HazeBase ultimate User manual

Instruction manual

www.hazebase.com

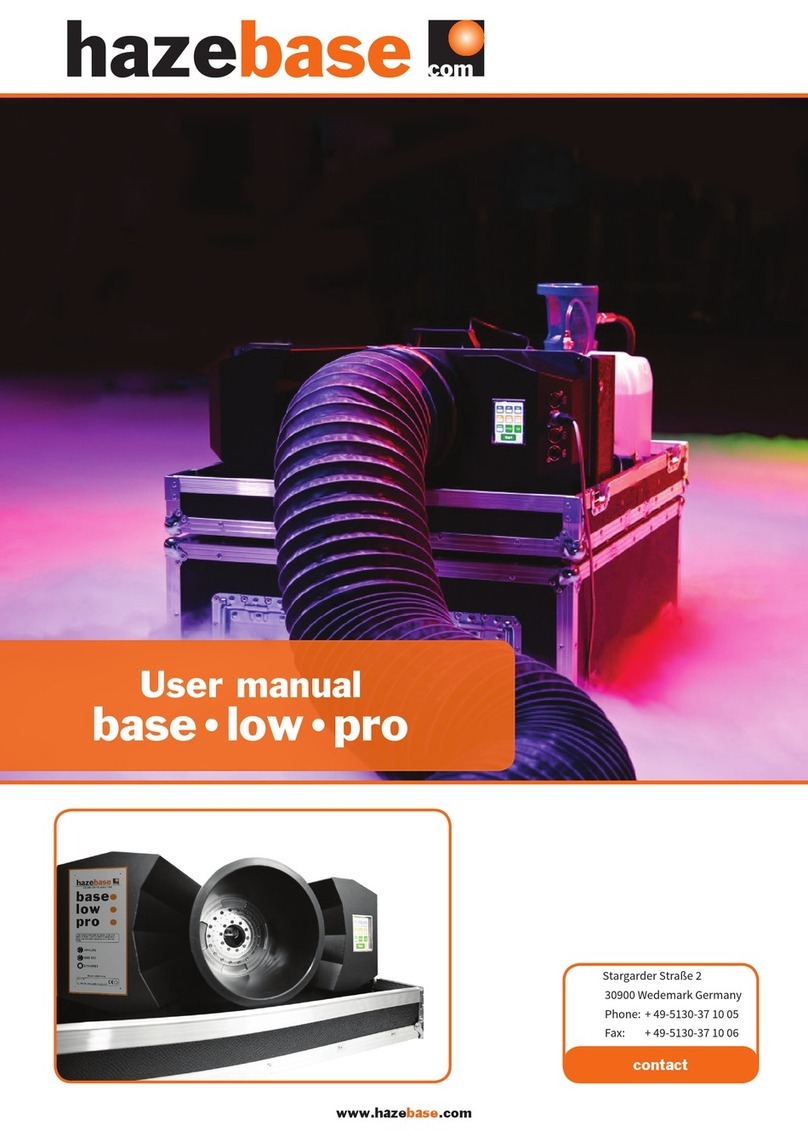

ultimate

Scope of delivery

1 ultimate

1 5l empty canister

1 tank cap with quick coupling

1 fluid hose with quick coupling and nozzle

1 power cable with TrueOne plug

1 tank holder

1 instruction manual

Please check that the delivery is complete.

1

ultimate

Table of Content

1. Introduction 3

2. Safety instructions 4

3. Description of the parts 5

4. Preparation 6

4.1 Selection of the location 6

4.2 Changing the canister 6

4.3 Hose cover 6

5. Fog fluids 6

6. Working with the ultimate 7

6.1 Control panel of the ultimate 7

6.2 Operating in stand-alone mode 8

6.3 Operation via DMX512/RDM 8

6.4 Operation via the AUX input 9

6.5 Operation via Modbus RTU 9

6.6 Operation via cable remote control (option) 10

6.7 Operation via radio remote control (optional) 11

6.8 Operation using the internal timer 12

7. Menu options items 13

7.1 Setting the fluid used 13

7.2 Setting the communication protocol of the XLR sockets 13

8. Care and maintenance 14

9. Troubleshooting 15

10. Technical data 16

11. Guarantee conditions 17

A Annex 19

2

ultimate

1. Introduction

The ultimate is a powerful fog machine with unique direct heating. It requires only the

shortest possible heating time (2 sec.) and also has a stainless steel housing with IP64

protection class.

The possible applications are varied and range from theme parks and fire drills to

large stages.

3

ultimate

2. Safety instructions

Very hot steam emerges from the mist outlet. Caution: Danger of burns !

During the fogging process, very hot fluid droplets may occasionally escape

from the fog outlet. Therefore, no persons or heat-sensitive objects may be

located within 1.5 m of the fog outlet.

