heatco HM SERIES User manual

1

OEMINSTALLATION INSTRUCTIONS

3035443

ANSI Z83.8 (2016) - CSA 2.6 (2016) –Gas-Fired Duct Furnace

HM Series Modules are a Recognized Furnace Component

Design Certified by Intertek Testing Services (ITS / ETL)

For Indoor or Outdoor Installation and

Installation Downstream from Refrigeration Systems

This Product is intended for installation by Original Equipment Manufacturers

Of Listed Heating Equipment in Duct or Cabinet mounted Applications

on the Positive pressure side of the circulating air blower

The duct furnace modules covered by these instructions become a component of a “Listed” product,

subject to the guidelines of application provided in these instructions and as

designated by the Certifying Agency in the Manufacturer’s Listing Procedure

Manufactured by

Heatco Inc

50 Heatco Court

Cartersville, Ga. 30120

HM-OEM-MAN-7-2016-E

HM and HH Series

Duct Furnace Modules

2

Inspection on Arrival

This duct furnace module was test fired and inspected at the factory prior to crating and was in satisfactory working order. A copy of

the Test and Inspection sheet is included in the information package provided. Inspect the packaging on delivery for any signs of

damage. Report any damage immediately to the transporting agency. After uncrating inspect furnace for any concealed damage.

Table of Contents

General Instructions..……………………..……………………………....3, 4

Furnace Module Application ………..….……………………………… 5

Airflow Distribution / Maximum Airflow………………………………..6

Auxiliary Limit and Airflow Proving Switch …………………………..7

Duct Furnace Installation ………………………………………..…….8

Combustion Air Supply …………………………………………………..8

Furnace Component Identification ……………………………….……9

Condensate Drains ………………………………………………………..9, 10

Gas Supply Piping…….…………………………………………………...10, 11

Venting ………………………………………….………………………...…11

Outdoor…………………………….…………….…………………11, 12

Indoor –Vertical (Category I)………………………………...…12, 13

Indoor –Horizontal (Category III)………………………………13, 14

Separated Combustion…………………………………………...14, 15

Operation, Adjustment, Start-up…………………………………….……16

Manifold Pressure Adjustment / Gas Valves…..……………….….…..16, 17

Electrical Supply and Ratings …………………………………..………..18

Wiring Diagrams & Instructions …………..………………….…………. 18

3

General Instructions for HM Series Furnace Modules

This furnace module must be installed in a non-combustible duct or cabinet on the positive pressure side of the

circulating air blower and is not designed to have any portion of the heat exchanger exposed outside the duct

or cabinet in which this furnace module is housed.

A Nameplate / Rating Plate is attached to the heater assembly to identify the model and serial number of this product. This plate

must be left attached when the module is installed in the product for identification purposes. This plate also contains information

including gas type, maximum and minimum input rating, manifold pressure, maximum and minimum inlet gas pressure, maximum and

minimum airflow requirements, output capacity and electrical ratings for this module.

This product must be applied in accordance with the requirements of its recognition. Consider maximum input ratings, maximum and

minimum temperature rise and maximum and minimum airflow.

The final determination of the safety and suitability of this product for the specific application shall be the responsibility of

the manufacturer of the “Listed” equipment and the listing Agency.

Equipment access panels and doors should be sized and located to provide easy access for servicing, adjustment and maintenance

of the heating units installed. Consideration should be given to components that might require replacement during the life of the

product. .All set-up and test points as well as operating controls should be visible and readily accessible from the front of the vestibule

or access opening.

General Information to include in Installation and Operating Instructions

The “Listed” equipment manufacturer’s Installation and Operating Instructions shall provide all necessary information as required by

ANSI Z83.8 –CSA 2.6 for the application, including but not limited to the following; Installation Codes, Hazard Warnings, gas piping,

electrical connection, Lighting Instructions, Sequence of Operation, Manual reset switches, Wiring Diagrams, Clearance to

Combustibles, Airflow and Rise ranges, Venting and troubleshooting, Minimum input rate adjustment, and for checking the gas

tightness of the safety shut-off valve(s) on at least an annual basis, as identified in the sections of the referenced standards identified

in “Instructions” and “Marking”.

Reference to the following information must be included in the instructions that the OEM provides with the finished product.

oAll unit installations must be in accordance with the National Fuel Gas Code ANSI Z223.1 (NFPA 54) in the US and

Can/CGA-B149 Installation Code in Canada and all applicable local codes and ordinances.

oA WARNING that the furnace is not certified or suitable for use in drying or process applications. Use in such applications

voids any warranty and manufacturer disclaims any responsibility for the duct furnace and/or application

oA WARNING that the Gas-fired furnaces are not designed for use in hazardous atmospheres containing, flammable vapors

or combustible dust, in atmospheres containing chlorinated or halogenated hydrocarbons, or in applications with airborne

substances containing silicone.

oA WARNING that the presence of chlorine vapors in the combustion air supply to gas fired heaters presents a substantial

corrosion hazard.

oA WARNING: The use and storage of gasoline or other flammable vapors and liquids in the vicinity of this appliance is

hazardous.

oWARNING label attached to exterior of cabinet as required by Z83.8-CSA 2.6 Sections 4.31.7.

oSafety, lighting, operating and shutdown instructions

oAll electrical equipment must be grounded and wired be in accordance with the National Electric Code (ANSI/NFPA 70) in

the US and the Canadian Electric Code (CSA C22.1) in Canada.

oA statement to cover replacement wiring “ If any original wire as supplied with the appliance must be replaced, it must

be replaced with wiring material having a temperature rating of at least 105 oC (221 oF).”

