ErgoPack 700 User manual

Original Operating Instructions

For ErgoPack

700/700E/713E/726E/745E

serial no.______________________

EN

V3

EU declaration of conformity

for the purposes of the EU machine directive 2006/42/EG

ErgoPack Deutschland GmbH

Hanns-Martin-Schleyer-Str. 21

89415 Lauingen

We hereby declare that the strapping systems "ErgoPack 700, 700E, 713E, 726E, 745E",

to which this declaration refers complies with all the relevant and basic health and safety

requirements because of their concept, type of construction and the model we have

brought on to the market.

This declaration loses its validity if a change is made to the system without our permission.

Respective

EC directives: EC Machine directive (2006/42/EG)

EC Guideline on electromagnetic compatibility

(2014/30/EU)

Applied standards EN 12100: 2010

EN 415-8: 2008

EN 61000-6-2:2005

EN 55011: 2018-05

EN 60 204-1: 2006

Since strapping system: 0319XXXX/9000

Since year of manufacture: 2019

Lauingen, 03th May, 2018

______________________

Andreas Kimmerle

CEO

Authorised representative for publishing technical documentation:

ErgoPack Deutschland GmbH

Hanns-Martin-Schleyer Str. 21

89415 Lauingen

Declaration of conformity

- 2 -

- 3 -

•The operation in these instructions is explained by using the

ErgoPack 726E as an example.

•As to ErgoPack 700, all the points in these instructions

referring to the operation of the sealing head and also all points

referring to the operation of the control box with the motor,

charger and rechargeable batteries are not applicable.

Also at all points in which the movement of the ChainLance is

described by using the joystick, at the ErgoPack 700 you

have to use the crank handle accordingly.

•All points in these instructions referring to the operation of

the sealing head are not applicable as far as the “ErgoPack

700E“ is concerned.

Validity of the operating instructions

These operating instructions are valid for the following models:

ErgoPack 700

Strapping system with manual drive via a hand crank,

without sealing head

ErgoPack 700E

Strapping system with electrical drive, electronically controlled via

a joystick, without a sealing head

ErgoPack 713E

Strapping system with electrical drive, electronically controlled via

a joystick, with a sealing head for strap width of

9-13 mm and a maximum tension of 1200 N

ErgoPack 726E

Strapping system with electrical drive, electronically controlled via

a joystick, with a sealing head for strap width of

12-16 mm and a maximum tension of 2500 N

ErgoPack 745E

Strapping system with electrical drive, electronically controlled via

a joystick with sealing head for strap width of

15-19 mm and a maximum tension of 4500 N

- 4 -

Table of contents

Page

1 Technical data 6

1.1 Strapping system 6

1.2 Sealing head 7-8

1.3 Battery and charger 9

2 General 10-11

2.1 Notes on environmental protection 11

3 Safety regulations 12-15

3.1 Safety regulations for battery pack and charger 15

4 Description 16

4.1 Construction 16

4.2 Operating panel strapping system 17

4.3 Operating panel sealing head 17

4.4 Indications of the Dual-Charger 18

5 Commissioning 19

5.1 Battery charger 19

5.2 Charging the battery pack 19-21

6 Operation 22

6.1 Setting strap width at the sealing head 22

6.2 Switching on the control unit 23

6.3 Setting strap tension range at the sealing head 24

6.4 Setting strap tension at the sealing head 25

6.5 Setting mode of operation at the sealing head 26

6.6 Select favorite 27

6.7 Changing strap coil 28-41

6.8 Strapping 42-46

6.9 Tensioning and sealing pallets above 70 cm height 47-50

6.10 Sealing control 51

6.11 Setting welding time 52

6.12 Tensioning and sealing of pallets

below 70 cm height 52-54

7 Service and repair 55

7.1 Cleaning the ChainLance 55

7.2 Replacing the ChainLance 56

7.3 Replacing individual chain links 57

7.4 Replacing the reversing sledge 58-59

7.5 Replacing the length adjusting belt 60-61

- 5 -

1. Technical Data

- 6 -

1.1 Strapping system

Weight:

ErgoPack 700 64,4 kg

ErgoPack 700E (incl. battery pack) 88,1 kg

ErgoPack 713E (incl. battery pack) 92,1 kg

ErgoPack 726E/745E (incl. battery pack) 92,9 kg

Dimensions (all types) Length 630 mm

Width 770 mm

Height 1200 mm

Maximum chain speeds

Mode A, strapping

Moving out horizontally: 40 m/min

Moving out vertically: 60 m/min

Moving in vertically: 44 m/min

Moving in horizontally: 54 m/min

Mode B: setting up/threading strap

Moving out 20 m/min

Moving in: 16 m/min

Max. chain thrust: 310 N

Measured A-graded

noise emission level L pa 79 dB (A)

(EN ISO 11202)

7.6 Changing the sealing head 62-63

7.7 Changing the control box with the motor 64-65

7.8 Cleaning/replacing the tension wheel at the sealing head 66

7.9 Cleaning/replacing the tooth plate at the sealing head 67

7.10 Replacing the cutter at the sealing head 68

8 Save moving and parking 69

9 Spare parts lists 69

10 General safety warnings for power tools 70-73

1.2 Sealing head

Weight: 3,8 –4,3 kg

(incl. spiral cable)

Dimensions length 335 mm

(incl. spiral cable) width 140 mm

height 180 mm

Tension

713E 150-1200 N

726E 400-2500 N

745E 400-4500 N

Tensioning speed 290 mm/s (713E)

220 mm/s (726E)

120 mm/s (745E)

Sealing friction welding

Measured A-graded

noise emission level

(EN ISO 11202) (EN 60745-1/2:2009)

713E L pa 79 dB (A) L paeq 77 dB (A)

726E L pa 78 dB (A) L paeq 82 dB (A)

745E L pa 79 dB (A) L paeq 81 dB (A)

Sound power level, on average

(EN 60745 -1/2:2009)

713E L waeq 88 dB (A)

726E L waeq 93 dB (A)

745E L waeq 92 dB (A)

Measuring inaccuracy K

713E 3,0 dB (A)

726E 3,0 dB (A)

745E 3,0 dB (A)

- 7 -

- 8 -

Strap width

713E, adjustable to 9-10 mm

12-13 mm

726E, adjustable to 12-13 mm

15-16 mm

745E, adjustable to 15-16 mm

18-19 mm

Strap thickness

713E 0,40 - 0,80 mm (PET)

0,50 - 0,80 mm (PP)

726E 0,50-1,00 mm (PET/PP)

745E 0,80-1,30 mm (PET/PP)

Hand arm vibrations without using a Tool-Lift

(EN 60745-1/2:2009)

713E a 2,4 ms-2

726E a 2,4 ms-2

745E a 2,3 ms-2

Measuring inaccuracy K

713E 1,5 ms-2

726E 1,5 ms-2

745E 1,5 ms-2

Plastic strap

Strap materials Polypropylene (PP)

Polyester (PET)

Charger 3 stage lead charger

Prim.: 100-240 VAC 50/60Hz max. 1,2A

Sec.: 2x 12V DC/2A

Total max. power 60W

Battery pack 24V lead AGM battery

Weight: 12.3 kg

Charging time: approx. 8 hours

Temperature range: 5 °C –40 °C

Number of strappings: 150 to 400 per charge, depending on pallet size,

tension, welding time and age of battery

Life span: approx. 300-500 charges

1.3 Battery and Charger

- 9 -

2. General

These operating instructions will help you to understand the strapping

system and how to use it according to regulations. The operating instructions

contain important notes on how to use the strapping system safely, properly

and economically.

Adhering to the notes helps you to avoid dangers, repairs and down times

and also increases the reliability and life span of the strapping system.

The operating instructions must be available where the strapping system is

used. It has to be read, understood and used by everybody who works with

the strapping system.

These works include operation, maintenance and repair.

In addition to the operating instructions and the rules in the country and

place of use for the prevention of accidents, the recognized special rules for

working safely and according to proper and professional standards also have

to be respected.

