07/20 Model VRKHO1 Page 2 of 4

Recommended Tools: 5/64” Hex Key wrench, 11/32” socket wrench or open-end wrench.

INSTALLATION PROCEDURE

Step 1: Remove grille, shut off water supply and disconnect power from 24VAC transformer.

Step 2: Remove bottom plate from fountain using 5/64” Hex key wrench.

Step 3: Remove sensor to be replaced using 11/32” socket wrench and disconnect leads to sensor.

*With older style 24VAC H.O. sensor, unplug sensor from cable assembly. Snip off the 3

position connect from cable assembly and tape off or, with a wire nut, insulate the white wire

(this wire, neutral, is not required with new style sensor.)

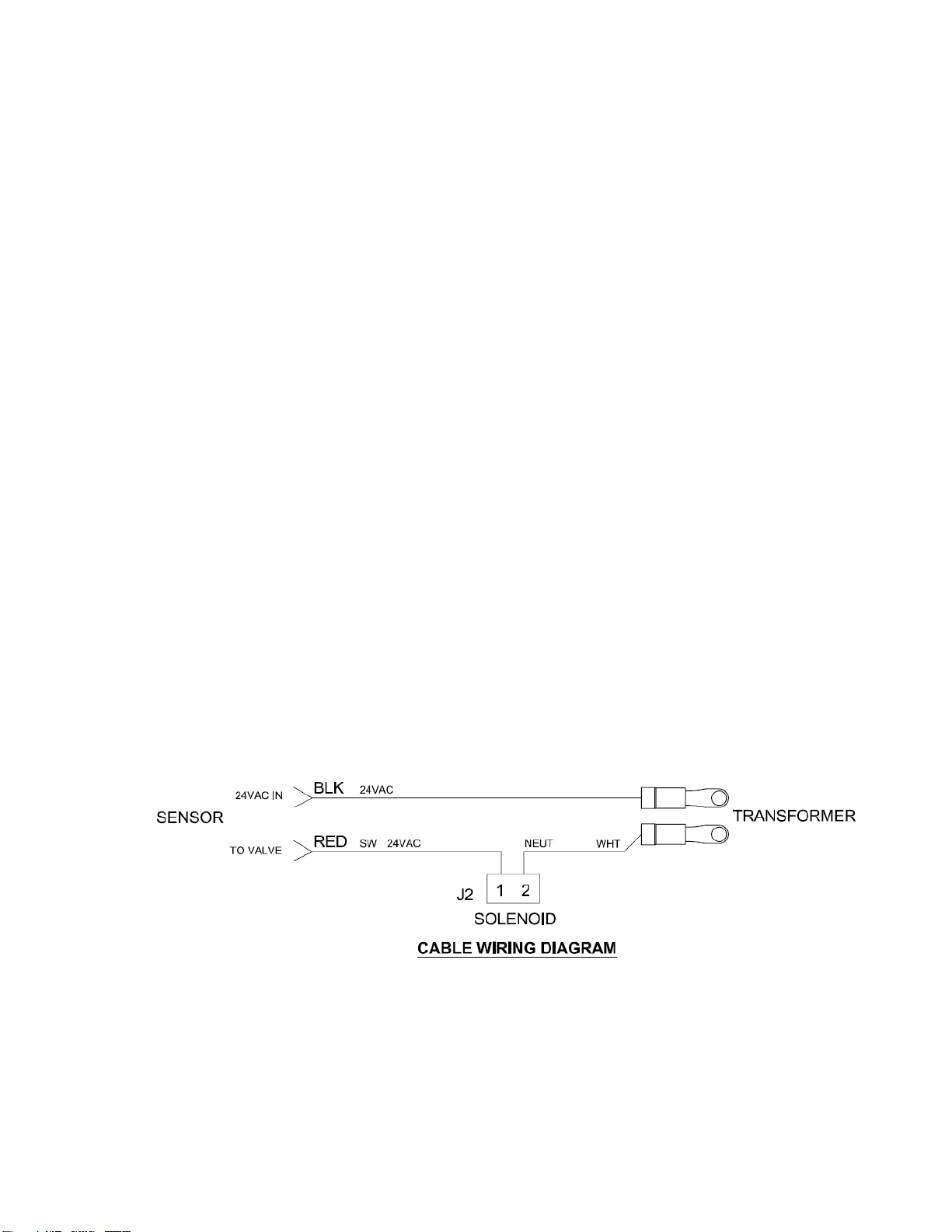

Step 4: Connect leads from cable assembly to sensor. Black lead to “24VAC IN” and red lead to “TO

VALVE”.

