8

leg must be connected, through a separate circuitbreaker

or fuse, directly to the power supply. No other equipment

should be supplied from this separate circuitbreaker or fuse.

Wire must be run continuously from power source to termi-

nals in the control unit. A 24V battery provides emergency

power. Refer to the CONNECTION DIAGRAM on pages 4-

5, for terminal connections.

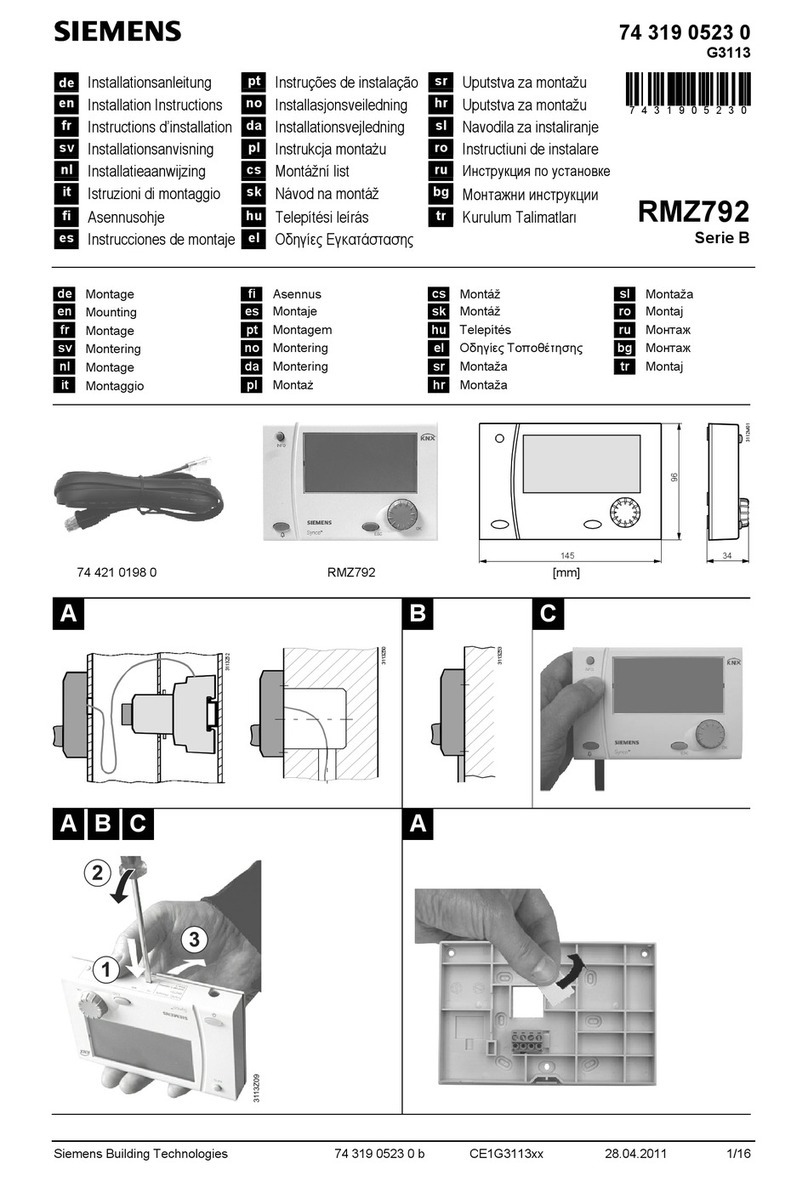

Installation of Conduit and Outlet Boxes

Install outlet boxes and run conduit between boxes and

control unit. Use 4 inch octagonal boxes for ionization,

photoelectric, flame, and plug-in thermal detectors. The

depth of the boxes should be determined by the NEC re-

quirements for the number and size of conductors used.

Do not mount boxes in direct air flow from air conditioning

or ventilating system supply registers.

The control unit, and all detectors and alarm circuit con-

duit, must be properly grounded. Insure that all conduit

has clean threads and makes good electrical contact be-

tween the control unit and outlet boxes.

Installation of Detector Bases

Wiring (Refer to CONNECTION DIAGRAM)

Run wire in accordance with wiring diagram. Use at least

No. 18 AWG, 300V insulation, color coded wire for the

detector circuits. Wiring between control unit and first de-

tector base, and all subsequent detector bases, must be

continuous; no splices, wire nuts, solder, or any other type

connection is permissible. On rare occasions an excep-

tion may be necessary due to an extremely long run. In

this case, the splice must be soldered.

The wire interconnecting the detector bases is continu-

ously supervised by a small electrical current flow through

the circuit to the end-of-line resistor (1. 8K ohms) mounted

in the base of the last detector. In order to keep this super-

vision complete, no parallel branching of wires is permis-

sible. Every base, except the last one, will have one set of

incoming and one set of outgoing wires.

Installing ases

Mount end-of-line resistor between appropriate terminals

of last base on circuit, as indicated on the CONNECTION

DIAGRAM. Mount all bases to outlet boxes. Manual sta-

tions, thermal detectors, air duct detectors, etc., are to be

connected to the circuit at this time. Please refer to wiring

diagrams for the specific equipment for connection de-

tails.

