OPERATION

Raise Saddle Assembly

1. Locate and close release valve by turning it clockwise

firmly,then pump the handle until the load is contacted.

2.Follow vehiclemanufacturersrecommendedprocedures

forremovingtheloadasoutlinedinvehicleservicemanual

orrepair guide.

3.Secure loadwith provided chains.

Important: Ensure the transmission is centered on the

jack. An off-center transmission could cause the jack to

tipoverresulting inpropertydamageor personalinjury.For

your safety, do not exceed 100tilt angle of the saddle

assembly in all directions.

Lower Saddle Assembly

Caution: Be sure all tools and personnel are clear

before lowering load. Dynamic shock loads are

created by quickly opening and closing the release valve

as the load is being lowered. The resulting overload may

cause hydraulic system failure.

1.Slowly, gently, turnreleasevalvecounterclockwisetolower

load. Nomorethan1/2fullturnuntillloadisfully lowered.

2. Secure the transmission to the jack with the chain.

3.For model HW93718,adjustthe boltto thedesiredchain

link. The transmission should be tightly secured to the

jack if proper adjustment is used.

MAINTENANCE

Important: Use only a good grade hydraulic jack oil.

Avoid mixing different types of fluid and never use brake

fluid, turbine oil, transmission fluid, motor oil, or glycerin.

Improperfluid cancause failureof thejack andthe

potentialfor sudden and immediate loss of load.

Adding Oil

1. With saddle fully lowered, set jack in its upright, level

position.Locateandremove oil fillerplug/ airvent screw.

2. Fill with oil until just below the rim of the oil filler hole,

then reinstall the oil filler plug/ air vent screw.

4

!

