HITROL HLT-1112 User manual

이 부분이 상부 방향으로 설치할 것.

(This part will install

in the up direction)

HITROL CO., LTD.

Always The Best Solution by

HEAD OFFICE, FACTORY, R&D INSTITUTE

141 Palhakgol-Gil, Jori-Eup, Paju-Si,

Gyeonggi-Do, Korea

Tel. : +82-31-950-9700 Fax : +82-31-943-5600

Website : www.hitrol.com

INSTRUCTION MANUAL

MAGNETIC COUPLING TYPE TANK LEVEL GAUGE

HLT-1112 & HLT-1212

Doc. No. : HLT-1112_M_Eng_2016, Rev. 0

Issued Date : 2016. 01

2ALWAYS THE BEST SOLUTION HITROL CO., LTD

Overview

Features

Operang Principle

General Specicaon

Applicaon

System Composion and Details of Parts

3

3

3

4

4

• HLT-1112 / Screw Type

• HLT-1212 / Flange Type

• Details of Parts

5

6

7

Installaon

* Condion for the installaon and adjustment

* Recommended Installaon Process

1. Installaon of Measuring Tape on Elbows

2. Installaon of Measuring Tape and Spring Motor (Inside the Tank)

3. Installaon of Measuring Tape (Weight Side)

4. Reference for the Boom Anchor Installaon

8

8

8

9

9

2.1 Installaon of Measuring Tape

2.2 Installaon of Spring Motor

* Assembly Inspecon

3.1 Folding of Measuring Tape

3.2 Connecon of the measuring tape to the weight

10

11

11

11

11

Direcon for the Installaon

Operang Check

Note

Warranty

12

12

12

12

Table of Contents

3ALWAYS THE BEST SOLUTION HITROL CO., LTD

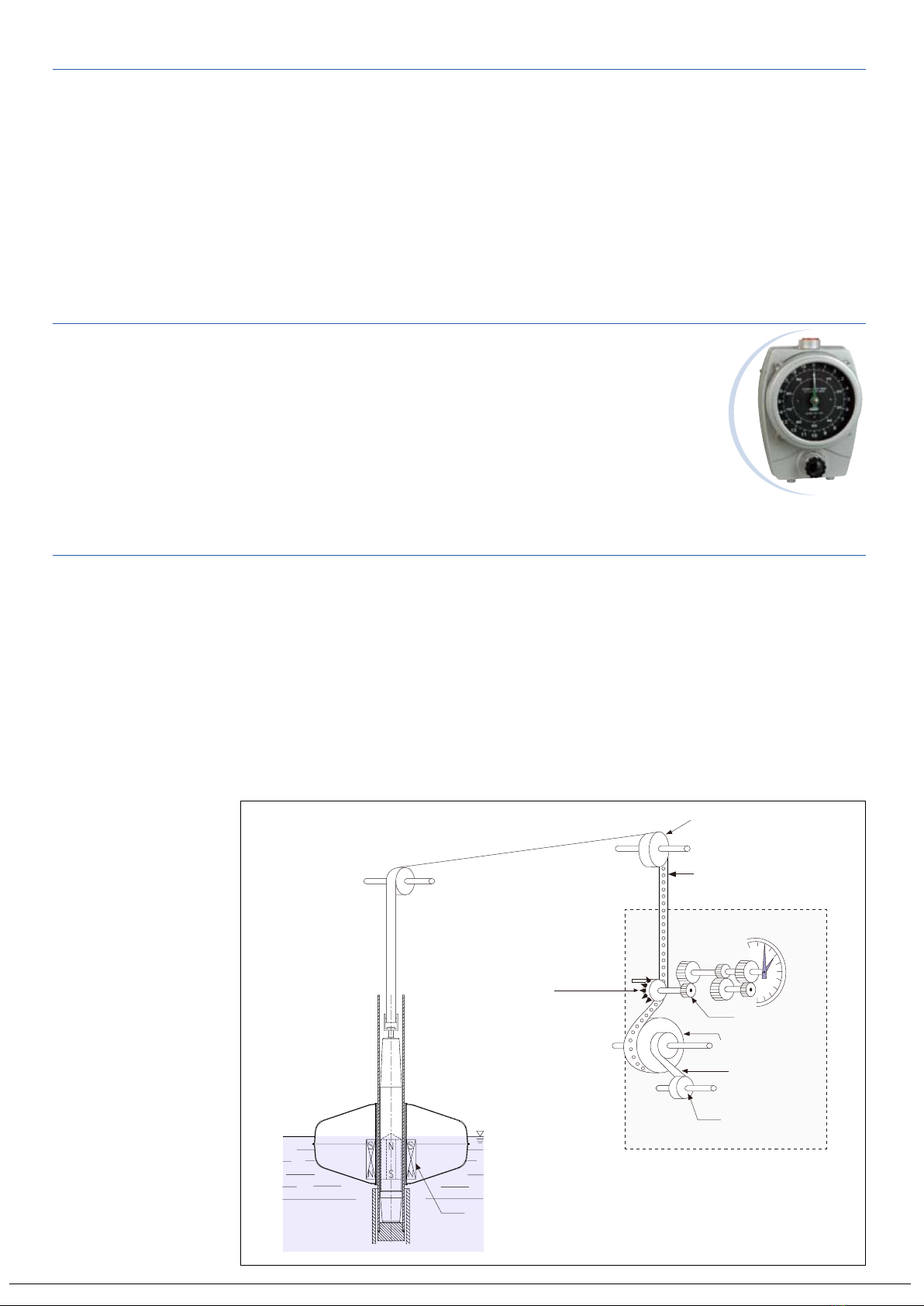

HLT-1112 (HLT-1212) is a magnec coupling type oat level gauge which measures

liquid level in a tank, by movement of a weight in a guide pipe according to a

movement of a oat, using a constant spring. Convenonal level gauge is hard to be

applied for corrosive and/or toxic liquids due to a corrosive vapor which is develped

in a tank and comes up along a guide pipe to gauge head, can corrode inside

components in a gauge head. On the other hand, magnetic coupling type float

level gauge is a closed type and prevent an inow of vapor into a guide pipe so it is

suitable for corrosive and/or toxic liquids.

