Heliodyne Delta T Pro User manual

INSTALLATION

GUIDE

DELTA T PRO

CONTROL UNIT

EXCELLENCE

BY DESIGN

CONTROL OVERVIEW

This Delta-T Pro solar controller has been specifically designed

to control solar thermal collector systems, including open loop,

closed loop with a heat exchanger, drain back, residential

domestic water heating with electrical ignition gas single tank

storage, combination systems with space heating, and commercial

systems with variable speed pump operation.

There are two versions of the Delta-T Pro, one with a 10Base-T

Ethernet connection (DLTA 000 001), and one with a Wi-Fi/802.11b

Connection (DLTA 000 002).

The controller comes loaded with interface software, accessed

like a web page through any PDA, handheld, phone, laptop or

computer with a rich HTML internet browser such as Microsoft‘s

Internet Explorer. Connecting the control to an existing home or

office network will enable any user on that network to view the

system parameters and thermal performance data.

For the most basic system, the control requires two SAS-10

(10,000 Ohm @ 77°F) thermistor sensors, while additional

inputs are required to take advantage of the more sophisticated

operations, like energy calculation and data storage. Please

see the table at the end of this manual for functions and their

explanations, as well as the inputs required to run them.

1.0. Description

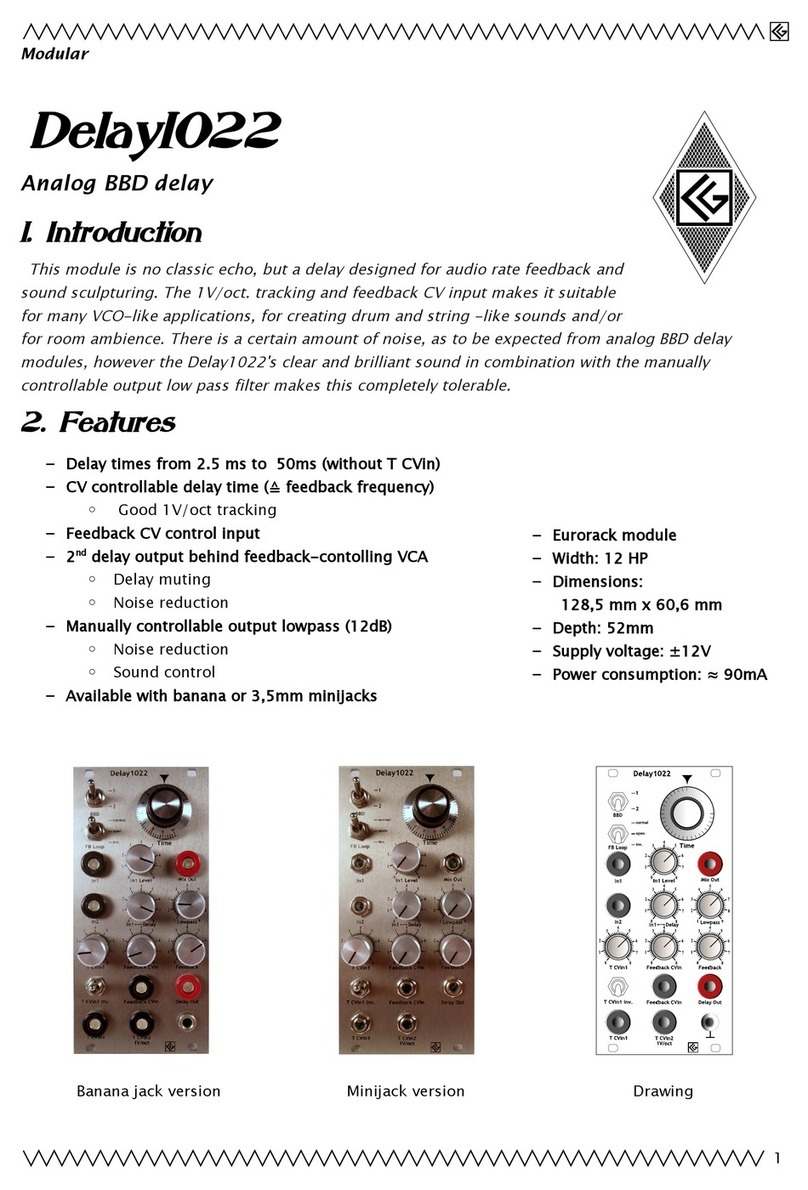

1. DELTA T PRO

ON:

OFF:

AUTO:

