution!

Never wet clean the machine!

Do not insert pointed or flat items into the import slot of the machine. This

can result in damage to the machine and instruments.

Do not insert items into the louvres of the machine. You may receive an

electric shock or the machine could be damaged.

Do not use the machine if you have any doubts about its safety.

The machine must not be installed or operated by persons under 16 years of

age.

The machine must not be operated unsupervised.

It is forbidden to operate the machine under the influence of drugs or alcohol.

Keep your hair,clothing and gloves away from moving parts.

Loos clothes, jewellery or long hair van be caught in moving parts.

The machine contains valuable materials that can be recycled and reused.

The machine should therefore be disposed of at a public disposal facility

near you.

The machine has been labelled in accordance with the European

2002/96/EC (WEEE) directive for scrap electrical and electronic equipment.

This directive governs the return and recycling of scrap equipment within the

EU.

In the event of conversion work or interventions to the equipment undertaken

without the express written permission of the manufacturer, the warranty

shall be deemed void and any liability for physical or material damage shall

be transferred to the operator.

hd 680 DEI-V

ValiDoc Pro

Page GB 9

9.693.018

Version 1.06

1.4 Advice for operating the sealing machine

Checking the sealing seam2

Each sealing seam must be subjected to a integrity check after the sealing

process and after sterilisation.

The sealing seam must be intact across the entire width and length and must

be fully sealed.

There must be no channels, kinks, folds, air pockets or indents.

There must be no visible signs of scorching or melting.

2 Before starting

2.1 Designated use

The machine is intended only for commercial and industrial use and must only be used for the

intended purpose and with the following materials.

Sealable materials

Pouches and reels in accordance with EN 868-5 and EN ISO 11607-1*

Paper pouches in accordance with EN 868-4*

Uncoated HDPE*

Aluminium laminate film

* also with side gusset

The correct sealing temperature must be identified by means of test sealings.

The machine output depends on the condition of the sealing material used.

These materials must not be sealed

Polyethylene films

Soft PVC films

Hard PVC foils

Polyamide films

Polypropylene films.

2

In the case of uncertainty, an ink test (see section 3.9) can be used for the purposes of visual inspection.

ENGLISH

hd 680 DEI-V

ValiDoc Pro

Before starting

Chapter 2

Page GB 10

9.693.018

Version 1.06

2.2 Installing the sealing machine

Place the machine on a horizontal surface.

Do not lift the machine by the infeed section.

The distance from the machine to a wall must be at least 200mm!

2.2.1 Configuring the interfaces

Function

Interface

Interface

Single device

PC

or

data collection system ht 180 PC

ValiDoc System

Printbox

for the ValiPrint label printer

IntelligentScan

barcode scanner

200 mm

Prior to installation, read the safety instructions in chapter 1.4

hd 680 DEI-V

ValiDoc Pro

Page GB 11

9.693.018

Version 1.06

2.3 Commissioning the sealing machine

Preparing the machine

Switching the machine on

Program version

Heating-up phase

Until the the set temperature

has been reached, after approx.

3-4 mins, the control light

flashes "okay"

