Heimeier Mikrotherm User manual

Pressurisation & Water Quality Balancing & Control Thermostatic Control ENGINEERING ADVANTAGE

Mikrotherm

Manual radiator valves with presetting

MANUAL RADIATOR VALVES - MIKROTHERM

2

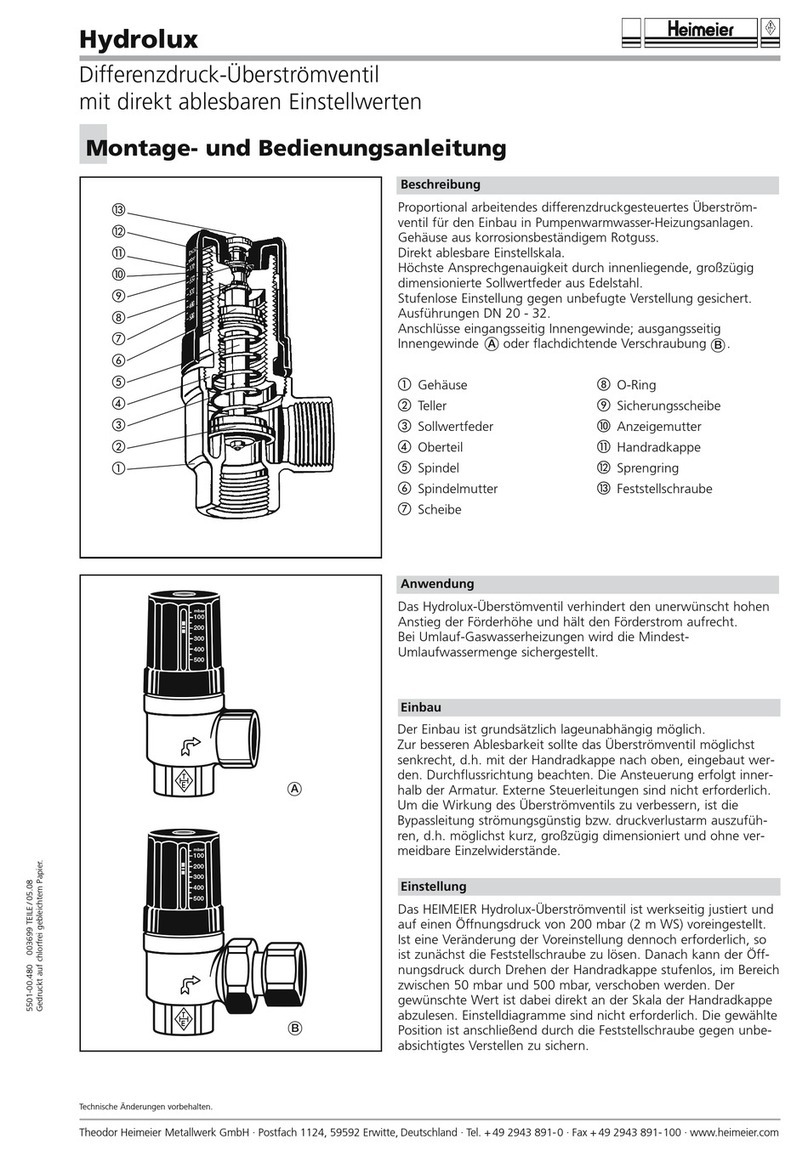

Technical description

HEIMEIER Mikrotherm manual radiator valves made of corrosion-resistant gunmetal,

with white plastic hand wheel cap, tight-packed with protection film.

Lengths according to DIN 3841 part 1. Accurate presetting of the mass flow and finest heat

apportioning through a non-rising double spindle with a Mikrotherm presetting cone with

tandem sealing (metal and O-ring sealing). Spindle for DN 10 to DN 25 with double O-ring

sealing. Spindle sealing for DN 32 through stuffing box packaging which can be tightened.

