hawo hd 650 DC EcoPak User manual

9.693.024

OPERATING INSTRUCTIONS

Valid for device versions hd 650 DC EcoPak as of 07/2020

hd 650 DC EcoPak

hd 650DC EcoPak

D

Contents

9.693.024

Page 2

V 1.02

1INTRODUCTION........................................................................................................................................ 3

1.1 PREFACE ...............................................................................................................................................3

1.2 LEGEND .................................................................................................................................................3

1.3 IMPORTANT NOTICE ................................................................................................................................4

1.4 CLEANING..............................................................................................................................................4

1.5 SAFETY INSTRUCTIONS ...........................................................................................................................5

2BEFORE STARTING.................................................................................................................................. 7

2.1 INTENDED USE........................................................................................................................................7

2.2 DESIGN AND FUNCTIONS .........................................................................................................................8

Sealing process sequence ......................................................................................................................... 8

2.3 INSTALLATION.........................................................................................................................................9

3BASIC FUNCTIONS................................................................................................................................. 10

3.1 SWITCHING ON THE DEVICE...................................................................................................................10

3.2 OPERATION..........................................................................................................................................11

3.3 PROCESS VARIABLES............................................................................................................................11

3.4 SETTING THE TEMPERATURE CONTROLLER.............................................................................................12

General settings ....................................................................................................................................... 12

3.5 CONTROL LIGHT FUNCTIONS..................................................................................................................13

3.6 FUNCTIONS OF THE BUTTONS................................................................................................................14

3.7 DEVICE SETTINGS.................................................................................................................................15

Sealing temperature entry........................................................................................................................ 15

Switch printer off and on........................................................................................................................... 15

Entry of a personnel code ........................................................................................................................ 16

Data entry................................................................................................................................................. 17

Select print data........................................................................................................................................ 24

3.8 INTELLIGENTSCAN,CONNECTION OF A BARCODE SCANNER.....................................................................26

3.9 SEALING SEAM TEST –“SEAL CHECK”....................................................................................................27

4TROUBLESHOOTING AND MAINTENANCE ......................................................................................... 28

4.1 TROUBLESHOOTING CHECKLIST.............................................................................................................28

4.2 CUSTOMER SERVICE.............................................................................................................................29

4.3 ALARM FUNCTIONS AND ERROR DISPLAYS..............................................................................................30

Alarm functions......................................................................................................................................... 30

Error displays............................................................................................................................................ 30

4.4 MAINTENANCE/CALIBRATION .................................................................................................................31

4.5 SPARE PARTS SERVICE .........................................................................................................................31

4.6 REPLACEMENT PARTS ORDERING –ALLOCATION OF ARTICLE NUMBERS ...................................................34

4.7 REPLACEMENT PARTS ORDERING -COMPREHENSIVE OVERVIEW..............................................................35

4.8 REPLACING WORN AND SPARE PARTS ....................................................................................................36

4.9 ADJUSTING THE PROCESS PARAMETERS ................................................................................................39

Temperature control................................................................................................................................. 39

Setting the serial interface transmission rate (baud rate)......................................................................... 41

5TECHNICAL DATA................................................................................................................................... 42

5.1 CIRCUIT DIAGRAM AND WIRING DIAGRAM HD 650 DC..............................................................................42

5.2 SPECIFICATIONS...................................................................................................................................43

6DECLARATION OF CONFORMITY......................................................................................................... 44

hd 650DC EcoPak

D

Introduction

9.693.024

Page 3

V 1.02

1 Introduction

1.1 Preface

First of all we would like to thank you for purchasing this sealing device.

In these instructions you will find information about using the device, servicing and care.

The sealing device is a microprocessor controlled rotary sealer with a printer for packaging sealable

transparent pouches and reels (med. packaging).

1.2 Legend

The exclamation mark in the triangle draws your attention to important notes in

the operating instructions, which must absolutely be observed.

This warning sign refers to measures that could result in danger to human health if

they are not observed. It is compulsory to observe it.