Once the set temperature has

been reached, the control light

remains permanently on

Machine is ready for sealing

Connect the mains plug to the mains

Switch the machine on using the mains

switch

Test the control lights and the display

Display program version

Display current actual temperature

Rated temperature is reached

Power switch

Power connection

hd 680 DEI-V

ValiDoc Pro

Page GB 12

9.693.018

Version 1.06

2.4 Commissioning the ValiDoc Pro®documentation system

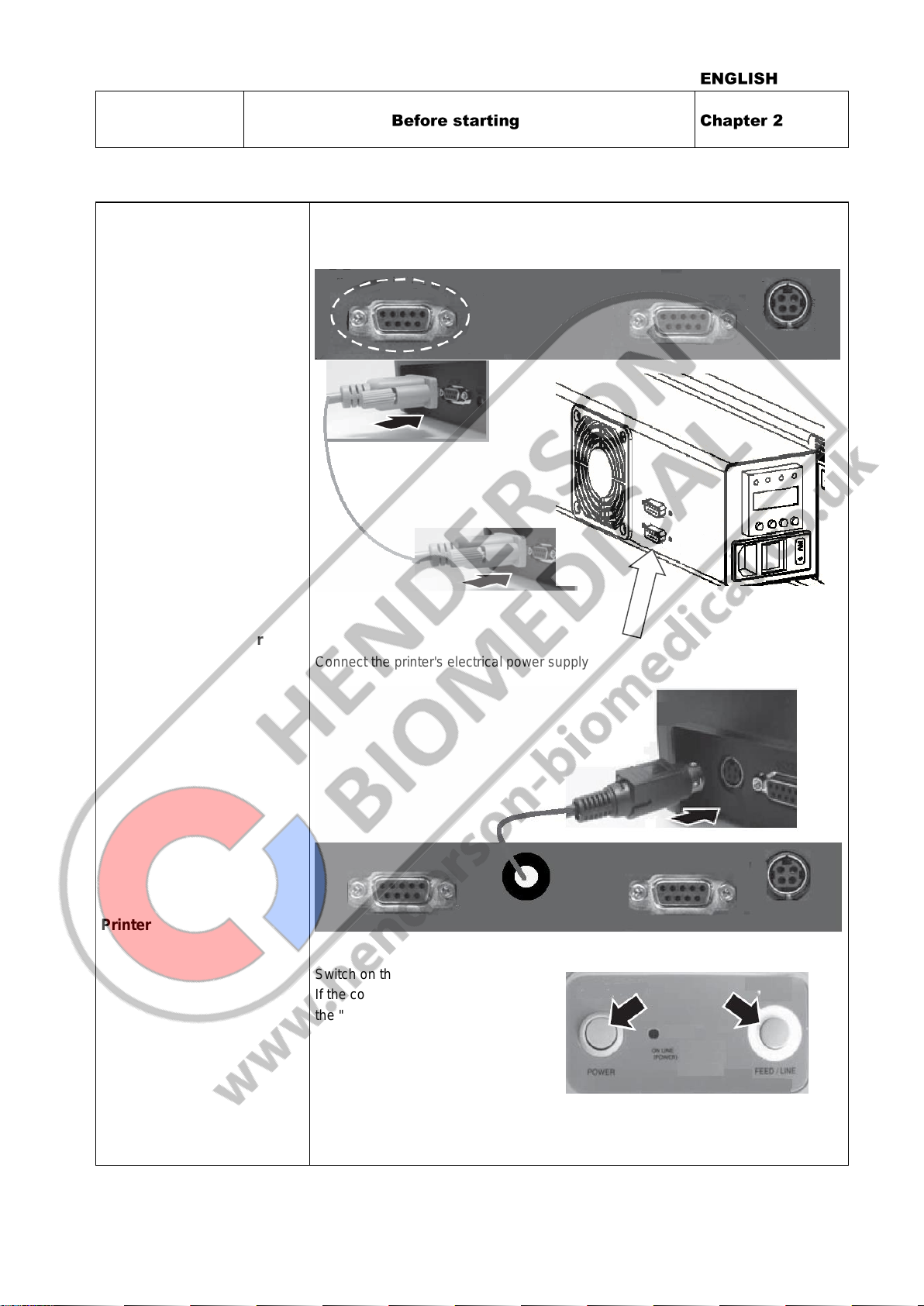

2.4.1 Printbox and printer

Sealing machine

Prepare the device

Printbox electrical power

supply

Printer interface cable

Switch off the sealing machine

Connect the mains cable of the

power supply unit to the mains

Connect the electrical power supply

to the Printbox

Connect the power supply unit plug

to the socket

Connect the interface cable to the printer

hd 680 DEI-V

ValiDoc Pro

Page GB 13

9.693.018

Version 1.06

Sealing machine interface

cable

Interface cable printer

Printer

Sealing machine

Connect the interface cable to the Printbox and sealing machine

Connect the printer's electrical power supply

Switch on the printer

If the control light is green, press

the "Feed" button once.