Wiring Test

NOTE: It is suggested that electrical tests be conducted

jointly by the installer and the manufacturers tech-

nician or representative. Written notice is requested

15 days prior to the tests so that the services of the

technician may be scheduled.

The installation of the wiring should be checked as follows:

1. Detectors should not be in their bases. Temporary jump-

ers should be inserted in all bases if not already in-

stalled. Install end-of-line resistor to appropriate termi-

nals of last detector on circuit for Class B wiring. For

Class A wiring, install the end-of-line resistor between

terminals 2 and 3 for Zone 1 and between terminals 5

and 6 for Zone 2. Wiring from bases should NOT be

connected to the Control Panel at this time.

2. Check the wiring of the detector circuit with an ohm-

meter. Resistance reading between wires connected

to terminals 1 and 4 of the Control Panel or terminals 5

and 8 for the other zone should be approximately 1.8K

ohms. Short the detector lines together and megger

the combined lines to chassis and conduit. There

should be at least 10 meg resistance reading between

wires and conduit or ground.

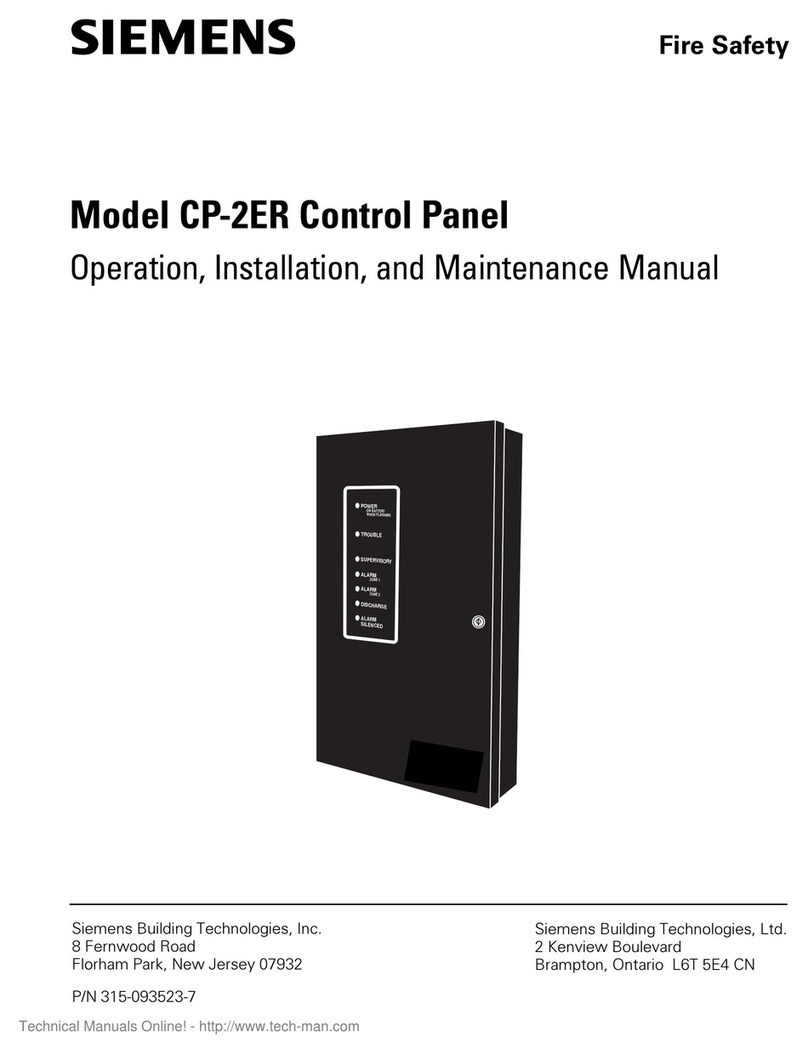

3. Connect wires to appropriate terminals of the Model

CP-2ER.

4. Remove the temporary jumpers from the bases. The

manufacturers Service Representative will then install

the detectors and check sensitivity.

System Operation Test

CAUTION: Be sure to prevent release of the agent.

1. See that the CP-2ER control unit is in normal standby

operation.

2. To test for supervision of initiating circuit, remove the

detector connected to the last device and check that

proper trouble indicators respond in the system. Re-

connect detector.

3. To test operation of initiating circuit, actuate a detec-

tor. Check that system fire indicators and alarm relay

contacts respond to the alarm.

4. Test operation of detector circuit: Activate each detec-

tor and manual station, one at a time, resetting each,

and check that detector base lamp and control unit

alarm controls operate. Each ionization detector may

be activated by blowing smoke into the chamber. The

manual station on the front panel should be checked

independently.

5. Check all basic system operational functions, particu-

larly the operation of the time delay functions, prior to

arming the agent releasing circuits.

POWER LIMITED WIRING

Effective May 1, 1995, all power-limited fire protective sig-

naling conductors must be separated a minimum of 1/4

inch from all of the following items located within a control

panel: electric light, power, Class 1, and non-power limited

fire protective signaling conductors .

To meet these requirements, the following guidelines must

be observed when installing modules and wiring to this

control panel.