- 10 -

Physical or chemical materials dangerous to health have not been used

for manufacturing the strapping system.

Concerning waste disposal, valid national rules and regulations have to

be considered. Take care about disposing packaging, the product itself

and parts accordingly.

Special dealers offer disposal according to proper environmental

protection.

- Do not open the battery

- Do not throw the used battery into the domestic waste bin, into fire or

into water.

2.1 Notes an environmental protection

- 11 -

Warning

Marks a hazard with moderate risk.

If not avoided, it can result in death or serious injury.

Caution

Marks a hazard with a minor risk.

If not avoided, it can result in a minor or moderate injury.

Attention

Marks a situation to be considered.

If not considered, it can lead to material damage or poor

operating results.

Meaning of warning symbols, usage conventions

Marks useful, additional information.

3. Safety regulations

- 12 -

Inform yourself!

Before usage, the manual has to be read and understood.

Service and maintenance has to be done by trained staff only.

Protect yourself!

Wear eye and hand protection (cut proof

gloves) and also safety shoes.

Attention: Laser beam!

Direct eye contact with the laser beam or reflecting radiation

may result in permanent eye injuries. Never look direct in the

laser.

Laser category 2 Power: 10 mW

DIN EN 60825-1:2015-07 Wavelength: 635 nm

Wear a safety helmet!

Wear a safety helmet, when strapping pallets higher than 1.20m.

The duty wearing a helmet, can be avoided, if the user was taught

about the risk of injury by the plastic chain falling.

This instruction has to be recorded in writing.

Warning:

Strap tensioning or strapping, danger of jamming and crushing.

Do not place hands or other body parts between the strap and

the packaged goods during the strapping process. Ensure that

there are no other persons in the hazardous zone..

For an emergency stop in the case of danger (trapped person):

•To release tension (before welding), open the rocker lever.

•After welding, cut the strap with a suitable tool (strap cutter)

- 13 -

Warning:

Following hazards can result in serious injuries:

Breaking strap, risk of injury

When being tensioned, the strap may break and rip. Do not stand in

line with the strap and wear eye protection.

Strap ends snapping back, risk of injury

When cutting strap, hold the upper portion and stand aside. Do not

stand in line with the strap and wear eye protection.

ChainLance, risk of tripping

When parking the strapping system, the ChainLance must be fully

inside the strapping system. The sledge must not stick out.

Strap waste, risk of tripping

Make sure any strap waste, which possibly appeared, will be removed

from the floor quickly.

Sealing head and ChainLance, risk of crushing

Do not put your fingers into the area of the tension wheel of the

sealing head and into the ChainLance.

Reversing sledge, risk of crushing

Especially around the entire surroundings of the reversing sledge,

there is a risk of squeezing.

Hazardous area, risk of crushing and risk of injury

Make sure before each strapping cycle, there is no person in the

hazardous area (especially of the ChainLance) and nobody can enter

that area. This is due, especially for the limited or bad visible area, on

the opposite site of the pallet (users view). During strapping, there

must not be any hands or body parts between strap and goods.

Power source, risk of injury

Before maintenance or repair works: Switch main switch to “0” and

unplug the cable from the battery.

EX Areas, risk of explosion

The system must not be used in areas with explosive atmospheres.

- 14 -

Attention:

Avoid damages:

Water damages

For cleaning do not use water or steam.

Visual inspection

Before using the strapping system the first time, a visual inspection

has to be done.

Only use original ErgoPack spare parts!

Warranty and liability become invalid if other parts are used.

Caution:

Following hazards can result in minor or moderate injuries:

Strap roll, risk of injury

If the strap roll is 20 kg or heavier, 2 persons need to lift it.

Tilting danger

Strapping pallets should, whenever possible, take place in areas with

an even surface. When using the strapping system on inclined

surfaces, after positioning and before strapping, the brakes of the

castor wheels on the strap side of the strapping system have to be

Warning:

Following hazards can cause serious injuries:

ChainLance, risk of injury

After the ChainLance moved up on the opposite side of the pallet, it

falls towards the user with its own weight.