Can be retrofitted as a thermostatic valve by replacing the Mikrotherm insert with a

thermostatic insert. Can be connected to a threaded pipe, or with compression fittings to a

copper, precision steel or multi-layer pipe. For HEIMEIER Mikrotherm, only use the auxiliary,

labelled HEIMEIER compression fittings (label e. g. 15 THE).

Permitted operating temperature TB 120°C (248°F). Permitted operating pressure

PB 10 bar, low pressure steam 110°C (230°F)/ 0.5 bar.

Assembly

Mikrotherm

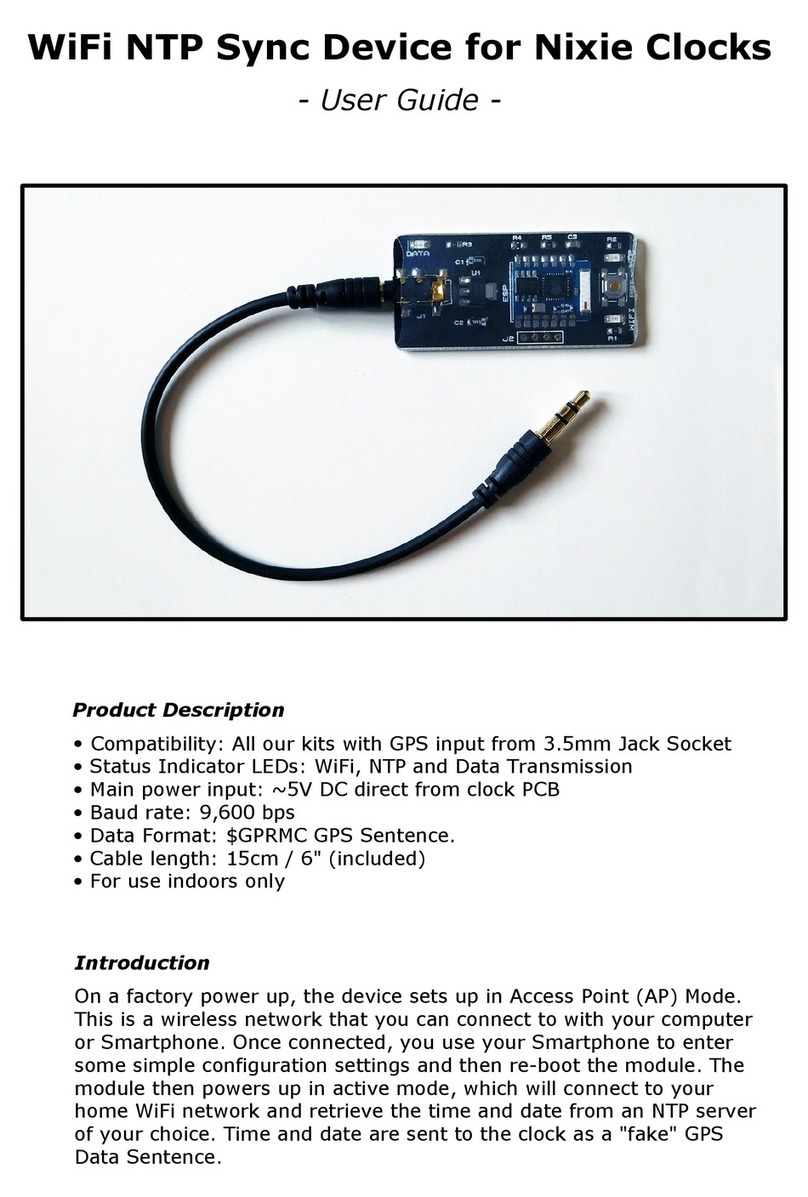

Application

The HEIMEIER Mikrotherm manual radiator valve is used in warm water pump heating systems, gravity or low pressure steam

systems. With models in angle and straight form from DN 10 to DN 32, the manual radiator valve can be used for a number

of different purposes. The non-rising double spindle with the Mikrotherm presetting cone makes hydraulic balancing through

presetting possible. The aim here is to provide e. g. all heat consumers with hot water according to their needs.

