HB-THERM HB-100 Setup guide

1 General

Read these instructions carefully before starting any work. The basic prerequi-

sites for working safely are compliance with all safety instructions and prudent

action by qualified personnel in order to avoid accidents that lead to personal

injury / property damage.

Safety instructions are marked by symbols:

Danger! / Warning! / Caution!

... indicates a hazardous situation which, if disregarded, may result in

injury (Caution!) or serious or fatal injury (Warning!, Danger!).

Danger due to electric shock!

... if disregarded, there is a risk of serious or fatal injury.

Hot surface!

... if disregarded, there is a danger of mild to severe burns.

Safety instructions

and quick guide

Temperature control units

Type HB-100/140/160Z61

Attention!

... indicates a potentially hazardous situation which, if disregarded, may

result in property damage.

Make sure that these instructions are accessible at all times in the immediate

vicinity of the unit.

Further instruction information is available via the help system on the unit, and

in detail via the «e-cockpit» app or http://knowledge.hb-therm.eu. If you have

any questions or if anything is unclear, please contact your country represent-

ative (see type plate) or our customer service www.hb-therm.ch.

1.1 Designated use

The temperature control unit is used to heat or cool a connected consumer

(e.g. mould) to a specified temperature by means of a heat transfer medium

(water) and to maintain this temperature. The unit is designed and constructed

exclusively for the specified values in accordance with its type plate.

Claims of any kind due to improper use are excluded.

1.2 General safety instructions

Observe local, legal and company safety regulations and requirements.

Always wear the legally and operationally prescribed protective equip-

ment for the respective work.

Operating materials can reach high temperatures and high pressures

during operation and cause burns on contact.

Do not touch hot surfaces without protective gloves.

Regularly check the entire system for leaks or damage. Check the hose

lines and screw connections for tightness. Remedy any defects immedi-

ately.

Always keep these instructions and all information on the unit clearly leg-

ible. Replace damaged or illegible information immediately.

Never override safety devices.

In the event of uncontrolled faults, set the main switch to the Oposition

to trigger an emergency stop.

Disconnect the unit from the power supply when opening it. Secure the

disconnection against switching on. Owing to charged capacitors, wait

5 minutes after switching off the power supply to work on the frequency

converter.

Carry out the requested maintenance work. Maintenance work may only

be carried out by qualified personnel.

Cool down, depressurise and switch off the unit before carrying out main-

tenance, repair or cleaning work. Check that it is pressure-free.

Maintenance work on the magnetic coupling of the pump is prohibited for

people wearing a pacemaker.

Only use original spare parts from the manufacturer.

2 Transport and packaging

Check the delivery immediately on receipt for completeness and for any trans-

port damage.

Transporting, crane and lifting equipment must be suitable and operated

by qualified personnel.

For transportation purposes, the unit must be completely empty (cooling

and system circuit).

For careful handling and in-plant transport, observe the symbols and in-

structions on the packaging.

To protect the unit, do not remove the packaging until shortly before in-

stallation.

When shipping a unit, use only the original or equivalent packaging. Only

transport the unit upright.

2.1 Procedure for carrying by crane

1. Pull out the lifting device at

the rear of the unit.

2. Attach lifting straps to the

lifting device

and to the front

handle.

3 Installation

Electrical installation and initial commissioning must be carried out by

qualified electricians.

Hydraulic installation and initial commissioning must be carried out by

hydraulics specialists.

To protect the entire system, the guide values for water quality must be

observed. Detailed information is available at http://knowledge.hb-therm.eu.