Never handle the mist outlet during operation or when activated.

The appliance must be installed in a location that is not heat-sensitive. Keep

a minimum distance of 60 cm to flammable, combustible and heat-sensitive

objects.

The fog fluid used contains a glycol which burns with a slightly bluish,

almost invisible flame. Therefore, never fog into strong ignition sources

such as open fire.

Never open the appliance connected to a power source.

During operation, isolated hot fluid droplets may escape. Care should

therefore be taken to ensure that these cannot become a danger to people.

Maintain a safety distance of 3m from the mist outlet nozzle.

Do not ingest the fog fluid and keep it away from children. In case of eye

contact, rinse with plenty of water. If inadvertently taken, consult a doctor.

Spilled or splashed fluid can cause slipping. Pick up fluid and dispose of it

according to regulations.

Do not allow visibility to fall below 2m, you are responsible for people

moving around in the fogged room.

The mist produced can trigger smoke detectors.

The method used here to produce artificial fog is largely harmless and is used

worldwide in the entertainment sector. We are not aware of any case in which a

healthy person would have been harmed by using this artificial fog. Nevertheless,

we recommend that sick persons or persons with previous respiratory tract

damage or allergies avoid contact with artificial fog!

4

ultimate

3. Description of the parts

Front view

Rear view

5

Handle

Fog nozzle

Hose cover

Tank holder

Fluid canister

Membrane

keyboard with

OLED Display

Fluid Inlet (1)

DMX/RDM,

Modbus and

radio interface

(2)

Remote control Input (3)

Case ventilation

Power supply

ultimate

4. Preparation

4.1 Selection of the location

The location where the ultimate must be operated

●have good ventilation

●be free of vibrations and shocks

●consist of a non-flammable floor space

●be far enough away from easily flammable objects

●have an ambient temperature between 5°C and 45°C

4.2 Changing the canister

1. Release the plug-in sleeve from the quick coupling by pressing the locking

button

2. Remove the canister safety device by pressing the locking pins

3. Remove the canister from the tank holder

4. Unscrew the tank cap from the empty canister and screw it onto a new or

full canister.

5. Slide the canister back into the tank holder.

6. Refasten the canister lock to the tank holder

7. Replace the connector sleeve in the fuel filler cap.

4.3 Hose cover

The ultimate is equipped with a hose cover (100mm). Please only use hoses that can

cope with the temperatures. The hose may only be pushed onto the adapter a

maximum of 50mm, so that the fog nozzle is surrounded by enough fresh and cold

air.

5. Fog fluids

Two different fluids are available for the ultimate (see chapter 7.1)

base*F is a very long lasting fluid

base*R is a very fast dissolving fluid

The type of fluid selected must be set on the unit, otherwise the fluid may

not evaporate correctly.

6

ultimate

6. Working with the ultimate

The ultimate is a fog machine with a strong output. From small fog clouds to dense,

room-filling fog, any desired effect can be achieved. The fine adjustment of the pump

allows fog output settings between 1% and 100%.

6.1 Control panel of the ultimate

The ultimate is operated using the four keys (Menu, Minus, Plus, Confirm) and the

OLED display. In the corners of the display are the menu fields, in the middle the

value field, which shows the value of the selected menu field. The individual menus

are selected by turning the menu key counter-clockwise. The corresponding value can

then be changed with the plus and minus keys and then saved with the confirmation

key.

7

Menu Fields

Confirmation button

Plus buttonMinus key

Value field

Menu key

ultimate

6.2 Operating in stand-alone mode

The simplest case of control is the stand-alone mode. For this purpose, the pump

value is set to the desired value and the confirmation key is pressed. The machine

immediately starts to heat up the heating element and starts the fogging process.

The pump value can also be changed during the fogging process.

Press the confirmation key again to stop the fogging process. A reheating process

flushes out all fluid residues still in the heating element. The heating is then switched

off again.

6.3 Operation via DMX512/RDM

When operating via DMX512, the

XLR input (2) must first be set to

DMX (see chapter Options).

As shown, "DMX" appears in the

upper right-hand menu field. The

DMX address can be changed with

the plus and minus keys and must

then be saved with the confirmation

key.

If a valid DMX signal is present, this is indicated by "active" in the top center. The

currently read pump value can be displayed by selecting the pump menu item. If the

value received is greater than zero, the ultimate starts the fogging process and stops

it at zero again.

Via RDM the ultimate is both configurable (DMX address) and readable (error or

temperature data). Furthermore, a firmware update can be carried out via this RDM

input.