Tips with a hand symbol next to them relate to daily practice.

Please read these operating instructions carefully before commissioning so that you are

familiar with the capabilities of the device and you can make optimum use of its functions.

hd 650DC EcoPak

D

Introduction

9.693.024

Page 4

V 1.02

1.3 Important notice

In accordance with the intended use, the CE marking is displayed based on

the following EU directives: 2006/42/EC, 2014/30/EU and 2011/65/EU.

The Medical Device Directive 93/42/EEC and Medical Device Regulation

2017/745 (MDR) is not applicable to sealing devices.

The limit values of IEC 60601-1 must not be applied in repeated electrical

inspections.

The manufacturer accepts no liability whatsoever for damage caused by tests in

accordance with standards not listed in the declaration of conformity.

In the event of conversion work or interventions to the device undertaken without

the express written permission of the manufacturer, the warranty shall be deemed

void and any liability for physical or material damage shall be transferred to

the operator.

1.4 Cleaning

Before cleaning, disconnect the mains plug from the socket and disconnect the device from the power supply

with the plug.

Clean the device only with a dry or damp soft cloth and a mild cleaning agent. (E.g.: isopropanol, spirit, etc.)

Do not allow any water to find its way into the device.

Caution! Never wet clean the device!

These operating instructions apply to products from

the hd 650 DC EcoPak series.

hd 650DC EcoPak

D

Chapter 1

9.693.024

Page 5

V 1.02

1.5 Safety instructions

1.

Our products are in a flawless condition in terms of safety technology when they

leave the plant.

2.

To maintain this condition, the contents of these safety instructions as well as type

plates, labelling and safety instructions attached to the device must be observed

while handling the device (transport, storage, installation, commissioning, operation

and maintenance).

3.

This device is suitable for processing laminated films in the heat-sealing process.

See also chapter 2.1 "Intended use".

4.

Please check the packaging, and lodge a complaint for any damage with the carrier

or parcel service immediately, before installing the device.

5.

Before commissioning, ensure that the device does not show any evidence of

damage. In case of doubt, contact the manufacturer or a service partner authorised

by the manufacturer.

6.

Do not operate the device if the power cable or the power plug is damaged.

Do not use the device if it does not operate correctly or it is damaged in any way.

If the mains cable or the device have been damaged, the device must be repaired by

the manufacturer or by one of the manufacturer's authorised service partners.

7.

The device must be connected using the mains cable included in the scope of

delivery to a protective contact socket with a stable voltage. Operation on

IT networks is not permitted.

8.

Place the device on a stable base.

9.

The device must not be installed or operated in potentially explosive areas.

10.

If the sealing device is brought directly from a cold environment into a warm

environment, condensation may form. Wait until temperature equalisation has taken

place.

Starting up the device when it contains condensation causes danger to life!

11.

Repairs and the replacement of wear parts / spare parts must be performed only by

the manufacturer or by one of the manufacturer's authorised service partners.

12.

Switch off the device when it is not in use, or remove the power plug from the socket.

13.

Before cleaning: Disconnect from the mains! Clean the device only with a dry or

damp soft cloth and a mild cleaning agent. Do not allow any water to find its way into

the device. Caution! Never wet clean the device!

14.

Do not insert pointed or flat items into the import slot of the device. This can result in

damage to the device and instruments.

15.

Do not insert items into the louvres of the device. You may receive an electric shock

or the device could be damaged.

16.

Do not use the device if you have any doubts about its safety.

17.

The device must not be installed or operated by persons under 16 years of age.

hd 650DC EcoPak

D

Chapter 1

9.693.024

Page 6

V 1.02

18.

The device must not be operated unsupervised.

19.

It is forbidden to operate the device under the influence of drugs or alcohol.

20.

Keep hair, clothing and gloves away from moving parts! Loose clothing, jewellery or

long hair can be caught by moving parts.

21.

The device contains valuable materials that can be recycled and reused.