• Applicable to a tank which has a pressure (Max. 5kg/cm2).

• Measurement in mm using spring balance

• Simplified design, high accuracy and durability

• Operating checkup using a Drive Checker

• Easy installation and maintenance

• Option for remote indication, control and switch for alarm

• Large scale dial enables legible indication even at a distant location.

The float in a tank floats on the surface of the liquid at the point which the float

weight and buoyancy are in equilibrium, and the magnet in the float sticks to the

magnetic in the weight which is installed in a guide pipe because the polarity of

them is contrary. When the liquid level changes, weight moves according to the

movement of the float and spring motor adjusts the measuring tape to maintain

the float position on the surface of the liquid. The measuring tape has a series of

holes set at regular intervals and as the tape rotates the sprocket, it in turn operates

the display indicator. The position of the measuring tape holes on the sprocket

compensates for the tape weight and prevents the tape from slipping.

Sheave Elbow

Measuring Tape

Gauge Head

Sprocket Wheel

Indicator

Gearing

Mechanism

Tape Drum

Spring Motor

Spring Motor

Drum

Magnet

OVERVIEW

FEATURES

OPERATING PRINCIPLE

4

ALWAYS THE BEST SOLUTION HITROL CO., LTD

APPLICATION

This tank level gauge can be used to measure and indicate liquid level in various

industries such as oil refineries, petrochemical, food, chemistry and water

treatment, etc. Details are as below.

• Oil refinery : Crude oil, gasoline, heavy oil, kerosene, naphate, organic liquids,

inorganic liquids, asphalt and sulfur, etc.

• Petrochemistry : Benzol, toluene, xylene, methanol and ethanol, etc.

• Food industry : Beer, whisky, soy sauce, etc.

• Chemistry : Caustic soda, hydrochloric acid and sulfuric acid, etc.

• Power plant : Heavy oil, water reservoir and distilled water, etc.

• Water treatment : Waterworks and sewage system, waste liquid, drinking water

and elevated water tanks, etc.