4

Additionally the Original Equipment Manufacturer of the “Listed” equipment shall provide the following in accordance with its

product listing:

An enclosed vestibule area to house and protect gas controls, burner assemblies, induced draft fans and electrical controls.

Openings for combustion air must be provided in a panel or door (except separated combustion systems) with direct access to

the vestibule area where the burners and draft inducer are located. This air opening(s) must be sized to provide a suitable supply

of air for combustion to the burner compartment. Combustion air openings in the cabinet should be sized to provide 1 sq. in

of free area per 4000 Btuh of input.

A vent discharge duct with a minimum cross-sectional area equal to outlet area of the draft inducer. In multiple unit applications,

heater modules must be individually vented. (See sections covering “Venting”)

An airflow switch in the cabinet or duct to prove circulating airflow. Prevents operation of the gas heater in the event of failure of

the circulating air fan or reduced airflow due to filter blockage An airflow probe should be installed upstream of the heating section.

A manual reset auxiliary limit to prevent overheating of the heating unit in the event of a circulating air fan failure or reverse air

flow.

Removable access panels in cabinet or duct immediately upstream and downstream of duct furnace to allow for inspection of

the heat exchanger (See Figure 1). These openings should be large enough to observe smoke or reflected light inside the casing to

inspect heat exchanger for leaks, and to check for hot spots on the heat exchanger due to poor air distribution or insufficient air

volume. Attach covers so as to prevent air leakage.

Figure 1 –Inspection panels

Access Panel

Duct

Furnace

Ductwork

Aiflow

Filters and filter rack components rated 250 oF (121 oC) or less must be located a minimum of 3 feet (.9m) downstream of heater

section.

Clearances to combustibles as appropriate for the product category, but in no case less than the following unless determined by

test as part of the manufacturer’s equipment listing:

Sides and back ………………………. 6 in. (152mm)

Bottom ………………………………… 2 in. (51mm)

Top ……………………………………. 6 in. (152mm)

Front …………………………………… 36 in. (914mm)

Vent pipe to any combustible surface 6 in. (152mm)

5

Furnace Module Application

Figure 2 –Typical Installation

Min. –40 oF

Max. Discharge

Temperature 160 oF

above inlet air

1.75" min / 2.75" max

Max. Rise = See Series Ratings (60 -100 oF)

2 ft. Min.

Heat Exchanger on positive

pressure side of circulating air fan

Fan sized on required

cfm air delivery &

pressure drop across HE

Provide uniform well

distributed air flow to

heating unit

Air Switch/

Probe

Integral High

Limit Switch

Auxiliary Manual

Reset Limit

The heat exchanger must be sheeted to provide an air tunnel properly sized to direct airflow over the heat exchanger and

eliminate by-pass air, as shown in Figure 3.

Figure 3 –Heat Exchanger Air Tunnel

Vest

Panel

.

2.0" to 4.0"

(51 to102mm)

Flush to HE

Support Bracket

Sheeting

Text

Text

If air tunnel opening is larger than heater profile, provide panels to block by-pass air and direct all airflow over heat

exchanger as shown in Figure 4 below.

Figure 4 –Air Tunnel

.

Text

Text

AHU Cabinet /

Air Tunnel

Block off

Sheeting

6

Airflow Distribution & Multiple Heaters Application

Selection of furnace modules to provide desired conditions requires careful consideration of necessary discharge air temperature,

airflow, pressure drop, air tunnel dimensions and furnace configurations. Furnace modules may be installed individually, in tandem or

in parallel. Refer to examples in Figure 5 for suggested configurations. The maximum allowable discharge air temperature is 160 oF

for multiple heater installations. Maximum allowable duct static pressure is 3.0” w.c.

Figure 5 –Recommended Heater Installations

Single Unit –Top View

Tandem Unit Top View

Parallel Unit –Top View

Maximum Airflow

When applying duct furnace modules, the system design should insure that airflow across the heat exchanger provides sufficient

temperature rise under all operating conditions to avoid continuous condensation in the heat exchanger or flueways. Condensation

can occur if flue gases inside the heat exchanger are cooled below their dew point or tube temperatures drop below the flue gas dew

point. Flue gas condensate is corrosive and operating in a continuous condensing mode, or accumulation of condensate, can lead

to premature heat exchanger failure.