Remove label(s)

Switch on the sealing machine

hd 680 DEI-V

ValiDoc Pro

Page GB 14

9.693.018

Version 1.06

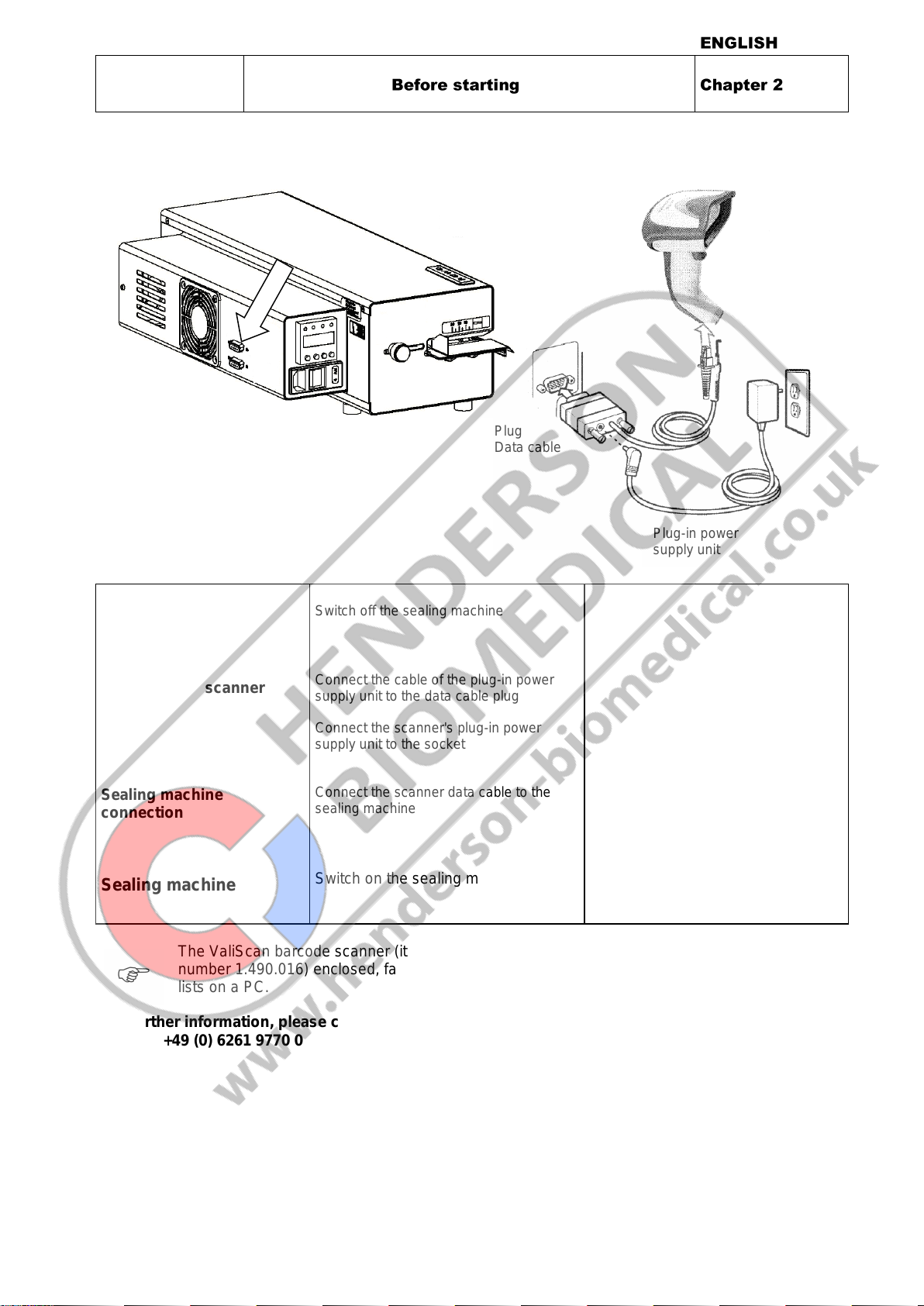

2.4.2 "IntelligentScan", connection of a barcode scanner

Sealing machine

Scanner

Preparing the scanner

Sealing machine

connection

Sealing machine

Switch off the sealing machine

Connect the cable of the plug-in power

supply unit to the data cable plug

Connect the scanner's plug-in power

supply unit to the socket

Connect the scanner data cable to the

sealing machine

Switch on the sealing machine

With the ValiScan barcode scanner

(item number 1.421.018) connected

to the "IntelligentScan" interface and

corresponding barcode lists,

different entries and functions can

be carried out.