Sample application

1. Double O-ring sealing

2. Double spindle

3. Tandem sealing

4. Presetting cone

• Body made of corrosion-resistant gunmetal nickel plated

• Double O-ring sealing (DN 10 – DN 25)

• Presetting through a non-rising double spindle

• Can be retrotted as a thermostatic valve

1. Mikrotherm

MANUAL RADIATOR VALVES - MIKROTHERM

3

Note

The contents of the heat transfer medium should comply with VDI guideline 2035 on damage and scale deposit formation in

warm water heating systems.

For industrial and long-distance energy systems, see the applicable codes VdTÜV 1466 and AGFW FW 510. Mineral oils in the

heat transfer medium or lubricants containing mineral oils of any type lead to strong swelling and in most cases cause EPDM

seals to fail.

When using nitrite-free frost and corrosion resistance solutions with an ethylene glycol base, pay close attention to the details

outlined in the manufacturers‘ documentation, particularly details concerning concentration and specific additives.

Operation

Presetting

1. Close the valve.

2. Unscrew the hand wheel fastening screw.

3. Screw in the control pin with a screw driver by turning it clockwise until it stops.

4. Use the diagrams to determine the presetting and preset by turning to the left.

5. Insert the hand wheel fastening screw and screw tight.

Notes:

– The insert should only be loosened or tightened when the valve is opened.

– After the first test heating with DN 32, check the stuffing box union nut and tighten if necessary.

Articles

Angle

DN kvs Article No

10 (3/8”) 1,71 0121-01.500

15 (1/2”) 1,99 0121-02.500

20 (3/4”) 3,30 0121-03.500

25 (1”) 6,60 0121-04.500

32 (1 1/4”) 10,10 0121-05.500

Straight

DN kvs Article No

10 (3/8”) 1,17 0122-01.500

15 (1/2”) 1,61 0122-02.500

20 (3/4”) 3,10 0122-03.500

25 (1”) 6,20 0122-04.500

32 (1 1/4”) 8,90 0122-05.500

MANUAL RADIATOR VALVES - MIKROTHERM

4

Accessories

Compression tting

for copper or precision steel pipes.

Metal-to-metal joint. Brass nickel-plated.

Female thread connection Rp 3/8 –

Rp 3/4. Support sleeves should be used

for a pipe wall thickness of 0.8 – 1 mm.

Follow the specifications of the pipe

manufacturer.

Ø Pipe DN Article No

12 10 (3/8”) 2201-12.351

15 15 (1/2”) 2201-15.351

16 15 (1/2”) 2201-16.351

18 20 (3/4”) 2201-18.351

22 20 (3/4”) 2201-22.351

Support sleeve

for copper or precision steel pipe with a

1 mm wall thickness. Brass.

LØ Pipe Article No

25,0 12 1300-12.170

26,0 15 1300-15.170

26,3 16 1300-16.170

26,8 18 1300-18.170

Compression tting

For multi-layer pipes.

Female thread connection Rp 1/2.

Nickel-plated brass.

Ø Pipe Article No

16 x 2 1335-16.351

Thermostatic insert

Conversion insert for valve bodies with

a «T label». Series to 1985.

DN Article No

10, 15 (3/8”, 1/2”) 4101-02.300

20 (3/4”) 4101-03.300

25 (1”) 2001-04.299

32 (1 1/4”) 2001-05.299

Thermostatic insert

Conversion insert for valve bodies with

a connector thread for the thermostatic

head. Series from 1985.

DN Article No

10, 15 (3/8”, 1/2”) 1302-02.300

20 (3/4”) 2001-03.300

Thermostatic insert

Standard. Conversion insert for valve

bodies with a boss marking. Series from

1994.

DN Article No

10, 15 (3/8”, 1/2”) 2001-02.300

Thermostatic insert

Presetting (V-exakt). Conversion insert

for valve bodies with a boss marking.

Brass numerical cap.

Series from 1994.