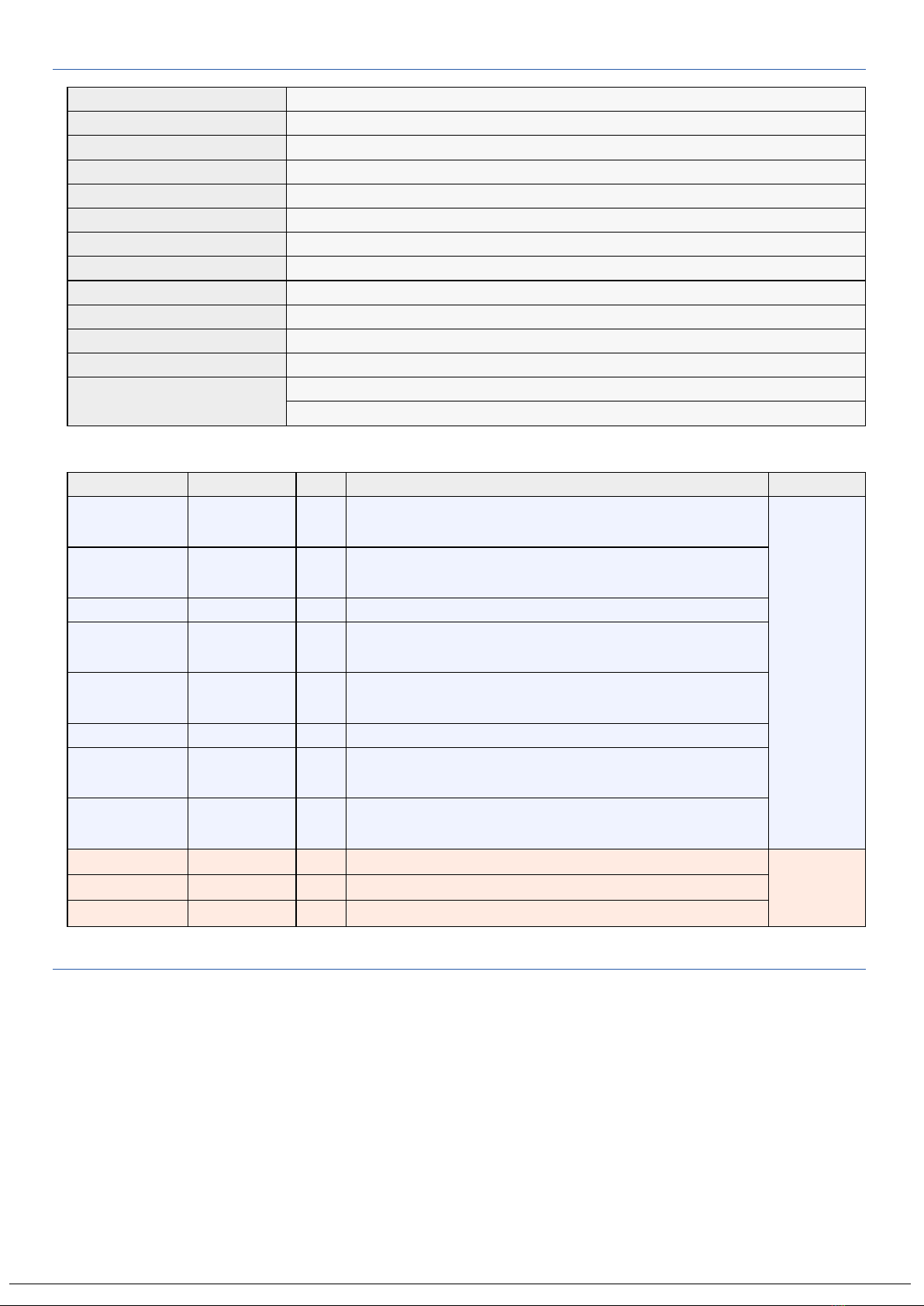

Type Magnec Coupling Type (Screw Type : HLT-1112 / Flange Type : HLT-1212)

Installaon Top or Side Mounng

Indicator 2-Points Dial

Ambient Temperature -20oC ~ 60oC

Fluid Temperature Max. 150oC

Operang Pressure Up to 5kg/cm2

Enclosure Weather Proof (IP65)

Applicaon Liquid

Measuring Range 2.5M / 5M

Specic Gravity 0.6 ~ 2.0

Accuracy ±2mm

Combinaon Transmier HAT-1000(-Ex), HAT-5000(-Ex)

Process Connecon Size Screw Type : 2" Flange + PT 1-1/2"(F) Socket (Std.)

