HeatLink 31355 Manual

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

1

www.heatlinkgroup.com

6

7

8

9

10

11

12

13

15 16 17 18

54321

17

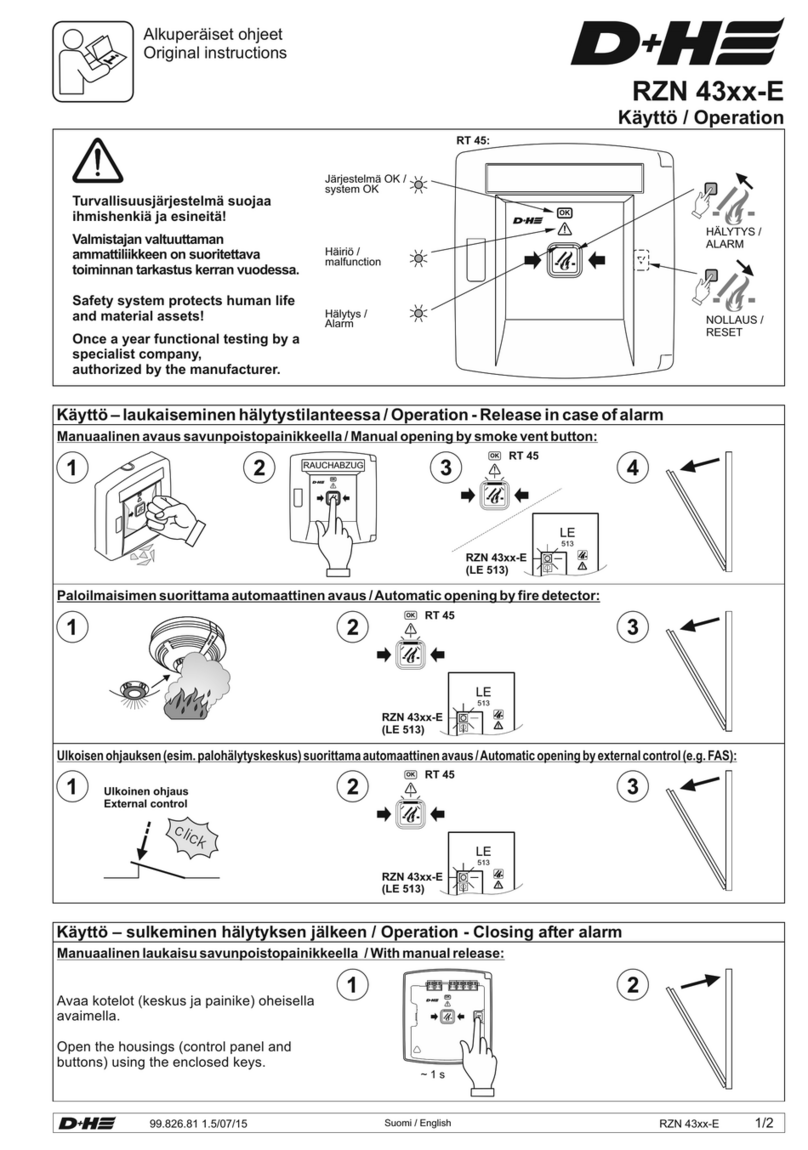

Terminal Functions

Compact Mixing

Reset Control 31355

Power: 24 V (ac) ±10% 50/60 Hz 100 VA (max)

Floating Output: 48 VA (max)

V (dc) Output: 3 kΩ min load (3 mA max)

Boiler Relay: 230 V (ac), 5A

Made in Canada

977-03K

2 (ON) /

1

2

3

4

5

6

7

8

9

10

11

12

15

16

13

18

Open / DDC Blk

Com / DDC Blu

Close / DDC Red

Timer Relay 1

Timer Relay 2

Indoor Sensor

Sensor Common

Mix Sensor

Sensor Common

Outdoor Sensor

Power 24 V (ac) “C”

Power 24 V (ac) “R”

Heat Demand “R”

Heat Demand

Pump

Boiler Relay

Boiler Relay

1 Setback (ON) / Off

3 Perm. Demand (ON) /

Ext. Demand

DIP Switch Functions

ON

123

No Power

Timer / Pump / Mixing Relays: 24 V (ac) 2A

Heat Demand: Low Voltage Dry Contact

INSTALLATION CATEGORY II

Refer to Literature

Installation and Setup Instructions

The Compact Mixing Reset Control 31355 regulates the supply water temperature of an automated mixing valve in

order to provide outdoor reset or setpoint operation. The 31355 provides a floating action or a 0/2 – 10 V (dc) signal

to adjust the mixing valve position. The 31355 also includes two separate night setback channels.

For a full color version of this document, download the PDF from the professional section of our website.

Description

• Outdoor reset for energy savings

• Setpoint

• Floating action

• 0 - 10 V (dc)

• 2 - 10 V (dc)

• Two night setback channels

Features

Table of Contents

Table of Contents........................................................ 1

DIP Switches and Display .......................................... 2

Dip Switches ....................................................... 2

Display ................................................................ 2

Symbol Description ............................................. 3

User Interface ..................................................... 4

Setup .......................................................................... 4

View Menu ......................................................... 5

Adjust Menu ........................................................ 6

Time Menu ......................................................... 8

Schedule 1 Menu ............................................... 9

Schedule 2 Menu ............................................. 10

Modes of Operation ................................................. 11

Sequence of Operation............................................. 13

Installation ............................................................... 17

Wiring ............................................................... 18

Cleaning the Control ................................................ 24

Testing ...................................................................... 24

Max Heat Feature..................................................... 24

Error Messages ........................................................ 25

Appendix I: Boiler Piping Options............................. 27

Appendix II: Load Piping Options ............................. 29

Technical Data .......................................................... 32

Warranty ................................................................... 32

L631355D

May 26, 2009

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

2

6

7

8

9

10

11

12

13

15 16 17 18

54321

17

Terminal Functions

Compact Mixing

Reset Control 31355

Power: 24 V (ac) ±10% 50/60 Hz 100 VA (max)

Floating Output: 48 VA (max)

V (dc) Output: 3 kΩ min load (3 mA max)

Boiler Relay: 230 V (ac), 5A

Made in Canada

977-03K

2 (ON) /

1

2

3

4

5

6

7

8

9

10

11

12

15

16

13

18

Open / DDC Blk

Com / DDC Blu

Close / DDC Red

Timer Relay 1

Timer Relay 2

Indoor Sensor

Sensor Common

Mix Sensor

Sensor Common

Outdoor Sensor

Power 24 V (ac) “C”

Power 24 V (ac) “R”

Heat Demand “R”

Heat Demand

Pump

Boiler Relay

Boiler Relay

1 Setback (ON) / Off

3 Perm. Demand (ON) /

Ext. Demand

DIP Switch Functions

ON

123

No Power

Timer / Pump / Mixing Relays: 24 V (ac) 2A

Heat Demand: Low Voltage Dry Contact

INSTALLATION CATEGORY II

Refer to Literature

6

7

8

9

10

11

12

13

15 16 17 18

54321

17

Terminal Functions

Compact Mixing

Reset Control 31355

Power: 24 V (ac) ±10% 50/60 Hz 100 VA (max)

Floating Output: 48 VA (max)

V (dc) Output: 3 kΩ min load (3 mA max)

Boiler Relay: 230 V (ac), 5A

Made in Canada

977-03K

2 (ON) /

1

2

3

4

5

6

7

8

9

10

11

12

15

16

13

18

Open / DDC Blk

Com / DDC Blu

Close / DDC Red

Timer Relay 1

Timer Relay 2

Indoor Sensor

Sensor Common

Mix Sensor

Sensor Common

Outdoor Sensor

Power 24 V (ac) “C”

Power 24 V (ac) “R”

Heat Demand “R”

Heat Demand

Pump

Boiler Relay

Boiler Relay

1 Setback (ON) / Off

3 Perm. Demand (ON) /

Ext. Demand

DIP Switch Functions

ON

123

No Power

Timer / Pump / Mixing Relays: 24 V (ac) 2A

Heat Demand: Low Voltage Dry Contact

INSTALLATION CATEGORY II

Refer to Literature

DIP Switches and Display

Dip Switches

DIP Switch 3: Permanent / External Demand

• Select whether the control should operate on a permanent

demand or on an external demand.

DIP Switch 2: Locked / Unlocked

• Select to lock or unlock the access level. Select ‘Lock’ to

prevent tampering.

DIP Switch 1: Setback / Off

• Select whether or not night setback is desired.

Display

MINMAX

VIEW

TIME

ADJUST

SCHD 1 2

Dem

AwayTmpy Perm

M

ACC

MODE

TYPE WWSD

SCHD TEST

°F°C

min

hr %

1 2

1 2 3 5 6 74

Item Field

Displays an abbreviated

name or symbol of the

selected item

Number Field

Displays the current value

of the selected item

Status Field

Displays the current

status of the control’s

inputs, outputs and

operation

Menu Field

Displays the

current menu

Access Levels

The control has 3 different access levels that restrict the number of viewable items.

1) Ad = Advanced: This is the highest access level. This level provides access to all settings on the control.

2) InS = Installer: This is the default access level. This level is suitable for the installer and for troubleshooting.

3) USEr = User: This is the lowest access level. This level is suitable for the building occupants.

Set the Locked /Unlocked DIP switch to the Locked position to allow the access level to be hidden from view. The Locked

position prevents unauthorized tampering with the access level.

The Access level for each item is shown in the View, Adjust, Time, Schedule 1 and Schedule 2 menu tables.

On Off

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

3

www.heatlinkgroup.com

ACCESS LEVEL

Shown when adjusting the access

level.

DEMAND

Shown when a permanent demand or

an external demand is present.

BOILER

Shown when the control requires the

boiler burner to fire.

PUMP

Shown when the control turns on

the pump. Flashes during the pump

purge.

LOCK / UNLOCK

A padlock is shown when the access

level is locked.

WARNING

Shown when an error message is

present on the control.

MIXING VALVE OUTPUT SCALE

The mixing valve position represented

as a bar graph. Arrows show whether

the valve is opening or closing.

TERMINAL UNIT

The type of space heating units. Select

one of 6 different types.

OUTDOOR TEMPERATURE

Shown together with the current

measured outdoor temperature.

INDOOR TEMPERATURE

Shown together with the current

measured indoor temperature.

TARGET

Shown together with another symbol to

indicate target temperature. Example

shown: Indoor Target Temperature.

DESIGN

Shown together with another symbol

to indicate design temperature.

Example shown: Outdoor Design

Temperature.

MIX

Shown together with another symbol

to indicate mixing parameters.

SUPPLY TEMPERATURE

Shown together with another symbol to

indicate supply temperature. Example

shown: Mix Supply Temperature.

ROOM

Shown when adjusting room

temperature.

MOTOR

Shown when adjusting motor speed.

MANUAL OVERRIDE

A temporary or permanent override

has been manually selected.

TEMPORARY

Atemporary override has been manually

selected.

PERMANENT

Apermanent override has been manually

selected.

WAKE

Wake time period event.

UNOCCUPIED

Unoccupied time period event.

OCCUPIED

Occupied time period event.

SLEEP

Sleep time period event.

AWAY

The away override has been manually

selected.

WWSD

The outdoor temperature above which

the heating is shut off.

TIMER 1

Shown when timer 1 schedule is in

night setback.

TIMER 2

Shown when the timer 2 schedule is

in night setback.

DAYS OF THE WEEK

1 = Monday

2 = Tuesday

3 = Wednesday

4 = Thursday

5 = Friday

6 = Saturday

7 = Sunday

Symbol Description

Display

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

4

User Interface

The 31355 has four buttons: Menu, Item, Up, Down.

Menu Button

Each press and release of the Menu button advances

the display to the next menu.

Five menus are available:

• VIEW

• ADJUST

• TIME

• SCHD 1 (Schedule 1)

• SCHD 2 (Schedule 2)

Item Button

Each press and release of the Item button advances the

display to the next item in the same menu.

Up or Down Button

Each press and release of the up or down button changes

the number value while in the ‘ADJUST, TIME, SCHD 1,

or SCHD 2’ menus.

VIEW

°C

ADJUST

°C

TIME

1

VIEW

°C

ADJUST

°C

TIME

1

VIEW

ADJUST

SCHD 1

°C

ADJUST

TIME

1

SCHD 1

SCHD 1

MODE

SCHD 1

TYPE

SCHD 2

SCHD 2

SCHD 2

MODE

Continue to

next item

Continue to

next item

Continue to

next item

Continue to

next item

Continue to

next item

Setup

All settings are stored in permanent memory which is not affected by power loss.

User Interface

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

5

www.heatlinkgroup.com

Item Field Range Access Description

VIEW

°C

-60 to 65°C

(-76 to 149°F)

Ad

InS

USEr

OUTDOOR

• The measured outdoor temperature.

•

Only available when outdoor design is not set to

off.

VIEW

°C

-30 to 130°C

(-22 to 266°F)

Ad

InS

USEr

INDOOR

• The measured indoor air temperature.

•

Only available when outdoor design is not set to off

and when an indoor air sensor is used.

VIEW

ADJUST

SCHD 1

°C

– – –, -30 to 130 °C

(– – –, -22 to 266°F)

Ad

InS

USEr

INDOOR TARGET

•The desired indoor air temperature.

•Only available when outdoor design is not set

to off and when an indoor air sensor is used.

VIEW

°C

-30 to 130°C

(-22 to 266°F)

Ad

InS

USEr

MIX SUPPLY

•The measured mix supply temperature.

•Not available in the User access level when

an indoor air sensor is used.

VIEW

°C

– – –, -30 to 130 °C

(– – –, -22 to 266°F)

Ad

InS

MIX TARGET

•The temperature target the control is to

maintain at the mixing valve outlet.

VIEW

SCHD

Wake , Unocc ,

Occ , Sleep ,

, , ,

Override

Ad

InS

USEr

SCHEDULE 1

•Schedule 1 operational status.

•Only available when DIP switch 3 is set to

External Demand.

VIEW

SCHD

Wake , Unocc ,

Occ , Sleep ,

, , ,

Override

Ad

InS

USEr

SCHEDULE 2

•Schedule 2 operational status.

•Only available when DIP switch 3 is set to

External Demand and the Schedule Mode is

not set to OFF.

VIEW

TYPE

J11 alternating with

74A

Ad

InS

TYPE

•The software version (J11 74 is constant).

The View menu items display the current operating

temperatures and status information of the system.

VIEW MENU

After the last item, the control returns to the first item in the menu.

Setup: View Menu

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

6

Item Field Range

Access

Description

ADJUST

°C

4.5 to 35.0°C

(40 to 95°F)

Ad

InS

USEr

INDOOR TARGET

•

Enter the desired indoor air temperature with indoor

temperature feedback.

•

The control adjusts water temperature to maintain desired

indoor air temperature.

• Only available when an indoor sensor is connected, and

outdoor design is not set to off and dip switch 3 is set to

permanent demand.

• For 2 event schedules: , .

• For 4 event schedules: , , , .

Wake Default =

21.0°C (70°F)

UnOccupied Default =

16.5°C (62°F)

Occupied Default =

21.0°C (70°F)

Sleep Default =

16.5°C (62°F)

ADJUST

°C

4.5 to 35.0°C

(40 to 95°F)

Default = 21.0°C (70°F)

Ad

InS

ROOM

• Increases or decreases the heat to the room when not

using indoor temperature feedback.

• Room setting fine tunes the mix supply water

temperature.

• Only available when there is no indoor sensor connected,

and outdoor design is not set to off.

ADJUST

°C

-51.0 to 7.0°C, OFF

(-60 to 45°F, OFF)

Default = -12.0°C (10°F)

Ad

InS

OUT DESIGN

• Enter the coldest annual outdoor temperature of your

area.

• Setting outdoor design to off disables outdoor reset and

enables setpoint operation.

ADJUST

1, 2, 3, 4, 5, 6 Ad

InS

TERMINAL

• Enter the type of heating terminal units installed.

1 = Underfloor Heating (Wet)

2 = Underfloor Heating (Dry)

3 = Fan coil

4 = Fin tube convector

5 = Radiator

6 = Baseboard

• Only available when outdoor design is not set to off.

ADJUST

°C

4.5 to 35.0°C

(40 to 95°F)

Default = 21.0°C (70°F)

Ad

MIX INDOOR

• The outdoor reset characterized heating curve starting

point.

• Only available when outdoor design is not set to off.

VIEW

ADJUST

°C

21.0 to 104.5°C

(70 to 220°F)

Default = 49.0°C (120°F)

Ad

MIX DESIGN

•

The water temperature required for heating on the coldest

annual temperature of your area.

• Only available when outdoor design is not set to off.

MIN

ADJUST

OFF, 1.5 to 65.5°C

(OFF, 35 to 150°F)

Default = OFF

Ad

MIX MINIMUM

• The minimum mix target outlet temperature.

• Only available when outdoor design is not set to off.

The Adjust Menu items are the programmable settings

used to operate the mechanical equipment.

ADJUST MENU

Continued on next page.

Setup: Adjust Menu

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

7

www.heatlinkgroup.com

Item Field Range

Access

Description

MAX

ADJUST

°C

27.0 to 107.0°C

(80 to 225°F)

Default = 60.0°C (140°F)

Ad

MIX MAXIMUM

• The maximum mix target outlet temperature.

• Only available when outdoor design is not set to off.

ADJUST

WWSD

°C

4.5 to 38.0°C, OFF

(40 to 100°F, OFF) Ad

InS

WARM WEATHER SHUT DOWN

•

The outdoor temperature above which the heating is shut

off.

• Only available when outdoor design is not set to off.

Wake Occ Default = 22.0°C (72°F)

Sleep UnOcc

Default = 15.5°C (60°F)

ADJUST

°C

15.5 to 93.5°C

(60 to 200°F)

Default = 38.0°C (100°F)

Ad

InS

MIX TARGET

• Setpoint mix target temperature.

• Only available when outdoor design is set to off.

ADJUST

MODE

0:10, 2:10, Flot

Default = Flot

Ad

MIX MODE

• The control can provide 3 different output signals to a

mixing valve actuator:

0:10 = 0 to 10 V (dc) analogue signal

2:10 = 2 to 10 V (dc) analogue signal

Flot = 24 V (ac) floating action

ADJUST

M

30 to 230 seconds

Default = 150 seconds

Ad

MOTOR SPEED

• The time to operate the mixing valve from fully closed to

fully open.

• The default value of 150s is the proper setting for the HeatLink

®

56121 DDC actuator and 58100 series mixing valve motors.

ADJUST

min

OFF, 0:05 to 10:00

Default = 0:20

Ad

mm:ss PUMP

• System pump purge time once the heat demand is

removed.

• Use of this feature without a bypass or continuous flow

loops can result in dead heading of the pump.

ADJUST

%

10 to 70%

(5% increments)

Default = 25%

Ad BOILER ON

• Boiler on trigger point as the mixing valve opens.

ADJUST

%

0 to 50%

(5% increments)

Default = 5%

Ad BOILER OFF

• Boiler off trigger point as the mixing valve closes.

ADJUST

AC C

USEr, InS, Ad

Default = InS

Ad

InS

ACCESS LEVEL

• The control has 3 access levels:

Ad = Advanced: All settings are available.

InS = Installer: The factory default access level allows basic

setting changes.

USEr = User: Access level for building occupants.

•

The access level hides certain settings from the View,

Adjust, Schedule 1 and Schedule 2 menus.

ADJUST MENU

Continued on next page.

Setup: Adjust Menu

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

8

Item Field Range

Access

Description

ADJUST

TEST

OFF, FLd, MAn

Default =

OFF

Ad

InS

TEST

• Select the field test (FLd) or Maximum Heat (MAn)

feature.

ADJUST

°C

°F, °C

Default =

°C

Ad

InS

USEr

TEMPERATURE UNITS

• Select either Celsius or Fahrenheit temperature units to

display temperature.

After the last item, the control returns to the first item in the menu.

Adjust Menu (3 of 3)

ADJUST MENU

Item Field Range Access Description

TIME

1

Ad

InS

USEr

CURRENT TIME AND DAY

• Displays the current time and day.

• Only available when the Setback DIP switch is set

to on.

TIME

1

00 to 59

Ad

InS

USEr

CLOCK MINUTES

• Set the minutes.

• Only available when the Setback DIP switch is set

to on.

TIME

1

00 to 23

Ad

InS

USEr

CLOCK HOURS

• Set the hours.

• Only available when the Setback DIP switch is set

to on.

TIME

1

1 = Monday

2 = Tuesday

3 = Wednesday

4 = Thursday

5 = Friday

6 = Saturday

7 = Sunday

Default = Monday

Ad

InS

USEr

DAY OF THE WEEK

• Set the day of the week.

• Only available when the Setback DIP switch is set

to on.

The Time menu items set the time clock and day.

Time Menu (1 of 1)

TIME MENU

After the last item, the control returns to the first item in the menu.

Setup: Adjust Menu & Time Menu

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

9

www.heatlinkgroup.com

Item Field Range Access Description

SCHD 1

OFF, , ,

, ,

, ,

, ,

Default = OFF

Ad

InS

USEr

MANUAL OVERRIDE

• Select a manual override for schedule 1.

• Ignores the regular schedule.

• Temporary manual override lasts 3 hours.

• Permanent and Away manual override remains until

manually changed.

SCHD 1

MODE

OFF, 2, 4

Default = OFF

Ad

InS

MODE

• Select the number of setback events per day for

schedule 1.

• Only available when the Setback DIP switch is set

to on.

SCHD 1

TYPE

24 hr, 5-11, 7dAY

Default = 24hr

Ad

InS

TYPE

• Select the type of repeating schedule for schedule

1.

• Only available when the Setback DIP switch is set

to on.

When a 5-11 or a 7 day schedule is selected, each day or group of days require individual event settings.

SCHD 1

1

– –:– – to 23:50 PM

Default = 06:00

Ad

InS

USEr

DAY 1 TO DAY 7 WAKE

• Select the starting time for the Wake event for

schedule 1.

• Only available when the Setback DIP switch is set

to on.

SCHD 1

1

– –:– – to 23:50 PM

Default = 08:00

Ad

InS

USEr

DAY 1 TO DAY 7 UNOCCUPIED

•

Select the starting time for the Unoccupied event

for schedule 1.

• Only available when the Setback DIP switch is set

to on.

SCHD 1

1

– –:– – to 23:50 PM

Default = 16:00

Ad

InS

USEr

DAY 1 TO DAY 7 OCCUPIED

• Select the starting time for the Occupied event for

schedule 1.

• Only available when the Setback DIP switch is set

to on.

SCHD 1

1

– –:– – to 23:50 PM

Default = 22:00

Ad

InS

USEr

DAY 1 TO DAY 7 SLEEP

• Select the starting time for the Sleep event for

schedule 1.

• Only available when the Setback DIP switch is set

to on.

The Schedule menu items set the schedule type, the

number of events per day, and the event times.

Schedule 1 Menu (1 of 1)

SCHD 1 MENU

After the last item, the control returns to the first item in the menu.

Setup: Schedule 1 Menu

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

10

Item Field Range Access Description

SCHD 2

CP1, On, OFF

Default = CP1

Ad

InS

USEr

SCHD

•

Select whether night setback 2 is operational.

CP1 (Copy 1)= Night setback schedule 2 copies

the event times of schedule 1.

On = Night setback schedule 2 operates on an

independent schedule.

OFF = Night setback schedule 2 is disabled.

SCHD 2

OFF, , ,

, ,

, ,

, ,

Default = OFF

Ad

InS

USEr

MANUAL OVERRIDE

• Select a manual override for schedule 2.

• Ignores the regular schedule.

• Temporary manual override lasts 3 hours.

• Permanent and Away manual override remains until

manually changed.

SCHD 2

MODE

OFF, 2, 4

Default = OFF

Ad

InS

MODE

• Select the number of setback events per day for

schedule 2.

• Only available when the Setback DIP switch is set

to on.

SCHD 2

TYPE

24 hr, 5-11, 7dAY

Default = 24 hr

Ad

InS

TYPE

• Select the type of repeating schedule for schedule

2.

• Only available when the Setback DIP switch is set

to on.

When a 5-11 or a 7 day schedule is selected, each day or group of days require individual event settings.

SCHD 2

1

– –:– – to 23:50 PM

Default = 06:00

Ad

InS

USEr

DAY 1 TO DAY 7 WAKE

• Select the starting time for the Wake event for

schedule 2.

• Only available when the Setback DIP switch is set

to on.

SCHD 2

1

– –:– – to 23:50 PM

Default = 08:00

Ad

InS

USEr

DAY 1 TO DAY 7 UNOCCUPIED

•

Select the starting time for the Unoccupied event

for schedule 2.

• Only available when the Setback DIP switch is set

to on.

SCHD 2

1

– –:– – to 23:50 PM

Default = 16:00

Ad

InS

USEr

DAY 1 TO DAY 7 OCCUPIED

• Select the starting time for the Occupied event for

schedule 1.

• Only available when the Setback DIP switch is set

to on.

The Schedule menu items set the schedule type, the

number of events per day, and the event times.

Schedule 2 Menu (1 of 2)

SCHD 2 MENU

Continued on next page.

Setup: Schedule 2 Menu

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

11

www.heatlinkgroup.com

4 4

22

The 31355 can function in three different modes of operation.

Modes of Operation

After the last item, the control returns to the first item in the menu.

Schedule 2 Menu (2 of 2)

SCHD 2 MENU

Item Field Range Access Description

SCHD 2

1

– –:– – to 23:50 PM

Default = 22:00

Ad

InS

USEr

DAY 1 TO DAY 7 SLEEP

• Select the starting time for the Sleep event for

schedule 1.

• Only available when the Setback DIP switch is set

to on.

Setup: Schedule 2 Menu and Modes of Operation

1) Outdoor Reset Multizone Operation

• Indoor temperature feedback from Thermostats by use of the external heat demand input contacts.

• The heat demand is activated whenever a thermostat calls for heat.

• Whenever the control is powered up, a heat demand is present and not in WWSD, the control operates the valve, boiler and

pump to maintain an outdoor reset mix target termperature at the mix supply sensor.

• The Room setting allows for manual parallel shifting of the heating curve.

• Two optional night setback schedules operate the Timer 1 and 2 relay contacts.

Required Settings:

• DIP Switch 3 = External Demand

• Indoor Air Sensor is not installed.

•

Outdoor Design = Set to the coldest

annual temperature in your area. Outdoor

Sensor

Mix

Supply

Sensor

Boiler Piping Option #1 (see Appendix I)

Mixing Option #3 (see Appendix II)

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

12

4 4

22

3) Setpoint Operation

• Optional indoor temperature feedback from Thermostats by use of external heat demand input contacts.

• The heat demand is active whenever a thermostat calls for heat (optional indoor temperature feedback) or when permanent heat

demand is enabled.

•

Whenever the control is powered up and a heat demand is present, the control operates the mixing valve, boiler and pump to

maintain a setpoint mix target temperature at the mix supply sensor.

• The setpoint mix target temperature is set through the Mix Target setting.

•

DIP Switch 3 = Permanent Demand:

Schedule “2” and relay “2” operational.

• DIP Switch 3 = External Demand: Two

optional night setback schedules operate

the Timer 1 and 2 relay contacts.

Required Settings:

• DIP Switch 3 = Permanent Demand or

External Demand

• Indoor Air Sensor is not installed.

• Outdoor Design = OFF

Modes of Operation

2) Outdoor Reset Single Zone Operation

• Indoor temperature feedback from external indoor air sensor.

• The control operates in permanent heat demand.

• Whenever the control is powered up and not in WWSD, the control operates the valve, boiler and pump to maintain an outdoor

reset mix target temperature at the mix supply sensor.

• Indoor temperature sensing allows for automatic parallel shifting of the heating curve.

• Single setback schedule

• Timer relay 1 and 2 operate in

parallel.

Required Settings:

• DIP Switch 3 = Permanent Demand

• Indoor Air Sensor is installed.

• Outdoor Design = Set to the coldest

annual temperature in your area.

Outdoor

Sensor

Indoor

Sensor

Mix

Supply

Sensor

Thermostats do not

effect operation of

31355 control

Boiler Piping Option #1 (see Appendix I)

Mixing Option #3 (see Appendix II)

Mix

Supply

Sensor

Boiler Piping Option #1 (see Appendix I)

Mixing Option #3 (see Appendix II)

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

13

www.heatlinkgroup.com

80

60

40

20

Supply Water Temperature °C

Outdoor Air Temperature °C

20 10 0 -10 -20

Warm Weather Shut Down

Warm Weather Shut Down ( ) occurs when the

outdoor air temperature is warmer than the WWSD setting

(±1°F). If a setback schedule is selected, the control

allows for two WWSD settings. If only one schedule is

active, WWSD occurs with the appropriate schedule. If

two schedules are active, “WWSD Wake

Occ” occurs when either one or both of the schedules

are in the Wake Sleep events; and “WWSD

Unocc Sleep” occurs when both schedules are in the

Unocc Sleep events. Whenever the control is in WWSD,

the segment is displayed.

Heat Demand

A heat demand is required in order for operation to occur.

A heat demand is present when:

1) Permanent Demand – DIP Switch 3 is set to

Permanent Demand.

or

2) External Demand – (DIP Switch 3 is set to external

demand). Whenever a contact closure (short) is

applied across the heat demand terminals (13 & 14)

The icon is turned on whenever a heat demand

is present.

Mixing Valve Operation

Whenever the control is powered up, a heat demand is

present and not in WWSD, the control provides a mixing

output to an actuator which drives a mixing valve to maintain

either an outdoor reset mix target temperature or setpoint

mix target temperature at the mix supply sensor.

Output Signal

The control can provide 3 different output signals to a

mixing valve actuator:

1) 0:10 = 0 to 10 V (dc) analogue signal

2) 2:10 = 2 to 10 V (dc) analogue signal

3) Flot = 24 V (ac) floating action. The control pulses the

open or close outputs to actuate the mixing valve.

The 31355 control has a 15 second delay before operating

the valve once a heat demand is applied. The 15 second

delay is to allow the pump to circulate the water in the

system and to stabilize temperatures so that the sensor

does not see any temperature spikes.

The time to change from closing the valve to opening

the valve is dependent on the Motor Speed and the PID

error difference between the mix supply sensor and the

mix target. Therefore, there is no fixed time to change

from close to open on the valve.

Outdoor Reset Operation

The control adjusts the mix target temperature with changing

weather conditions using a characterized heat curve. An

outdoor sensor is required. Outdoor reset adjusts the

mixing valve supply water temperature to compensate for

additional heat loss as the outdoor temperature falls.

Sequence of Operation

Sequence of Operation

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

14

Terminal Unit Mix Design Mix MAX Mix MIN

Underfloor Heating

(Wet) (1)

49°C

(120°F)

60°C

(140°F) OFF

Underfloor Heating

(Dry) (2)

60°C

(140°F)

71°C

(160°F) OFF

Fancoil

(3)

88°C

(190°F)

99°C

(210°F)

38°C

(100°F)

Fin-Tube Convector

(4)

82°C

(180°F)

93°C

(200°F) OFF

Radiator

(5)

71°C

(160°F)

82°C

(180°F) OFF

Baseboard

(6)

66°C

(150°F)

77°C

(170°F) OFF

There are 8 required settings for outdoor reset operation:

1) Indoor or Room

Indoor Sensor Feedback

• The indoor setting is only available when an indoor air sensor is

present.

•

Indoor sensor feedback allows the control to compensate for internal

indoor heat gains and additional heat losses such as wind loss which

outdoor reset does not account for.

• When an indoor sensor and a permanent demand is present, the

Timer 1 and Timer 2 contacts are disabled. Instead, there are up to

four separate Indoor Target temperature settings.

Room Setting (No Indoor Sensor Feedback)

•

When an indoor air sensor is not present, the outdoor reset water

temperature can be adjusted using the room setting.

• This provides fine tune adjustment by parallel shifting the entire

heating curve.

2) Outdoor Design - The Outdoor Design is the coldest

annual temperature in the area. If the Outdoor Design is set

to OFF, the control operates in the setpoint operation and

disables outdoor reset.

3) Terminal Unit - There are 6 different terminal units. When a

terminal unit is selected, the control automatically changes the

mix design, the mix minimum, and the mix maximum default

settings. The defaults can be changed to better match the

installed system.

4)

Mix Indoor - The Mix Indoor is the starting point of

the characterized heating curve. This is typically set to 21°C

(70°F).

5) Mix Design - The water temperature required to heat

the building on the coldest day of the year.

6) Mix Minimum - The lowest mix water target

temperature.

7) Mix Maximum - The highest mix water target

temperature. This can be used to help prevent overheating

on a radiant floor.

8)

Warm Weather Shut Down - When the outdoor temperature

exceeds the Warm Weather Shut Down (WWSD) setting, the

heating system is shut down by closing the mixing valve.

Underfloor Heating (Wet) (1)

Underfloor Heating (Dry) (2)

Fancoil (3)

Fin-Tube Convector (4)

Radiator (5)

Baseboard (6)

Terminal Units

Sequence of Operation

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

15

www.heatlinkgroup.com

SCHD 1

the valve to the fully open position and then back to the

fully closed position.

TEST will be displayed during exercising and can be

exited by pressing the down button.

Setting the Time

The control has an internal time clock. The time is

maintained for at least 4 hours in the case of power loss.

The time is visible in the ‘TIME’ menu only when DIP

switch 1 is set to setback.

To set the time:

1) Press and release the Menu button until the ‘TIME’

menu is found.

2) Press and release the Item button. The minute

numbers will flash. Press the up or down button

to set the minutes.

3)

Press and release the Item button.The hour

number will flash. Press the up or down button

to set the hour.

4) Press and release the Item button. The day of the

week number will flash. Press the up or down

button to set the day of the week.

Night Setback

• The control can also operate either one or two night setback

channels. The night setback operates by opening or closing

the timer 1 relay contact or the timer 2 relay contact at the

event time. This causes thermostats to operate at their night

setback temperature.

•

When an indoor sensor and a permanent demand is present,

the Timer 1 and Timer 2 contacts are disabled. Instead,

there are up to four separate Indoor Target temperature

settings.

• When the control is in single zone operation (Remote indoor

sensor connected and DIP set to permanent demand),

only channel 1 setback program is available. The channel

2 setback program is not shown and the control operates

both the channel 1 relay and the channel 2 relay at the same

time.

• The second night setback channel ‘SCHD 2’ can be set to

one of three settings:

1) CP1 = schedule 2 copies schedule 1 event times.

2) On = setback schedule 2 is on and separate from

schedule 1.

3) OFF = setback schedule 2 is off.

Setpoint Operation

The control can operate the mixing valve to maintain a

fixed setpoint outlet temperature.

To enter the setpoint mix target temperature:

Press the Menu button to enter the ‘ADJUST’ menu.

Press the Item button to find Outdoor Design

and set to ‘OFF’.

Press the Item button to find Mix Target and set

the mixing valve outlet temperature.

Boiler Output

Output Signal

The control operates the boiler relay as a boiler enable.

The “Boiler ON” setting allows the adjustment of the boiler

enable point as the mixing valve is opened (default of

25%). The “Boiler OFF” setting allows the adjustment

of the boiler shut off point as the mixing valve is closed

(default of 5%).

The boiler contact has a 3 minute minimum on time

regardless if heat demand is removed. The pump is

on while the boiler contact is on. Once the demand is

removed, the mixing valve is closed. The minimum off

time for the boiler relay is 20 seconds.

Warning:

The boiler minimum on time can cause the dead

heading of the pump if no bypass or continuous flow

loops are present.

Motor Speed

The control requires the motor speed time to operate the

mixing valve from fully closed to fully open. The default

value of 150s is the proper setting for the HeatLink®56121

DDC actuator and 58100 series mixing valve motors.

Pump Operation

The control includes a powered boiler pump. When the

DIP switch is set to permanent heat demand, the pump

runs continuously except when control is in WWSD.

When the DIP switch is set to external heat demand,

the pump only operates when an external heat demand

is applied and the control is not in WWSD. The pump

symbol is shown while in the View menu and the pump

is operating. Once the heat demand is removed, the

pump continues to operate for the time set by the pump

purge setting. During the pump purge, the pump symbol

flashes while in the View menu.

Exercising

The control includes a feature which exercises the system

pump and mixing valve in order to prevent corrosion and

precipitate build-up due to prolonged periods of inactivity.

If the pump has not run in the past 3 days, the pump will

run for 10 seconds. If the mixing valve has not operated

its full stroke in the past 3 days, the control will operate

Sequence of Operation

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

16

Setting Event Times

• For each scheduled setback event, a time between

00:00 and 23:50 must be set.

• If it is desired to skip the scheduled setback event, set

the event time to – –:– –.

• – –:– – is found between 23:50 and 00:00.

Temporary Override

• When an indoor sensor is present, the desired indoor

temperature can be temporarily overridden by pressing the

up or down button.

•

The temporary override remains in effect for 3 hours.

• To cancel the temporary override, press and hold the up

and down buttons together.

SCHD 1

MODE

SCHD 1

TYPE

VIEW

Tmpy

°C

Manual Override

• Select a manual override to prevent the scheduled event

from happening.

OFF = operate on scheduled night setback. This is the

default setting.

Temporary Wake = temporarily operate at the

Indoor Target Wake temperature or close the timer contact

for 3 hours.

Permanent Wake = permanently operate at

the Indoor Target Wake temperature or close the timer

contact.

Temporary Unoccupied = temporarily operate

at the Indoor Target Unoccupied temperature or close

the timer contact for 3 hours.

Permanent Unoccupied = permanently operate

at the Indoor Target Unoccupied temperature or close

the timer contact.

Temporary Occupied = temporarily operate

at the Indoor Target Occupied temperature or close the

timer contact for 3 hours.

Permanent Occupied = permanently operate

at the Indoor Target Occupied temperature or close the

timer contact.

Temporary Sleep = temporarily operate at the

Indoor Target Sleep temperature or close the timer

contact for 3 hours.

Permanent Sleep = permanently operate at

the Indoor Target Sleep temperature or close the timer

contact.

Away = operate the indoor target at 17.0 °C (62.5°F) or

close the timer contact. When using outdoor reset, the

warm weather shut down occurs at 17.0°C (62.5 °C).

MODE

• Select how many night setback events should occur

each day.

OFF = no night setback

2 = 2 setback events per day: ,

4 = 4 setback events per day: , , ,

TYPE

• Select the type of repeating schedule.

24 hr = schedule repeats every 24 hours.

5-11 = schedule repeats every week. The 5 weekdays

event times are grouped together. Saturday and Sunday

have separate event times.

7dAY = schedule repeats every week. There are separate

event times for each day.

Sequence of Operation

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

17

www.heatlinkgroup.com

Installation

Step 1 – Contents

Type 31355 includes:

• One 31355 Mixing Control

• One Outdoor Sensor 30070

• One Universal Sensor 30071

• One Tie Strap

• One Mounting Bracket M3049

• One Data Brochure L631355D

• One Data Brochure L630070D

• One User Brochure L631355U

Step 2 – Mounting the Control

Step 2.1 – Mounting the Control to an Electrical Box

• Install the control on an interior wall with an electrical box

approximately 1.5 m (5') above the floor.

• Do not mount the control in a location that may be affected

by localized heat sources or cold drafts.

• Fasten the supplied Mounting Bracket screws onto a variety

of electrical boxes using the supplied M3.5 x 0.6 x 40 mm

(long) screws. Ensure the raised ‘bump’ face outwards.

• Fasten the control onto the Mounting Plate using the supplied

M3 x 0.5 x 8 mm (short) screws.

2.2 – Mounting the Outdoor Sensor 30070

• Mount the Outdoor Sensor 30070 on a north facing wall to

avoid direct sunlight.

• Install the Outdoor Sensor away from heat sources.

• Install at a height above the ground that will prevent

accidental damage or tampering.

2.3 – Mounting the Mix Sensor 30071

Sensor with

rear entry

wiring

Sensor with

bottom entry

wiring

• The Universal Sensor 30071 is used to measure the mix

temperature. Install the 30071 downstream of the mixing

valve and the pump.

• The 30071 can be strapped onto copper pipe using the

supplied tie strap. Cover the sensor with insulation.

• The 30071 can be installed into a temperature well when

using steel pipe.

Note: Raised ‘bump’ faces outward.

Installation

Cover removal:

Grasp the top and bottom

of the cover and pull while

pushing a pin into the hole on

the side of the control.

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

18

Input / Output Mixing Control 31355

Terminal

Wire Voltage Connects To... On Device...

24 V (ac)

Floating Action

1 Switched “C” Open Mixing Valve Motor

58130, 58150 or

58199

2 “R” Common

3 Switched “C” Close

0 - 10 V (dc) 1 “C” Blk DDC Actuator

56121

2 “R” Blu

3 Analog signal Red

2 - 10 V (dc) 1 “C” 3rd Party Actuator

2 “R”

3 Analog signal

Timer 1 4 Switched “R” Timer 1 StatLink®module

40226 (Optional)

Timer 2 5 Switched “R” Timer 2 StatLink®module

40226 (Optional)

Indoor Sensor 6 Analog signal Sensor wire Indoor Sensor

30076 (Optional)

7 Analog signal Sensor wire

Mix Sensor 8 Analog signal Sensor wire Mix Sensor

30071

9 Analog signal Sensor wire

Outdoor Sensor

9 Analog signal Sensor wire Outdoor Sensor

30070

10 Analog signal Sensor wire

Power 11 “C” C Transformer

12 “R” R

Pump Signal 12 “R” 2 24Vac Pump Relay

45112

13 Switched “C” 7

External

Demand

15 24V Dry contact StatLink®module

40226

16 24V Dry contact

Boiler 17 24V (external) T Boiler

18 24V (external) T

Step 3 – Wiring

• Only qualified and competent personnel should attempt installation of the control.

• The power supply must be disconnected before starting with the installation.

• All wiring as per local electrical codes.

• Use 18 AWG (0.75 mm2) wire and marrettes to extended sensor wires if needed.

• All wires are to be stripped to a length of 3/8" (9 mm) to ensure proper connection.

Installation - Wiring

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

19

www.heatlinkgroup.com

6

7

8

9

10

11

12

13

15 16 17 18

54321

C R WC NTC

W

R

C

1

2

1

1

2

2

4

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

6 5 4 3

78 1 2

N

CR

6 5 4 3

78 1 2

C R WC NTC C R WC NTC C R WC NTC

6

7

8

9

10

11

12

13

15 16 17 18

54321

ES ES ES

N

Blk

Com

Blu

Opn

Red

Cls

46000 Series

Thermostat

56200 Series

Actuators

40226 StatLink®module

Installation - Wiring

30071

Supply Water

Sensor

30070

Outdoor

Sensor

(not required

for setpoint

control)

24 V ~

31355

C

R

56121

DDC Actuator

DIP Switch 3: External Demand

58100 Series

Mixing Valve Motor

OR

45112 24Vac Pump Relay

Boiler Contact

When using a single transformer, “R”

on the 31355 must be the same as the

“R” on the 40226. “C” and “R” cannot

be crossed between the two.

For multiple transformers see page 21.

R C

31355 Wiring for Outdoor Reset Multizone Operation or Setpoint Operation with StatLink®

46000 Series

Thermostat

46000 Series

Thermostat 46000 Series

Thermostat

56230 Series Actuators w/Endswitch

and 56200 Series Actuators

30071

Supply Water

Sensor

30070

Outdoor

Sensor

(not required

for setpoint

control)

24 V ~

31355

C

R

56121

DDC Actuator

DIP Switch 3: External Demand

58100 Series

Mixing Valve Motor

OR

45112 24Vac Pump Relay

Boiler Contact

Blk

Com

Blu

Opn

Red

Cls

31355 Wiring for Outdoor Reset Multizone Operation or Setpoint Operation without StatLink®

When using a single transformer, “R” on the 31355 must be the same as the

“R” for the thermostats. “C” and “R” cannot be crossed between the two.

For multiple transformers see page 21.

HeatLink®Compact Mixing Reset Control Stk# 31355

®

Heat Link

www.heatlinkgroup.com

20

6

7

8

9

10

11

12

13

15 16 17 18

54321

C

R

W

C

NTC

4

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

W

R

C

1

2

1

1

2

2

6 5 4 3

78 1 2

CR

N

Installation - Wiring

Blk

Com

Blu

Opn

Red

Cls

46000 Series

Thermostat

(optional)

56200 Series

Actuators

(optional)

40226 StatLink®module

(optional)

30076/77

Indoor

Sensor

(not required

for setpoint

control)

30071

Supply Water

Sensor

30070

Outdoor

Sensor

(not required

for setpoint

control)

24 V ~

31355

C

R

56121

DDC Actuator

DIP Switch 3: Permanent Demand

58100 Series

Mixing Valve Motor

OR

45112 24Vac Pump Relay

Boiler Contact

When using a single transformer, “R”

on the 31355 must be the same as the

“R” on the 40226. “C” and “R” cannot

be crossed between the two.

For multiple transformers see page 21.

R C

31355 Wiring for Outdoor Reset Single Zone Operation or Setpoint Operation

Table of contents

Other HeatLink Control Panel manuals

Popular Control Panel manuals by other brands

Siemens

Siemens CP-2ER Operation, installation, and maintenance manual

Nordelettronica

Nordelettronica NE274-TVDL instruction manual

Zeta

Zeta Premier EXPRO User manual, maintenance guide & log book

Coopers

Coopers MK4 Troubleshooting steps

Air Comm Systems

Air Comm Systems ACS 296 installation manual

Bentel Security

Bentel Security OmniaTAST-R user manual