UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

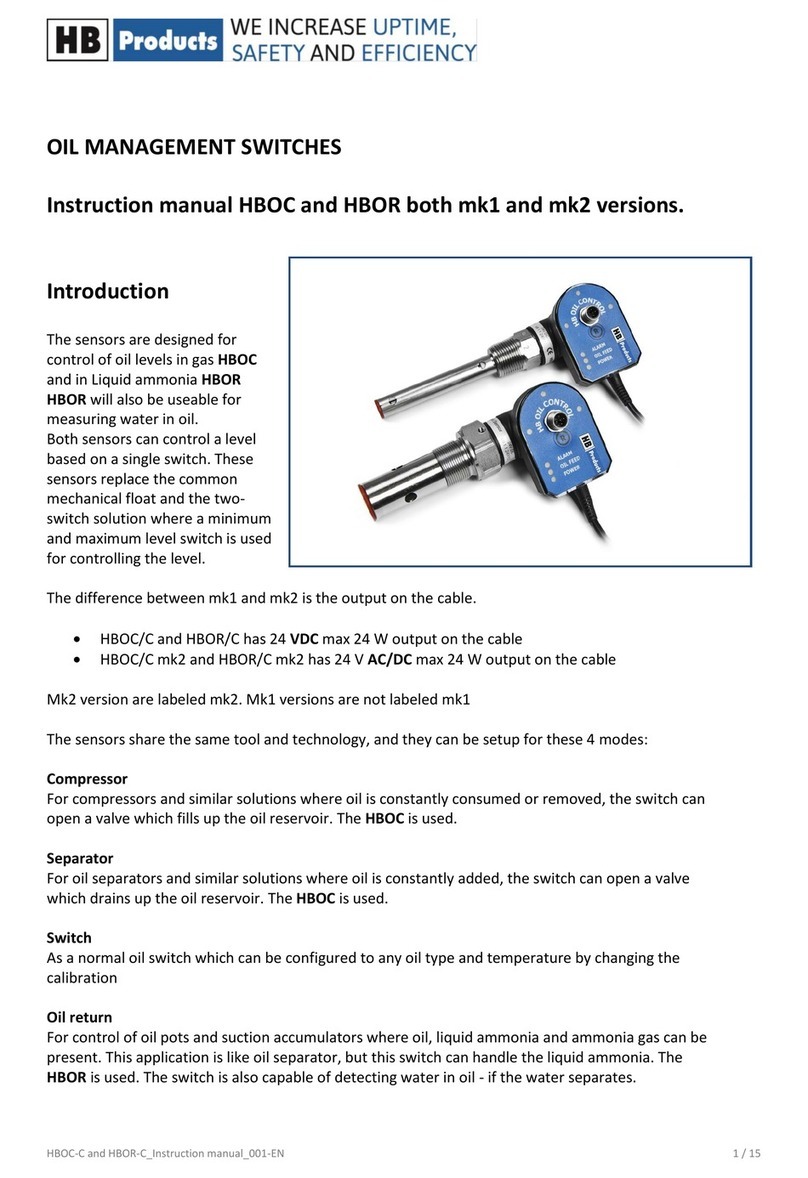

Introduction

HBSR is a level switch for detection of liquid

refrigerants, including NH3 , HFC and brine.

