Hein Lanz D1-333-121-34 Series User manual

$8?EPDFÏÏV Page 1 / 43

$8

S

SSI Indicators for Use with

Single-Turn or Multi-Turn SSI Encoders

%

:SSI display unit only

$

: SSI display unit with analogue output

$

: SSI display unit with two presets and outputs

$

: SSI display unit with serial interface RS232 and RS485

x

Clear LED display (15 mm / 0.59’’ size) with adjustable brightness

x

Master- or Slave operation with clock rates up to 1 MHz

x

Suitable for all SSI formats from 8 to 32 bits

x

Numerous supplementary functions like Linearization, Bit Blanking etc.

Operating Instructions

$8?EPDFÏÏV Page 2 / 43

S

Safety Instructions

x

This manual is an essential part of the unit and contains important hints about

function, correct handling and commissioning. Non-observance can result in

damage to the unit or the machine or even in injury to persons using the

equipment!

x

The unit must only be installed, connected and activated by a qualified electrician

x

It is a must to observe all general and also all country-specific and application-

specific safety standards

x

When this unit is used with applications where failure or maloperation could cause

damage to a machine or hazard to the operating staff, it is indispensable to meet

effective precautions in order to avoid such consequences

x

Regarding installation, wiring, environmental conditions, screening of cables and

earthing, you must follow the general standards of industrial automation industry

x

- Errors and omissions excepted –

General instructions for cabling, screening and grounding can be found in the

SUPPORT section of our website http://

WWWHEINLANZCOM

Version:

Description:

03b /af/hk//Feb 08

Range of PM-Factor, SSI zero position and preselection mode

1 / 2 increase to [-199999, 999999];

load on the current output max. 300 Ohm

07a = 08a/kk/hk/Apr.09

Extensions: Linearization, Activation of serial transmission

09a/kk/hk/Feb.10

Extension from 25 to 32 bits

10a/kk/hk/June.10

Missing encoder alarm, remote start of serial string

10b/af/nw/March 13

Correction of the basic parameter “Analogue Characteristics”

$8?EPDFÏÏV Page 3 / 43

T

Table of Contents

1. Terminal Assignment ................................................................................................... 4

1.1. Power Supply ................................................................................................................................5

1.2. Aux. Voltage Output .....................................................................................................................5

1.3. Control Inputs A, B and C .............................................................................................................5

1.4. Adjustable Analogue Output ($ only)................................................................................6

1.5. Optocoupler (transistor) outputs ($ only) ..........................................................................6

1.6. Serial RS232 / RS485 interface ($ only) ...........................................................................7

2. How to Operate the Front Keys .................................................................................... 8

2.1. Normal display state ....................................................................................................................8

2.2. Selection and Setting of Parameters ...........................................................................................9

2.3. Teach operation..........................................................................................................................10

2.4. Set all parameters to “Default“ .................................................................................................10

2.5. Code Locking of the Keypad .......................................................................................................10

3. The Operator Menu.................................................................................................... 11

3.1. Overview of Basic Parameters ...................................................................................................11

3.2. Overview of Operational Parameters.........................................................................................12

4. Setup Procedure......................................................................................................... 13

4.1. Basic Parameters........................................................................................................................13

4.2. Operational Parameters..............................................................................................................15

4.3. Additional Parameters for the Analogue Output (model $)............................................18

4.4. Additional Parameters for Preselections and Switching Outputs (model $) ................20

4.5. Additional Parameters for Units with Serial Interface (model $)..................................22

5. Hints for Application .................................................................................................. 26

5.1. Master and Slave Operation ......................................................................................................26

5.2. Evaluation of Encoder Bits..........................................................................................................27

5.3. Scaling of the Display.................................................................................................................28

5.4. Basic Modes of Operation..........................................................................................................29

5.5. Testing Functions........................................................................................................................33

5.6. Error Messages...........................................................................................................................33

6. Special Functions....................................................................................................... 34

6.1. Linearization ...............................................................................................................................34

6.2. Manual Input or „Teaching“ of the Interpolation Points ...........................................................36

7. Technical Appendix.................................................................................................... 38

7.1. Dimensions .................................................................................................................................38

7.2. Technical Specifications.............................................................................................................39

7.3. Parameter-List ............................................................................................................................40

7.4. Commissioning Form ..................................................................................................................42

$8?EPDFÏÏV Page 4 / 43

*1'

9&',1

,QSXW$

,QSXW%

*1'

9'&287

*1'DQDORJXH

9DQDORJXH

P$DQDORJXH

3(*1'

9$&

9$&

9$&

&/.