The ValiScan barcode scanner (item number 1.421.018) is supplied with a CD (item

number 1.490.016) enclosed, facilitating the generation and recording of the barcode

lists on a PC.

For further information, please contact your authorised service partner or the hawo Service

Hotline: +49 (0) 6261 9770 0

Plug

Data cable

Plug-in power

supply unit

hd 680 DEI-V

ValiDoc Pro

Page GB 15

9.693.018

Version 1.06

3 Basic functions

3.1 Design and functions

3.2 Operation and sealing process

After the sterilization packaging has been inserted, the feed process is started

automatically by means of photoelectric cell.

The sterilization packaging is now fed and the sealing seam area is heated up to the set

sealing temperature by the heating units located at the top and bottom. The sealing

temperature is monitored.

The sealing seam, which is now heated, is pressed together by the sealing roller and

sealed.

The contact pressure and the sealing speed in monitored.

The finished sterilization packaging is transported to the extraction side.

If no item to be sealed is fed in, the feed switches off after approximately 30 seconds.

The set parameters remain saved after the device is switched on or off, or after a power

failure. The date and time are updated automatically (Autosafe).

Adjustable sealing

edge setting

Temperature controller

Mains Mains fuses

Power switch

hd 680 DEI-V

ValiDoc Pro

Page GB 16

9.693.018

Version 1.06

3.2.1 Important note regarding the sealing process

The material to be sealed must be sealed according to the manufacturer's instructions.

Set the peel edge width:

After releasing the locking device, the peel edge can be steplessly adjusted by between

0 mm and 35 mm by moving the infeed section. Sufficient overhang must be present

between the sealing seam and the reel interface on the extraction side.

Sterilisation packaging must be inserted from the left-hand side, always with the paper side

face down.

The drive is switched on automatically.

Remove the sealed sterilisation packaging and leave briefly to cool.

Sealable pouches and reels must only be filled to ¾ full. The limited filling prevents

too great a load being placed on the sealing seams.

The correct sealing temperature must be identified by means of sealing tests.

Sealing must be performed in such a way that the sealing seam meets the quality

characteristics required in EN ISO 11607-2, even with varying material

thicknesses. The following quality characteristics must be met:

Intact sealing across the entire sealing seam width

No channels or open seals

No punctures or tears

No delamination or material separation

The hawotest SEAL CHECK is considered to be suitable for checking the quality

criteria. The hawotest SEAL CHECK seal indicators are available separately.

hd 680 DEI-V

ValiDoc Pro

Page GB 17

9.693.018

Version 1.06

3.2.2 Control light functions

Function

Switch the machine on

Heating-up phase

flashes

off

off

off

Sealing temperature

= ± 5°

Contact pressure

= ± 20%

Sealing speed

= ± 10%

on

off

on

off

Sealing temperature

<> ± 5°

Contact pressure

<> ± 20%

Sealing speed

<> ± 10%

off

on

off

on

Standby

off

on

off

on

Heating up after standby

or changing the set

temperature

flashes

off

off

on

hd 680 DEI-V

ValiDoc Pro

Page GB 18

9.693.018

Version 1.06

3.2.3 Functions of the buttons

Menu level 1

Activation of menu level 2

Press 3 s

Activation of menu level 3

Press 7 s

Enter personal

identification

Activation of "seal check"