8

DMX signal DMX mode

ultimate

6.4 Operation via the AUX input

The ultimate has an aux-input (3), with which the

machine can be controlled via 0-10V. The pin

assignment of this input is shown on the right. Pin 1

and 4 are used to supply possibly connected

consumers (12V, max. 100mA). A voltage between

1V and 10V can be applied to pin 2. From a voltage

of 1V the fogging process starts. The pump value is adjusted according to the applied

voltage. 10V at the input corresponds to the maximum set pump value. Below 1V the

machine is switched off again.

Pin 3 is an output (24V, 50mA) that indicates whether the machine has a fault.

6.5 Operation via Modbus RTU

When operating via Modbus RTU, the XLR input (2) must first be set to Modbus (see

chapter Options). The interface is designed as RS485 half-duplex connection.

The communication parameters of the connection can be set in the "Modbus"

submenu. First the menu item Modbus must be selected. “Enter" is displayed in the

value field. The sub-menu for Modbus is entered with the confirmation key.

9

ultimate

In the Modbus submenu, the menu fields are replaced. The address of the unit can be

set at the top left. The baud rate of the communication is set at the bottom left and

the data width, parity and stop bits at the bottom right. The settings are made in the

same way as in the main menu.

To exit the sub-menu, select the menu item "exit" and confirm with the confirmation

key.

In the appendix you will find the definitions of the registers that are necessary for

programming the PLC.

6.6 Operation via cable remote control (option)

When operating via cable

remote control, the XLR input

(2) must first be set to Remote

(see chapter Options).

When the wired remote control

is plugged in, the ultimate

automatically recognizes that

an analogue wired remote

control has been plugged in.

On the cable remote control

there is a switch and a potentiometer for adjusting the pump value.

10

ultimate

6.7 Operation via radio remote control (optional)

When operating via radio

remote control, the XLR input

(2) must first be set to Remote

(see chapter Options).

When the radio remote control

is plugged in, the ultimate

automatically recognizes that a

radio remote control has been

plugged in.

Up to 60 different hand transmitters can be taught on the machine. To do this, the

sub-menu "Remote" must first be selected.

In the Remote submenu, the

menu fields are replaced. The

channel (key on the handheld

transmitter) can be selected in

the top left-hand corner. A

new remote control transmitter

is tuned in at the bottom left

and the tuned-in remote

controls are deleted at the

bottom right.

A new handheld transmitter is trained as follows. First select the menu item add and

confirm it with the confirmation key. "Adding" now appears at the bottom left. The

machine is now waiting for a valid radio signal. To do this, press any key on the

hand-held transmitter. The teach-in process is now complete and "add" appears

again at the bottom left. Afterwards you can still select the key and save it.

To delete the handheld transmitters which have already been tuned in, select the

menu item "del" and confirm it. "Deleting" now appears in the bottom right-hand

corner. The deletion process is now in progress. After the deletion process has been

successfully completed, the display returns to "del".

To exit the sub-menu, select the menu item "exit" and confirm with the confirmation

key.

11

ultimate

6.8 Operation using the internal timer

To set and activate the internal

timer, you must first switch to

the Timer sub-menu.

Here too, the menu fields are

changed accordingly. In the

upper left corner you can now

set the pump value that is used

in timer mode. At the bottom left

the waiting time can be set in

0.1 minute (6 sec.) steps. Similarly, the fogging time can be set in steps of seconds at

the bottom right.

To activate the timer, you can press the confirmation key during either the wait time

or the fog time. This enables or disables the timer. Depending on the selected menu

item, the timer starts with the waiting time or the fogging time.

The pump value can still be changed even when the timer is activated.

If you exit the "Timer" sub-menu, the timer is also deactivated again.

12

ultimate

7. Menu options items

In the "options" sub-menu, you can set the type of fluid used and also select the

protocol of the XLR sockets.

7.1 Setting the fluid used

After activating the submenus,

the menu fields in the corners

are changed. The menu item

"Fluid" now appears at the

bottom left and the menu item

"Input" at the bottom right.

In the menu item "Fluid" you

can choose between the fluid

type base*F and base*R. Set the

desired fluid type and confirm this with the confirmation key.

ATTENTION ! The fluid types have different boiling points, so that a wrong

setting can lead to spitting of hot fluid drops or to unpleasant odors when

nebulizing. Therefore, always set the type of fluid used.

7.2 Setting the communication protocol of the XLR sockets

In the menu item "Input", you can select the communication protocol of the XLR

sockets. The following protocols can be selected here:

DMX/RDM

Modbus

Remote (cable or radio)

Please select the desired protocol and confirm it with the confirmation key.

13

ultimate

8. Care and maintenance

●Avoid running the ultimate without fluid. Otherwise, the pump will run dry.

●Avoid overheating the unit due to direct sunlight or direct spotlight. The

permissible ambient temperature can be found in the technical data.

●Immediately wipe up any escaped fluid.