&/.

'$7

'$7

,QSXW&5HVHW

$:

:Display with two presets and outputs

*1'

9&',1

,QSXW$

,QSXW%

,QSXW&5HVHW

*1'

9'&287

&20

287

287

3(*1'

9$&

9$&

9$&

&/.

&/.

'$7

'$7

$

: Display with serial interface

*1'

9&',1

,QSXW$WUDQVP

,QSXW%

,QSXW&5HVHW

*1'

9'&287

7['%

3(*1'

9$&

9$&

9$&

&/.

&/.

'$7

'$7

*1'

5['$

1.ÏTerminal Assignment

$

:Displayunitonly

All connections are as shown below, except for terminals 8, 9 and 10 which are unconnected

%

: Display with analogue output

$8?EPDFÏÏV Page 5 / 43

1

1.1. Power Supply

The unit accepts DC supply from 17 V to 30 V when using terminals 1 and 2. The consumption

depends on the level of the supply voltage

(typical 130mA at 30V or 190mA at 17V, plus current taken from aux. output).

For AC supply the terminals 0 VAC, 115 VAC or 230 VAC can be used.

The total AC power is 7.5 VA.

The diagrams below show a dotted line for grounding to PE.

This connection is not really necessary, neither for safety nor for EMC. However, for some

applications, it may be desirable to ground the common potential of all signal lines.

When using this earthing option, please observe:

xAll terminals and potentials marked “GND“ will be earthed.

xPlease avoid multiple earthing, i.e. when you use a DC power supply where

the Minus is already connected to earth etc.

1.2. Aux. Voltage Output

Terminal 7 provides an auxiliary output of 24 VDC / 120 mA max. for supply of sensors and

encoders.

1.3. Control Inputs A, B and C

With models $, input A is used to activate a serial transmission (rising edge, see

4.5.2). Input B is not in use.

Input C operates as a Set / Reset input (static function, active "HIGH", see 5.3).

In the basic setup menu, the inputs can be configured to PNP (signal must switch to +) or to

NPN (signal must switch to -). This configuration is valid for all three inputs at a time.

The factory setting is always PNP.

x

Where NPN setting is used, please observe:

Open NPN inputs will always represent a logical HIGH state

Consequently, Input C has to be connected to GND externally to allow normal operation.ÏIf

unconnected, the unit would be kept in a continuous Reset state.

With models

$

, also Input A must be tied to GND, and opening this connection willÏ

generate a rising edge to start a serial transmission

x

Where your use 2-wireNAMUR type sensors, please select NPN, connect the negativeÏ

wire of the sensor to GND and the positive wire to the corresponding input.

$8?EPDFÏÏV Page 6 / 43

T

Typical input circuit of control input

313

N

*1'

*1'

9LQW

,QSXW

N

*1'

,QSXW

9LQW

131

The minimum pulse duration on the Reset input (C) must be 5 msec.

1.4. AdjustableAnalogueOutput

$

only)

A voltage output is available, operating in a range of 0 ... +10 V or –10 V ... +10 V according to

setting. At the same time, a current output 0/4 – 20 mA is available. Both outputs refer to the

GND potential and the polarity changes with the sign in the display. The outputs are

proportional to the display value and provide a 14 bits resolution.

The maximum current on the voltage output is 2 mA, and the load on the current output can vary

between 0 and max. 300 ohms.

The response time of the analogue output to changes of the encoder position is appSox. 7 NTFD

1.5. Optocoupler (transistor) outputs (

$

only)

The outputs provide programmable switching characteristics and are potential-free. Please

connect terminal 8 (COM+) to the positive potential of the voltage you like to switch

(range 5V....35V). You must not exceed the maximum output current of 150 mA. Where you

switch inductive loads, please provide filtering of the coil by means of an external diode.