3.1 Installation conditions

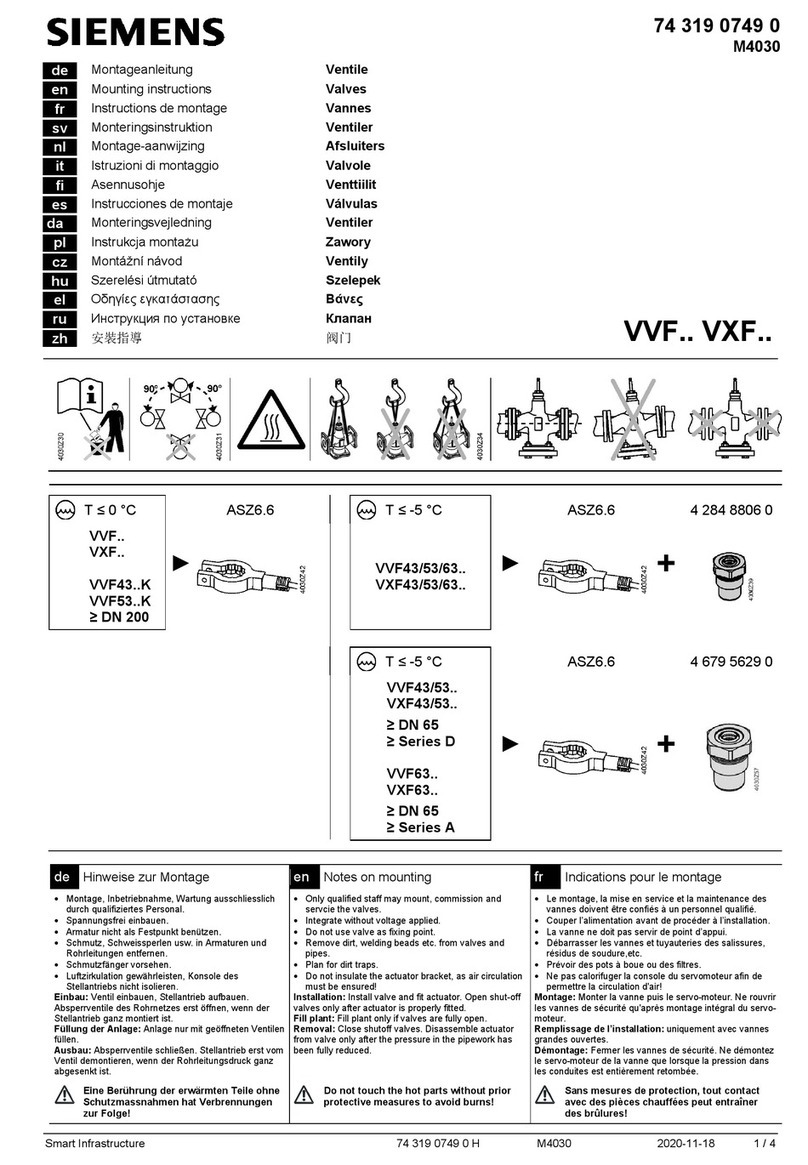

EN (Translation of original instructions)

>60°

>60°

Unit location water-protected indoor area

suciently good ventilation

Max. installation altitude 3000 m above sea level

Installation area horizontal, stable and low-vibration surface

Permissible ambient

temperature

5–40 °C

Relative humidity 35–85 % RH (non-condensing)

Main switch and emergency

stop

Access at any time

Secure unit Lock the brake on the front castors.

Secure units on elevations to prevent them from falling.

External cables Cables must not touch hydraulic lines or parts whose

surface temperatures are above 50 °C.

3.2 Connections

Use only suitable pressure- and temperature-resistant connections,

screw connections and hose lines.

Use assembly pastes for all screw connections, as these tend to seize up

(especially stainless steel on stainless steel).

The use of a type B residual current device (RCD) is recommended. A

type A RCD is not suitable as the unit is equipped with a frequency con-

verter.

Type of unit power cable CE H07RN-F/H07BQ-F

UL/CSA SO/SOW/SOOW

Cross-section

Mains cable to unit

U

= 400/460 V 4x2,5 mm2(CE)

4xAWG 12 (UL/CSA)

U

= 220 V 4x6,0 mm2(CE)

4xAWG 10 (UL/CSA)

Overvoltage category II

Degree of contamination 2

O8402-EN 2022-01

Main line, return line Thread G¾

Resistance pmax (see type plate),

ϑ= 20 + ϑmax (see type plate)

Cooling water,

separate system water

Thread G⅜ (cooling water),

G¼ (separate system water)

Pressure p= 2–5 bar

Resistance p= 10 bar, ϑ= 100 °C

Compressed air

(with additional ZG)

Thread G¼

Pressure p= 2–8 bar

Resistance p= 10 bar, ϑ= 100 °C

Electrical mains connection Mains voltage U(see type plate)

Maximum pre-fuse Imax (see type plate)

3.3 Procedure

1. Connect the cooling water inlet and outlet to the cooling

water supply.

2. Connect the main line (OUT) and return line (IN) to the mould circuit.

3. Optionally connect the system water inlet (S1) and outlet (S2) to a sep-

arate system water supply.

4. Connect the compressed air inlet (AIR IN) to the compressed air supply

and the outlet (AIR OUT) to a pressure-free tank or discharge water

outlet (with additional ZG).

5. Connect to the electrical mains.

6. Connect the optional OPC UA data interface.

7. Connect the optional HB data interface.

8. Connect the optional external control (with additional ZB).

9. Connect the optional external sensor (with additional ZE).

→ Press the menu button → press ʹSettingʹ → press ʹExternal

sensorʹ → press ʹExternal sensor typeʹ and select type

4 Commissioning

When initially starting-up, all electrical connections must be checked.

4.1 Main switch and emergency stop

Before switching on again after an emergency stop, make sure that the

cause of the emergency stop has been eliminated and all safety devices

are functioning.

As a rule, switch the unit off using the On/Off button and only in an

emergency use the main switch.

The main switch switches the power supply in the unit to all poles and is also

an emergency stop switch. In position II(mains ON), the unit initialisation starts

and during the initial start-up, the setup-assistent starts automatically. «Ready

to operate» appears on the display.

After an emergency stop due to a hazardous situation, the following applies:

1. Disconnect the unit from the power supply. Secure the disconnection

against switching on.

2. Follow local and company safety instructions and emergency proce-

dures.

3. It is essential to engage qualified personnel for troubleshooting and

functional testing.

4.2 SwitchingOn/O

By pressing the On/Off button , the unit starts in the defined operating mode.

If necessary, it is filled and vented.

The unit switches off by pressing the On/Off button again. If necessary,

it is cooled, emptied and depressurised.

4.3 Changing the set temperature

The input keyboard is displayed by pressing ʹSet temperatureʹ on the basic

screen. Enter the desired set value and confirm with Enter.

Further instruction information:

The type plate is located on the rear panel of the unit and on the inside of the

door.

OFF

O

The following information can be taken from the type plate:

→Type

→Unit number

→Performance values

→Additional

→Connected values

→Year of manufacture

→Protection class

→Manufacturer

→Service point

This manual suits for next models

2

Other HB-THERM Control Unit manuals

Popular Control Unit manuals by other brands

Neptune Systems

Neptune Systems AI Wireless Module Setup guide

Allen-Bradley

Allen-Bradley 1792-IB16 Series B installation instructions

Team Blacksheep

Team Blacksheep TBS FUSION manual

Nitto

Nitto Hydranautics HYDRAcap60 Technical service bulletin

Dell EMC

Dell EMC MXG610s installation guide

Lingo

Lingo SoundPoint ImpactConnect Hosted PBX Guide