HB Products HBSC2-SSR User manual

Instruction manual switches with large electronic unit 05 March 2021

Instruction manual

HB switches with large electronic unit

Covers: HBSC2-SSR, HBSR-SSR, HBSO-SSR

Functionality

The switches are used for detecting liquid in gas or air (HBOR detect oil in liquid ammonia). The mechanical elements have

different design because they are optimized to different liquids. The switches use the capacitive measuring principle and react to

the difference in dielectric constant between liquid and gas.

The switches have different calibration and parameter settings in the electronic unit. The basic electronic unit exist in two

versions 24 V and 90-240 V, and it must match the mechanical part.

Standard switches available from HB-products

Switches from HB-products are suited for different fluids, different temperature ranges and supply voltages. There is a special

program for oil switches. The two tables show the recommended products.

Oil switches

Instruction manual switches with large electronic unit 05 March 2021

Liquid switches

What can happen if the switch is installed outside the recommended

temperature range

The HB-products web page has temperature specifications for the switches, and these will be different from the recommended

temperature specifications. The switches will operate outside the recommended range but will not be optimal. For oil switches

the switch point will change with temperature and this means there is a risk that the switch will not detect oil or detect without

oil. For sensors installed in low temperatures condensation might occur and water run into the connection between the

mechanical and electrical unit. This might disturb the measurement. Sensors designed for low temperatures has treaded union

which is waterproof.

Labelling:

The switches are delivered as NO/NC. The switches setting is printed on the small silver label on the switch together with the

type code. On the same label you find a combined version number and manufacturing date and in second row a unique

production number.

VERSION:VU10 DATE:080319 DDMMYY

Production no. 400000

Instruction manual switches with large electronic unit 05 March 2021

Safety Instructions

CAUTION! Read the instruction manual before commencing work! Heed all warnings. Installation of HBSR requires technical

knowledge of both refrigeration and electronics. Only qualified personnel should work with the product. The technician must be

aware of the consequences of an improperly installed sensor and must be committed to adhering to the applicable local

legislation.

If changes are made to type-approved products, this type approval becomes void. The product's input and output as well as its

accessories may only be connected as shown in this guide. HB Products assumes no responsibility for damages resulting from

not adhering to the above.

Intended use, conditions of use. The switch is manufactured to detect liquid. If the switch is to be used in a different way or for

another purpose, and if the operation of the product in this function is determined to be problematic, prior approval must be

obtained from HB Products.

Prevention of collateral damage. Make sure that qualified personnel assess any faults and take necessary precautions before

attempting to make replacements or reparations, to avoid collateral damage.

Disposal instructions: The switch is built so the modules can easily be removed and sorted for disposal.

Electrical connection

The switch exists in two versions one supplied with 24V AC/DC and one with 90-240V AC. The switch is delivered as NO

(normally open) or NC (normally closed) and this refers to the contact in the switch in dry conditions. The 24 V version switch

can be changed between NO and NC –this is described in a later section. The switch is connected to the power source on pin1

and pin 2. The contact is potential free relay and it is connected to pin 3 and pin 4

24 V

90-240 V

LED indication

Male M12

1 Brown +24 VDC or 24 V AC

2 White - common or 24 V AC

3 Blue Output potential free

4 Black Output potential free

5 Grey Communication

1 Brown 90-240 V AC

2 White 90-240 V AC

3 Blue Output potential free

4 Black Output potential free

3x green LED´s indicate liquid detection

Yellow LED “RELAY” or “ON” indicates closed contact between pin 3 and pin4

Green LED “POWER” indicate power is connected and switch is active when

flashing

Irrespective of the output function NO/NC, the three LEDs are activated

when liquid is detected.

Some switches have a LED labeled “ALARM” which is not in use.

Instruction manual switches with large electronic unit 05 March 2021

Mechanical installation

The switch is installed in a vessel or compressor, using Teflon tape or liquid sealant, for those with NPT thread. Switches with a

straight tread is delivered with a washer kept in place by an O-ring or a plastic spring. These two should be removed before

installation.

Switches installation in ammonia, water and alcohol has a mechanical element covered with PTFE. This is a part of the switch

and should remain on when installed.

All switches can be installed horizontally except for switches in cold conditions, where the liquid has high viscosity. For these

switches, make sure liquid can drain from the switch. This can be done by sloping the switch 1- 5 degrees downwards

Long weld adapters should be avoided because gas pockets can build up and disturb the measurement

Switches pointing upwards can collect liquid which disturb the measurement.

Apply Teflon or liquid gasket on sensors with a conical thread.

For other thread types, solid gasket is used.

Fasten the mechanical part with a suitable spanner

(tightening torque 80-150 Nm, depending on thread type).

Mounting the electronic unit

The electronic unit is mounted with either a threaded union or with two set of screws in a V-track. The threaded union is mainly

used for switches operating in cold conditions. The set screws are tightened with a torque of 5 Nm and the threaded union is

tightened firmly by hand or by using pliers to secure a good electrical connection. For cold installations where condensation

occur the treaded union should be used to avoid poor contact between electrical contact between mechanical and electrical

unit.