The optocoupler outputs provide a response time of approx. 5 msec with resistive load.

Opto Opto

33 R

Com+ (5 ... 35 V)

Output 1 (max. 150 mA)

Output 2 (max. 150 mA)

33 R

$8?EPDFÏÏV Page 7 / 43

1

1.6. Serial RS232 / RS485 interface (

$ÏONLY

)

Ex factory the unit is set to RS232 communication. This setting can be changed to RS485

(2-wire) by means of an internal DIL switch. To access the DIL switch, you must remove the

screw terminal connectors and the backplane. Then pull the board to the rear to remove the

PCB from the housing.

21',3

',/6ZLWFK

Removal of the back plane Location of the DIL switch

x

Never set DIL switch positions 1 and 2 or DIL switch positions 3 and 4 to

“ON” at the same time!

x

After setting the switch, shift the print carefully back to the housing and

avoid damage of the front pins for connection to the front keypad plate.

5[' 5['

7['7['

*1'

6FUHHQ

3&

'

9

6XE'

10

8

Connection of the RS232 interface

3/&

'

$

%

$

%

Connection of the RS485 interface

$8?EPDFÏÏV Page 8 / 43

2

2. How to Operate the Front Keys

For setup and other operations the unit uses three front keys which subsequently will be

denominated as follows:

«

ENTER

(Input)

SET

(Setting)

Cmd

(Command)

The functions of the keys are depending on the actual operating state of the unit.

The following three operating states apply:

x

Normal display state

x

Setup state

a.) Basic setup

b.) Operational parameter setup

x

Teach operation

2.1. Normal display state

You can only change over to other operation states while the unit is in the

n

normal display state.

Change over to

Key operration

Basic setup

Keep EENTER and SSET down simultaneously for 3 seconds

Operational

p

parameter setup

Keep EENTER down for 3 seconds.

Teach operation

Keep CCmd down for 3 seconds

The Cmd key is only used to execute the Teach procedure with linearization. For more details

please refer to sections 6.1 and 6.2.

$8?EPDFÏÏV Page 9 / 43

2

2.2. Selection and Setting of Parameters

2.2.1. How to select a parameter

The E

ENTER

key will scroll through the menu. The S

SET

key allows to select the corresponding

item and to change the setting or the numeric value. After this, the selection can be stored by

ENTER

again, which automatically changes over to the next menu item.

2.2.2. How to change parameter settings

With numerical entries, at first the lowest digit will blink. When keeping the S

SET

key

continuously down, the highlighted digit will scroll in a continuous loop from 0 … 9 , 0 … 9.

After releasing the S

SET

key, the actual value will remain and the next digit will be highlighted

(blink). This procedure allows setting of all digits to the desired values. After the most

significant digit has been set, the low order digit will blink again and you can do corrections if

necessary.

With signed parameters, the high order digit will scroll from “0” to "9" (positive) followed by

“-“ and "-1" (negative)

2.2.3. How to store settings

To store the actual setting, press the E

ENTER

key, which will also automatically scroll forward

the menu.

At any time the unit changes from programming mode to normal display operation, when you

keep the E

ENTER

key down again for at least 3 seconds.

2.2.4. Time-out function

A “time-out” function will automatically conclude every menu level, when for a break period of

10 seconds no key has been touched. In this case, any changes which have not been confirmed

by E

ENTER

yet would remain unconsidered.

$8?EPDFÏÏV Page 10 / 43

2

2.3. Teach operation

The Time

-out function will be switched off during all Teach operations

Key

Function

«

ENTER will conclude or abort any Teach operation in progress

SET function is fully similar to normal set-up operation

Cmd will store the display value to the register and will change over to the

next interpolation point.

For details of the Teach procedure see section 6.2.

2.4. Set all parameters to “Default“

At any time you can return all settings to the factory default values.

The factory default settings are shown in the parameter listings in section 6.