Flange Type : 2" Flange (Std.)

● PARTS LIST

Part Name Material Q'ty Remark Scope

Head AL.C 1 Screw Type : PT 1-1/2"(F) (Std.)

Flange Type : ANSI 1-1/2" 150# RF (Std.)

Hitrol Scope

Sheave Elbow AL.C (Std.)

304 SS (Opt.)

2Screw Type : PT 1-1/2"(F) (Std.)

Flange Type : ANSI 1-1/2" 150# RF (Std.)

Measuring Tape 316 SS 1

Guide Pipe 304 SS (Std.)

316 SS (Opt.) 1

Float 304 SS (Std.)

316 SS (Opt.) 1

Weight 304 SS 1

Pipe Support C.S (Std.)

304 SS (Opt.)

nRequired quanty depends on the tank height.

Gauge Support C.S (Std.)

304 SS (Opt.) 1

Seal Pipe - - 1-1/2" Pipe (Std.)

User ScopeBoom Anchor - - Refer to details of parts on page 7.

Nozzle Part - - Refer to connecon part on page 7. [ANSI 2" 150# RF (Std.)]

GENERAL SPECIFICATION

5ALWAYS THE BEST SOLUTION HITROL CO., LTD

SYSTEM COMPOSITION AND DETAILS OF PARTS

HLT-1112 : SCREW TYPE

6

ALWAYS THE BEST SOLUTION HITROL CO., LTD

HLT-1212 : FLANGE TYPE

7

ALWAYS THE BEST SOLUTION HITROL CO., LTD

DETAILS OF PARTS

Head Parts

Connecon Part

Material : Aluminium

<Screw Type> <Flange Type>

Connecon Type

• Screw : PT 1-1/2"(Std.), NPT 1-1/2", PF 1-1/2" and other

• Flange : ANSI, JIS and DIN

Material

• 304SS, 316LSS and other

Connecon

Pipe (User Scope)

Connecon

Socket

Flange for

Guide Pipe

Nozzle Flange

(User Scope)

Guide Pipe

Connecon Pipe

w/Flange

(User Scope) Flange for

Guide Pipe

Nozzle Flange

(User Scope)

Guide Pipe

• Sheave Elbow (AL.C) • Float

• Boom Anchor

(User Scope)