DN Article No

10, 15 (3/8”, 1/2”) 3501-02.300

Thermostatic insert

Finest presetting (F-exakt). Conversion

insert for valve bodies with a boss mar-

king. Nickel-plated brass numerical cap.

Series from 1994.

DN Article No

10, 15 (3/8”, 1/2”) 3420-02.300

MANUAL RADIATOR VALVES - MIKROTHERM

5

Technical data

Diagram DN 10 (3/8“)

Angle / Straight

0121-01 / 0122-01

Diagram DN 15 (1/2“)

Angle / Straight

0121-02 / 0122-02

60

50

30

20

10

5

3

2

1

0,1

0,2

0,3

0,5

35 10 20 30 50 100 200 300 500 1000 2000

ª “

600

500

300

200

100

50

30

20

10

1

2

3

5

6000

5000

3000

2000

1000

500

300

200

100

10

20

30

50

∆

p[kPa]

∆

p[mbar]

¥ /æ

230

∆

p[mm WS]

0,056 0,1

0,14

0,18 0,35 0,65 1

DM

æ 1,17 1,45

EM

æ 1,71

234567899

10

*)

60

50

30

20

10

5

3

2

1

0,1

0,2

0,3

0,5

35 10 20 30 50 100 200 300 500 1000 2000

ª “

600

500

300

200

100

50

30

20

10

1

2

3

5

6000

5000

3000

2000

1000

500

300

200

100

10

20

30

50

∆

p[kPa]

∆

p[mbar]

¥ /æ

230

∆

p[mm WS]

0,056 0,1

0,14

0,21 0,4 0,74

1,13 DM

æ 1,61

1,75

EM

æ 1,99

23456789

910

*)

*) Screwdriver rotations

MANUAL RADIATOR VALVES - MIKROTHERM

6

Diagram DN 20 (3/4“)

Angle / Straight

0121-03 / 0122-03

Diagram DN 25 (1“)

Angle / Straight

0121-04 / 0122-04

60

50

30

20

10

5

3

2

1

0,1

0,2

0,3

0,5

35 10 20 30 50 100 200 300 500 1000 2000

ª “

600

500

300

200

100

50

30

20

10

1

2

3

5

6000

5000

3000

2000

1000

500

300

200

100

10

20

30

50

∆

p[kPa]

∆

p[mbar]

¥ /æ

230

∆

p[mm WS]

0,064 0,11

0,15 0,32

0,54 1,12 1,98

DM

æ 3,1

2,5

EM

æ 3,3

23456789

10

10

*)

10 20 30 50 100 200 300 500

1000 2000

ª “

30

0,46 0,77 1,27 2,3 3,4

4,4

5,3

DM

æ 6,2

5,8

EM

æ 6,6

2

¥ /æ

60

50

30

20

10

5

3

2

1

0,1

0,2

0,3

0,5

∆

p[kPa]

3000 5000

50

30

3456789

12

12

600

500

300

200

100

20

10

1

2

3

5

6000

5000

3000

2000

1000

500

300

200

100

10

20

30

50

∆

p[mbar]

∆

p[mm WS]

*)

*) Screwdriver rotations

MANUAL RADIATOR VALVES - MIKROTHERM

7

Diagram DN 32 (11/4“)