Menu level 2

Entering sealing temperature

Temperature value

+1

Temperature value -1

Confirm entry

Menu level 3

3.1

Sealing parameter view

3.2

Data input

Changeover

3.1 - 3.2

Input value +1

Changeover

3.1 - 3.2

Input value -1

Confirm entry

S

hd 680 DEI-V

ValiDoc Pro

Page GB 19

9.693.018

Version 1.06

3.3 Machine settings

3.3.1 Enter sealing temperature

Press button 3s

Change set temperature

Display for 1s

Display the current temperature setpoint

3.3.2 Switching printer off and on

Press the button

Switch printer off and on

Display for 1s

Display the current setting

Printer switched on

Printer switched off

S

Confirm entry

hd 680 DEI-V

ValiDoc Pro

Page GB 20

9.693.018

Version 1.06

3.3.3 Entering personal number

Press the button

Select new number

Display for 1s

Display the current personal number

On this display, an

alphanumeric code has been

entered via the barcode scanner

3.3.4 Data input

Activate

Press button 7s

Toggle to data input

3.3.4.1 Key lock

Activated

Enter 1 - 9999

Deactivated

Enter 0

S

Confirm entry

Confirm selection

Confirm entry

Table of contents

Other hawo Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

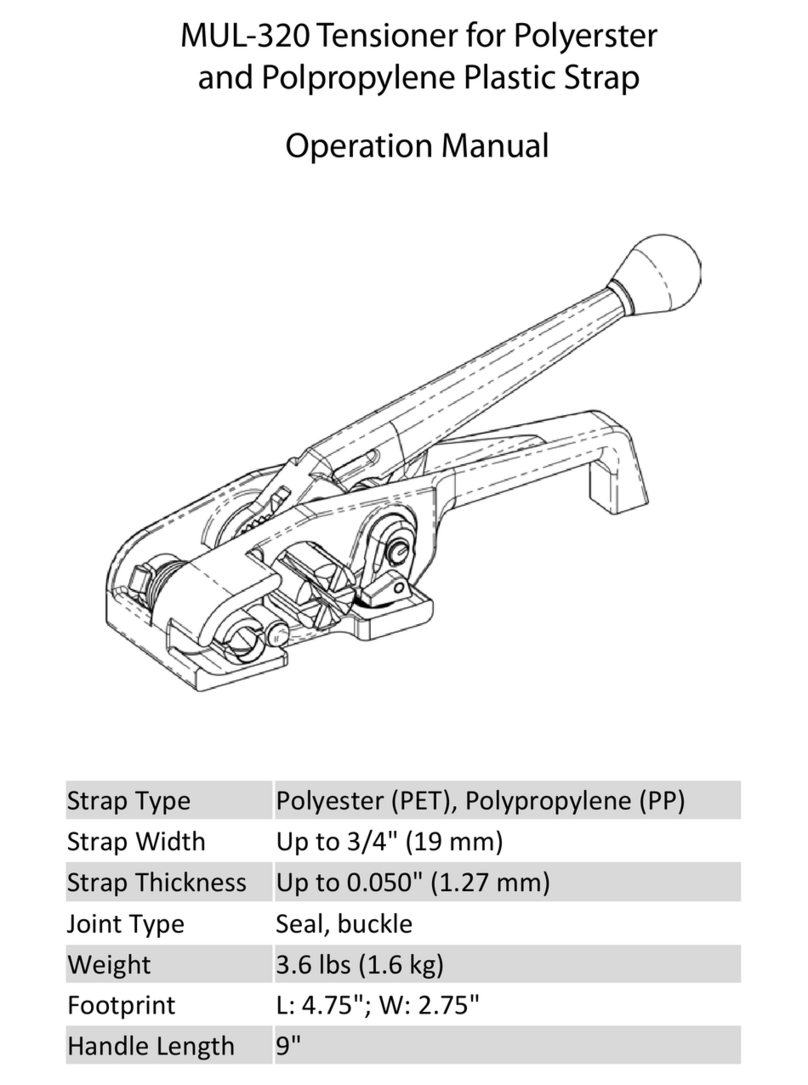

Strapack

Strapack i-10 quick start guide

Polychem

Polychem PHT801 Operation manual and spare parts list

Minipack-Torre

Minipack-Torre eco modular instruction manual

ErgoPack

ErgoPack 700 Original operating instructions

coesia

coesia FlexLink WL Maintenance manual

ALLpaQ Packaging Group

ALLpaQ Packaging Group Genesis Series Operator user manual