• Weight

• Gauge Support

8ALWAYS THE BEST SOLUTION HITROL CO., LTD

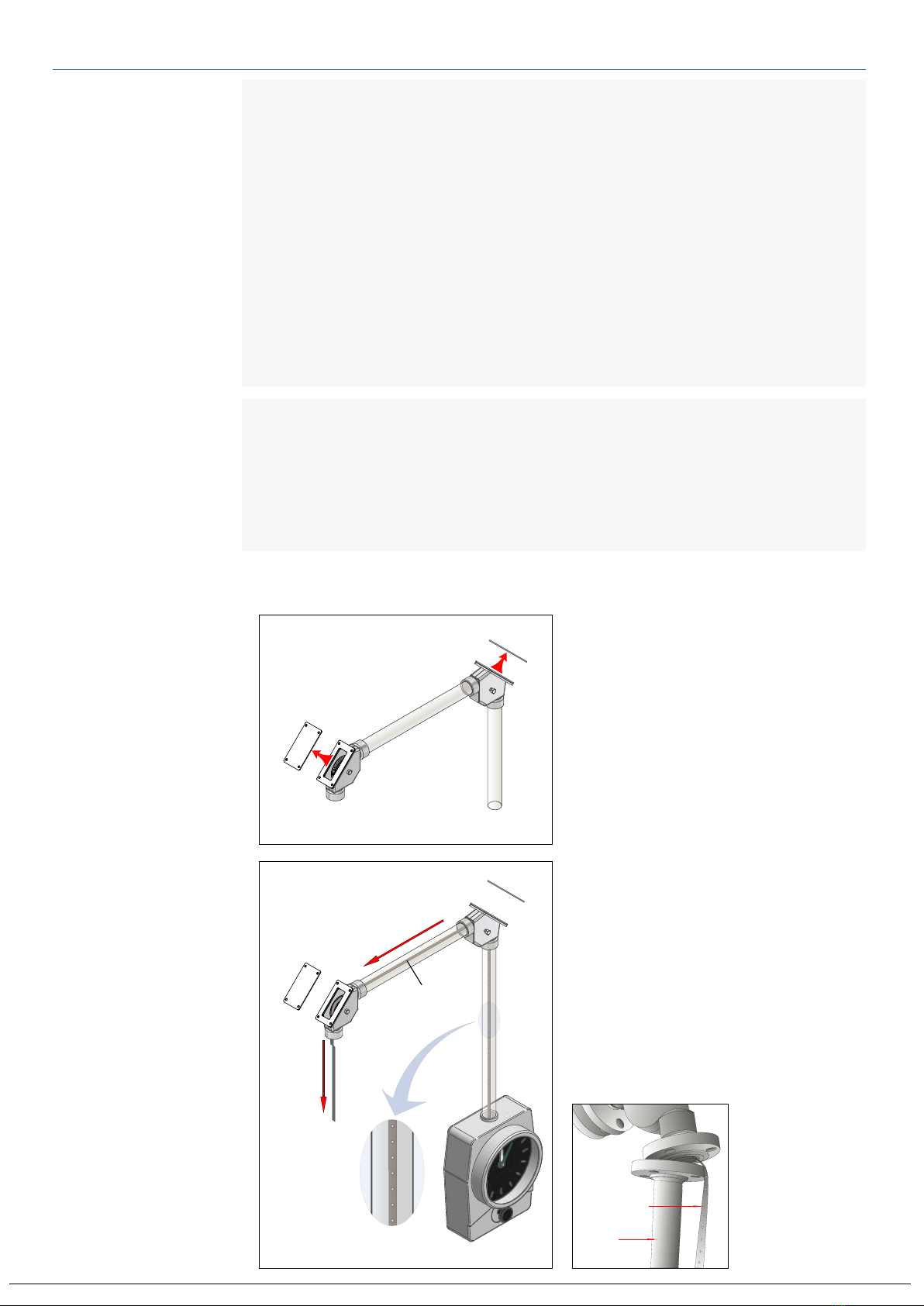

[Fig.1]

Elbow-B

Elbow-A

(Tank Side)

(Gauge Side)

[Fig.2]

Measuring Tape

Elbow-B

(Gauge Side)

Elbow-A

(Tank Side)