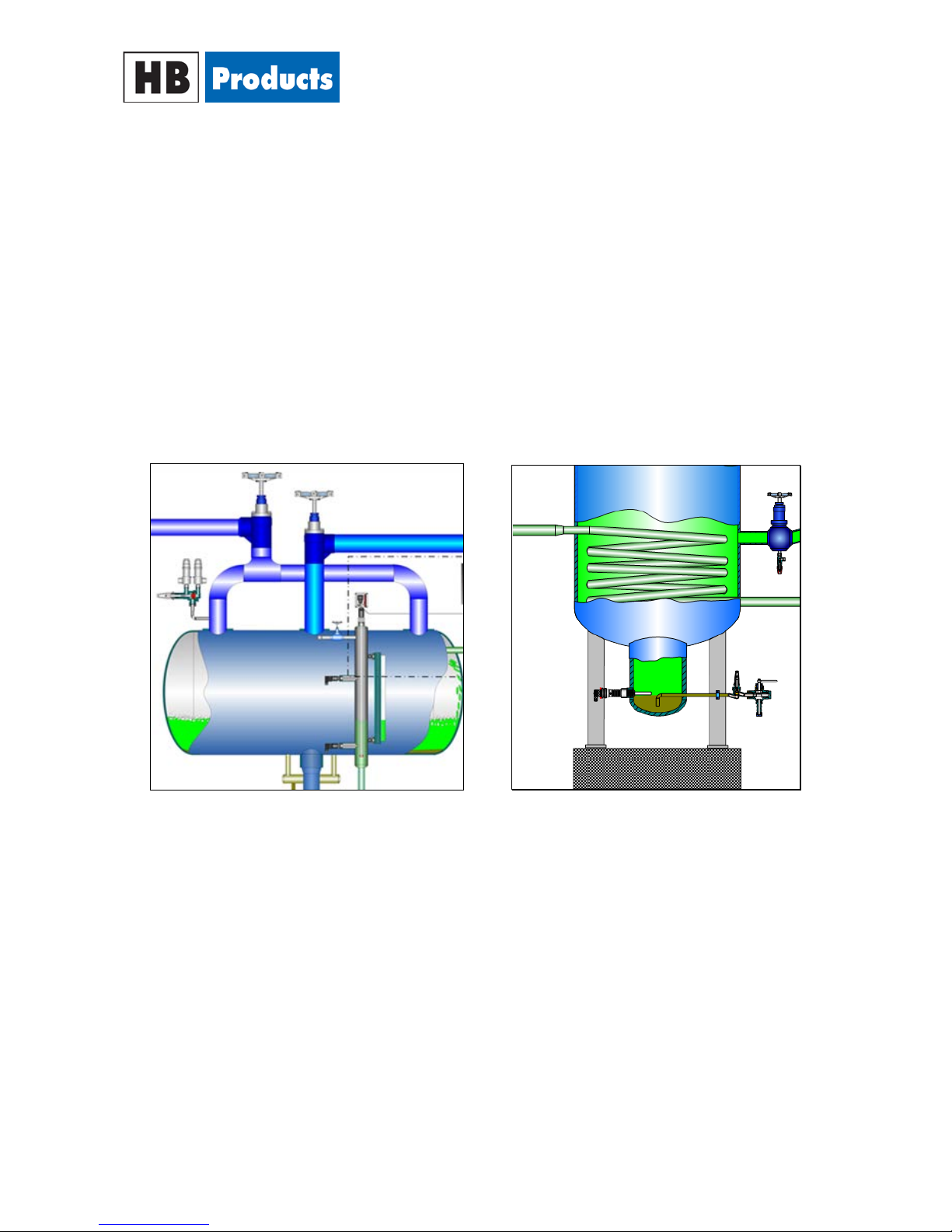

Typically it is installed in/on the reciever, pump

separators, economisers, heat exchangers, or as

an oil-accumulation-alarm in ammonia systems.

The sensor's measurement principle makes it

unique for these purposes, since the properties

of the measurement principle enable it, among

other things, to detect phase separation between

oil and ammonia.

The sensor is also built to resist high pressure and

low temperatures.

HBSR is not suited for use on CO2systems. Here

the HBSC2 switch type must be used.

Measurement principle

The sensor is a capacitive sensor. The capacitive measurement principle is based on the electrical

properties in the proximity of a capacitor. A capacitor is an electrical component that is capable of building

and sustaining an electrical charge.

Principally, a capacitor consists of two plates.

When a charge is applied to a plate, the other

plate will be charged with the opposite polarity

and retain the charge until it has been grounded.

The magnitude of the charge (the capacitance)

that can be generated depends, among other

things, on what is found between the plates.

The substance between the plates is referred to

as a dielectric.

Rather than two plates, the sensor for level

measurement is shaped as a cylindrical rod.

When liquid covers the sensor, the measured

capacity changes.

The conductivity of a material can vary depending

on temperature, chemical composition, and the

homogeneity of the material, and therefore it can

in some cases require a different factory

calibration.

HB Products sensors are calibrated so that they differentiate between conductive and non-conductive

liquids.

In refrigeration systems, the oil, HFCs and liquid CO2are not regarded as conductive fluids, whereas

refrigerants such as ammonia, and brine are regarded as conductive.

