Contents

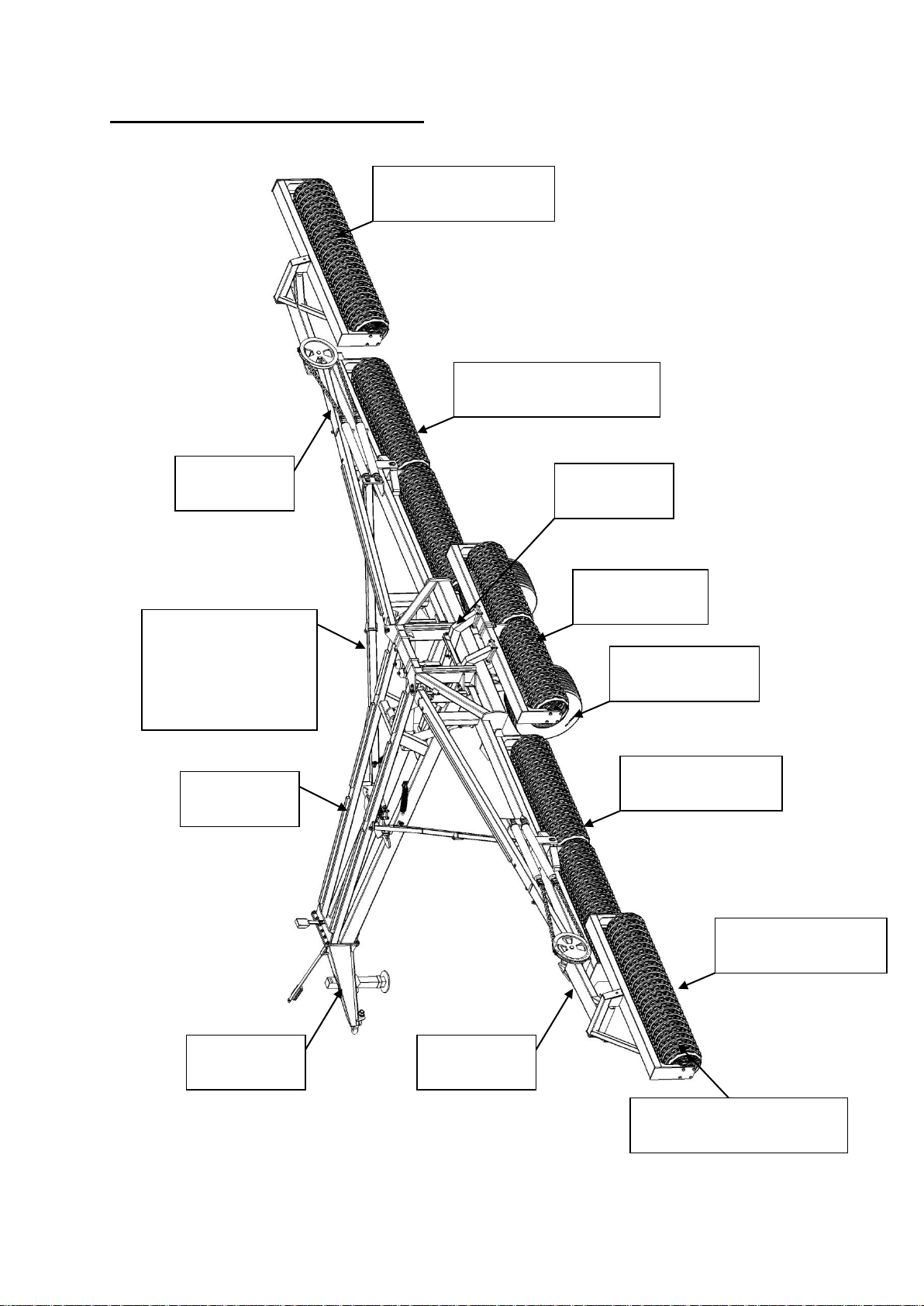

SUMMARY DRAWING / CONTENTS................................................................................................................1

EC DECLARATION OF CONFORMITY............................................................................................................2

MACHINE DESCRIPTION ...................................................................................................................................3

FIELDS OF APPLICATION.........................................................................................................................................3

DELIVERY CHECK...............................................................................................................................................3

INSTRUCTIONS REGARDING UNLOADING AND FINAL MOUNTING ............................................................................3

SAFETY INSTRUCTIONS.....................................................................................................................................5

GENERAL INFORMATION ........................................................................................................................................5

INSTRUCTIONS ON TRANSPORT ON PUBLIC ROADS..................................................................................................5