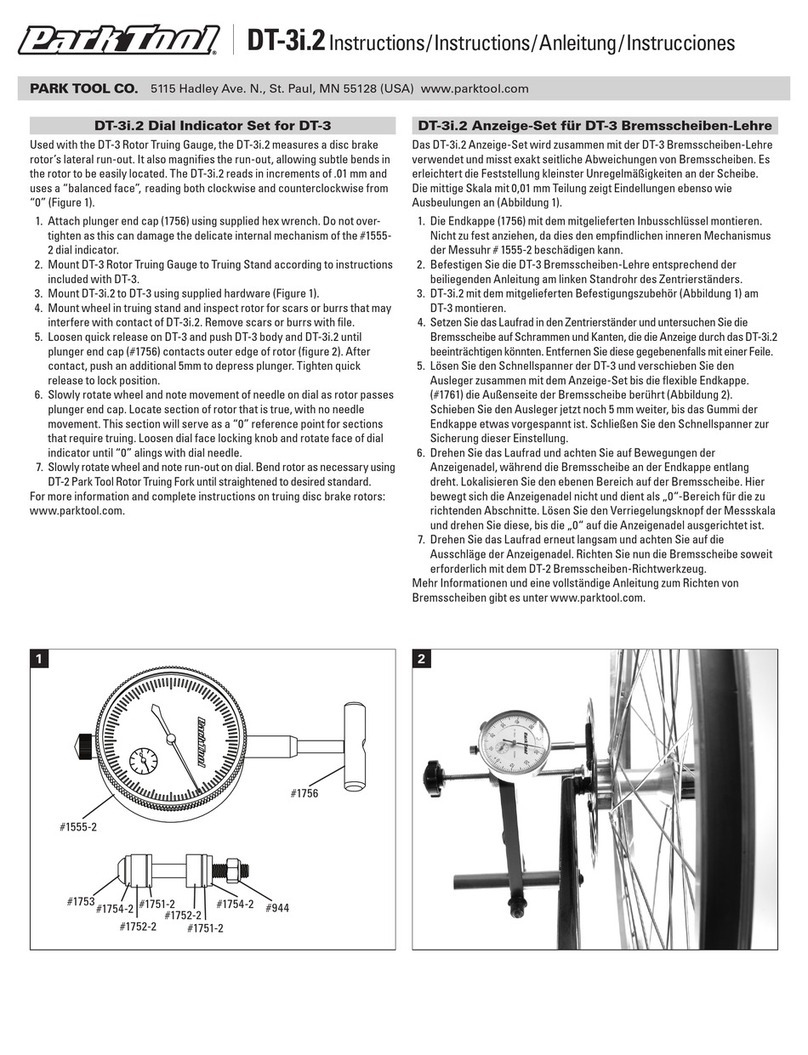

1. INSTALLATION OF MEASURING TAPE ON ELBOWS

INSTALLATION

* INSTALLATION PROCESS (RECOMMENDED)

(Aer installaon of Guide Pipe, Float and Boom Anchor to inside the tank),

1. Pass the measuring tape through the 90o sheave elbows.

2. Install the measuring tape aer disassembly of the gauge head.

3. Install the spring motor to spring loaded drum (1) and (2) in the gauge head.

4. Connect the weight.

Before installation of measuring tape

on elbows, install the seal pipes as

shown in [Fig.1] in advance. But, install

the seal pipe on nozzle (tank) side aer

installation of measuring tape and

weight.

Unfasten the bolts on covers of Elbow-A

and Elbow-B and open covers.

* CONDITION FOR THE INSTALLATION AND ADJUSTMENT

1. Seal pipe and boom anchor should be prepared by user.

2. Installaon of elbow and seal pipe in advance is ne. However, install the

seal pipe on nozzle side to the elbow aer installaon of measuring tape and

weight (Refer to page 8 and 11).

3. Inside the tank should be empty and there should be nothing which can

disturb the installaon of the level gauge.

4. Tank nozzle should be installed in advance, suitable with our connecon

part and it should not be dangerous for work inside the tank.

5. There should be no leakage of the medium.

6. The environment for performing of the installaon and adjustment safely

should be prepared.

Pass one end of measuring tape (not

perforated) from Elbow-B to the

direcon of Elbow -A as shown in [Fig.2]

and make sure that the measuring tape

with hole (perforated) side should be

positioned in a gauge head, not in a

tank.

If seal pipe on nozzle side is already

installed, pull out the measuring tape

•

•

•

•

through elbow

and seal pipe

aer unfastening

of them for the

installaon of the

weight. (Refer to

le image)

Seal Pipe

Measuring Tape

9ALWAYS THE BEST SOLUTION HITROL CO., LTD

elbow to inside of the tank through the hole of connecon.

4) Pass the measuring tape through the space between the sprocket and tape

guide as shown in Fig. 3 with a careful aenon for the xing of spikes on

the sprocket to the holes on the measuring tape. The distance between

the sprocket and tape guide can be adjusted with a screw.

5) Fix the end of measuring tape to the locking screw with bolt.

6) Aer xing of measuring tape, wind it counterclockwise to give a tension

to the measuring tape. The measuring tape without holes (not perforated)

should not be posioned in the gauge head.

2. INSTALLATION OF MEASURING TAPE AND SPRING MOTOR (INSIDE THE TANK)

2-1. Installaon of Measuring Tape

1) Open the back cover of gauge

head.

2) Disassemble the inside Spring

Loaded Drum (1) and (2) in the

gauge head rst.

3) Pull down the measuring tape

which is out from the upper

Tape Guide

Sprocket

Spring Loaded Drum (1)

Spring Loaded Drum (2)

Tape Storage Sheave

Measuring Tape

[Fig.3]

Measuring Tape

Sprocket

Tape guide

screw

2mm

Sprocket

Tape drum

Tape locking screw

Tape guide

Spring loaded

drum (smaller)

Locking screw

Spring loaded

drum (larger)