The likelihood of condensing operation increases for make-up air units (return air less than 40 oF), modulating furnaces on constant

volume airflow applications and applications where duct furnace module is over-sized for “typical” heat load and runs at 50% of

maximum input or less the majority of the time.

Providing a variable speed circulating air fan with modulating systems or a dampered bypass in constant volume applications will

typically provide necessary control of airflow to avoid condensation.

4939 CFM

45 oF Entering

Air Temp

300,000 Btuh

Input

45 oF Rise

90 oF

Discharge

Air Temp

9978 CFM

45 oF Entering

Air Temp.

300,000 Btuh

Input

22.5 oF Rise

300,000 Btuh

Input

22.5 oF Rise

90 oF

Discharge

Air Temp

300,000 Btuh

Input

45 oF Rise

9978 CFM

45 oF Entering

Air Temp

9978 CFM

45 oF Entering

Air Temp

mp

90 oF

Discharge

Air Temp

Pressure Drop .22” w.c.

Pressure Drop .78” w.c. per section

Total Pressure Drop 1.56” w.c.

Pressure Drop .22” w.c.

Based on equal airflow of

4939 cfm thru each section

300,000 Btuh

Input

45 oF Rise

7

Auxiliary Limit and Airflow Proving Switch

An airflow proving switch and auxiliary manual reset temperature limit must be installed in the duct furnace module application.

The airflow switch proving prevents operation of the gas furnace in the event of failure or restriction of the circulating air fan. An

airflow probe should be installed upstream of the heating section (See Fig. 6) to detect a positive pressure when the circulating air fan

is operating during heating cycle. The airflow switch shuts off electrical supply to the ignition controller if a positive pressure is not

detected by the switch, due to lack of air flow through the heat exchanger. An airflow proving switch kit is available for this heating

unit.

A manual reset auxiliary limit prevents overheating of the furnace module in the event of a circulating air fan failure or reverse air

flow. Under these conditions the integral primary high limit would cycle the heater resulting in possible heat build-up and damage to

the heating unit. A properly located auxiliary limit (See Fig. 6) will function to shut-off the gas supply to the furnace module. An

auxiliary manual reset limit kit is available for this heating unit.

Figure 6 –Auxiliary Limit & Air Probe Locations

6.00"

Auxiliary Manual

Reset Limit

6.00 " 3.00 "

Air Probe

Airflow

Air Duct

Air Probe

Airflow

Direction

6.00"

6.00"

Auxiliary Manual

Reset Limit

Airflow

Air Probe

6.00"

6.00"

Auxiliary Manual

Reset Limit

Air Probe 6.00"

Airflow

Horizontal Air Flow

Set Auxiliary Limit @ 180 oF

Vertical Air Flow (Downflow)

Set Auxiliary Limit @ 120 oF

Vertical Air Flow (Upflow)

Set Auxiliary Limit @ 200 oF

Air Flow Probe Installation

8

Installation

Verify that the following before installing the furnace module

1. Electrical supply and gas supply match ratings and gas type marked on the furnace module rating plate before

installing the duct furnace insert.

2. Furnace module is to be installed in orientation marked on vestibule. Orientation is specific to airflow direction

through the heating section of the unit.

Carefully support and lift furnace into position and slide into cabinet. Provide proper support or rigging using vest

panel and tube support brackets to support furnace during installation into cabinet. Fasten to cabinet.

The following must be included as part of the installation in the heating unit:

1. A properly designed vent system connected to the furnace module to convey the products of

combustion (flue gases) outside the building. For outdoor applications be sure the flue gases are

directed away from any combustion air inlets.

2. Electrical control panels mounted in a well ventilated area away from heated surfaces.

3. Completed electrical connections from furnace to the control panel (shipped loose). Wiring

connections are quick-connect type to provide interconnection to the furnace gas valves, pressure

switches and limits.

4. Properly supported wiring in vestibule area. Wiring should not contact metal surfaces which may

be hot during furnace operation.

5. Pipe sealant resistant to LP gases on all thread gas connections.

Combustion Air Supply

The furnace module needs an ample supply of air for proper and safe combustion of the fuel gas. Do not block or

obstruct air openings to the area where the heating unit is installed. Openings for combustion air must be

provided in a panel or door with direct access to the vestibule area where the burners and draft inducer are located.

This air opening(s) must be sized to provide a suitable supply of air for combustion to the burner compartment and

have a minimum free area of 1 sq. in. (625mm2) per 4,000 Btuh (2,345 W) of rated input for total input. The minimum

dimension of any air opening should not be less than 3 inches. Air handling unit must be installed so that air access to

inlet openings are unobstructed.

For outdoor installations, combustion air inlet and flue gas outlet must be located in the same pressure zone to

minimize effects of wind on burner and heater performance.