When you decide to set all parameters to „default“, please be aware that all

p

previous settings

will be lost and you will need to do the whole set-up

procedure once more

To execute the „Default“ setting function:

xPower the unit down.

xPress the ENTER key.

xPower the unit up again while the ENTER key is kept down

2.5. Code Locking of the Keypad

When the code locking of the keypad has been switched on, any key access first results in

display of

To access the menu you must press the key sequence

«

«

«

within 10 seconds, otherwise the unit will automatically return to the normal display mode.

$8?EPDFÏÏV Page 11 / 43

3

3. The Operator Menu

The menu provides one section with “Basic Parameters” and another section with “Operational

Parameters”. On the display you will only find those parameters which have been enabled by

the basic settings. E.g. when the Linearisation Functions have been disabled in the basic set-

up, the associated linearization parameters will also not appear in the parameter menu.

All parameters, as good as possible, are designated by text fragments. Even though the

possibilities of forming texts are very limited with a 7-segment display, this method has proved

to be most suitable for simplification of the programming procedure.

The subsequent table shows the general structure of the whole menu only.

Detailed descriptions of all parameters will follow in section 4.

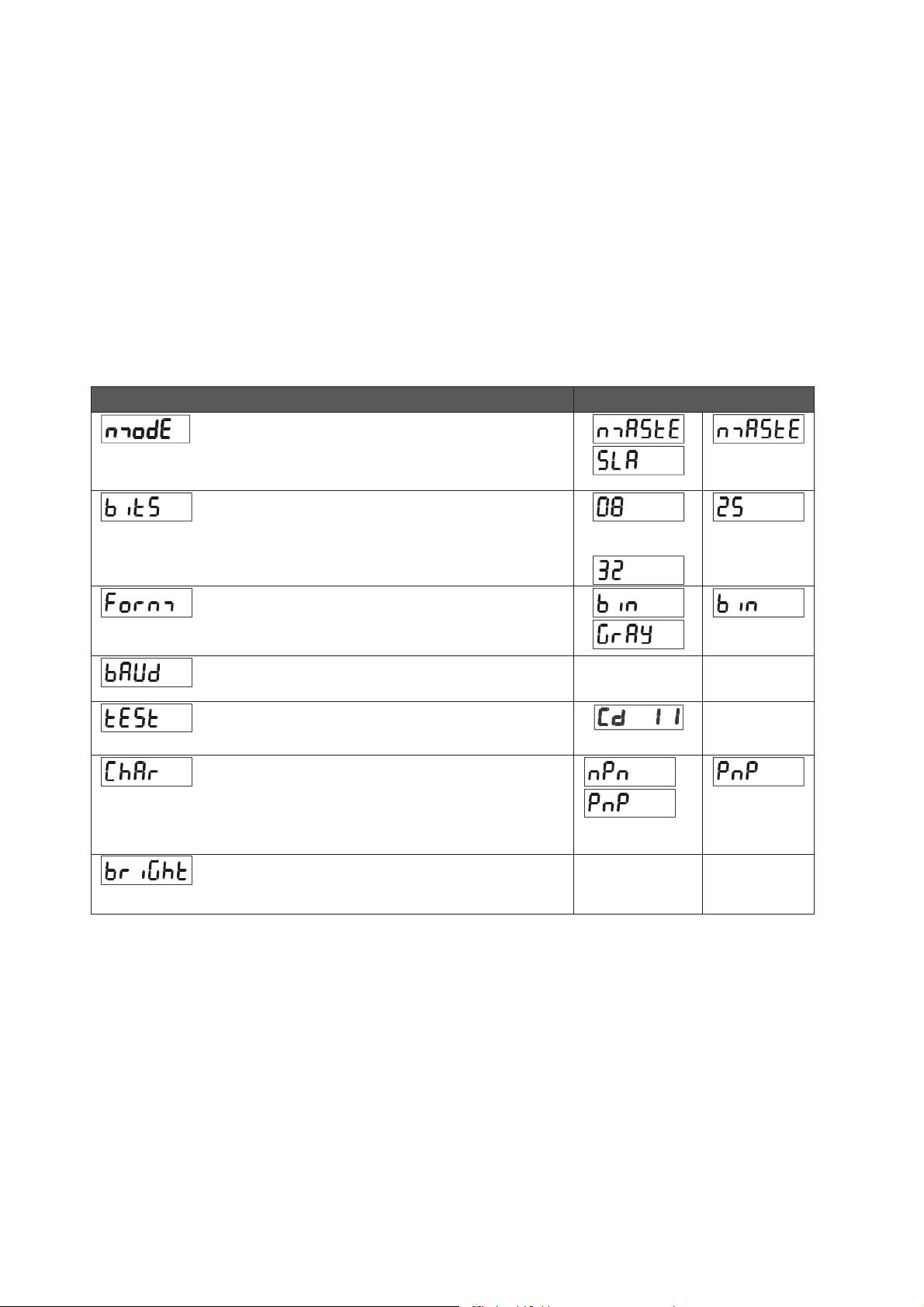

3.1. Overview of Basic Parameters

$

$

$

$

SSI_Mode

SSI_Mode

SSI_Mode

SSI_Mode

SSI_Bits

SSI_Bits

SSI_Bits

SSI_Bits

SSI_Format

SSI_Format

SSI_Format

SSI_Format

SSI_Baud Rate

SSI_Baud Rate

SSI_Baud Rate

SSI_Baud Rate

SSI_Test

SSI_Test

SSI_Test

SSI_Test

Characteristics

Characteristics

Characteristics

Characteristics

Brightness

Brightness

Brightness

Brightness

Code Locking

Code Locking

Code Locking

Code Locking

Linearization Mode

Linearization Mode

Linearization Mode

Linearization Mode

Analogue Characteristics

Preselection_Mode 1