Disconnect the electronic unit by loosening the

treaded union or the two set screws

In cold conditions the switches can be installed

with a downward slope

Instruction manual switches with large electronic unit 05 March 2021

Electrical specifications

Supply AC/DC 24V ± 10 % or 90-240V AC

Connector: M12 IEC 61076-2-101

•5 pin A type for 24 V

•4 pin B type for 90-240 V

Relay output

•24 V current max 1A

•90-240 V max 40 W

Changing from NO to NC and NC to NO

Setting up the switch

The HB tool has two pages of settings. Most fields

will be shown in grey when they are not

relevant/active with the setting chosen. Detailed

explanations of the individual fields will show up

when the mouse is moved over the field. Only the

latest version of the tool has this feature.

To change the sensor from NO to NC or opposite

you connect the switch to a pc using the USB cable

Under basic settings you can change the “alarm

output signal” in the dropdown menu. After

changing the value, you store the data by clicking

“save to sensor”. The data is then saved and stored

in the sensor and remains there even when the

power supply is disconnected.

Connecting the sensor

All sensors are connected to a PC using an USB/M12

cable

Here you select NO or NC

Other parameters can be

changed if needed

Instruction manual switches with large electronic unit 05 March 2021

Fault detection

In case of fault, it is normally enough to replace the electronic part.

Fault

Possible Reason

Correction of fault

No LED is on when the sensor is

in the medium.

No supply to the sensor or defective

cable/plug.

Check the power supply or replace

the power supply cable.

Output and 3xLEDs are

constantly activated, even

though liquid is not in contact

with the sensor.

Water or moisture shortcut the

sensor between the mechanical and

electrical part

Use a sensor with treaded union or

dry the parts and make a suitable

cover against water

Sensor repair:

The sensor electronics are completely embedded and can therefore not be repaired.

In case of faults with the sensor, it will typically only be necessary to replace the electronics.

If you have a faulty product, please contact the HB Products dealers/distributors.

Their complaints procedures must be followed before returning the sensor.

Further information

For further information, please visit our website, www.hbproducts.dk, or send an email to: supp[email protected].

This manual suits for next models

2

Table of contents

Other HB Products Switch manuals

HB Products

HB Products HBSC2 User manual

HB Products

HB Products HBSC2 User manual

HB Products

HB Products HBSC2-SSR User manual

HB Products

HB Products HBOC User manual

HB Products

HB Products HBOR User manual

HB Products

HB Products HBSC2 User manual

HB Products

HB Products HBSR User manual

HB Products

HB Products HBOC/C User manual

Popular Switch manuals by other brands

KTI Networks

KTI Networks KS-2240 installation guide

Castelle

Castelle Office Connect user guide

Monroe

Monroe 636 instruction manual

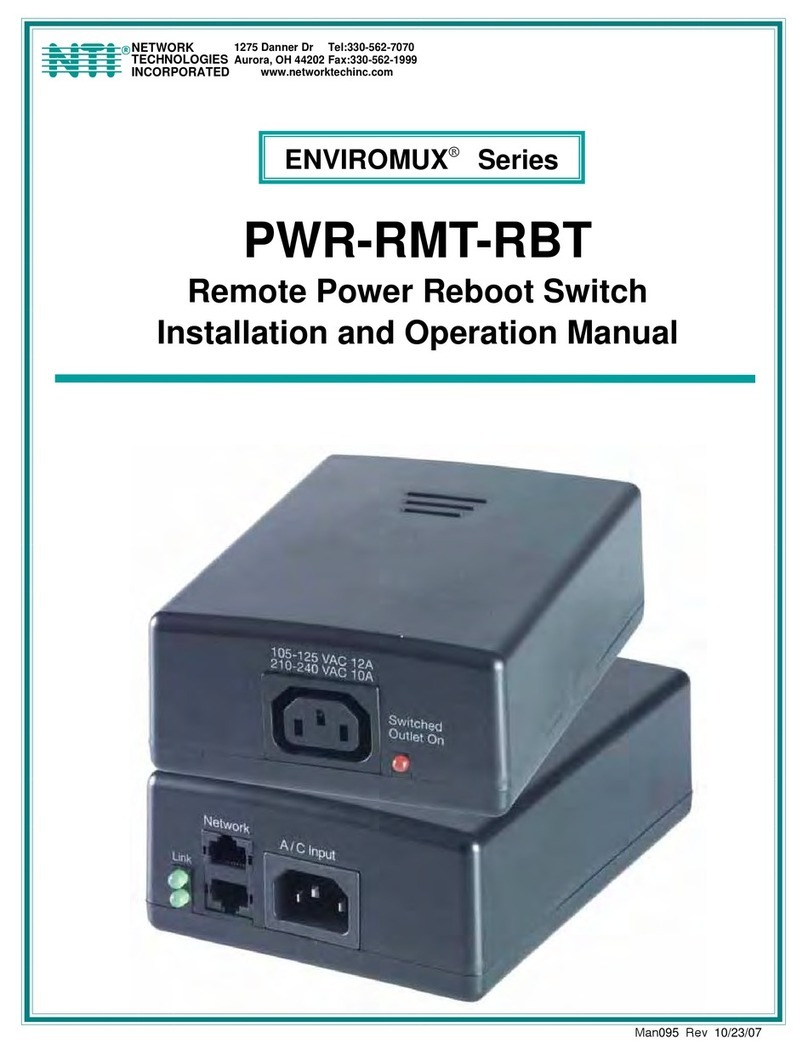

Network Technologies

Network Technologies PWR-RMT-RBT Installation and operation manual

Leviton

Leviton Powerswitch MDS30-AX installation instructions

AMX

AMX Multi Preview Operation/reference guide