For indoor installations, locate heating unit to insure an adequate supply of fresh air to replace air used in the

combustion and ventilation process. Air must also enter the appliance location to replace the air exhausted through the

vent system. Refer to installation codes for specific requirements and guidelines.

WARNING !

Do not use heat exchanger tubes, combustion blower support bracket or manifold pipe as load

bearing support during handling or installation of furnace in cabinet. Severe damage may result

to combustion air blower, heat exchanger tubes, tube joints or burner assembly that result in

unsafe operation, severe personal Injury, death or significant property damage.

9

Figure 7 -Furnace Component Identification

Condensate Drains

Heating units located downstream of a refrigeration system or a cooling coil will typically experience condensation during

operation of the air conditioning. Heat exchanger surfaces may be cooled below the dew point temperature of the moist

ambient air inside the heat exchanger resulting in condensation of water vapor in the heat exchanger and flue

collector(s). This condensate is not harmful to the heat exchanger provided it is drained continuously. A ¼” NPT

condensate drain connection is provided in the flue box for duct furnaces with vertical or horizontal top mounted

burner tray, to remove condensate from heat exchanger.Condensate drain lines must be connected. Condensate

drain lines should have corrosion resistance at least equal to that of 304 SS.

Heat exchangers are under negative pressure and a P-

trap should be provided as shown in figure below. The

use of a “Tee” fitting allows for cleaning the trap. Use

plug in cleanout opening.

5.00" 2.00"

Tee Fitting

Plug

Collector Box

Modulator Valve

(Modulating systems only)

Two-Stage

Gas Valve

Flame

Rollout

Switch

Flame Sensor

Hi Limit Switch

Manifold

Pressure Tap

Spark Igniter

Wire Harness

to JB/Ignition

Control

Motor Support

Bracket

Draft Inducer

Motor

Induced Draft

Fan Assy.

Gas Inlet

Connection

Combustion Air

Pressure Switch

Condensate Drain

Fitting

10

In furnace modules with bottom mounted horizontal burner, condensate will drain from the open end of the tubes. A

condensate collection pan which attaches to the burner assembly is available as an option.

Additionally, condensation may form on surfaces such as the furnace vestibule panel (header plate) in contact with the

conditioned air. Depending on operating conditions, condensate may collect in the lower vestibule pan. Provisions

should be made to drain and remove this condensate as well, if such operating conditions exist.

Typically, condensation does not occur in mid-efficiency furnaces during heating operation. However, in applications

with modulating controls or with 100% make-up air, some condensation may occur in the heating cycle. In these

applications, connection of the drain line is required to prevent condensate buildup and possible heat exchanger

damage. Flue gas condensate is corrosive and may result in shortened heat exchanger life. Use corrosion

resistant metal tubing. Copper tubing is not suitable for flue gas condensate.

Disposal of condensate is subject to local codes and ordinances. Some municipalities require that the acidic condensate

produced be neutralized before being discharged into the sanitary sewer. A condensate neutralizer kit is available.

When neutralizer kits are provided they should be installed where they are readily accessible for inspection and

maintenance

Gas Supply, Piping and Connections

1. Installation of piping must conform with local building codes and ordinances, or in the absence of local

codes with ANSI Z223.1 the National Fuel Gas Code. In Canada, installation must be in accordance with

CAN/CGA –B149.1 for Natural gas and B149.2 for propane units. Use a pipe sealant resistant to LP

gases on Gas supply connections to heater.

2. Properly support gas valve with back-up wrench, during supply pipe installation to prevent loosening

valve or damage to burner assembly or manifold.

3. Gas piping must be sized for the total Btu input of all units (heaters) serviced by a single supply.

4. Be sure that gas regulators servicing more than one heater have the proper pipe and internal orifice size

for the total input of all heating units serviced by the regulator. (See Fig. 8)

5. Individual duct furnace modules require a minimum inlet gas pressure as shown below.

Natural Gas Propane Gas

Minimum (50,000 to 400,000 Btuh models) 5.0” w.c. 11.0” w.c.

Minimum (401,000 and higher Btuh models) 6.0” w.c. 12.0” w.c.

Maximum Inlet 13.5” w.c. 13.5” w.c.

6. Connect a fitting suitable for connection to a pressure gauge capable of measuring gas pressure to 1/8” NPT tap

provided on the inlet side of the gas valve (Fig. 16) or manual shut-off valve tapping (See Fig. 9). Measure inlet

pressure to each heater serviced by a single regulator with all heaters in operation. (See Fig. 8)

Figure 8

7. A drip leg (sediment trap) and a manual shut off valve must be provided immediately upstream of the gas

control on the heating unit. To facilitate servicing of unit, installation of a union is recommended. (See Figure 9)

Unit 1

Unit 2

Unit 3

Max. 13.5” w.c.

Min. Inlet pressure

Pressure

Regulator

Gas

Supply

11

Figure 9

8. The duct furnace module gas piping was leak tested prior to shipping. However, during shipping and installation connections

may have loosened. Check for leaks using a soap solution and correct any leaks before placing furnace in operation.

The individual heat module inlet gas supply pipe connection size is ¾” NPT for gas inputs up to 400,000 Btuh

and 1” NPT for gas inputs between 401,000 and 600,000 Btuh for all control systems.

Venting

The venting system is designed for direct discharge of flue gases to the outdoors. The vent discharge opening should be located to

provide an unobstructed discharge to the outside and should be located as far from the combustion air inlet as possible but in the

same pressure zone. Flue gases must be directed to avoid possible recirculation into the combustion air supply.

Outdoor Installation

Figure 10 –Outdoor Horizontal Venting - Outdoor furnaces must be individually vented.

Combustion Air Opening

AHU

Cabinet

Rain Hood

(Optional)

Flue Gas flow unobtructed

Comb

Blwr.

Mesh Screen

AHU

Cabinet Combustion Air

Inlet Cover

Mesh Screen

Rain Hood

(Optional)

Vent duct should pitch down toward outlet, to insure that any condensate that occurs in vent duct drains away from combustion

blower fan housing. The duct opening should be protected by a ½ in. x ½ in. (12mm x 12mm) mesh screen. An optional rain hood

may be used over the discharge opening to prevent wind driven rain from entering the vent duct, but should not intersect the flue gas

discharge path.

WARNING !

1. All field gas piping must be pressure /

leak tested prior to operation. NEVER

use and open flame to check for leaks.

Use a soap solution or other leak

detecting solution..

2. Gas pressure to appliance controls

must never exceed 13.5” w.c. (1/2 PSI)

WARNING !

1. When pressure testing at ½ PSI or less,

close the manual shut-off valve on the

appliance before testing.

2. When pressure testing gas supply line at

½ PSI or higher, close manual gas valve

and disconnect heater from supply line to

be tested. Cap or plug the supply line.

12

Where sufficient clearance for proper horizontal venting cannot be provided, or in jurisdictions requiring a 4 foot separation between

flue gas discharge and combustion air inlet, flue gases need to be vented vertically. Refer to Figure 11 for suitable venting method. A

vent adaptor is required to transition from the rectangular ID fan discharge to round vent pipe. Joints in the vestibule must be sealed.

Single wall vent pipe in the vestibule space must be insulated.

Vent pipe must terminate at least 1 ft. above the cabinet. The vent must be located on the same side of the appliance as the

combustion air inlet opening. Condensation in the vent pipe is likely during heater start-up cycle and provision for drainage must be

provided in closed vent piping.

Figure 11 –Outdoor Vertical Venting

Combustion Air Opening

ID

Fan

Rectangular to

Round adapter

Condensate

Drain

AHU

Cabinet

4 ft. Min.

12 in. Min

Field Starkap or equal

listed Vent cap

Indoor Installation

Duct furnace module must be connected to a properly designed venting system to convey flue gases outside of

the heated space.

Category 1 Vent systems must be sized and installed in accordance with the National Fuel Gas Code, ANSI Z223.1 (NFPA 54)

Chapter 13 in the United States or CAN/CGA-B149 Natural and propane gas installation code, Section 8 and Annex C, in Canada.

Vent pipe should be sized based on furnace input as listed in Table 1.

Table 1-Vent Sizing

Models Input Rating (Btuh) Input Rating (W) Vent Pipe Dia.

HX(D, G) 050-175 50,000 –175,000 14653 –51287 5 in. (126 mm)

HMG200-400, HMD200 200,000 –400,000 58614 –117228 6 in. (152 mm)

HX(A,B)150-400 150,000 –400,000 43960 –117228 6 in. (152 mm)

HX(A,B) 450-600 450,000 –600,000 131881 –175842 7 in. (178mm)

A vent connector adaptor is available that transitions the induced draft fan outlet (rectangular) to round vent pipe. This adaptor must

be installed on the outlet of the ID fan to provide a connection point for the vent pipe.

Vertically Vented Duct Furnaces –Category I

Proper venting of the heating units is the responsibility of the installer. UL Listed Type B vent or single wall metal pipe may be used

for Category 1 vents. Single wall vent pipe shall have seams and joints sealed with pressure sensitive aluminum tape or silicone

rubber sealant, rated for 400 oF or higher. Joints should be secured with at least two corrosion resistant fasteners.

1. Vent connector runs should be kept as short as possible with a minimum number of elbows. Each 90o elbow is equivalent to 5

feet (1.5m) of straight vent pipe run.

2. Maximize the height of the vertical run of vent pipe. A minimum of six (6) feet (1.8m) of vertical pipe is required.

3. All vertical runs must be terminated with a Listed vent cap.

4. Horizontal runs should be pitched upward ¼” per foot (21mm/m) and should be supported at 3 foot (1m) intervals.

5. Dampers must not be used in vent piping runs. Spillage of flue gases into the occupied space could result. Vent connectors

serving Category 1 furnaces must not be connected into any portion of a mechanical draft system operating under positive

pressure.

13

Figure 12 –Indoor Vertical Venting

5 ft. Min.

(1.52m)

Condensate

Drain

Listed Vent

Terminal

Use Insulated

Vent Outdoors

Roof

2 ft. Min

(0.61m)

Thimble

10 ft. (3.05 m) Max.

(Not to exceed 75%

Vertical Flue Height)

1/4in. (6mm) pitch per

1ft. (305mm) horizontal

run

See Table 1 for

vent diameter

Horizontally Vented Duct Furnaces -Category III

Pressures in Category III venting systems are positive and therefore care must be taken to avoid flue products from

entering the heated space. Use only vent materials and components that are UL listed and approved for Category

III venting systems when venting horizontally.

All vent pipe joints must be sealed to prevent leakage into the heated space. Follow instruction provided with

approved venting materials used. The proper vent pipe diameter must be used, to insure proper venting of combustion

products. See Table 1.

The total equivalent length of vent pipe must not exceed 50 ft. (15.25m). Equivalent length is the total length of straight

sections, plus 5 ft. (1.52m) for each 90o elbow and 2.5 ft (0.76m) for each 45o elbow.

The vent system must also be installed to prevent collection of condensate. Pitch horizontal pipe runs downward ¼ in.

per foot (21mm per meter) toward the outlet to permit condensate drainage. Insulate vent pipe exposed to cold air or

routed through unheated areas. Insulate vent pipe runs longer than 10 ft. (3m). Insulation should be a minimum of ½ in.

(12mm) thick foil faced material suitable for temperatures up to 500 oF. Maintain 6in. (152mm) clearance between vent

pipe and combustible materials.

A Vent Cap listed for horizontal venting must be provided. Vent cap inlet diameter must be same as the required vent

pipe diameter. The vent terminal must be at least 12 in. (305mm) from the exterior wall that it passes through to prevent

degradation of building material by flue gases. The vent terminal must be located at least 1 ft. (305mm) above grade, or

in snow areas, at least 3 ft. (1m) above snow line to prevent blockage. Additionally, the vent terminal must be installed

with a minimum horizontal clearance of 4 ft. (1.2m) from electric meters, gas meters, regulators or relief equipment.

14

Figure 13 –Indoor Horizontal Venting

Exterior Wall

AHU

Z

Pitch pipes down1/4in. (6mm) pitch

per 1ft. (305mm) horizontal run to

allow for condensate drainage

Condensate

drain Dispose in

accordance with

local codes

Tee Fitting w/ Bird Screens

(See Note for Alternate)

Note: Listed Horizontal Vent

Termination may be used

In place of T Fitting

1 ft.

(0.3m)

Min.

5 ft. (1.52 m) Min.

50 ft. (15.2m) Max. Equiv. Length

3 ft. (0.9m)

Above grade

or expected

snow depth

EACH APPLIANCE MUST HAVE ITS OWN INDIVIDUAL VENT PIPE AND TERMINAL. Do not connect vent system from

horizontally vented units to other vent systems or a chimney.

Separated Combustion Systems

HM and HH duct furnace modules may be applied to systems for operation in separated combustion systems. The

module must be mounted with the burner section in a reasonably airtight vestibule compartment, as these systems

provide combustion air from outside the heated space and vent the products of combustion outdoors. No air openings

are to be provided in the vestibule access door or panel and sealing grommets or gaskets should be provided for gas

and electrical entry points into the vestibule to maintain a reasonably airtight seal. Additionally the heating unit must

include the following:

1.) A suitable airtight gasket on the vestibule door or access panel.

2.) An observation window in the door to permit observation of ignition and main burner flame during operation and

servicing.

3.) A door or panel interlock switch to insure that door or panel is closed or in place during operation.

4.) Openings into the vestibule space for attachment of inlet air supply pipe and vent pipe, sized for the Btuh (W)

input rating.

5.) Approved vent terminals on both the supply air inlet and flue gas exhaust. NOTE: The inlet and outlet

terminals must be located in the same pressure zone to provide for safe appliance operation.

6.) Instructions covering installation and operation for the separated combustion system must be included in the

equipment manufacturer’s Installation and Operation Manual.

Proper installation of air inlet and flue gas exhaust piping are essential to proper operation of the heat module. Inlet air

pipe must be same size as vent pipe based on input ratings. See Figures 14 and 15 for recommended installation.

Separated combustion systems may not be common vented. Each heater must have its own

individual air supply and flue gas exhaust vent

15

Figure 14 –Vertical Venting

AHU

Roof Deck

2.5 ft. (0.75m)

Min.

Listed Vent

Terminals

6 ft. (1.8 m) Min.

To Wall or

Adjoining Building

Exhaust Vent

18 in.

(0.3m)

Min.

18 in. (0.46m)

Min.

(* See Note)

Combustion Air

Inlet

* Note: Provide sufficient

clearance (height) to exceed

expected snow depth.

Tee Fitting with

Drip Leg and

Cleanout Cap

(Both Pipes)

NOTE:

For multiple heater installations provide independent air supply and vent to each heating unit

Figure 15 –Horizontal Venting- Separated Combustion

Exterior Wall

18" (0.46m)

Min. @ CL

1 ft.

(0.3m)

Min.

Listed Horizontal

Vent Terminal(s)

5 ft. (1.52 m) Min.

25 ft. (7.6 m) Max. Equiv. Length

Pitch pipes down1/4in. (6mm) pitch

per 1ft. (305mm) horizontal run to

allow for condensate drainage

2 ft.(0.6m)

Min.

3 ft. (0.9m)

Above grade

or expected

snow depth

AHU

Note: Be sure that the vent cap used for horizontal venting applications is approved for horizontal application.

Certain manufacturer’s vent terminals are approved for vertical installation only.

16

Operation and Adjustment

1. This furnace module does not have a pilot. It is equipped with a direct spark ignition device that automatically

lights the gas burner. DO NOT try to light burners by hand.

2. BEFORE OPERATING, leak test all gas piping up to heater gas valve. Smell around the unit area for gas. DO

NOT attempt to place heater in operation until source of gas leak is identified and corrected.

3. Use only hand force to push and turn the gas control knob to the “ON” position. NEVER use tools. If knob does

not operate by hand, replace gas valve prior to staring the unit. Forcing or attempting to repair the gas valve

may result in fire or explosion.

Start-up

1. Turn temperature controller to its lowest setting or open heat enable contact

2. Turn off power and gas supply.

3. Install a tapped fitting in the manifold pressure tapping for attachment to a manometer, or other gauge suitable

for measuring up to 10” w.c.

4. Wait 5 minutes for any gas to clear out. If you smell gas, see Step 2 above and correct leak. If you don’t smell

gas or have corrected any leaks, go to the next step.

5. Open all manual gas valves

6. Turn power on at disconnect switch

7. Set controller to its highest position or close heat enable to initiate call for heat and maintain operation of unit.*

8. Draft inducer will run for a 15 to 30 second pre-purge period (See Sequence of Operation provided)

9. At the end of the pre-purge the direct spark will be energized and gas valve will open

10. Burners ignite.

11. Verify

12. On the initial start-up, or after unit has been off long periods of time, the first ignition trial may be unsuccessful

due to need to purge air from manifold at start-up.

13. If ignition does not occur on the first trial, the gas and spark are shut-off by the ignition control and the control

enters an inter-purge period of 15 to 90 seconds, during which the draft inducer continues to run.

14. At the end of the inter-purge period, another trial for ignition will be initiated.

15. Control will initiate up to three ignition trials on a call for heat before lockout of control occurs.

16. Control can be brought out of lockout by turning controller to its lowest position or opening the heat enable

contact and waiting 5 seconds and then turning the controller back to the previous temperature setting or

closing the heat enable contact. Some controls provided will automatically reset after one hour and initiate a

new ignition sequence if call for heat is maintained.

Note: If modulating controls are provided on furnace module, a separate set-up sheet is included with this manual.

Refer to that set-up sheet for complete start-up instructions

Manifold Pressure Adjustment

The correct heat capacity of the furnace module is controlled by the burner orifices and the gas manifold pressure. A

pressure tap is provided in each module manifold for measuring the gas manifold pressure. Manifold pressure must be

checked at start-up and during any service or maintenance. All control systems require a manifold pressure of

3.40 to 3.50 in. w.c. at maximum input on Natural Gas,and 9.8 to 10.0 in. w.c. on Propane Gas. See Figure 16 for

Gas Valve adjustment locations. Verify proper low fire adjustments as outlined in the Sequence of Operation for the

operating control system provided.

17

Figure 16A–Honeywell VR8305Q Gas Valve

Figure 16B –White Rodgers 36H Gas Valve

Figure 16C –Honeywell V8944 Gas Valve

1/8” NPT Inlet

Pressure Tap

Manifold Pressure Adjustment

Remove Brass cap and adjust

with plastic screw

Electrical

Connection Block

Manual Shut-off

1/8” NPT Inlet

Pressure Tap

2nd Stage (Hi Fire) Manifold

Pressure Adjustment

(3/32” Allen Key)

1st Stage (Lo Fire) Manifold

Pressure Adjustment

Manual Shut-off

Control Knob

Electrical

Connection Block

18

Electrical Controls & Wiring

All electrical wiring must be done in accordance with the National Electric Code, ANSI/NFPA No. 70.

Operating electrical controls are mounted to a panel and shipped in a separate carton.

Mounting locations should be selected to prevent exposing the controls to the following:

Moisture, especially wind driven rain or snow

High temperatures- surfaces or ambient conditions must be less than 160 oF

Avoid mounting controls on or adjacent to surfaces that may be hot during heater operation –especially vent ducts or piping.

Wiring connections are quick-connect type to facilitate interconnection to the heat module gas valves, pressure switches and limits.

Minimize length of high voltage spark lead(s) and route this wire independently of all control wiring to reduce radio frequency

interference (RFI) with the electronic controls

Electrical Supply

The furnace control system requires both line voltage and low voltage circuits with correct polarity, and clean neutral and

ground. Line voltage readings between L1 and Neutral as well as L1 and Ground should be within +/- 3 volts.

Refer to electrical supply information on duct furnace rating plate.

Instructions and Wiring Diagrams

Each heater module is shipped with its own wiring diagram, sequence of operation and control diagnostic information for the control

system provided on the heater module as part of this OEM information package.

Each heater is test-fired at the factory and a copy of the Test and Inspection sheet is also included.

These documents should be retained by the air handling unit manufacturer for future reference.

A separate Operating and Maintenance Instruction package is provided with each heating including these documents. This package

should be included with the manufacturer’s instructions sent with the air handling unit.

Heatco Inc.

50 Heatco Court

Cartersville, Ga. 30120

Other manuals for HM SERIES

2

This manual suits for next models

1

Table of contents

Other heatco Control Unit manuals

Popular Control Unit manuals by other brands

Ion Technologies

Ion Technologies IT- DS05-S Operation & maintenance manual

Bed-Check

Bed-Check Classic-Check Quick programming guide

G.R.A.S.

G.R.A.S. 12AR instruction manual

EOS

EOS ECON H4 Installation and operating instruction

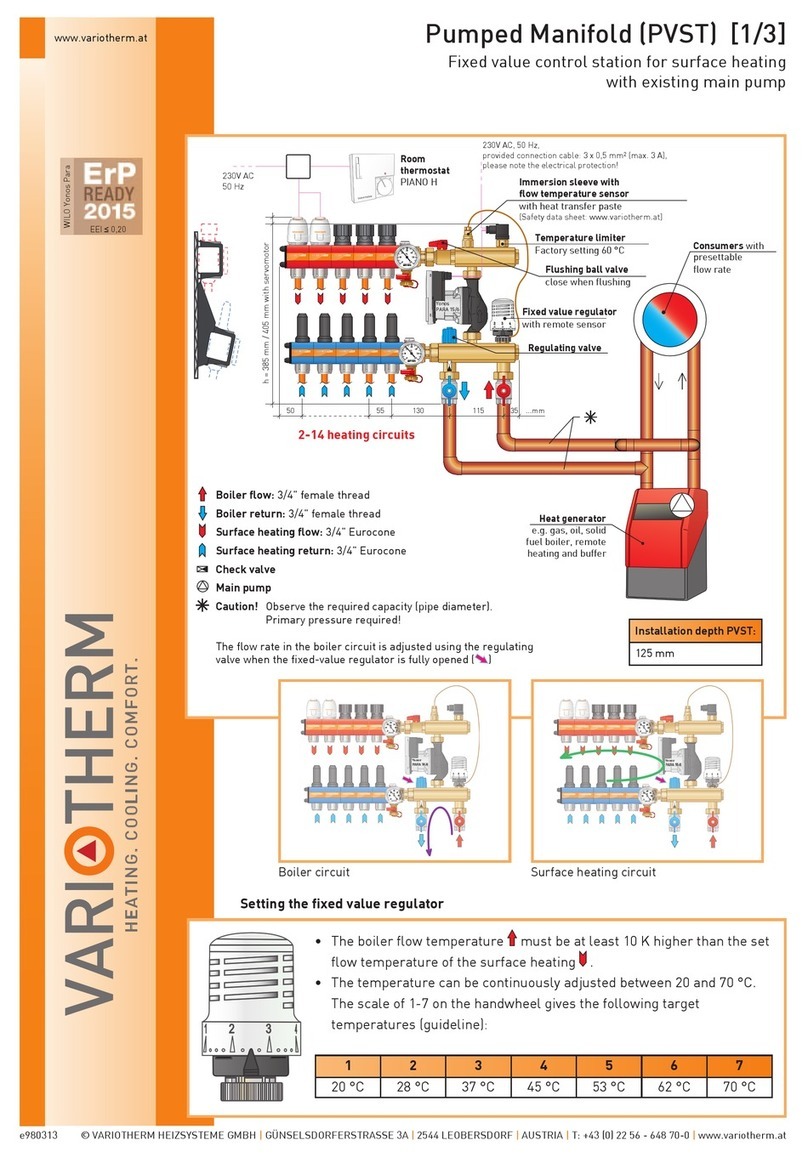

VarioTherm

VarioTherm Pumped Manifold manual

Panasonic

Panasonic BMED500 - CAMERA CONTROL UNIT operating instructions