JSA300AJ 4 01/13/14

ThisisthesafetyalertsymbolusedfortheOPERATINGINSTRUCTIONSsectionofthismanualtoalertyoutopotentialpersonalinjuryhazards.

Obeyallinstructionstoavoidpossibleinjuryordeath.IMPORTANT:Beforeattemptingtoraiseanyvehicle,checkvehicleservicemanualfor

recommended lifting surfaces.

OPERATION

1. Putvehicletransmissioninparkoringearandthenapplytheemergencybrake.

To raise load:Turnthehandleinaclockwisedirectionuntiltight.Positionthejackundertheload.Proceedtopumpthehandleinordertoraisethelift

arm to the load. As the saddle at the end of the lift arm gets closer to the load, reposition the jack so the saddle will contact the load firmly and the load is

centeredonthesaddle.Makesurethesaddleiscorrectlypositioned.Raisetheloadtothedesiredworkheight.Placejackstandsofappropriatecapacity

at the vehicle manufacturers's recommended support areas that provide stable support for the raised vehicle. DO NOT CRAWL UNDER VEHICLE WHILE

LIFTING VEHICLE OR PLACING OR REMOVING THE JACK STANDS!Oncejackstandsarepositioned,turnthejackhandleVERYSLOWLYinacounterclockwise

direction to lower the load to rest on the jack stands. Inspect the relationship between the jack stands and load to make sure the setup is stable and safe.

If the setup is not stable or safe, follow the preceding steps until corrected.

2. To lower load:Followtheproceduresmentionedin"Toraiseload"sectionoftheOPERATINGINSTRUCTIONSinordertoraisetheloadoffthejackstands.

Once the load has cleared the jack stands, remove the jack stands from under the load and away from the work area. DO NOT CRAWL UNDER VEHICLE

WHILE LIFTING VEHICLE OR PLACING OR REMOVING THE JACK STANDS! Turn handle very slowly in a counter clockwise direction until the load is completely

lowered to the ground. Once the jack's lifting saddle has cleared the load, remove the jack from under the load. CAUTION: Keep hands and feet away from

the hinge mechanism of the jack.