Relay Operation Bypass Pins

SHORT PINS 1-2 & 5-6

OPEN ALL PINS

SHORT PINS 1-2

Internally Powered Outputs

120 / 240 VAC

10kΩThermistor Sensors

100mA Fuse

Reset

WiFi:

Voltage Switch

6

5

4

3

2

1

3

2

1

3

2

1

Pin

JUMPER 5

JUMPER 6

Figure 1.0.-1 Delta T Pro I/O

CONTROL INSTALLATION 3

2.0. General Notes

This control conforms to the National Electric Code and is certified by the Underwriters Laboratory. Installation should adhere to all

national and local electric codes, and be installed by a qualified electrician or contractor. Any electrical wiring or modifications to the

control I/O should be performed with the power disconnected.

SOLAR HOT WATER

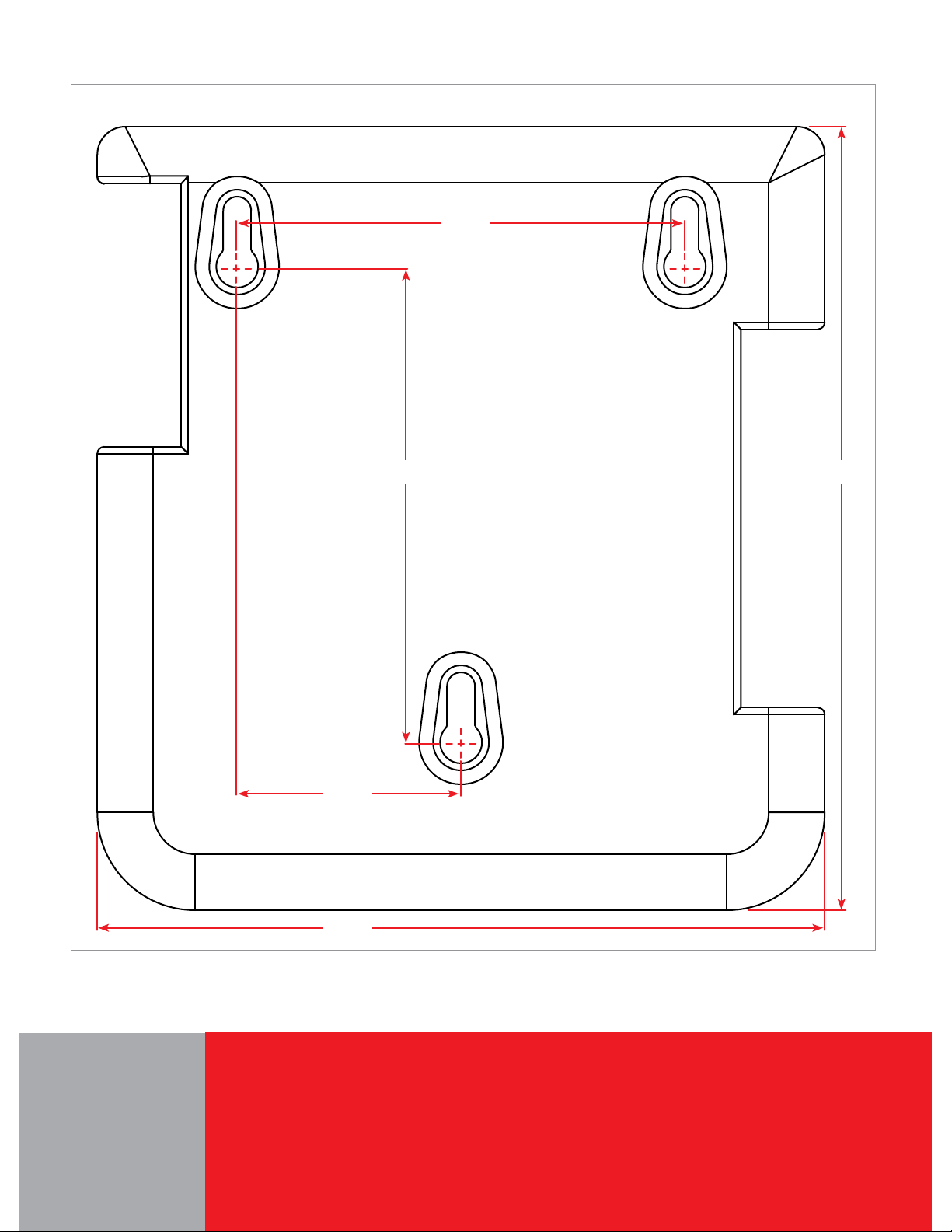

2.1. Mounting

The Delta-T Pro should be mounted on a wall indoors, away from

weather and interference. Using the mounting holes on the back

of the box, securely install 3 screws into mounting plane leaving

1/4” between the wall and the back of the bolt head; place control

back upon screws and slide down to secure box tightly into screw

pattern. The back page of this manual has a screw template.