Used without paying attention, the ChainLance can fall on the head

of the user and cause injuries. When using the system, watch out

and be concentrated and catch the ChainLance, when it falls over.

Loose and falling goods

Check the weld. Never transport or move strapped goods with an

improper welded strap.

Intended use

This strapping system is designed for strapping pallets/ loading carriers. The

strapping system has been developed and constructed for safe operation

when strapping.

The system is only to be used for strapping with plastic straps

(polypropylene and polyester). Strapping with a steel strap is not possible

with this strapping system.

The system is not designed to strap aliments which are not packaged.

The set up tension force must correspond to the packaged goods to be

strapped. The construction of the strapping system does not consider any

risk to damage goods, because of the strapping itself and/ or improper set

tension force.

3.1 Safety regulations for battery pack and

charger

•Check the plug and the cable before each use and have them replaced

by a specialist if they are damaged

•Do not use any batteries from other manufacturers, use original spare

parts only.

•Keep the connection plug to the battery pack away from non-related

objects and dirt.

•Protect the charger from moisture; operate it in dry rooms only.

•Do not open the battery and protect it from shock, heat and fire.

Danger of explosion!

•Store batteries in a dry frost-proof place. The ambient temperature

must not exceed 50°C and must not fall below -5°C.

•Damaged batteries may not be reused.

- 15 -

4. Description

4.1 Construction

Control unit with drive

Cutter

Strap brake

- 16 -

Sealing head

Sliding window with safety switch

Tool-Lift

Cover of battery pack

Fig. 2

Fig. 3

Fig. 4

Fig. 1

4.2 Operating panel strapping system

- 17-

4.3 Operating panel sealing head

Fig. 5

Joystick to move “ChainLance“ in and out

with precision speed control.

LED display

Permanent light green = battery full

Permanent light

green + yellow = battery will soon be empty

permanent yellow light = battery empty, control unit

switches off

(Control unit switches off when battery voltage ≤ 23,7V)

Flashing green + yellow = teaching mode

Flashing light green or yellow = setup mode

Quickly flashing red = sliding window open

Rotary switch: A = strapping mode

B = setup mode

Main switch “power supply 1/0“

1 "Favorite"

2 "Welding time"

3 "Operating mode"

4 "Plus & Keylock"

5 "Tensioning force"

6 "Minus & Soft tension"

a Display "Information symbols„

b Status indicator bar “Tensioning/Welding“

c Display "Messages"

Fig. 6

Display activated.

Welding process is finished, tool can be removed

Application error: temporary system error, can be rectified by the operator

Tool fault: static system error, rectify error.If the error cannot be rectified

-> Service department ErgoPack

4.4 Indications of the Dual-Charger

- 18-

LED indication

Inside the red battery housing there are two 12V batteries installed.

The dual charger charges each of the two batteries separately.

The dual charger has one LED- indication for each of the two 12V

batteries. (Output I and Output II), indicating the charging status of

each battery.

LED permanent yellow = Charging battery. Do not remove

battery pack from the charger!

LED permanent green = Battery fully charged, charger witches

into preserving mode.

Note: The battery pack only is fully charged, if both LED indication

lights are permanent green!

Fig. 7

5. Commissioning

5.1 Battery charger

The main voltage must comply with the details on the type plate.

The charger is only suitable for charging the delivered 24V lead battery.

5.2 Charging the battery pack

- 19 -

1.) Connect charger to the main voltage.

