MechanicalInstructions

SiteSelection

ReviewtheNEMATyperatingoftheheaternotedonthe

HEATREXApplicationData.Donotinstallaheaterinanareanot

consistentwithitsrating.

Allowsufficientfreespacearoundheaterinstallationsite.Work

spaceforheatermaintenanceshouldbeatleastthreefeetin

frontandoneithersideoftheheater.Theminimumpullspace

fortheheatingelementinstallationorremovalfromthe

pipe/tubeshouldbeatleastfourfeet.Theheatingelementis

designedtobeflexibleandcanbecurvedifnecessary.

Electricheatersarecapableofdevelopinghightemperatures.

Therefore,extremecareshouldbetakento

avoidmountingheatersinanatmospherecontaining

combustiblegases,vapors,dusts,orfibersunlessproperly

markedassuitableforthecondition.

HeaterOrientation

Thisstyleofheaterisintendedforhorizontaluseonly.Theopen

coilresistancewiremustnotbemountedinaverticalorientation

orfailurecouldoccurfromthecoilsagging.

Theheatermustbemountedplumbhorizontallytoassure

properoperation.

Thermalexpansionoftheheaterpipesmustbeconsideredwhen

locatingtheheater.Itcanbeapproximatedas:

Pipe

Length

(Inches)

x.00001x

MaxPipe

Operating

Temp(°F)

‐70°F

2

Iftheheaterisinstalledinapressurizedtank,areliefvalvemust

beinstalled.Asaminimum,thevalvemustbesizedtorelieveat

arateequaltotheratethattheheatercanthermallyexpand

fluidinthetank.

PipeInstallation

OnheaterpipesprovidedwithANSIflangedconnections,take

caretopreventscratchingtheflangefaces.HEATREXsuppliesa

non‐asbestosnitrilebondedfiberflangegasketunlessotherwise

requested.Theusermustconfirmthatthegasketissuitablefor

theapplication.Theusermustsupplyhighstrengthstudsorbolts

andnuts,suchasA‐193GR.B7andA194GR.2H,ratedforthe

designconditions.Boltsmustbeproperlyinstalledandtightened

topreventleaks.

Whenheaterpipesareweldeddirectlytotheuser’stankwall,

removetheheatingelementfromthepipebeforewelding.Refer

tothefollowinginstructionsforhandlingandremovingheating

elements.

Heaterpipesmustbesupportedinsidetheuser’stank.Supports

mustnotpreventthepipesfromthermallyexpanding.Supports

shouldbelocatedonamaximumspacingof10feet.

Wherebuildupofsolidsinthebottomofthetankisexpected,

thepipemustbelocatedabovethatlevel.Thepipemustalsobe

locatedbelowtheminimumoperatingfluidlevelofthetank.

Heaterpipesmustbeperfectlycleanbeforeinstallationof

heatingelement.Useonlyacleandryclothtoclean.Neveruse

alubricant.Compressedairwithalongwandmaybeusedto

removeceramicchips,etc.

IftheheaterpipeisnotsuppliedbyHEATREX,ensurethepipe

lengthiscorrectbymeasuringtheheatingelementoveralllength

(OAL),thecoldlengthfromthestartofthecoiledwiretothe

frontendoftheheatingelement(CL),andthelengthofthe

heaterpipenotincludingthepipecap(PL).

ThepipelengthPLmustbegreaterthanorequaltoOAL.When

locatingtheheaterpipeinthetank,thedistancefromthefront

endofthepipetotheexteriortankwallmustbelessthanor

equaltoCLtoensuretheheatedareaisinthefluid.

HeatingElementInstallation&Removal

Toremovetheheatingelementfromaheaterpipeorshipping

tube,firstremovethefasteningnutattheterminalend.Hold

theceramicinsulatorfirmlyinordertoavoidunduepressureon

theceramicandpossiblebreakage.Ifobstructionsare

encountered,rotatetheheaterslightlybackandforthwhile

pullingout.

Sinceheatingelementscanbeofconsiderablelength,itmaynot

alwaysbepossibletoremovetheelementinastraightline,due

tospacelimitations.Sincetheelementbarisflexible,the

elementmaybecurvedonaradiusof4feetminimum.Itis

recommendedthatatleast2peoplebeusedforthisprocedure,

inordertoavoidbreakingtheceramics.

Aftertheelementbarhasbeenremoved,itshouldbecarefully

stretchedoutonacleantableforinspection.Brokenceramics

mustbereplacedandburnspotsshouldbecleanedwithadry

cleanpaperorclothtowel.Oilorothercontaminationonthe

heaterwillcauseafailure.

Wheninstallingtheheatingelementintotheheaterpipe,reverse

thestepsnotedabove.