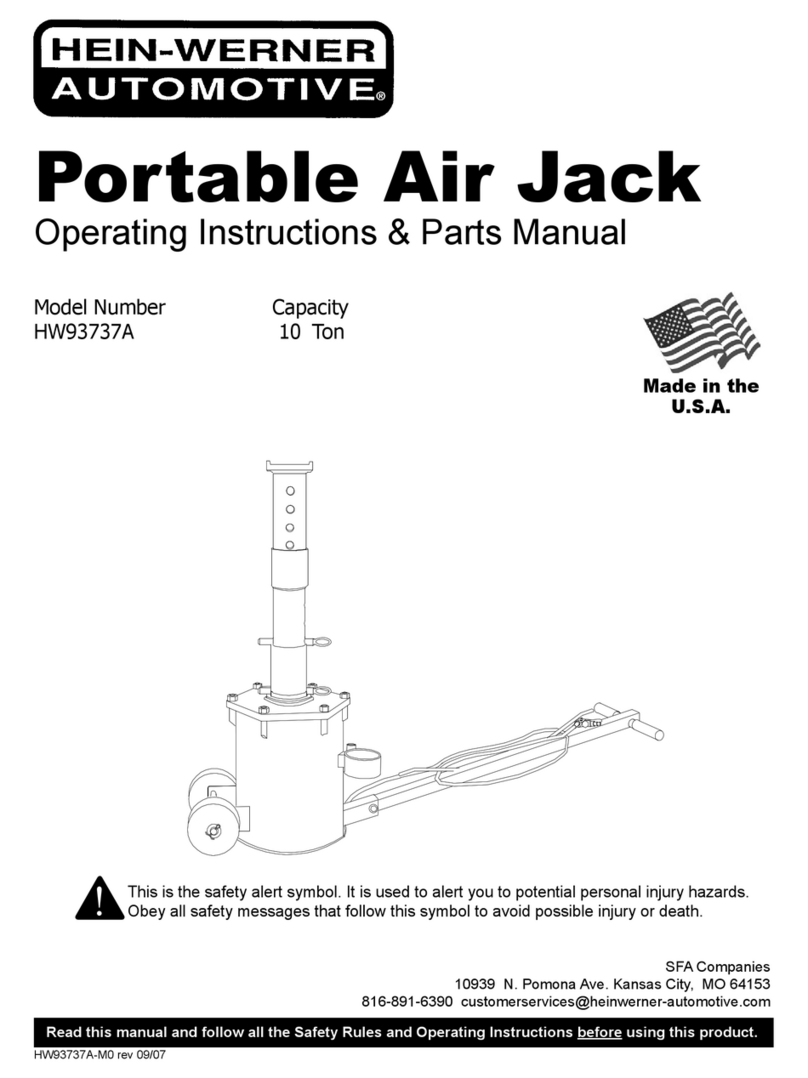

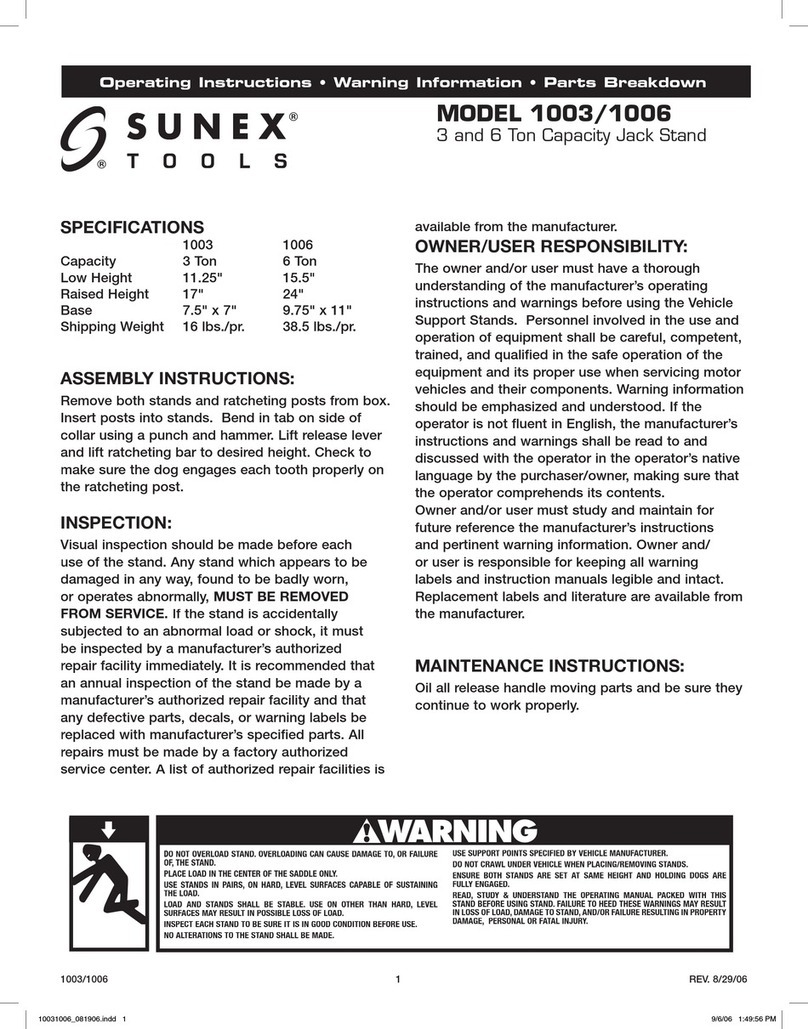

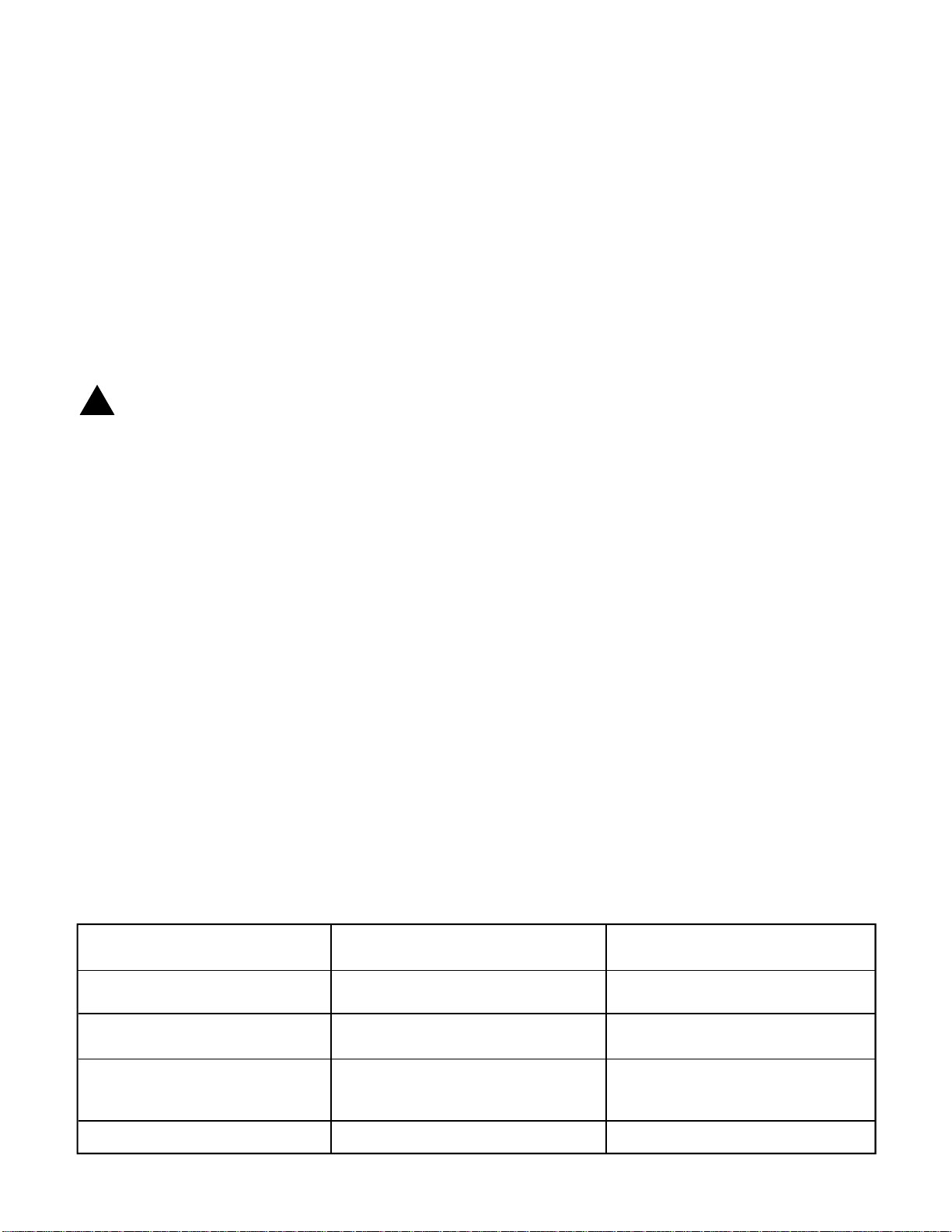

PossibleCauses Corrective Action

Jack will not lift load or bleeds off

afterlift

Will not lift to full extension •Fluidlevel low

•Fluidlevel low

•Air trapped (Apply to HW93718 only)