Angle / Straight

0121-05 / 0122-05

*) Screwdriver rotations

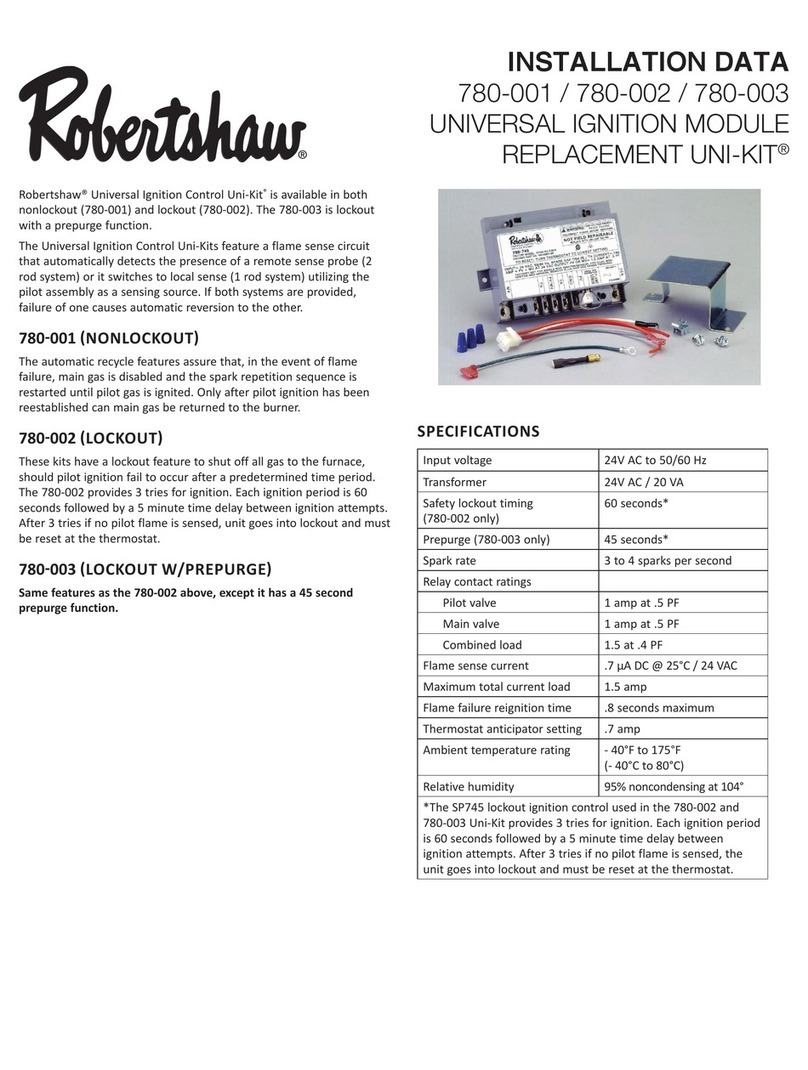

Sample calculation

Target: Preset value

Given: Heat flow º= 2210 W

Temperature spread t = 20 K (70/50°C)

Pressure loss in manual valve DN 15 pv = 30 mbar

Solution: Mass flow ª= º/ (c · t) = 2210 / (1,163 · 20) = 95 kg/h

Screw driver turns from

diagram DN 15 = 6.5 turns

10 20 30 50 100 200 300 500

1000 2000

ª “

30

0,57

0,79

1,42 2,2 3,8

5,3

DM

æ 8,9

6,6 EM

æ 10,1

2

¥ /æ

60

50

30

20

10

5

3

2

1

0,1

0,2

0,3

0,5

∆

p[kPa]

3000 5000

50

30

345678

10

12

12

7,9

600

500

300

200

100

20

10

1

2

3

5

6000

5000

3000

2000

1000

500

300

200

100

10

20

30

50

∆

p[mm WS]

∆

p[mbar]

*)