10ALWAYS THE BEST SOLUTION HITROL CO., LTD

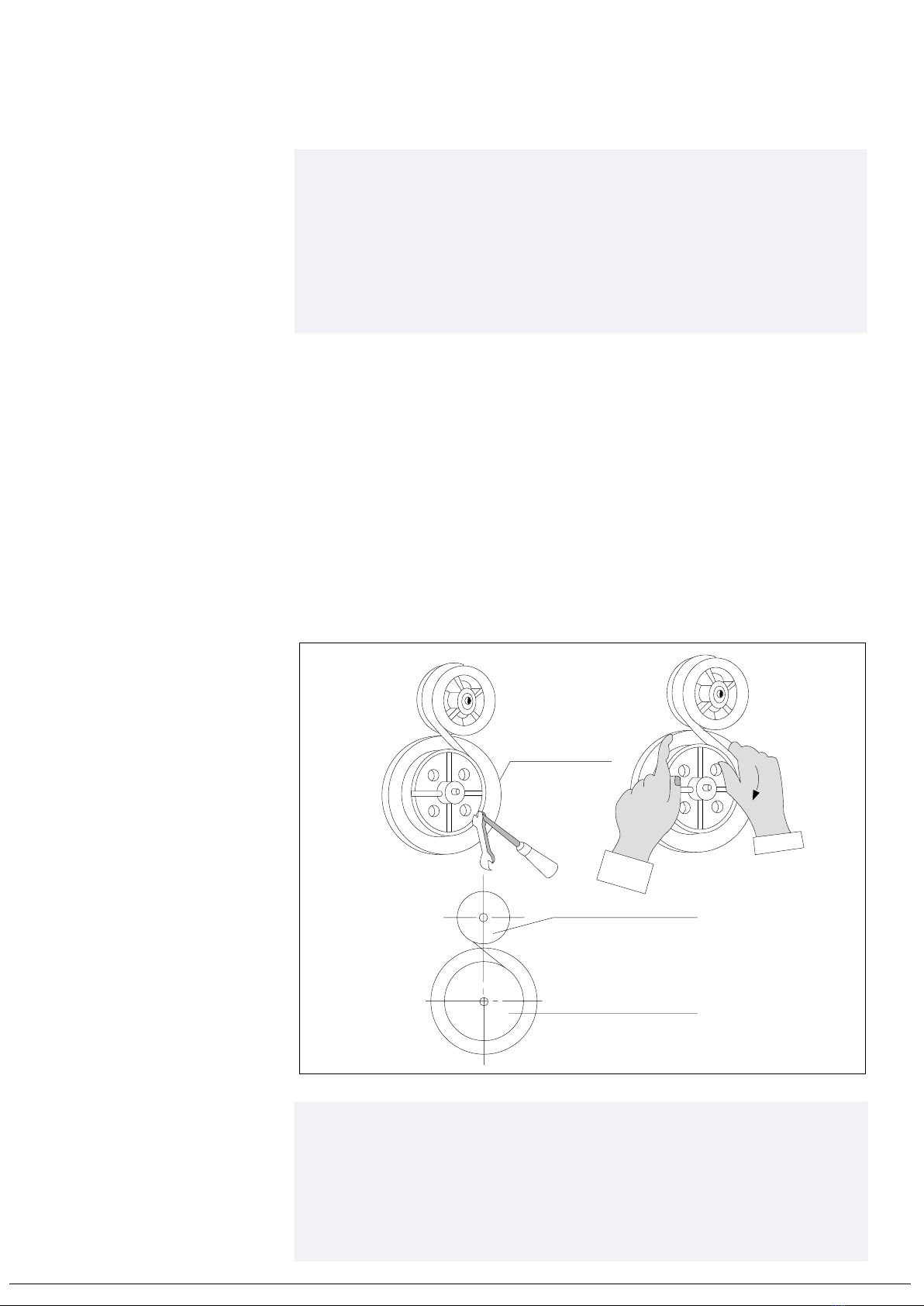

2-2. Installaon of Spring motor

The spring motor should be set aer the measuring tape has been stretched

in posion.

1) Put disassembled spring loaded drum (1) and (2) in places.

2) Fix the spring on spring loaded drum (1) to the locking screw on spring

loaded drum (2) with a bolt. The spring should be wound clockwise so

locking screw should be posioned right side when the spring is xed to

the spring loaded drum (2) as shown in Fig. 4.

3) Wind the spring clockwise about two or three turns in order to prevent the

derailment of the spring from spring loaded drum.

4) Aer winding of spring, x the spring loaded drum (2) to the tape storage

sheave.

5) Complete the installaon of spring motor aer xing by upper locking ring.