Ser_Unit_Nr

Analogue Offset

Preselection_Mode 2

Ser_Format

Analogue Gain

Hysteresis 1

Ser_Baudrate

Hysteresis 2

$8?EPDFÏÏV Page 12 / 43

3

3.2. Overview of Operational Parameters

$

$

$

$

Preselection 1

Preselection 2

M-Factor

M-Factor

M-Factor

M-Factor

D-Factor

D-Factor

D-Factor

D-Factor

P-Factor

P-Factor

P-Factor

P-Factor

Decimal point

Decimal point

Decimal point

Decimal point

Display

Display

Display

Display

Hi_Bit (MSB)

Hi_Bit (MSB)

Hi_Bit (MSB)

Hi_Bit (MSB)

Lo_Bit (LSB)

Lo_Bit (LSB)

Lo_Bit (LSB)

Lo_Bit (LSB)

Direction

Direction

Direction

Direction

Error

Error

Error

Error

Error_Polarity

Error_Polarity

Error_Polarity

Error_Polarity

Round Loop

Round Loop

Round Loop

Round Loop

Time

Time

Time

Time

Reset

Reset

Reset

Reset

Zero Position

Zero Position

Zero Position

Zero Position

Analogue Begin

Ser_Timer

Analogue End

Ser_Mode

Ser_Value

P01_X *)

P01_X *)

P01_X *)

P01_X *)

P01_Y*)

P01_Y*)

P01_Y*)

P01_Y*)

Æ

Æ

Æ

Æ

P16_X *)

P16_X *)

P16_X *)

P16_X *)

P16_Y *)

P16_Y *)

P16_Y *)

P16_Y *)

*) appears only when Linearization has been enabled in the Basic Menu

$8?EPDFÏÏV Page 13 / 43

4

4. Setup Procedure

For better understanding the following sections 4.1 and 4.2 explain settings for the display only.

Model-specific settings for Analogue Output, Preselections and Serial Link will be explained

separately, later.

4.1. Basic Parameters

The subsequent settings are of unique nature and must only be made upon the very first setup.

The basic setup selects the desired operation mode of the unit, the input characteristics

PNP/NPN and the desired brightness of the LED display.

Menu

Setting Range

Default

SSI--Mode

Setting of Master Mode or Slave Mode

For details see section 5.1

SSI--Bits

Bit length of the SSI string

For more details see section 5.2 .....

SSI--Format:

Setting of the SSI code (Binary or Gray)

SSI--Baud Rate

0.1 ... 1000.9

kHz

100.0

k

kHz

SSI Test

SSI Self test functions (see 5.5.)

etc.