The device should therefore be disposed of at a public disposal facility near you.

The device has been labelled in accordance with Directive 2002/96/EC (WEEE)

on waste electrical and electronic equipment.

This directive governs the return and recycling of scrap equipment within the EU.

hd 650DC EcoPak

D

Chapter 2

9.693.024

Page 7

V 1.02

2 Before starting

2.1 Intended use

SEALING MATERIALS

Sealable paper pouches in accordance with EN ISO 11607-1/EN 868-4

x

Sealable pouches and tubes in accordance with

EN ISO 11607-1/EN 868-5 made of film and paper as per EN 868-3

x

Sealable pouches and tubes in accordance with

ISO EN 11607-1/EN 868-5 made of film and uncoated materials made of

polyolefins as per EN 868-9 (e.g. Tyvek®1)

x

Sealable pouches and tubes in accordance with

ISO 11606-1/EN 868-5 made of

PP fleece or PP non-woven

x2

NON-SEALABLE MATERIALS

Soft PVC films

Polyamide films

Coated HDPE

Aluminium-laminate film

Polyethylene films

Hard PVC films

Polypropylene films

1Tyvek® is a registered trademark of E.l. du Pont Nemours.

2Release and / or test required

hd 650DC EcoPak

D

Chapter 2

9.693.024

Page 8

V 1.02

2.2 Design and functions

Sealing process sequence

Step 1: After the med. packaging has been inserted, the feed is automatically switched on.

Step 2: The med. packaging is now fed and the sealing seam area is heated up to the set

sealing temperature by the heating units located at the top and bottom.

Step 3: The sealing seam, which is now heated, is pressed together by the sealing rollers

and sealed.

Step 4: The finished med. packaging is transported to the extraction side.

Step 5: If no item to be sealed is fed in, the feed switches off after

approximately 30 seconds.