[Fix all spring loaded drum (1) and (2)]

* PRECAUTION :

• When the spring motor gets out of the spring loaded drum (larger) or

excessive force is applied to it, it produces non-uniform torque which

may be cause of erroneous indication.

• At the stage to wind the spring motor from the smaller drum to the

larger one, do not leave your hand from the larger drum until the

measuring tape is tensed finally.

* ASSEMBLY INSPECTION :

• Aer the installaon of measuring tape and spring motor is nished,

pull out the measuring tape which is out from gauge head and check

if there is a jam or derailment. When the tape is loosed, the spring

should be wound. If there is a jam or derailment aer pulling out the

measuring tape, adjust nely using a screw.

Spring loaded drum (1)

Spring loaded drum (2)

(smaller)

(larger)

Locking screw

screw + nut

[Fig.4]

11ALWAYS THE BEST SOLUTION HITROL CO., LTD

1 2 3 4

3. INSTALLATION OF MEASURING TAPE (WEIGHT SIDE)

4. REFERENCE FOR THE BOTTOM ANCHOR INSTALLATION

1. Boom Anchor is a user scope so it should be prepared by user.

2. It is recommended to install the boom anchor before installaon of tank level

gauge in order to prevent a change of it's locaon.

3. It is recommended to put the boom anchor to the boom of our guide pipe

rst and adjust the upper posion. Aer xing of the upper posion, x the

boom anchor to the tank boom.

1. Connect the folded measuring tape to the weight as above. The length of bolt

should not be over 10mm because long bolt can cause a malfuncon of the

gauge.

2. Put the weight connected with the measuring tape to inside the tank through

the seal pipe.

3. Aer put of weight, check whether the measuring tape gets out of the roller

or not. If not, complete the installaon of measuring tape aer assembly of

elbow cover.

3-1. Folding of Measuring Tape

Fold the measuring tape on Elbow-A as below order.

•

* PRECAUTION :

• Temporarily fixing the measuring tape on upper elbow

suitable for each site condition.

• Take care not to bend or give damages to the measuring

tape when folding of it.

3-2. Connection of the measuring tape to the weight

Folding

Folding

1 2 3 4

12ALWAYS THE BEST SOLUTION HITROL CO., LTD

WARRANTY

Warranty and Aer Sales Service

Warranty of the product is 2 years after shipment and it can be warranted for

malfunction occurred under use in normal condition, but it maybe charged

regardless of warranty period in case that after sales service is requested not for

malfunction of the product.

After sales service can be requested at our website or to our factory.

Headquarter ∙ Factory ∙ R&D Center

Address : 141 Palhakgol-Gil, Jori-Eup, Paju-Si, Gyeonggi-Do, Korea

Tel. : +82-31-950-9700

Fax : +82-31-943-5600

OPERATING CHECK

The tank level gauge can be used right aer properly installaon as instructed and

specicial operating procedure or order is not required. Operating can be checked

using a drive checker as below.

Handling of Drive Checker

The drive checker is used for confirming of

level indicaon and operaon of the tank level

gauge at the me of calibraon.

1. If the checker knob is turned clockwise

about 90o (1/4 turn), the oat is slightly

lied.

DIRECTION FOR THE INSTALLATION

1. Use the galvanized or stainless steel pipe for outside tank.

2. Non linearity due to exure of pipe must be limited within ±5mm.

3. If the medium in the tank is highly corrosive, use the pipe which is lined.

4. The oat should be posioned as far away from the liquid inlet or tank srrer as

possible. This will limit the eects of turbulence and prevent ow directly hing

the oat.

5. Take care not to fold or kink the measuring tape.

6. During the installaon, take care not to allow the measuring tape to get out of the

sheave elbows or balancer roller and check if it is posioned properly in a groove

of them.

7. Do not loosen or unfasten the thumb screw. Otherwise, spring motor winds

rapidly and it can bring an accident.

Check Handle

Gauge Head

Drive Checker

NOTE

Above information should be fully acquainted by user and the temperature of

the medium in a vessel should not be exceed max. +150oC. And also, ambient

temperature should not be exceed -20 ~ +60oC.

2. Above handling of drive checker can conrm the operang of each parts through

the indicator.

This manual suits for next models

1

Table of contents

Other HITROL Measuring Instrument manuals