Characteristics *)

Switching characteristics of the Reset input

NPN: switch to "-" *)

PNP: switch to "+"

Brightness

20%, 40%, 60%

80% and 100%

100%

Brightness of the 7-segment LED display

*) Please observe hints given in chapter 1.3

$8?EPDFÏÏV Page 14 / 43

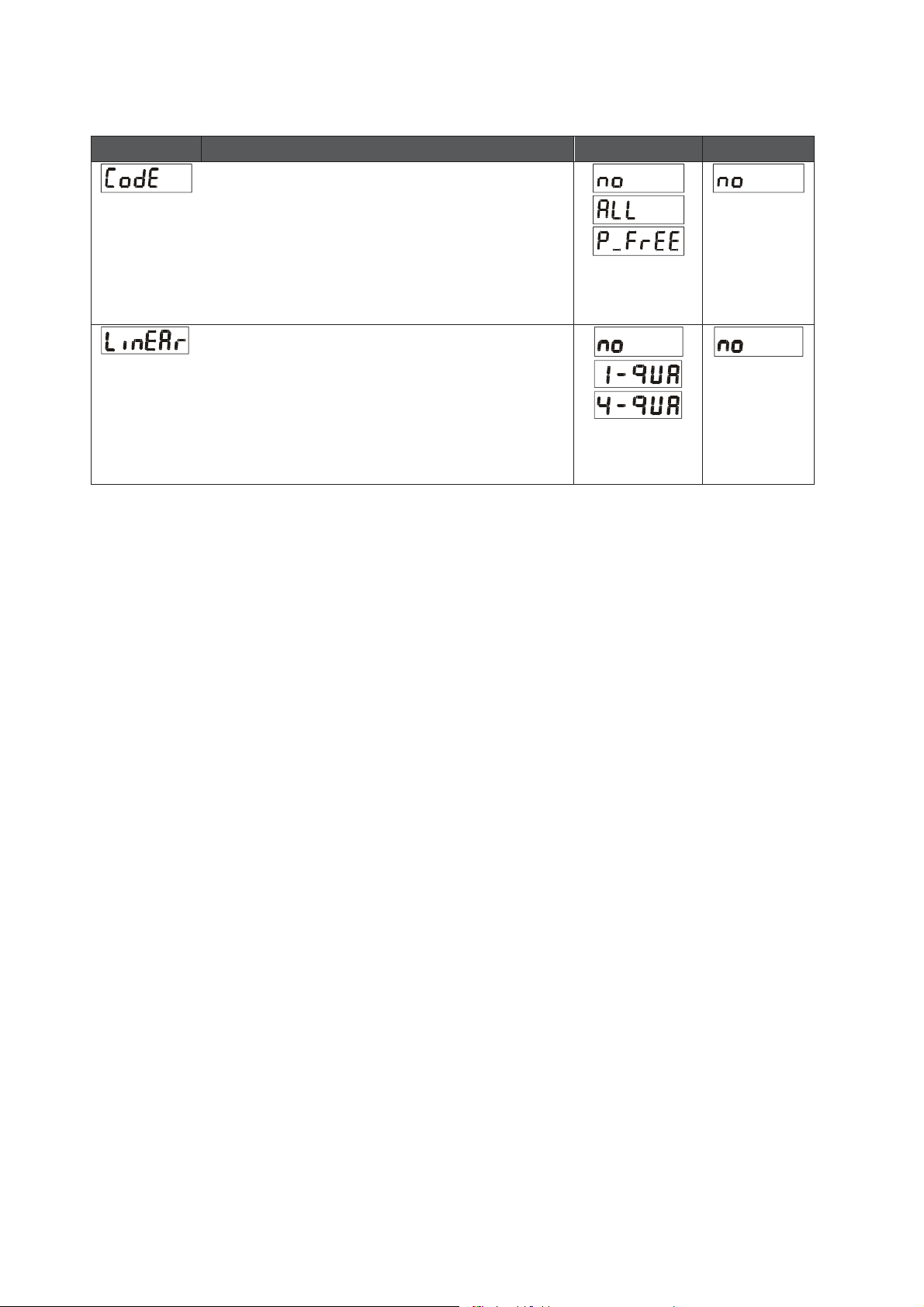

MMenu

SSetting Range

DDefault

Code Locking

Interlock of keypad access (see 2.5)

no:

Keypad accessible at any time

All:

Keypad interlock for all functions

P-Free:

Keypad interlock except for PreselectionÏ

Settings Pres 1 und Pres 2 (model $)

Linearization Mode

For details please see 6.1 und 6.2.

no:

Linearization is switched OFF *)

1

-qua:

Linearization settings for the positive range

only (negative values will appear as a mirror).