2.2. Power and Wiring

This control comes pre-wired with an electric line cord for plug-in operation. The voltage is factory set to accept 115 VAC nominal.

If 230 VAC operation is desired, switch the red slider to reveal 230; modification of the line cord may be necessary to adapt to the

field plug receptacle. The operation voltage determines the relay output voltage.

Wire solar loop pumps into Relay 1, using the Normally Open (NO) terminal on the relay. The Normally Closed (NC) terminal can be

used to supply power to a unit for use when the collectors are not heating the storage, like a swimming pool or hot tub. See Figure

2 below, and the reference table at the end of this manual for use descriptions.

2.3. Thermistor Sensors

The SAS-10s sense temperature by conduction, and are not for liquid immersion, or inside collectors.

For a proper reading, ensure the copper lug on the sensor is firmly against the desired surface using

an SS pipe clamp across the flat surface or bolted via the through hole. Use surrounding insulation

to avoid ambient temperature and other sources of reading interference.

The sensor leads are 24 GA Class II wiring and carry 4 VDC. Use a conductor 18-24 GA zip or bell

wire to run from the sensor location to the control. Use caution when installing to avoid wire damage.

Shielded wire is not necessary.

2. INSTALLATION

Solar Loop

Connections

Connection for powering use

opposite to solar operation Temperature operated relay for Combi-Systems, etc*

*The minimum operation temperature is user set

Gas tank operation in DHW mode

OR

Extraneous heat use in Combi mode*

Figure 2. Relay Connections

CONTROL SETTINGS

3. SETTINGS

3.0. Network Connection

The Delta-T Pro comes preset with network parameters that in

most cases will not be compatible with existing network configu-

rations.

IP Address: 169.254.148.50

Subnet Mask: 255.255.0.0

Gateway: 169.254.148.1

If the above parameters are acceptable to your current configu-

ration, connect an Ethernet cable to the RJ 45 jack on the con-

trol, and connect the other end into your network hub. If these

settings must be adapted for your existing network, or you do

not have a network, then you must connect the Ethernet cable

directly to your computer to view the software.

After connection, wait for the computer to resolve the IP address

(up to 30 seconds depending on computer speed), then enter

the IP Address above into an internet browser to bring up the

system user interface.

3.1. Helio-Pak Pro Systems and DLTA 000 002

The Helio-Pak Pro systems and DLTA 000 002 come pre-pack-

aged with the Wi-Fi signal and the appropriate network settings.

Users must disable any ethernet connection first, and then can

connect to the “DTT Pro WiFi” network with a Wi-Fi enabled

device when the Helio-Pak is installed and powered up.

3.2. Changing the Network Settings on the 001

If the above parameters are not acceptable to your network con-

figuration, the control must be directly hooked up to a computer

or laptop with an RJ 45 / Ethernet port. (DLTA 000 002 WIFI

models are part of an Ad Hoc network, and the settings cannot

be changed at this time.)

With the control connected and powered up, enter the above IP

Address into an internet browser. After it has loaded, navigate

to the “Settings” page, then to the “Network” tab on the settings

page. Enter the appropriate site specific network parameters

into each box and write them in this manual using a pencil in

case of modifications:

My IP Address:

My Subnet Mask:

My Gateway:

Now press “Save”. You will no longer be able to access the

control via the default address, and must now use the last saved

IP Address to access the control software. If the last setting is

unknown, short the reset pins 1&2 at Jumper 5 directly on the

board, and press the reset button. The default network settings

and password have been reset. See Figure 1 for JP5 location.

3.3. Setting the System Clock

After the network settings have been adjusted to meet the

installed environment, the system clock must be set to ensure

optimal system performance and accurate energy graph data.

3.4. Setting System Parameters

The default operation setting for the Delta-T Pro is closed loop

residential domestic water heating system. If this configuration

does not match what has been installed, the operation system

type must be changed immediately before the control is set into

operation. For more information on functions and settings, see

the table at the end of this manual.