Design

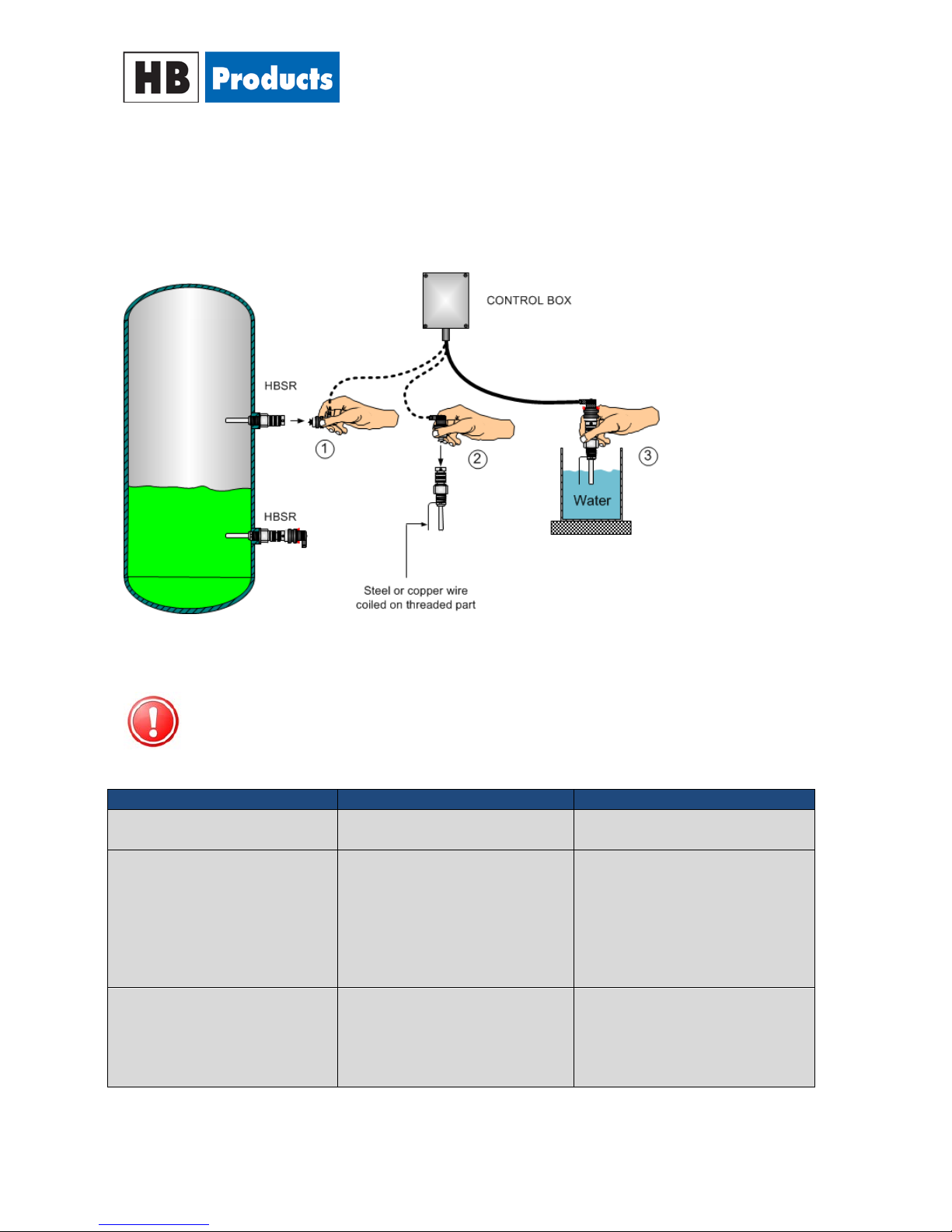

The sensor consists of a mechanical part and an electronic part. These are easily separated by loosening 2

grub screws, or for mechanisms with mounting tabs, by pressing the electronic part in towards the

mechanical part and turning the housing counter-clockwise until a wave washer presses it out of the

mounted position. The electronic part is designed in accordance with IP65 waterproof rating and so as to

withstand vibrations. The mechanical part is produced in AISI304/PTFE and tested to withstand high

pressure.