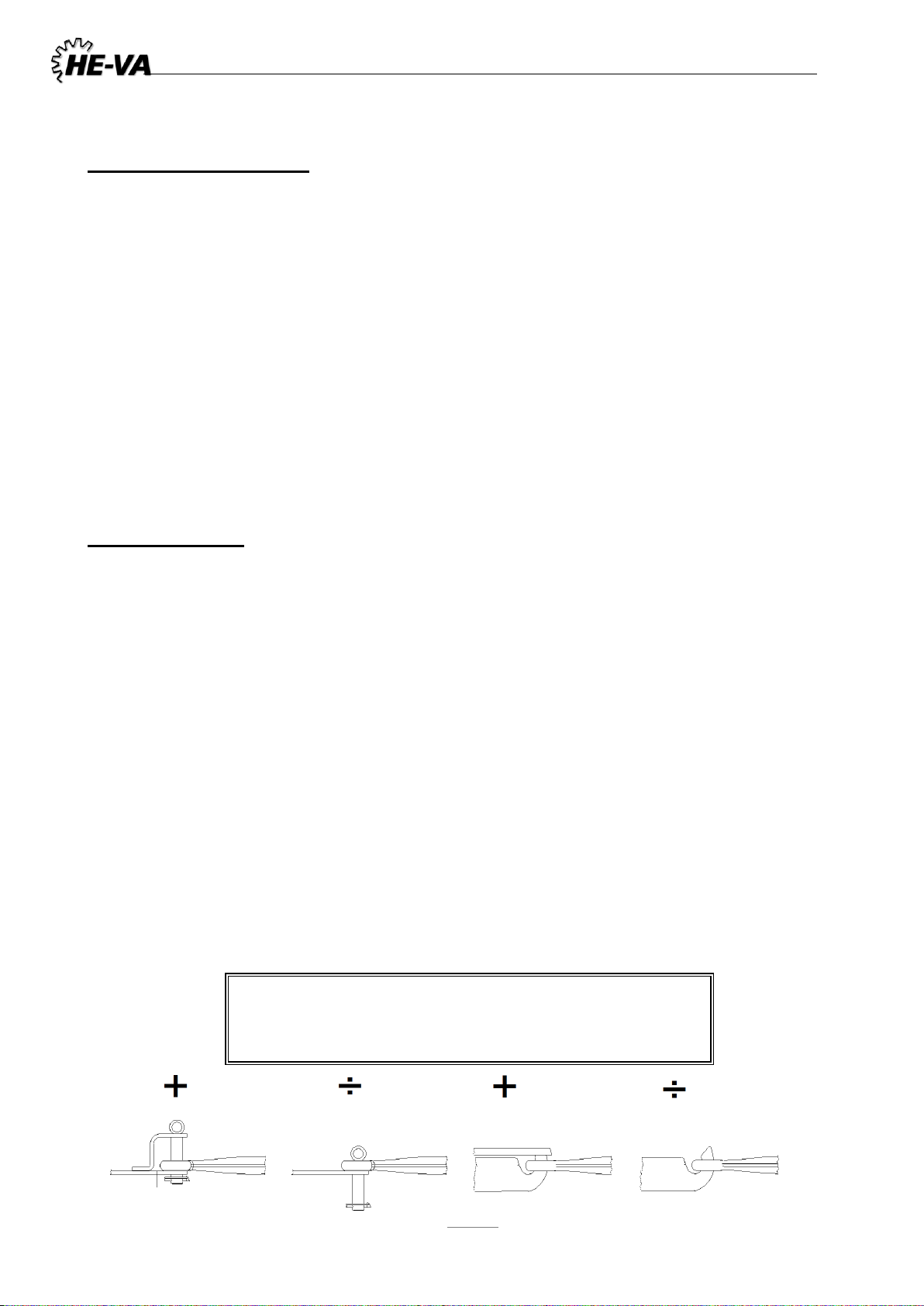

FRONT AXLE LOAD.................................................................................................................................................5