Heaterpipesmustbeperfectlycleanbeforeinstallationof

element.Useonlyacleandryclothtoclean.Neverusea

lubricant.Compressedairwithalongwandmaybeusedto

removeceramicchips,etc.

Theheatingelementintendedonlytobeinstalledwiththesheet

metalstriponthebottom.Donotrotatetheheaterinthepipe.

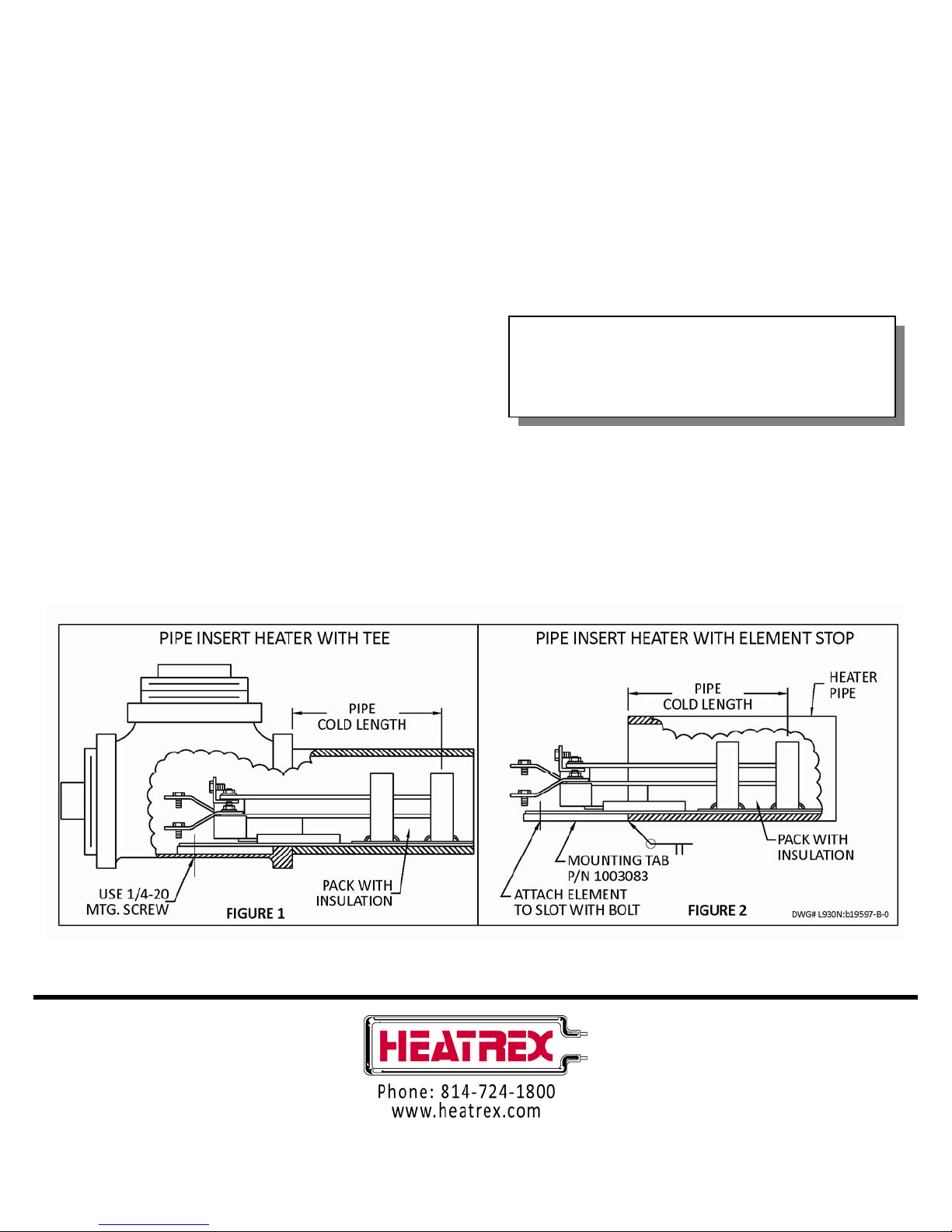

CAUTION -Hazard of Electric Shock

Heatersmustbeboltedintopositionattheterminalend

topreventmovement,whichcouldallowtheheaterto

shortoutagainstthepipe.

Seefiguresattachedformountingconfigurations.

Thermalinsulationmustbeinstalledbetweenthefirstfew

ceramicsinthe“cold”sectionoftheheaterwheretheresistance

wireisnotcoiled.Aloosefillcerafiber(HEATREXP/N1008466)

orequal,ratedfor2000°F,ispreferred.Theinsulationmustbe

freeofmoistureorcontaminationinordertoprovideelectrical

isolation.Theinsulationisnecessarytoallow90°Cratedfield

wiring.