HBOC/C and HBOR/C quick guide 001 EN December 2021

Electrical connections

HBOC/C and HBOR/C can supply a magnetic valve, or it can be connected to the central control via the

sensor's control/alarm output. See the diagrams below for the two

HBOC/C and HBOR/C - mk1 (DC version –DC supply and DC output on cable)

DC version

HBOC/C and HBOR/C –mk2 (AC version –AC/DC supply and AC/DC output on cable)

AC version

The sensor controls the valve independent of other parts of the system. The function starts to work when

the supply is connected. The control function can be activated/deactivated via an external run signal with

"Run in" (pin 5) or work continuously

Quick guide for OIL MANAGEMENT SWITCHES

Covers HBOC and HBOR both mk1 and mk2 versions.

Setup information is available in the manual which is available under download on www.hbproduct.dk

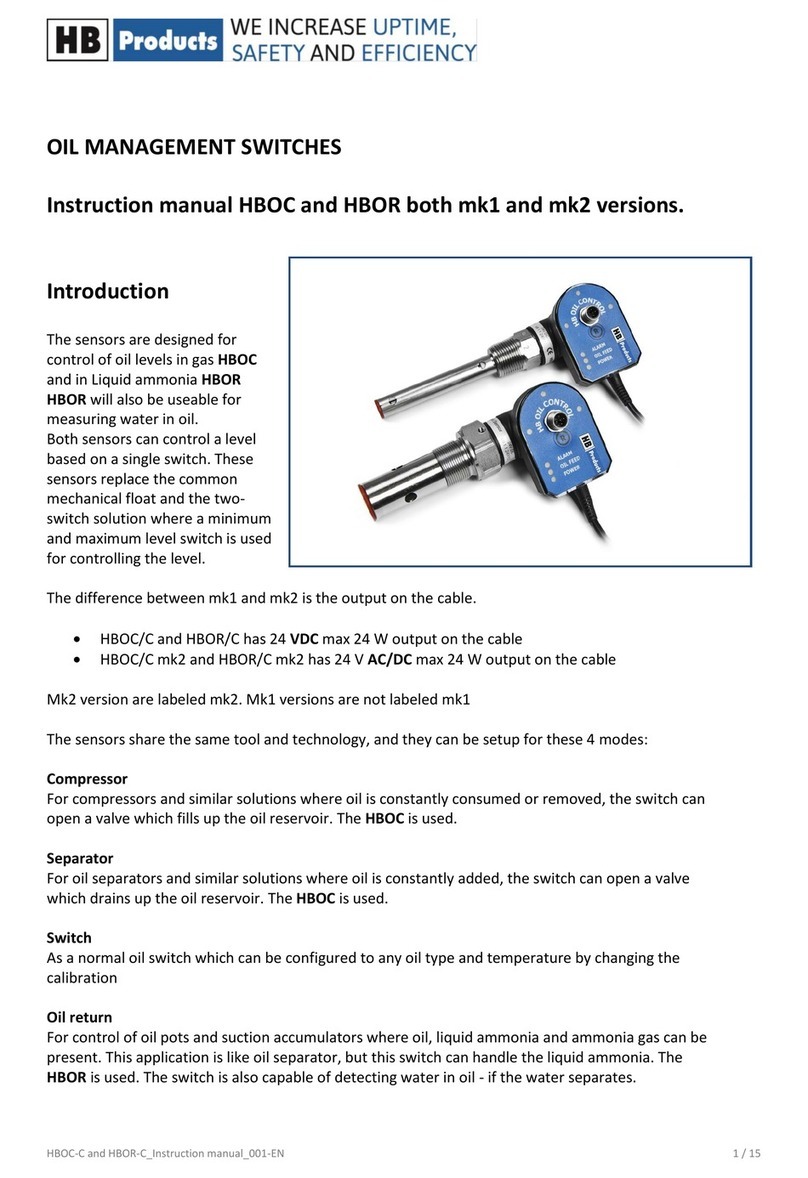

Introduction

The sensors are designed for control of oil levels in

gas HBOC and in Liquid ammonia HBOR

HBOR will also be useable for measuring water in

oil.

Both sensors can control a level based on a single

switch. These sensors replace the common

mechanical float and the two-switch solution

where a minimum and maximum level switch is

used for controlling the level.

The difference between mk1 and mk2 is the

output on the cable.

•HBOC/C and HBOR/C has 24 VDC max 24 W output on the cable

•HBOC/C mk2 and HBOR/C mk2 has 24 V AC/DC max 24 W output on the cable

Mk2 version are labeled mk2. Mk1 versions are not labeled mk1

Installation

The sensor is mounted either on a compressor or an oil separator. On a compressor, an adapter flange can

be provided as an accessory. The sensor is sealed with Teflon tape or liquid gasket before installation.

Dependent upon the thread type, the gasket consists of:

•NPT thread = Teflon tape or liquid gasket

•BSPP & UNEF = Aluminum washer/gasket