cv= kv

0,86

kv= cv· 0,86

MANUAL RADIATOR VALVES - MIKROTHERM

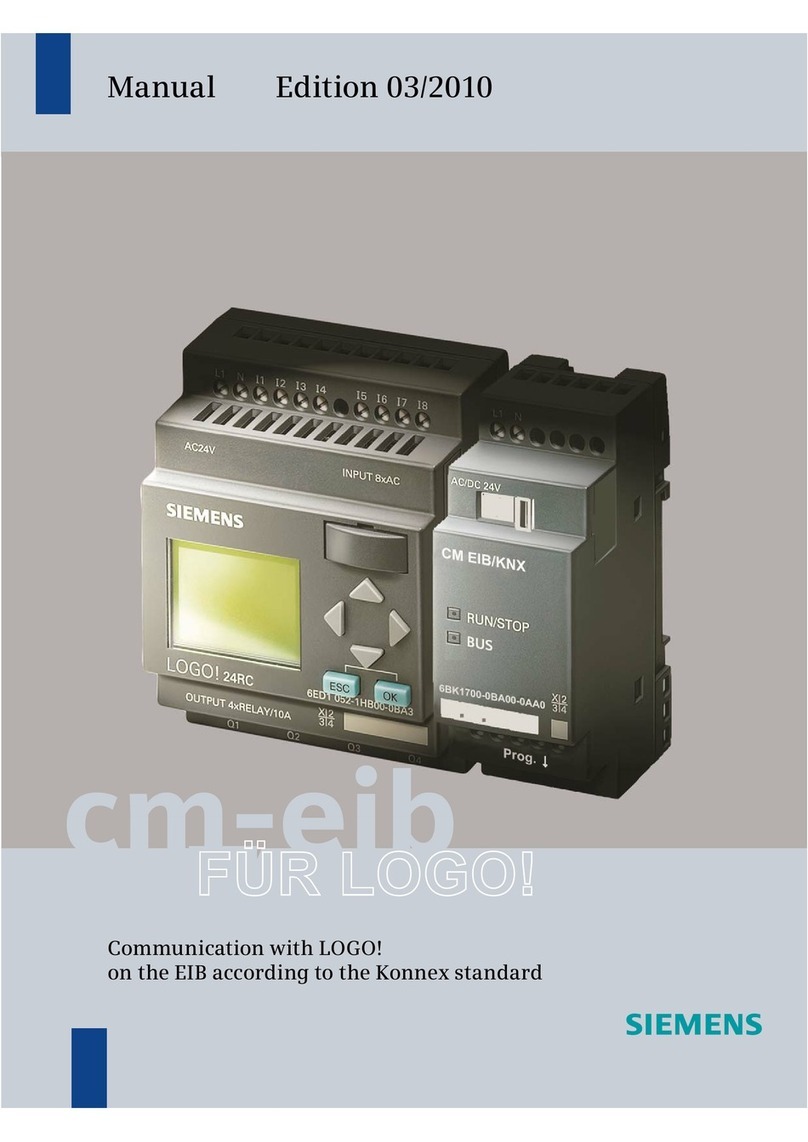

Dimensions

Lengths according to DIN 3841, part 1

Angle form Straight form

Spanner opening

DN D b d1d2l1l2l3l4l5l6SW1SW2H1D1

10 Rp3/8 10,1 G5/8 R3/8 59 85 26 52 22 6 22 27 56 42

15 Rp1/2 13,2 G3/4 R1/2 66 95 29 58 26 7 27 30 56 42

20 Rp3/4 14,5 G1 R3/4 74 106 34 66 29 8 32 37 58 42

25 Rp1 13 G1 1/4 R1 84 118 40 75 30,5 9 41 47 73 55

32 Rp 1 1/4 15 G1 1/2 R1 1/4 95 135 46 85 39 10 49 52 74 55

α= 70° (±10°)

Ø D

1

l

6

d

2

d

1

α

l

3

l

4

D

b

H

1

l

5

SW

2

SW

1

d2

d1

α

l1

l2

SW2

b

H1

D

SW1

Ø D1

l6

The products, texts, photographs, graphics and diagrams in this document may be subject to alteration by TA Hydronics

without prior notice or reasons being given.

For the most up to date information about our products and specifications, please visit www.tahydronics.com.

4100-18.483 03.2011

partner in your country

www.tahydronics.com

Table of contents

Other Heimeier Control Unit manuals

Popular Control Unit manuals by other brands

Sun Oracle

Sun Oracle Sun Blade X6275 M2 installation guide

AUROOM

AUROOM DICIA D Installation and operation manual

Watts

Watts Ames 986GD Installation, operation and maintenance manual

SEW-Eurodrive

SEW-Eurodrive BMV operating instructions

Parallax

Parallax 28560 manual

Automated Logic

Automated Logic UNI/59 Technical instructions