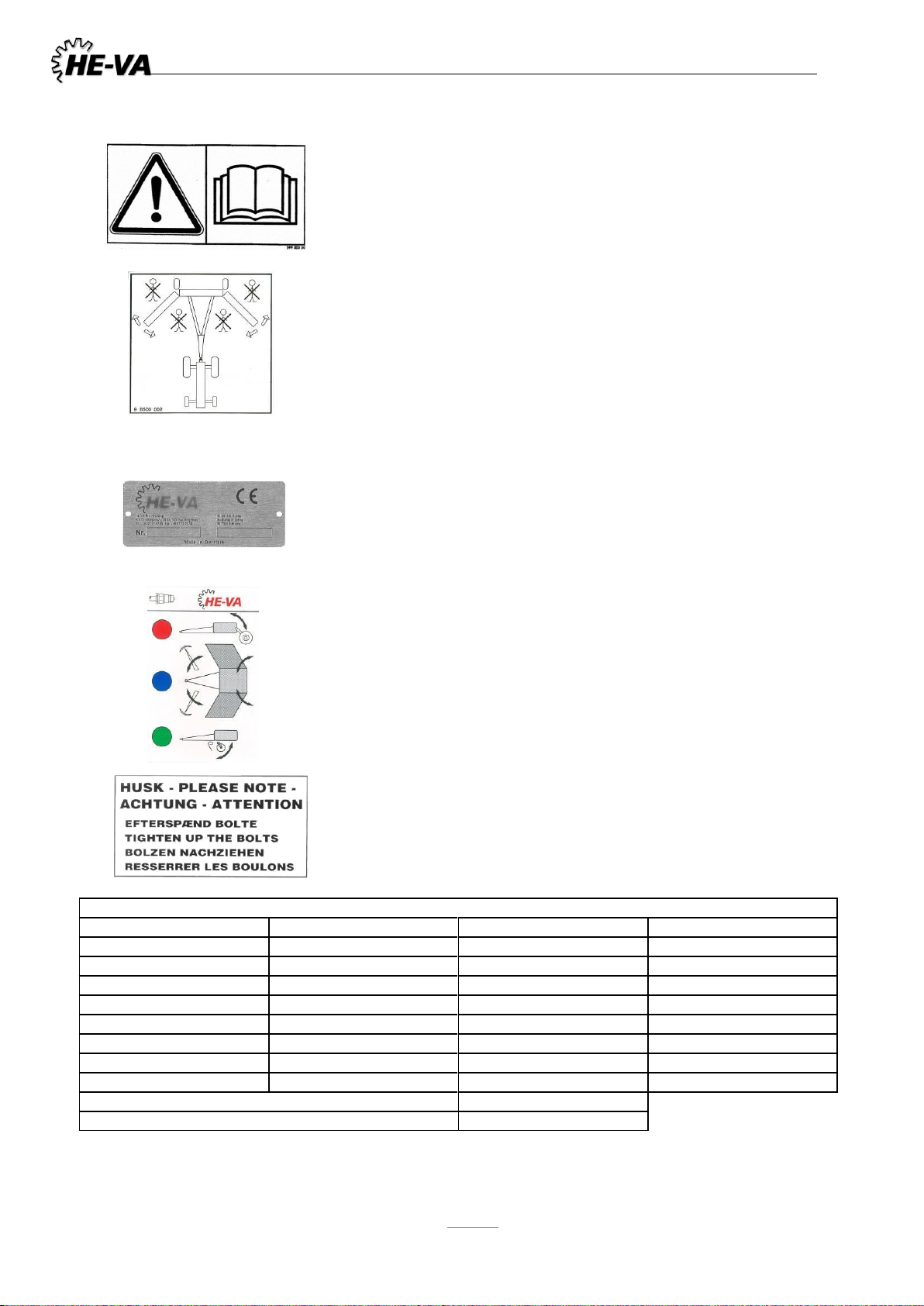

SAFETY –AND OTHER MARKINGS ON THE MACHINE...............................................................................................6

MAINTENANCE.....................................................................................................................................................7

