- 3 -

8. Specifications .............................................................................................................................................. 37

8.1 Pin Layouts of the Interface Boards .................................................................................................... 37

8.1.1 Pin Layout of the 11µApp Interface Board ............................................................................... 37

8.1.2 Pin Layout of the 1Vpp Interface Board ................................................................................... 37

8.1.3 Pin Layout of the TTL Interface Board .....................................................................................38

8.1.4 Pin Layout of the HTL Interface Board.....................................................................................38

8.2 Pin Layout of the Power Supply Socket on PWM 8 ............................................................................ 38

8.3 Specifications of PWM 8 Base Unit..................................................................................................... 39

8.4 Specifications of 11µApp Interface Board ........................................................................................... 40

8.5 Specifications of 1Vpp Interface Board ............................................................................................... 40

8.6 Specifications of TTL Interface Board ................................................................................................. 41

8.7 Specifications of HTL Interface Board................................................................................................. 42

8.8 Specifications of Power Supply Unit ................................................................................................... 42

9. Description of FST 2 Leak Tester................................................................................................................ 43

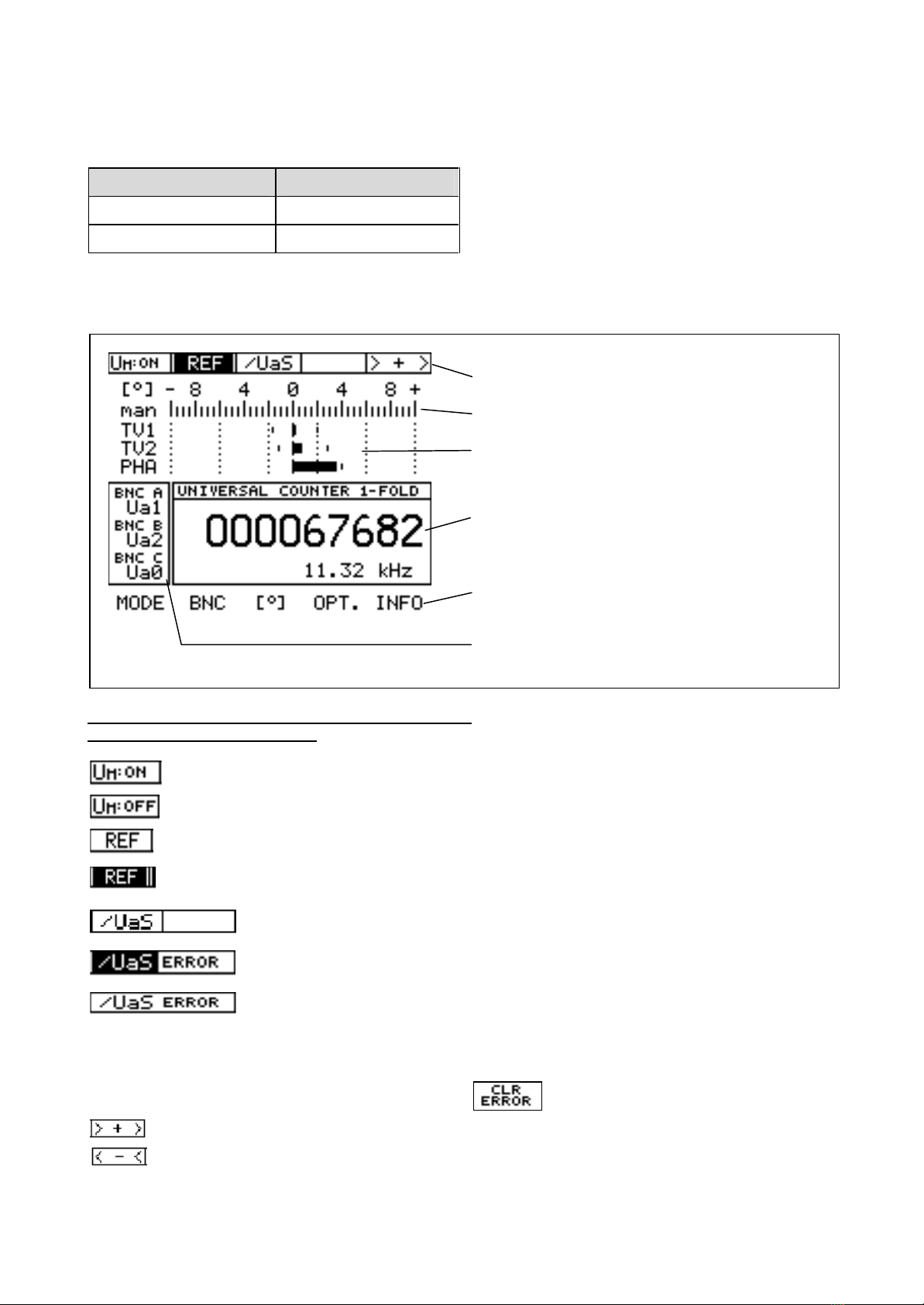

9.1 Explanation of the Controls and Displays ........................................................................................... 43

9.2 Example for Application....................................................................................................................... 44

9.3 Specifications of FST 2 ....................................................................................................................... 45

10. Description of ROD 450 Rotary Encoder .................................................................................................. 46

10.1 Specifications of ROD 450 ................................................................................................................ 46

11. Description of Connecting Cable 10-30V DC ............................................................................................ 46

12. Measuring Setup and Tolerances of the Output Signal............................................................................. 47

12.1 Description of the Output Signal ....................................................................................................... 51

12.1.1 Output Signals........................................................................................................................ 51

12.1.2 Output Signals........................................................................................................................ 52

12.1.3 Output Signals........................................................................................................................ 53

12.1.4 Output Signals........................................................................................................................ 55

13. Adapter Connectors .................................................................................................................................. 57

13.1 Overview of the Adapter Connectors ................................................................................................ 57

13.2 Adapter connector for exposed linear encode .................................................................................. 58

13.3 Adapter-connector for ERN 1387...................................................................................................... 59

14. Pin Layouts of Standard HEIDENHAIN Cables......................................................................................... 60

15. Description of the interface board, 1 Vpp, absolute (with Zn/Z1-track; EnDat/SSI;

SSI-programmable) ................................................................................................................................... 64

15.1 General information........................................................................................................................... 64

15.1.1 1 Vpp measuring systems with Zn/Z1 track .......................................................................... 64

15.1.2 1 Vpp measuring systems with EnDat interface.................................................................... 65

15.1.3 1 Vpp measuring systems with SSI interface and 5V supply voltage ................................... 65

15.1.4 1 Vpp measuring systems with SSI interface and HTL supply voltage................................. 66

15.1.5 1 Vpp measuring systems with programmable SSI interface................................................66

16 Items supplied ............................................................................................................................................ 67

16.1 Hardware........................................................................................................................................... 67

16.2 Adapter Cables overview .................................................................................................................. 67

16.3 Incremental Zn/Z1 ............................................................................................................................. 68

16.4 Absolute EnDat/SSI .......................................................................................................................... 69

16.5 Absolute EnDat/SSI motor encoder .................................................................................................. 70