4--qua:

Linearization over the full numeric range

*) The menu will not display any further linearization parameters

$8?EPDFÏÏV Page 15 / 43

4

4.2. Operational Parameters

Menu

Setting Range

Default

M--Factor *):

Multiplying factor for the SSI value

(after consideration of possible bit blanking)

-9.999 … 9.999

1.000

D--Factor *):

Dividing factor for the SSI value

(after consideration of possible bit blanking)

0.001 … 9.999

1.000

P--Factor *):

This signed value will be added to the SSI result

(after consideration of possible bit blanking)

-199999

…

999999

0

Decimal Point

Setting according to the decimal formats shown in

the display

000000

00000.0

...

0.00000

00000.0

Display:

Display mode of the unit

norm:

regular scaling of the display

359.59:

Angular display format 359° 59' with use of

the Round Loop Function

norm

359.59

norm

Hi Bit **):

1 … 32

25

Bit Blanking Function: Defines the highest bit for

evaluation. To evaluate all encoder bits this

parameter has to be set to the total number of bits

according to setting

Lo Bit **):

1 … 31

1

Bit Blanking Function: Defines the lowest bit for

evaluation. To evaluate all encoder bits this

parameter has to be set to "01"

*) Scaling details are explained under 5.3

**) For more details about Bit Blanking see 5.2

$8?EPDFÏÏV Page 16 / 43

MMenu

SSetting Range

DDefault

Direction

Parameter to negate the SSI value, resulting in

reversal of the direction of the encoder count.

riGht:

ascending values with forward motion

LEFt::

decreasing values with forward motion

riGht

LEFt

riGht

Error: (please refer to 5.6)

Defines the control of presence of an encoder and

the location of the Error Bit in case of error.

00:

No error bit available

Control of presence of an encoder is off

01:

No error bit available

Control of presence of an encoder is on

>01:

Location of the error bit

Control of presence of an encoder is on

0 ... 32

0

Error--Polarity *):

Defines the polarity of the Error Bit in case of error.

0

0:

Error Bit is Low in case of error

1: Error bit is High in case of error

0

1

0

When an error occurs, „

„Err-b“

appears on the display.

The same function can also be used to monitor the Power Failure Bit of an encoder

(mostly called „PFB“).

Round Loop

Defines the number of encoder steps per revolution

with use of the Round Loop Function (see 5.4.2).

0:

Normal display of the encoder data, no

Round Loop Function

>0:

Number of steps per Round Loop Cycle

0 ... 999999

0

Time

Sets the update cycle of the display (and of the

analogue output or the switching outputs where

applicable). The fastest possible update time is

3 msec. respectively one telegram length including 4

pause clocks. With Slave operation the next update

will occur when the unit synchronizes again to the

Master pause following to the expiration of the

update time.

0.000 ... 1.009

sec

0.01 sec

$8?EPDFÏÏV Page 17 / 43

MMenu

SSetting Range

DDefault

Reset

A Reset command is available to store the actual SSI

position to register „Zero Position“. As a result, the

display value will become zero at the actual encoder

position, and all further operation will refer to this

new datum point. The zero position remains

memorized also after power-down.

no:

Reset function disabled

Front:

Reset function by the front SET key

E_tErn:

Reset function by the remote Reset input

FR u E:

Reset via key and remote input

Zero Position: *)

Defines the zero position of the display. When you

set this parameter to e.g. "1024", the unit will

display zero when the encoder position is 1024.

Zero Position can be set directly via keypad or by

means of an external Reset command.

-199999

...

999999

0

P01_X **)

Linearization Point 1_X

X value of the first interpolation point.

-199999

... 999999

999999

P01_Y

Linearization Point 1_Y

Y value of the first interpolation point.