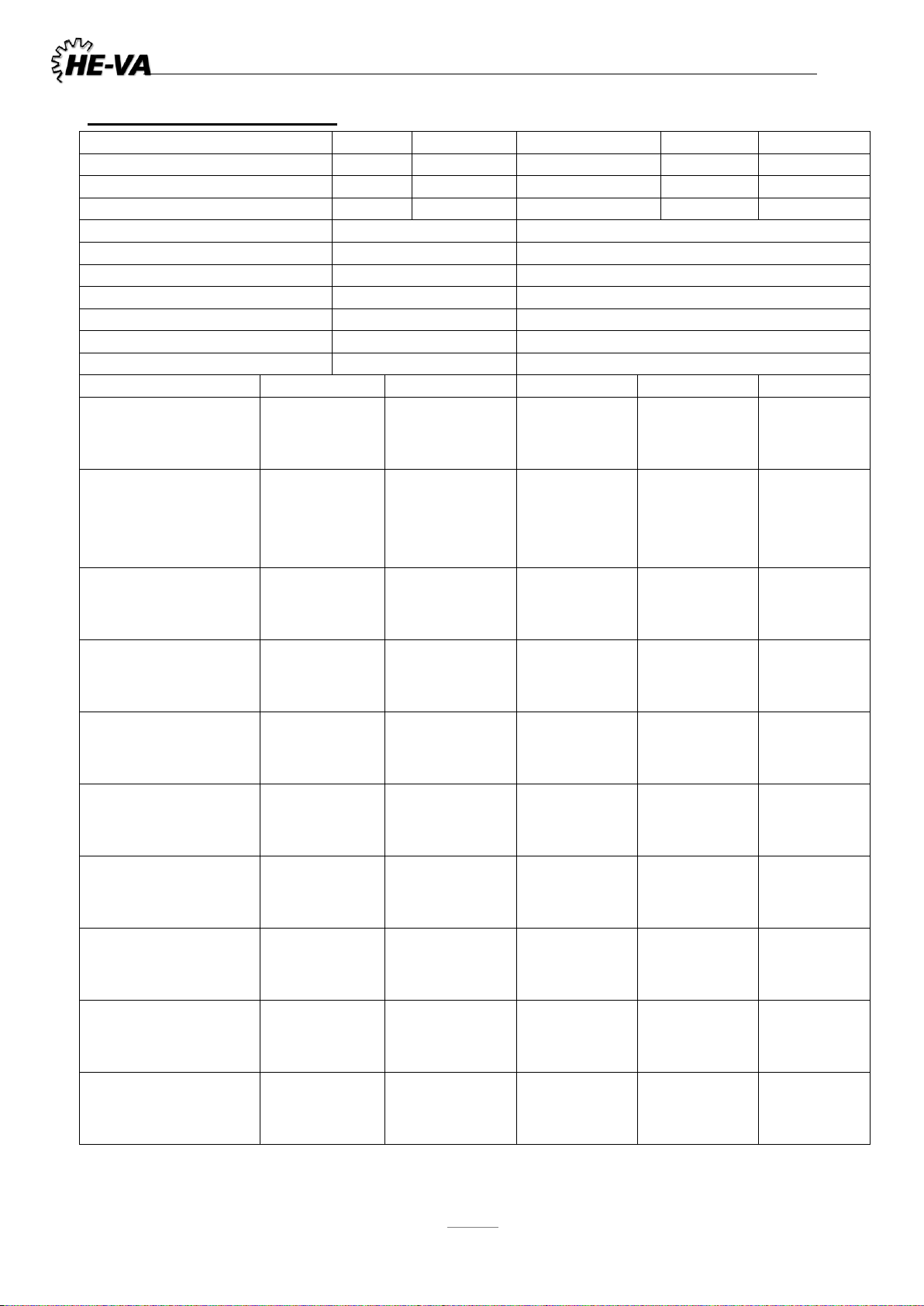

TECHNICAL SPECIFICATIONS.........................................................................................................................8

UNFOLDING...........................................................................................................................................................9

FOLDING.................................................................................................................................................................9

CONSOLIDATION .................................................................................................................................................10

SAT-SYSTEM..........................................................................................................................................................11

SPAREPARTS:........................................................................................................................................................12

BLOCK OF RINGS NO.1+5 (12,3+15,3M) ................................................................................................................12

BLOCK OF RINGS NO.1+5 (16,3+18,3+20,3M).......................................................................................................14

BLOCK OF RINGS NO.3...........................................................................................................................................17

BLOCK OF RINGS NO.2+4.......................................................................................................................................20

RING TYPES:...........................................................................................................................................................23

INNER WING:..........................................................................................................................................................24

STABILIZER BAR 15.3M..........................................................................................................................................27

STABILIZER BAR 16.3M -18,3M –20,3M................................................................................................................28

WHEEL FRAME 12,3 -15,3M...................................................................................................................................29

WHEEL FRAME 16,3 -18,3 –20,3M.......................................................................................................................30

TRIANGLE UNTIL MACHINE NO:347247.................................................................................................................31

TRIANGEL FROM MACHIN NO.347248....................................................................................................................32

DRAWBAR 12,3 -15,3M.........................................................................................................................................33

DRAWBAR 12,3 -15,3 -16,3 -18,3 -20,3M,..........................................................................................................34

DRAWBAR 12,3 -15,3 -16,3 -18,3 -20,3M,..........................................................................................................35

CHASSIS.................................................................................................................................................................36

OUTER WING..........................................................................................................................................................38

OUTER WING SECTION............................................................................................................................................39

INNER WING SECTION.............................................................................................................................................40

CENTERSECTION ....................................................................................................................................................41

HYDRAULICS.........................................................................................................................................................41

BRACKET FOR ACCUMULATOR ..............................................................................................................................41

HYDRAULIC CIRCLE:CENTRE SECTION /CHAIN CYLINDER FOR OUTER WING SECTION...........................................42

HYDRAULIC CIRCLE:SIDE SECTION /WHEEL FRAME /LOCKING CLAW .................................................................44

HYDRAULIC CIRCLE:SUPPORTING LEG ..................................................................................................................46

BRAKES...................................................................................................................................................................47

HYDRAULIC BRAKE................................................................................................................................................47

AIR BRAKE.............................................................................................................................................................48

LED -LIGHT SET....................................................................................................................................................50

LIGHTING SET:EL.DIAGRAM .................................................................................................................................51

NOTES:.....................................................................................................................................................................52