●Check the suction strainer in the tank from time to time. Clean it or replace

it.

●If the same fluid canister is used frequently, you should rinse it thoroughly

before each filling with fresh fluid. In this way you avoid contamination.

●The tank holder can be unscrewed for permanent installation. Please note:

The difference in height between the external canister and the machine

must not exceed 1.5 meters, otherwise the pump will not be able to suck in

the fluid).

●If necessary, clean the surface of the device with a suitable, solvent-free

cleaning agent

●Check the seals on the machine from time to time. Defective seals or

housing parts can result in the machine no longer having moisture

protection (IP64).

●PLEASE NOTE: The vaporizer of our foggers does NOT need to be

cleaned! Cleaning liquids that are available on the market can damage the

vaporizer! In this case the guarantee becomes void.

14

ultimate

9. Troubleshooting

The ultimate does not fog

Check external control

Check power source

Check fluid quantity

Check the connection on the fluid tank for leaks

Check suction strainer in the tank for contamination

Check fluid hose and connector for leaks

The ultimate suddenly switches off

The temperature inside the appliance is too warm. Remove the external

heat source. The unit switches on again after it has cooled down.

The ultimate hums loudly when fogging

The pump runs dry. This must be avoided at all costs.

Refill fluid

Check hose and coupling, if necessary re-engage.

The ultimate shows the error message "machine too hot" in the display

The temperature inside the unit is too high. After cooling down, the error

disappears again.

The ultimate shows the error message "vaporizer faulty" in the display

The vaporizer module has an error or no longer responds. In this case the

unit must be sent for service.

15

ultimate

10. Technical data

16

Device type

Directly heated evaporator fog machine

Performance

200-250V~, 50-60 Hz, 3300 W

(PowerCON TRUE1)

Heating time

approx. 2 seconds

Fluid consumption

up to 90ml/min

Tank capacity

5 liters

Operation

1.3" OLED display, membrane keyboard

Interfaces

5pin XLR In/Out, Aux-In (Analog 0-10V)

Supported Protocols

DMX512, RDM, Modbus RTU

direct SPS control

Control

DMX, analogue, integrated timer, stand alone

Accessories (option)

Radio remote control, cable remote control

Protection class

IP64

Fluid types

base*F (long lasting)

base*R (fast resolution)

Dimensions (LxWxH)

487 x 210 x 235 mm

(height with tank holder 388mm)

Weight

12,5 kg

Ambient temperature

+5°C to 45°C

ultimate

11. Guarantee conditions

For the purchased fog machine ultimate hazebase provides a guarantee according to

the following conditions:

1. We will remedy free of charge in accordance with the following conditions (nos.

2 to 6) any damage or defects in the device which are demonstrably based on

factory defects if they are reported to us immediately upon discovery and within

24 months of delivery to the end user. A guarantee obligation is not triggered by

minor deviations from the nominal quality, which are insignificant for the value

and usability of the device, by damage from the effect of water and generally

from abnormal environmental conditions or force majeure.

2. The guarantee is provided in such a way that defective parts are repaired free of

charge or replaced by faultless parts at our discretion. Devices for which a

warranty service is claimed with reference to this warranty are to be handed

over to us and sent free of charge.

The proof of purchase with purchase and/or delivery date must be presented.

Replaced parts become our property.

3. The warranty claim expires if repairs or interventions are carried out by persons

who are not authorized by us to do so or if our devices are fitted with

supplementary or accessory parts which are not matched to our devices.

Furthermore, the warranty claim expires if a fog fluid other than the original

hazebase fog fluid is used. If the units are sent to us without prior removal or

emptying of the fluid canister, the warranty will also expire, as well as in the

case of proven disregard of the operating instructions or errors due to improper

treatment/handling as well as damage due to the use of force.

4. We do not grant any performance claims for components or component groups

that are subject to natural wear and tear or normal wear and tear. In particular,

all fluid-conveying parts such as pumps and heating elements are deemed to be

wearing parts. A goodwill regulation will be checked in each individual case.

5. Warranty services do not extend the warranty period, nor do they initiate a new

warranty period. The warranty period for installed spare parts ends with the

warranty period for the entire device.

17

ultimate

6. If a damage or defect cannot be remedied by us, or if we refuse or unreasonably

delay the remedy, we will, at the request of the end user, within 6 months of the

purchase/delivery date either

a. replacement delivered free of charge or

b. the reduced value is reimbursed or

c. take back the equipment against reimbursement of the purchase price, but not

exceeding the usual market price.

7. Any further or other claims, in particular those for compensation for damages

incurred outside the device, are excluded - unless liability is mandatory by law.

18

ultimate

AAnnex

19

Table of contents

Other HazeBase Fog Machine manuals