•Overloadcondition

• Hydraulic unit malfunction •Remedyoverloadcondition

•Contact Snap-on Tech.Service

•Ensureproperfluidlevel

•Ensureproperfluidlevel

•Withram fullylowered, removeoil

filler plug to bleeds air

Poorliftperformance

Jackwill notlower after unloading •Reservoiroverfilled

•LinkageBinding •Drain fluidtoproper level

•Cleanand lubricatemoving parts

Symptom

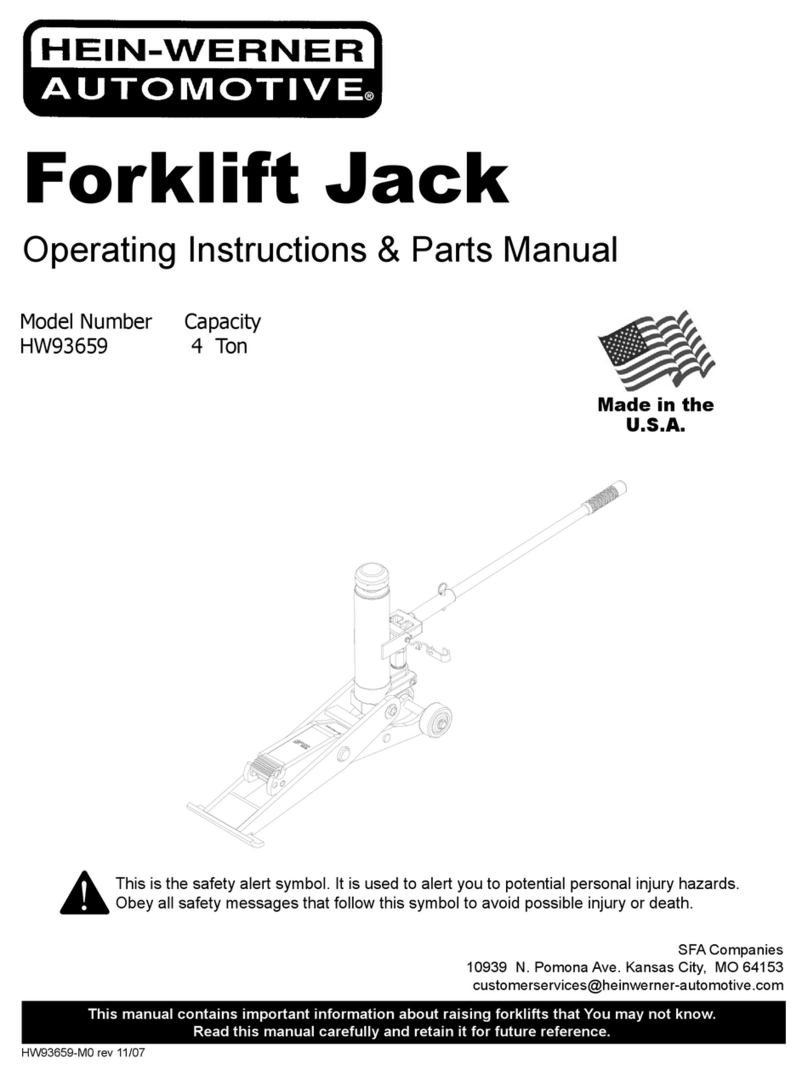

REPLACEMENT PARTS

Not all components of the jack are replacement items,

butare illustratedas a convenientreference oflocation

and position in the assembly sequence. When ordering

parts,give Modelnumber, parts numberand description

on pages 5-8. Call or write for current pricing:

Phone:(888)332-6419or contactHein-WernerCustomer

or 10939 N. PomonaAve. Kansas City, MO 64153

Changing Oil

Forbest performanceandlongest lift,replace the

complete fluid supply annually.

1. With saddle fully lowered, and pump piston fully

depressed,remove oil fillerplug/air ventscrew.

2. Lay the jack on its side and drain the fluid into a

suitablecontainer.

Note: Dispose of hydraulic fluid in accordance with local

regulations.

3. Set jack in its level, upright positon and fill with oil until

just below the rim of the oil filler hole.

4. Reinstall the oil filler plug / air vent screw.

Librication

1. A periodic coating of light lubricating oil to pivot points,

axles, and hinges will help to prevent rust and assure

thatwheels,castors, and pumpassemblies movefreely.

2. When used on a daily basis, air pump model should be

internally lubricated before each use. Use only good

quality air tool lubricant.

Cleaning

Periodically inspect the ram for signs of rust or corrosion.

Clean as needed and wipe with an oily cloth.

Note: Neveruse sandpaper orabrasivematerial onthese

surfaces!

Storage

When not in use, store the jack with ram fully retracted.

TROUBLESHOOTING

MAINTENANCE contd...