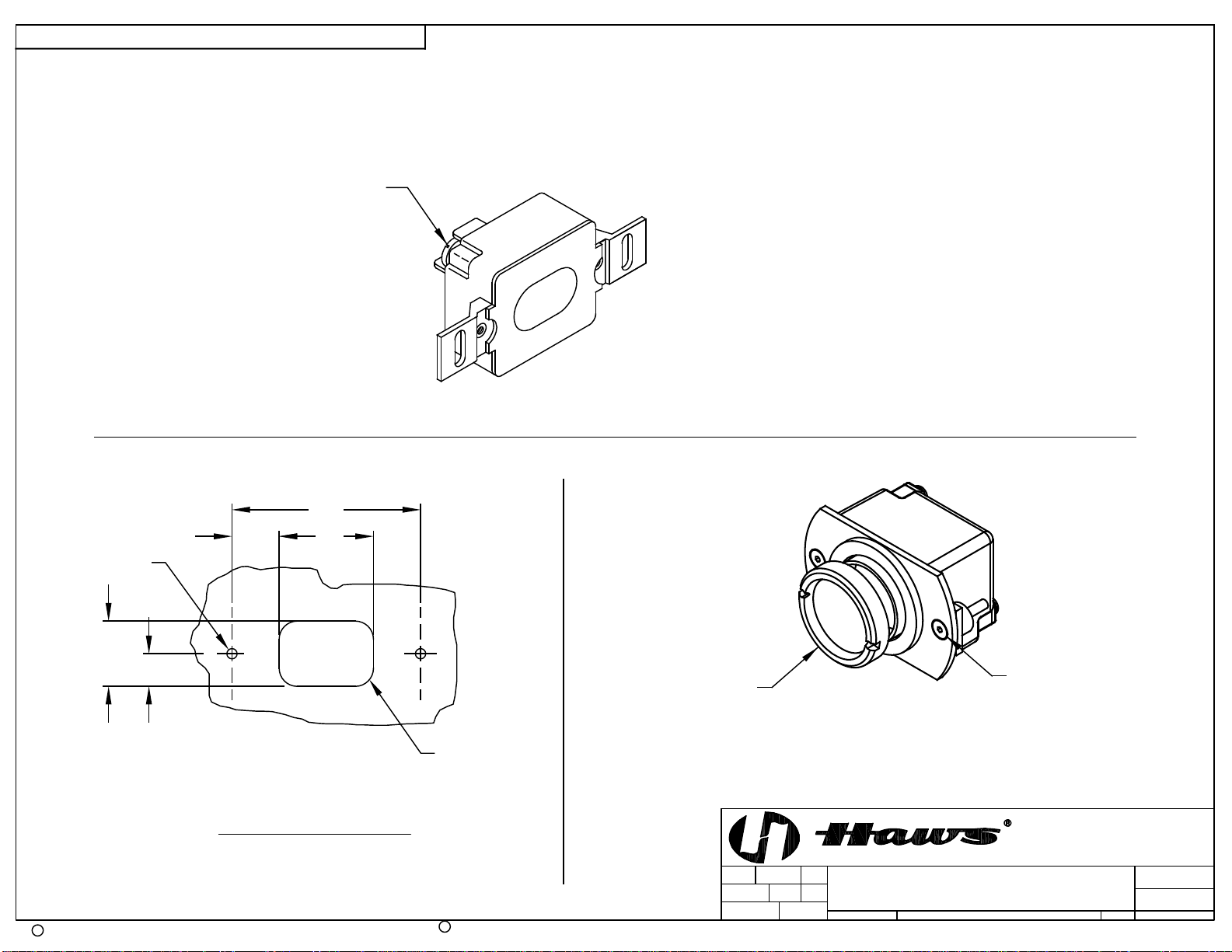

Step 5: Install sensor.

Step 6: Reconnect power to the 24VAC transformer. This will initiate the sensor’s “start-up mode”.

“Start-up mode”for the H.O. sensor will take approximately five (5) minutes to complete its

full cycle of self-calibration. It is important that no object is in front of sensor during this time.

A steady red light visible in the center of the sensor window indicates the sensor is in “start-

up mode”. If the red light is flashing, this indicates that the sensor is picking up an object.

Unless this object is a permanent fixture, (i.e. a wall, a plant, etc.), it must be removed from

the view of the sensor. The sensor will adapt itself around such permanent fixtures. In this

mode, the sensor will take up to ten (10) minutes to calibrate.

NOTE:

1. If the 24VAC power supply is interrupted for more than fifteen (15) seconds, the “start-up

mode” will automatically repeat itself when power is restored.

2. If the indicator light flashes three (3) times quickly, then three (3) times slowly and

continues to repeat this sequence, this indicates incorrect wiring or a short in the 24VAC

power supply.

3. When someone remains standing in front of the sensor for more than thirty (30) seconds,

the sensor will automatically shut off the water supply to the bubbler. To restart, stand to

the side for a moment, then return to a position in front of the sensor.

Step 7: Turn water supply on and adjust the bubbler’s flow using the black regulator mounted next to

the solenoid valve. Finally, check fountain for leaks. Verify the chiller turns off after water

reaches proper temperature. If there are any problems, refer to sensor’s Troubleshooting

Guide.

Step 8: Re-install bottom plate and grille.