The Delta-T Pro has many user adjustable functions which can

be accessed via the settings page, behind a password protected

area. The user and changeable default password are:

User name: Admin

Password: caution

hp://169.254.148.50/

CONTROL SOFTWARE MAP 5

SOLAR HOT WATER

169.254.148.50:80.

INDEX

Navigation

Bar

50

0

1

148

0

148

254

255

254

80

169

255

169

SOFTWARE OVERVIEW / SETTINGS

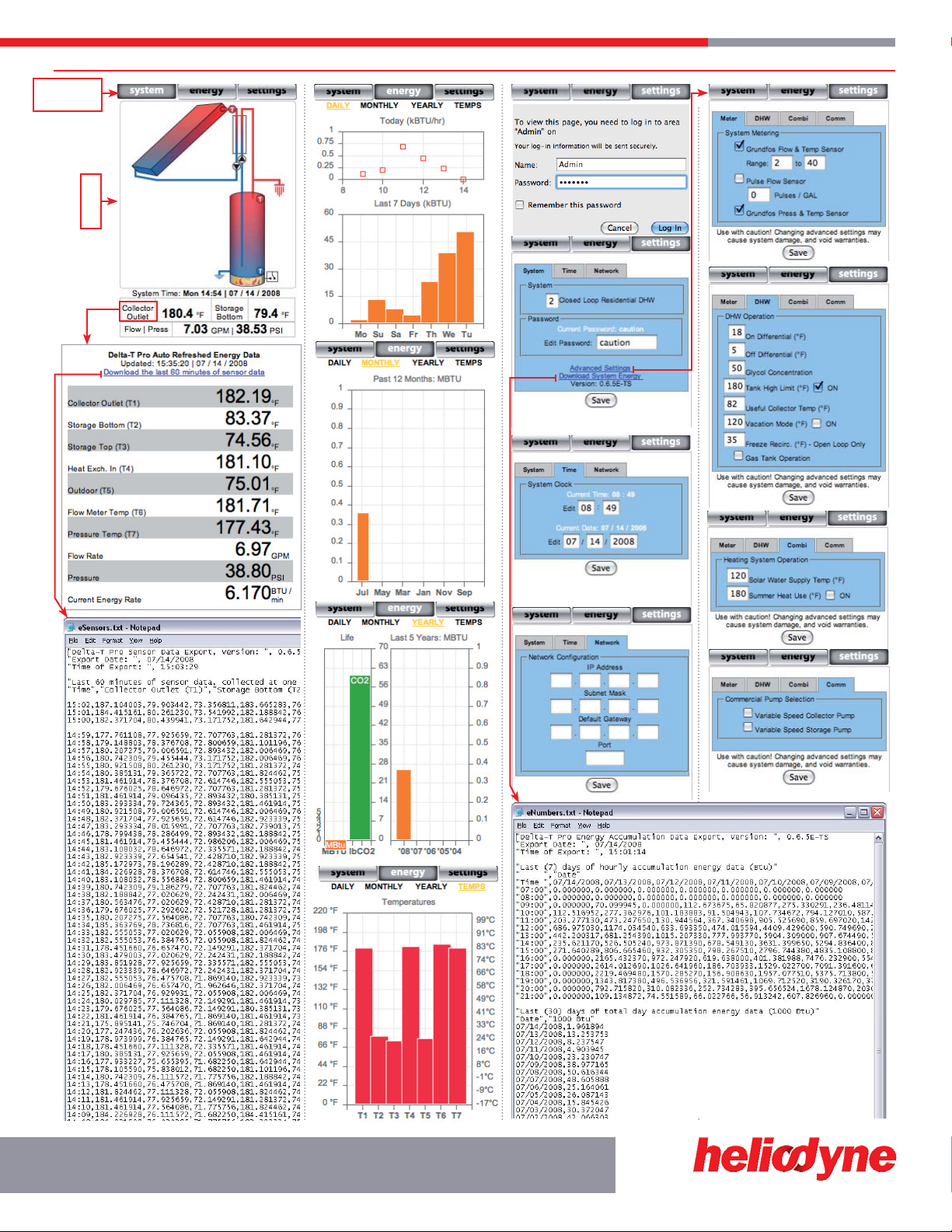

4.1. Energy Page Graphs4.0. Energy Exporting

4.2. Settings Page

TAB VARIABLE VARIABLE TITLE DESCRIPTION

Sys System Controlled System System selection and description: 1 = Open Loop, 2 = Closed Loop Residential,

3 = Closed Loop Commercial, 4 = Combination DHW + Heating (Default = 2)

Password Settings Password Change password from the default “caution” password.