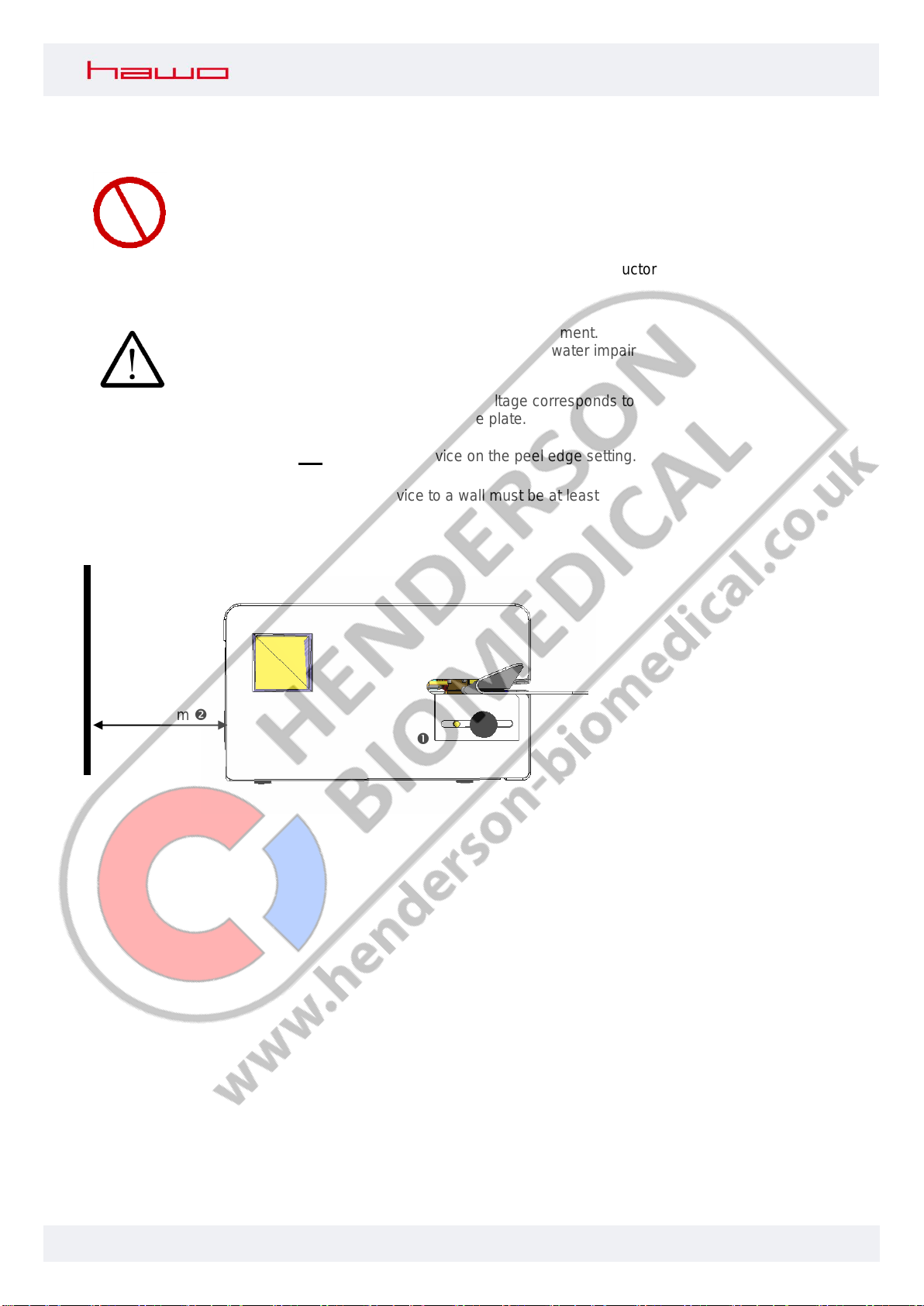

Mains connection

with fuse

Controller

Sealing edge adjustment

hd 650DC EcoPak

D

Chapter 2

9.693.024

Page 9

V 1.02

2.3 Installation

The device must not be installed or operated in potentially

explosive areas.

Only use sockets that are equipped with a protective conductor

and where the mains voltage is stable.

The device may only be installed in a dry environment.

Heavy dust, steam, dripping water or splashing water impair

the function of the device.

Please make sure that the operating voltage corresponds to

the specifications on the device's type plate.

Please do not transport the device on the peel edge setting.

The distance from the device to a wall must be at least

200mm!

200mm

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 10

V 1.02

3 Basic functions

3.1 Switching on the device

Plug the mains cable into the mains connection.

Switch on the device with the mains switch in position "1".

Set the required sealing temperature on the temperature controller as described in Chapter 3.3.

The device is heated up and ready for operation as soon as the set sealing temperature is

displayed.

Mains connection

with fuse

Controller

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 11

V 1.02

3.2 Operation

Set the required sealing edge width. After loosening the knurled screw, the lower insertion

plate can be continuously adjusted for sealing edge widths of 0 - 30mm.

Insert packaging into the device from the left via the insertion plate.

Remove the sealed package on the outlet side and allow to cool down briefly.

Check of the sealing seam

If leaks appear, the sealing temperature must be increased. If the film melts, the set

temperature is too high.

As per DIN 58953 -7, the suitable sealing temperature is to be determined by test

sealing.

3.3 Process variables

Sealing temperature

The temperature is monitored electronically by means of a temperature sensor.

If this varies from the set value by 5°C (requirements set out in DIN 58953-7),

the drive is locked.

Intelligent Scan

Serial port RS232

Sealing edge adjustment

Knurled screw

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 12

V 1.02

3.4 Setting the temperature controller

General settings

Switching on

the sealing device

Self-test runs for approx. 5 s

(see Chapter 2.3)

Until the set temperature has

been reached, after approx.