-199999

... 999999

999999

…

P16_X

Linearization Point 16_X

X value of the 16. interpolation point.

-199999

... 999999

999999

P16_Y

Linearization Point 16_Y

Y value of the 16. interpolation point.

-199999

... 999999

999999

*) Please observe that Parameter P_Fac will cause an additional displacement of the zero position

**) Parameters P01_X to P16_Y appear only when the linearization has been enabled in the basic menu

$8?EPDFÏÏV Page 18 / 43

4

4.3. Additional Parameters for the Analogue Output

(model

$

The following additional settings for the analogue output appear in the Basic Menu:

Menu

Setting Range

Default

Analogue Characteristics

You can set the following output options:

+/- 10 V (bipolar),

0 - 10 V (positive only),

4 - 20 mA

0 - 20 mA.

With setting +/-10 Volts the polarity of the output

voltage will follow the sign in the display

Analogue Offset:

Set this parameter to 0 when you expect your

analogue signal to start with 0 V (or 0 mA / 4 mA

respectively). Where another zero definition is

desired it can be set by this parameter. Setting of

e.g. 5.000 will already produce 5 volts with the

output in zero state.

-9,999..+9,999

0,000

Analogue Gain:

Parameter to set the analogue output swing. Setting

10.00 will allow full swing of 10 V or 20 mA, setting

8.00 will reduce the swing to 8 V or 16 mA.

00,00..99,99

10,00

The following Operational Parameters provide scaling of the analogue output:

Menu

Setting Range

Default

Analogue--Begin

Start value of the analogue conversion range

-199999...999999

0

Analogue--End

End value of the analogue conversion range

-199999...999999

100000

By means of these two parameters any window of the whole display range can be mapped onto

the analogue output.

$8?EPDFÏÏV Page 19 / 43

The subsequent example shows how to convert the display range from 1400 to 2000 into an

analogue signal of 2 - 10 volts.

66,'LVSOD\9DOXH

9ROWV

$QDORJXH2XWSXW

A--ChAr = 0 --110 V

AnAbEG = 1400

OFFSEt ==2.000

AnAEnd ==2000

GAin = 8.00

All settings refer t

o the scaled values shown in the display of the unit,

and not to the original SSI encoder data

$8?EPDFÏÏV Page 20 / 43

4

4.4. Additional Parameters for Preselections and Switching Outputs

(model

$

The following additional settings for the Preselections appear in the Basic Menu:

Menu

Default

Switching Characteristics of Output 1

Greater/Equal. Output to switch statically ON

when Display Value

Preselection1

Lower/Equal. Output to switch statically ON

when Display Value Preselection1

Greater/Equal. Output to switch dynamically ON

when Display Value

Preselection1

(timed output pulse) *)

Lower/Equal. Output to switch dynamically ON

when Display Value

Preselection1

(timed output pulse) *)

Switching Characteristics of Output 2

See above, but Preselection2

See above, but Preselection2

See above, but Preselection2

See above, but Preselection2

Output to switch statically ON when

Display Value Preselection1 – Preselection2

**)

Output to switch dynamically ON when

Display Value Preselection1 – Preselection2

**)

HYSt 1

Hysteresis 1

Adjustable hysteresis for output 1

Setting range 0 ... 99999 display units

0

HYSt 2

Hysteresis 2

Adjustable hysteresis for output 2

Setting range 0 ... 99999 display units

0

*) Timed output pulses have a fixed duration of 500 msec (factory adjustable only)

**) Trailing Preset to generate an anticipation signal with a fixed distance to the main signal

This manual suits for next models

4

Table of contents

Other Hein Lanz Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

enertexbayern

enertexbayern Enertex KNX Smartmeter 85A (RT) Manual and Configuration

ABQINDUSTRIAL

ABQINDUSTRIAL HORIBA U-50 Series instruction manual

Ono Sokki

Ono Sokki DS 0297 manual

Blackline Safety

Blackline Safety G6 Dock Technical user's manual

CCL ELECTRONICS

CCL ELECTRONICS C8437 user manual

Tek-Trol

Tek-Trol Tek-Flux 1400A instruction manual