Press the reset button on the control PCB for changes to take effect.

Advanced Settings Opens the advanced system settings page

Download System

Energy

Opens a new window with text values in comma delimited format of stored system data

Right click on the link and choose save as for best formatting results.

Time Current Time Adjust current hour and minute of 24 hour system clock

Current Date Adjust current day of system clock

Network IP Address Browser address for accessing user software

Subnet Mask Value for network subnet control is installed on

Gateway Address of network gateway

4. SOFTWARE

DAILY: Displays two graphs; the top graph displays

energy rate of collection for the current day, hour by

hour from the start of collection (in kBTU / hr). The

lower graph displays the collection over the week,

starting with the current day (in kBTU).

MONTHLY: Displays a graph with total monthly

collection for the past year, starting with the current

total for the current month (in MBTU).

YEARLY: Displays two graphs; the left side graph

contains information for the total system produc-

tion since control installation, showing CO2offset (in

1000 Lbs.) and energy production (in MBTU)

TEMPS: Displays the current temperature readings

for temperature sensors T1-T7.

T1 Collector Outlet T5 Outdoor Ambient

T2 Storage Bottom T6 Digital Sensor Temp @ Flow

T3 Storage Top T7 Digital Sensor Temp @ Pressure

T4 Hot into Heat Exchanger (Energy) or Indoor Ambient

Both versions of the Delta-T Pro store sensor and calculated energy data

in a comma delimited text file format for easy import into spreadsheet

applications. The Delta-T Pro can export:

eSensors.txt:1.

The past hour’s accumulated sensor readings (Temperature•

sensors 1 to 7, flow sensor and pressure sensor). Sensors not

connected will read 0.

eNumbers.txt:2.

Last (7) days of hourly energy production (BTU)•

Last (30) days of daily energy production (kBTU)•

Last (12) months of monthly energy production (MBTU)•

Last (5) years of yearly energy production (MBTU)•

Total energy production (MBTU)•

Total C0• 2offset (kLbs.)

Right click on the appropriate link and choose the “save as” option. If the

file to be exported has the same name as an existing file in that location,

you will need to change the name of the file you are saving for it to

export properly. Upon spreadsheet application import, choose “separate

columns by commas”.

FUNCTION REFERENCE 7

5.0. Advanced Settings Page Function Reference

TAB VARIABLE TITLE DESCRIPTION DEFAULT

Meter

Grundfos Flow & Temp

Sensor Checkbox for use of a digital Grundfos flow and temperature sensor checked

Range Text field for entering range of Grundfos flow sensor in Liters / Minute 2-40

Pulse Flow Sensor Checkbox for use of a pulse (analog) type flow meter unchecked

Pulses / GAL Text field for entering pulse meter calibration value 0

Grundfos Press & Temp

Sensor Checkbox for use of a digital Grundfos pressure and temperature sensor unchecked

DHW

On Differential Value in °F (T1) must be greater than (T2) by to turn solar loop circulators on 18 / CL, 9 / OL

Off Differential Value in °F (T1) must be equal to or less than (T2) to turn solar circulators off 5 / CL, 4 / OL

Glycol Concentration Percent by volume of glycol to water (Volume Glycol / Total Collector Volume * 100) 50 / CL, 0 / OL

Tank High Limit Highest storage tank value accumulated in °F read from (T3) or the average of (T2,

T3 if installed) if checked. Always use a cold water mixing valve to prevent scalding. 180, checked

Useful Collector Temp Lowest value in °F read at (T1) for solar loop operation with a satisfactory differential 80

Vacation Mode Value in °F read at (T3) for which collectors radiate storage tank heat through

collectors at nightime (with correct system clock setting), if checked.

120,

unchecked

Freeze recirc Value in °F read at (T1) at which collectors will circulate water to prevent freeze OL only

Gas Tank Operation Operates Relay 3 for use in conjunction with single tank gas storage systems. For

use only with electrical ignition gas tanks. May lower system overall performance. unchecked

Combi

Solar Water Supply Temp Minimum value in °F read at (T3) or average of (T2, T3 if installed) to operate

Relay 2, provided system selection = 4 and any Thermostat input is closed 120

Summer Heat Use Minimum value in °F read at (T3) or average of (T2, T3 if installed) to operate Relay

3, provided system selection = 4 and box is checked Unchecked

Comm

Variable Speed Collector

Pump

Operates 4-20 mA controlled current output (C1) for variable speed pump operation

on collector pump when checked. Adjusts pump speed to match optimum

differential throughout solar day, while minimizing parasitic pump electricity for

maximum payback. When used in conjunction with High Limit, slows down pump

as high limit is approached to avoid collector stagnation. Relay 1 is operated if

there is no variable speed storage side pump.