3-4 mins, the control light

flashes "okay"

Once the set temperature has

been reached, the control light

remains permanently on

Test the control lights and

the display

Software version indicator

Configuration test

Display current actual temperature

Selected actual temperature

is reached

The sealing device is ready

for operation

Control light "okay" flashes

Control light "okay" on

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 13

V 1.02

3.5 Control light functions

Function

Sealing device switched on

Heating-up phase

flashes

off

off

off

Sealing temperature

= ± 5°

on

off

on

off

Sealing temperature

<> ± 5°

off

on

off

on

Standby

off

on

off

on

Heating up after standby

or changing the set

temperature

flashes

off

off

on

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 14

V 1.02

3.6 Functions of the buttons

Menu level 1

Activation of menu level 2

Press 3 s

Activation of menu level 3

Press 7 s

Switch printer off/on

Enter personal

identification

Activation of "seal check"

Menu level 2

Entering sealing temperature

Temperature value + 1

Temperature value + -1

Confirm entry

Menu level 3

3.1

Sealing parameter view

3.2

Print data configuration

3.3

Data entry

Changeover

3.1 - 3.2 - 3.3

on

Entry value +1

Changeover

3.1 - 3.2 - 3.3

off

Entry value -1

Confirm entry

S

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 15

V 1.02

3.7 Device settings

Sealing temperature entry

Press button 3s

Change set temperature

Display for 1s

Display the current

temperature setpoint

Switch printer off and on

Press the button

Switch printer off

and on

Display for 1s

Display the current setting

Printer switched on

Printer switched off

S

Confirm entry

Confirm entry

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 16

V 1.02

Entry of a personnel code

Press the button

Select new code

Display for 1s

Displays the current personnel code

On this display, an

alphanumeric code has been

entered via the barcode scanner

Confirm entry

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 17

V 1.02

Data entry

Activate

Press button 7s

Toggle to data entry

Key lock

Activated

Enter 1 - 9999

Deactivated

Enter 0

Date and time

Enter the day

Enter month

Enter year

Enter hour

Enter minute

S

Confirm selection

Select data

Confirm selection

Confirm entry

Confirm selection

Confirm entry

Confirm entry

Confirm entry

Confirm entry

Confirm entry

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 18

V 1.02

Expiry date

Batch

Enter 0000 - 9999

On this display,

an alphanumeric code has

been entered via the barcode

scanner

Package content quantity

Enter 0 - 99

Confirm selection

Confirm entry

Confirm entry

Confirm entry

Confirm selection

Confirm entry

Confirm selection

Confirm entry

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 19

V 1.02

Sterilisation type

Select the sterilisation method

Steam

Ethylene oxide

Formaldehyde

Plasma

Dry heat

Ionising radiation

Personnel code

Select new code

Displays the current personnel code

Confirm selection

Confirm selection

Confirm entry

Confirm selection

hd 650DC EcoPak

D

Chapter 3

9.693.024

Page 20

V 1.02

Batch counter

Enter 0 - 9999

Select counting direction

If the counting direction is selected

downwards, a signal sounds

on reaching the value 0

Switch off batch counter

Counting direction upwards

Counting direction downwards

Switch off batch counter

Standby

Enter 0 –60min

If the motor does not start until

the set time is reached,

the temperature is automatically

set to 50°C / 122°F.

By briefly inserting a package, the temperature

returns to it previously set value. Once this is

reached, the sealing device is ready for use

again

Operating data

View operating hours and

the absolute batch counter

Select view

Operating hours

Absolute batch counter

Confirm selection

Confirm entry

Confirm selection

Confirm selection

Confirm entry

Confirm selection

Confirm selection

Table of contents

Other hawo Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

HUALIAN

HUALIAN HVC-260T/1A user manual

Atlantis

Atlantis TP-701 Operation manual & spare parts list

Valko

Valko CVE Series Instructions for installation, use and maintenance

GRAPHTEC

GRAPHTEC F-MARK2 quick start guide

ACME

ACME DTP-125 Operation, parts and safety manual

MSW Motor Technics

MSW Motor Technics MSW-MST25 user manual