Heliodyne DELTA T 84 User manual

INSTALLATION

GUIDE

DELTA T 84 & 94

CONTROL UNIT

EXCELLENCE

BY DESIGN

CONTROL OVERVIEW & INSTALLATION

1.0. Description

This Delta-T solar controller has been

specifically designed to control the basic solar

thermal collector system, including open loop,

closed loop with a heat exchanger, and drain

back, for residential domestic water heating

There are two versions of the Delta-T, the 84

is a hardwire model and can be supplied with

120 VAC or 240 VAC. The 94 model comes

with a pre-wired plug and grounded outlet for

installation ease.

For operation, the control requires two SAS-

10 (10,000 Ohm @ 77°F) thermistor sensors.

The differential and other settings have limited

adjustability using the DIP switch on the

control PCB.

1.1. General Notes

This control conforms to the National Electric Code and is certified

by ETL. Installation should adhere to all national and local electric

codes, and be installed by a qualified electrician or contractor. Any

electrical wiring or modifications to the control I/O should be per-

formed with the power disconnected.

1.2. Mounting

The Delta-T should be mounted on a wall indoors, away from weather

and interference. Using the mounting holes on the back of the box,

securely install 3 screws into mounting plane leaving 1/4” between

the wall and the back of the bolt head; place control back upon

screws and slide down to secure box tightly into screw pattern. The

back page of this manual has a screw template.

1.3. Power and Wiring

Wire solar loop pumps into Relay 1, using the Normally Open (NO)

terminal on the relay. The Normally Closed (NC) terminal can be

used to supply power to a unit for use when the collectors are not

heating the storage, like a swimming pool or hot tub. The voltage of

the controller will determine the relay output voltage.

1.4. Thermistor Sensors

The SAS-10s sense temperature by conduction, and are not for liquid

immersion, or inside collectors. For a proper reading, ensure the

copper lug on the sensor is firmly against the desired surface using

an SS pipe clamp across the flat surface or bolted via the through

hole. Use surrounding insulation to avoid ambient temperature and

other sources of reading interference.

The sensor leads are 24 GA Class II wiring and carry 4 VDC. Use a

conductor 18-24 GA zip or bell wire to run from the sensor location

to the control. Use caution when installing to avoid wire damage.

Shielded wire is not necessary.

Install the collector sensor on the outlet header connection; install

the tank sensor on the bottom of the storage tank, so it is in contact

with the metal part of the tank. Insulate the sensors from ambient

conditions.

1.6. Operation

The function switch on the right side of the controller should be

set in the center, ‘AUTO’, position for automatic pump control.

When the switch is in the ‘ON’ position, Relay 1 will be on

continuously, regardless of temperature difference. With the

switch in the ‘OFF’ position, Relay 1 will remain off.