Unchecked

Variable Speed Collector

Pump

Operates 4-20 mA controlled current output (C2) for variable speed pump

operation on storage side pump when checked. Adjusts pump speed to match

optimum differential throughout solar day, while minimizing parasitic pump

electricity for maximum payback. When used in conjunction with High Limit (High

Limit is checked), slows down pump as high limit is approached to avoid collector

stagnation.

Unchecked

SOLAR HOT WATER

5. ADVANCED SETTINGS

5.1. Useful Conversion Factors

1 kBTU = 1,000 BTU; 1 MBTU = 1,000,000 BTU; 1 THERM = 100,000 BTU; 1 kWh = 3,412 BTU

Heliodyne, Inc. • 4910 Seaport Avenue • Richmond, CA 94804

T: 510.237.9614 • F: 510.237.7018

www.heliodyne.com

7.00”

SCALE = 1:1

4.25”

2.00”

6.50”

7.00”

Delta-T Pro Case Mounting Template

Other manuals for Delta T Pro

1

Table of contents

Other Heliodyne Control Unit manuals

Popular Control Unit manuals by other brands

Honeywell

Honeywell RV181 installation instructions

encompass

encompass AccuMax Quantum Usage instructions

IFM

IFM ecomatDisplay CR1202 operating instructions

Magnum Energy

Magnum Energy ME-CB installation manual

CG Products

CG Products Delay1022 instructions

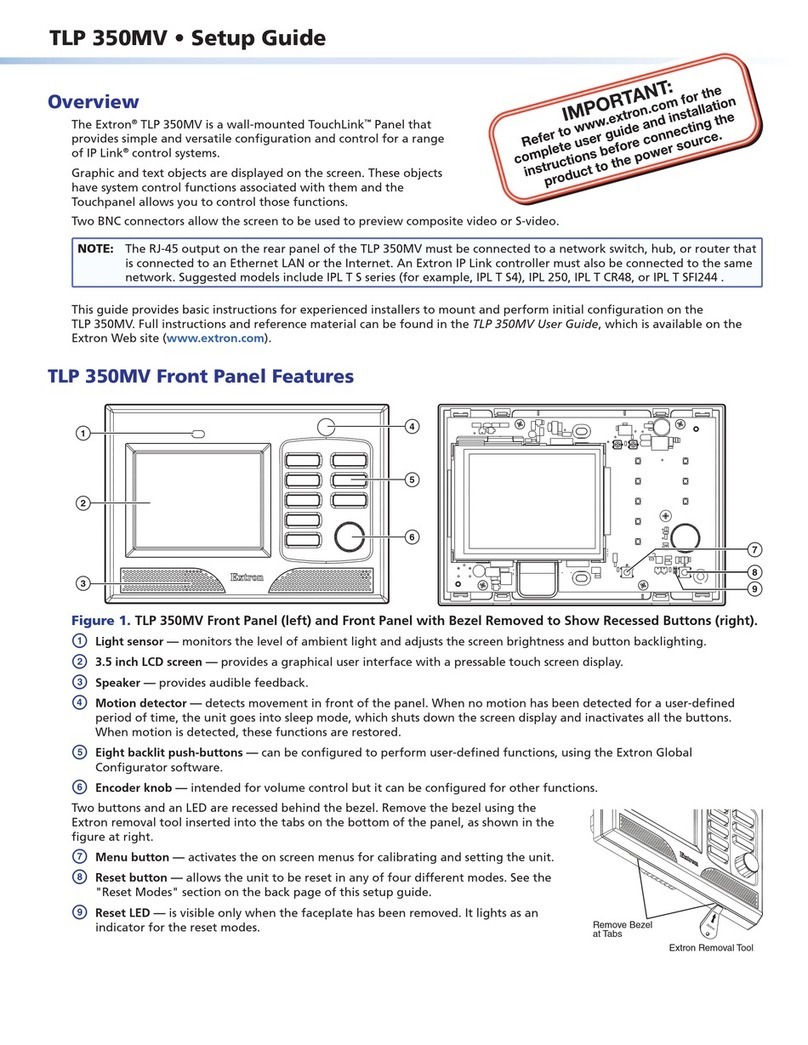

Extron electronics

Extron electronics TLP 350MV Setup guide