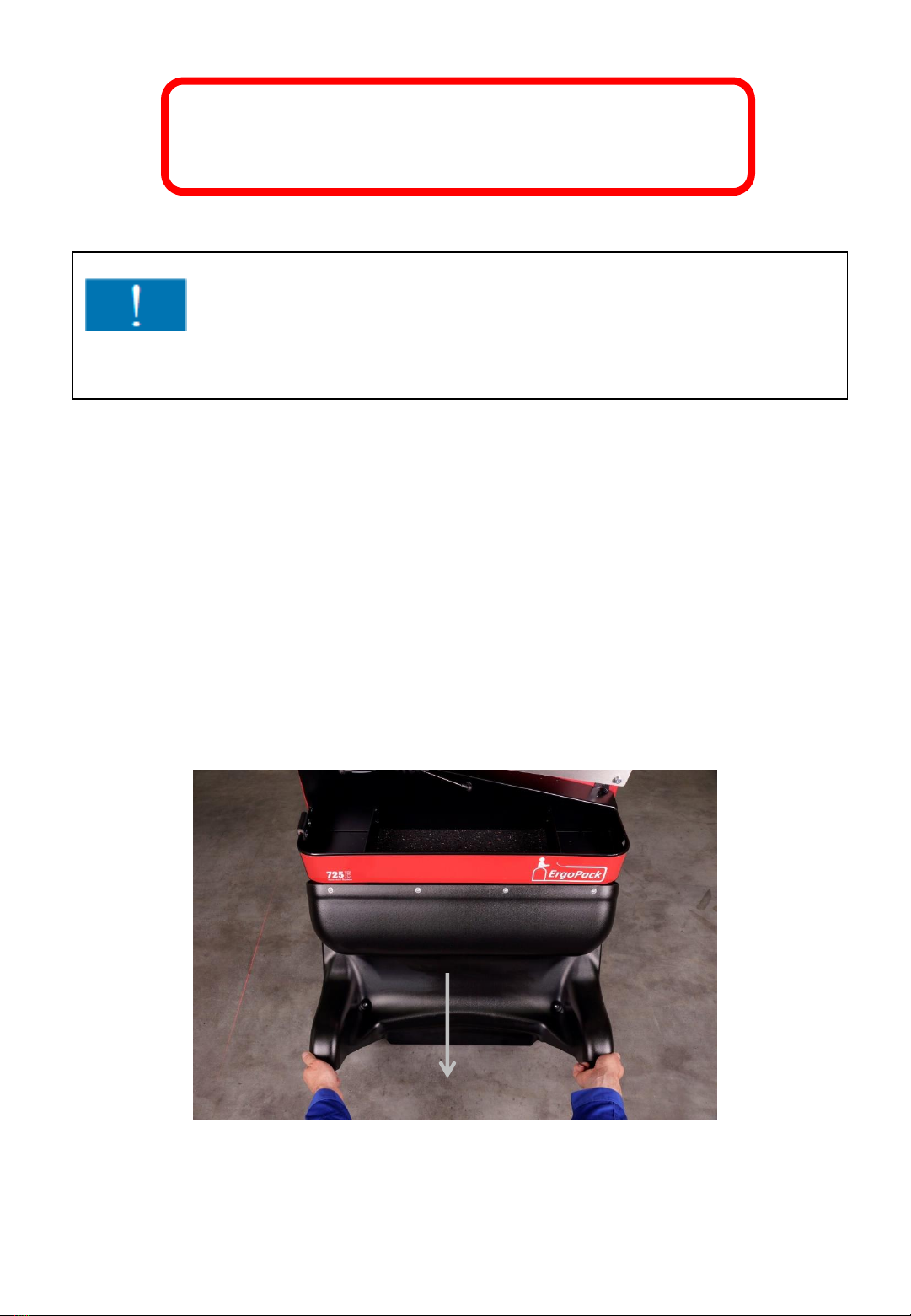

2.) Open cover of battery case (by pulling at

the outer corners as shown below.)

Fig. 8

Attention!

Before using the strapping system for the first time, a visual inspection for

exterior damages has to be done.

5.) Put the plug (14) of the charger into the blue charging socket of the battery

pack (7) as shown in Fig 10b by slanting to the lower left corner. Thereafter turn

the plug clockwise by 45°as shown in Fig. 10c until final snap in

Fig. 10b

14

Fig. 10c

- 20-

3.) Turn the red ring (12) of the plug (13)

on the battery pack (7) counter clockwise.

4.) Disconnect the plug (13) from the battery pack and

put it into the hole of the storage box above.

12

13

7

Fig. 9

Fig. 10a

Warning!

Charge the battery pack only with the ErgoPack Dual-3-step

charger through the blue socket!

This manual suits for next models

4

Table of contents

Other ErgoPack Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual