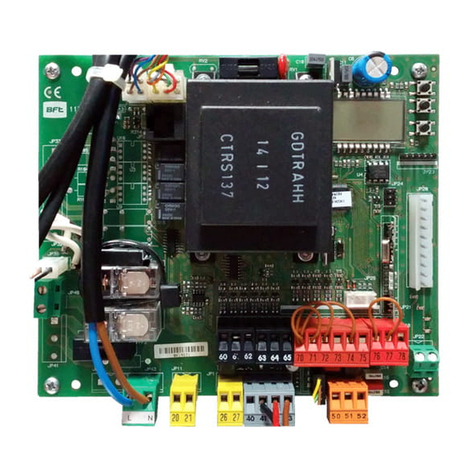

E5 BT A18 E

40 41 42 43 44 45

- REF SWE

SW 1

10 11

M1

14 15

+

M2

-

+

-

SW 2

11

tipo otore - type de oteur - otorentyp - otor type - tipo otor:

E5 BT A12 12

tipo otore - type de oteur - otorentyp - otor type - tipo otor:

M2 M2 M1

M1

M1 M1 M2

M2

60

COM

1

2

3

4

M1 +

M1 -

COM

- REF SWE

SW 1

M1

5

1

2

3

4

M2 +

M2 -

COM

- REF SWE

SW 2

M2

5

E5 BT A18 E5 BT A12

Maximum power 40W 40W

Maximum cycle

20 cycles/h 100 cycles/h

LEAF MAX see the motor’s manual see the table below

Maximum cable length 30m 30m

= 1 (ext)

open in other direct.

= 0 (int)

open in other direct.

change mot = change mot =

E5 BT A12

ON pedestrian gates, adjust the speed so as to limit the energy of the leaf within a

maximum value of 1.69 Joule (as required by the EN16005 regulation).

Use the table to determine the minimum closing times between 90°and 10°.

Table with the leaf manoeuvre minimum times

Leaf width (mm)

)Leaf weight (kg)

50 60 70 80 90

750 mm 3,0 s 3,0 s 3,0 s 3,0 s 3,5 s

850 mm 3,0 s 3,0 s 3,5 s 3,5 s 4,0 s

1000 mm 3,5 s 3,5 s 4,0 s 4,0 s 4,5 s

1200 mm 4,0 s 4,5 s 4,5 s 5,0 s 5,5 s

The approaching phase (from 10° to the limit switch position) must take place in at least 1.5 s.

Example: if the leaf weighs 80 kg and has a width of 1000 mm, adjust the manoeuvre speed from 90° and 10° in at least 4.0 s.

For intermediate values, use the higher value: if the leaf weighs 75 kg consider a value of 80 kg, if its width is 1100 mm use a value of 1200 mm.

IMPORTANT: Low-energy operation is not considered a proper safety measure if the leaf is used by elderly, invalid, disabled people and children.

In this case, provide additional safety measures, according to the provisions of the legislation in force.

Select the correct

motor model

8 - THALIA

D814123 0AA00_01