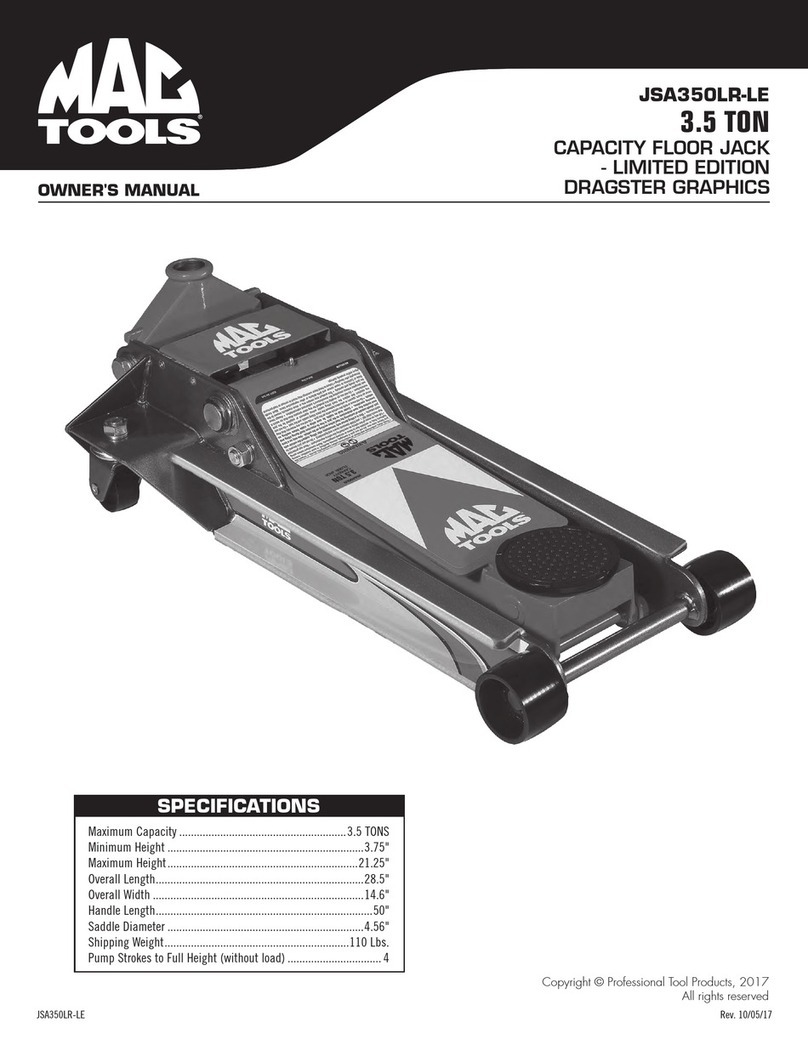

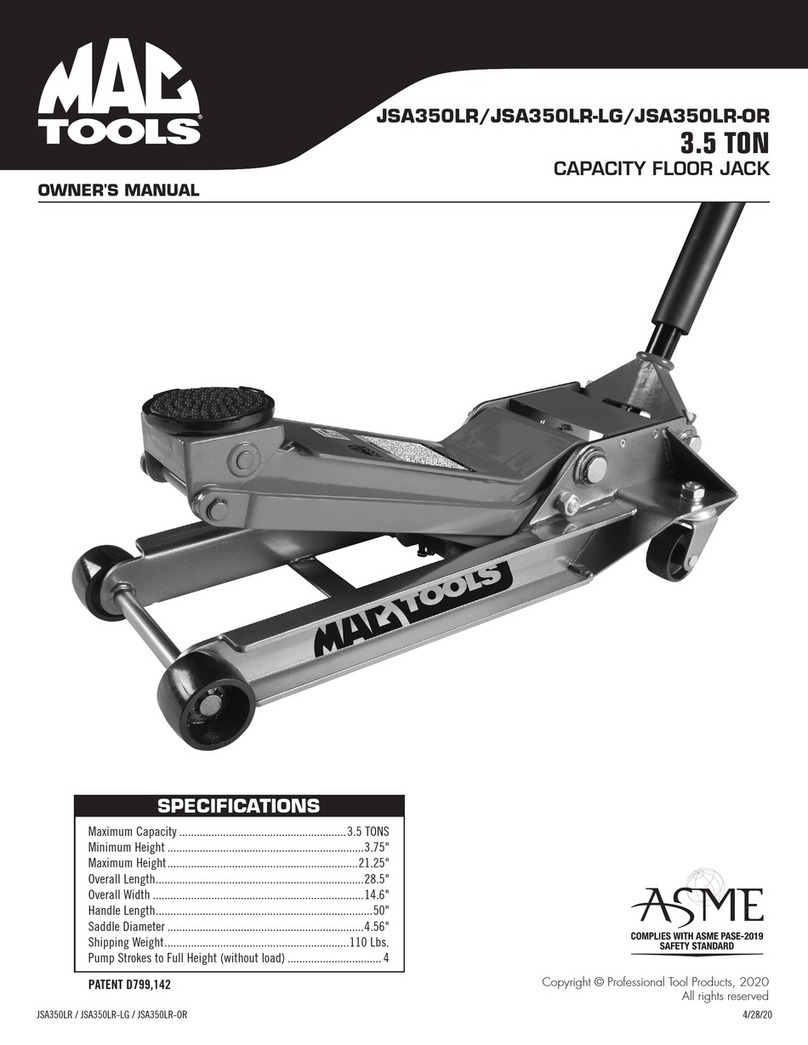

SET UP

OPERATINg INSTRUCTIONS

JSA300AJ

3 TON

CAPACITY ALUMINUM

FLOOR JACK

1. Depress the upper handle lock in the upper handle while simultaneously inserting the end of the upper handle in the lower handle. Rotate the upper handle

back and forth until the handle lock seats in the lower handle lock hole.

2. Unscrew the handle socket bolt so that it will not interfere with the insertion of the handle in the handle socket. Insert the handle in the handle socket and

rotate the handle assembly back and forth until the release valve (see page 7) fits in the receiver in the bottom of the handle. Secure the handle in the

handle socket by tightening the handle bolt.

3. Sometimes air gets trapped in the hydraulic system during shipping and handling. If the pump feels spongy, or there is not a full incremental pump stroke,

or the jack will not raise to maximum height, follow these instructions in order to purge air from the system:

a. With the lift arm in its completely retracted position and the pump handle rotated all the way in a clockwise direction until it stops,

rotate the pump handle in a counterclockwise direction two full revolutions.

b. Proceed to pump the jack 15 full incremental pump strokes.

c. Rotate the pump handle clockwise until it stops and proceed to pump the handle until the lift arm reaches maximum height.

d. Repeat steps "A" through "C" until all air is purged from the system.

IMPORTANT: Before attempting to raise any vehicle, check vehicle service manual for recommended lifting surfaces.

ThisisthesafetyalertsymbolusedforthePREVENTATIVEMAINTENANCEsectionofthismanualtoalertyoutopotentialpersonalinjuryhazards.

Obey all instructions to avoid possible injury or death.

PREVENTIVE MAINTENANCE

1. Always store the jack in a well protected area where it will not be exposed to inclement weather, corrosive vapors, abrasive dust, or any other harmful

elements. The jack must be cleaned of water, snow, sand, grit, oil, grease or other foreign matter before using.

2. The jack must be lubricated periodically in order to prevent premature wearing of parts. A general purpose grease must be applied to caster wheels,

front axle, elevator arm, handle base pivot bolts, release mechanism and all other bearing surfaces. Worn parts resulting from inadequate or no

lubricationarenoteligibleforwarrantyconsideration.IMPORTANT:Inordertopreventsealdamageandjackfailure,neverusealcohol,hydraulicbrake

uid,ortransmissionoilinthejack.Usehydraulicjackoil,alightturbineoil,ChevronAWISO32orUnocalUnaxAW150.

3. Everyjackownerisresponsibleforkeepingthejacklabelscleanandreadable.Useamildsoapsolutiontowashexternalsurfacesofthejackbutnotany

moving hydraulic components. Contact Mac Tools for replacement label if your jack label is not readable.

4. Inspect the jack before each use. Do not use the jack if any component is cracked, broken, bent, shows sign of damage or leaks hydraulic fluid. Do not use

the jack if it has loose or missing hardware or components, or is modified in any way. Take corrective action before using the jack again.