1. DELTA T

Internally

Powered Output

Power

Pumping

10kΩ

Thermistors

1

2

3

4

5

6

BIT

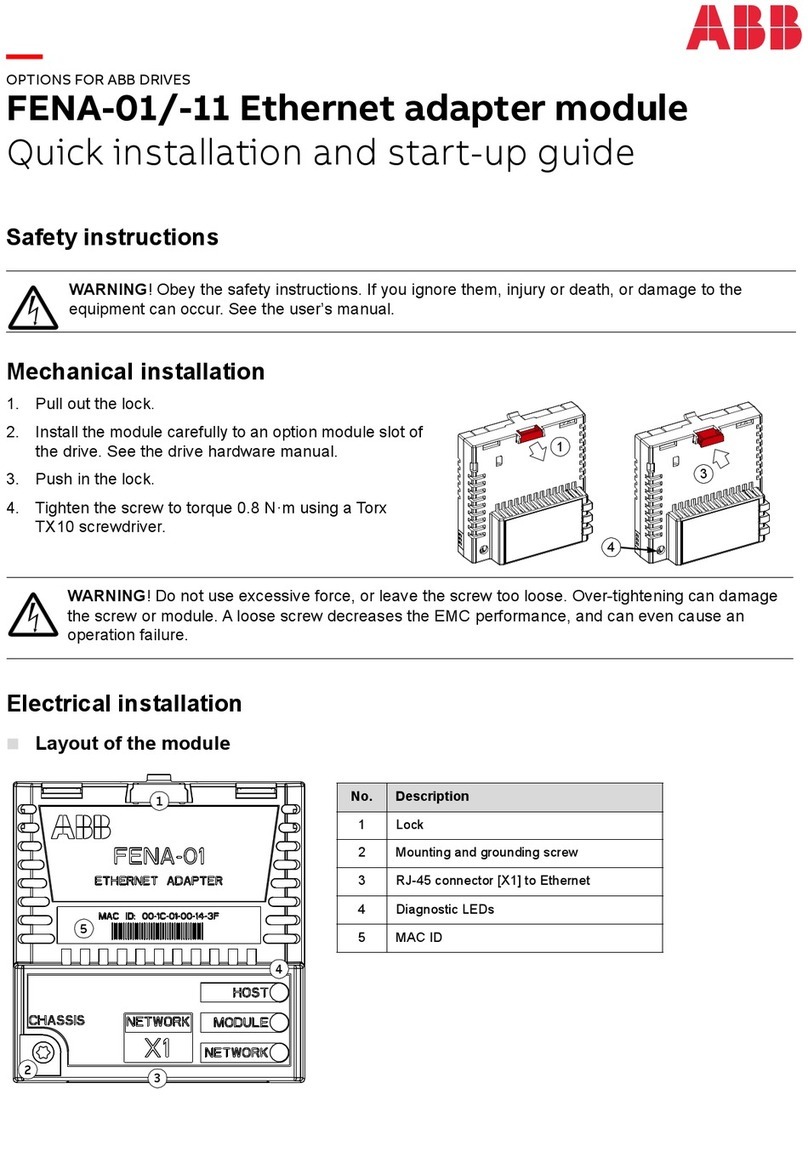

Figure 1.0.-1 Delta-T 84 / 94 I/O

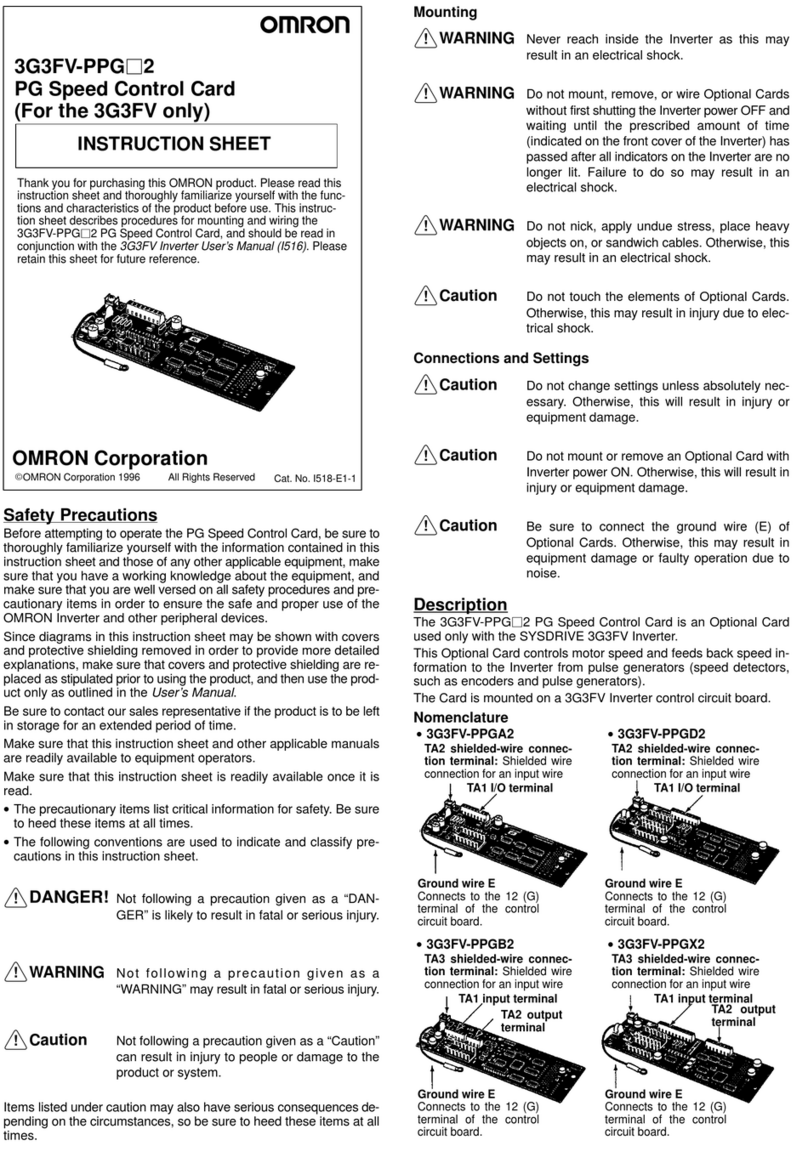

Figure 1.4.-1 SAS-10 Sensor

CONTROL SETTINGS, TROUBLESHOOTING AND WARRANTY 3

1.5. DIP Switch Settings

BIT SWITCH # FUNCTION DESCRIPTION SETTING WHEN LEFT (OFF) SETTING WHEN RIGHT (ON)

1Tank high limit shutoff - automatically turns off Relay 1 when the

storage sensor reads switch 4 setting of 160 or 180°F No high limit function High limit ON

2Freeze recirculation - automatically turns on the

Relay 1 when the collector sensor reads 42°F or below No freeze recirculation Freeze recirc. ON

3

Useful collector temperature - automatically turns off Relay 1 when

the collector sensor reads 80°F or below, even with a satisfactory

differential (Freeze recirc. can override this function)

No useful collector

temperature monitor

Useful collector

temperature monitor ON

4Tank high limit shutoff temperature - choose which temperature to

turn the tank off at 160 or 180°F 180°F 160°F

5 &6

Differential setting - sets which temperature differential will turn on

and off Relay 1 (Heliodyne recommends both switches OFF for glycol

systems, and both switches ON for open loop or direct systems)

18°F ON

5°F OFF

9°F ON

4°F OFF

1.7. Troubleshooting

If a controller stops working, most often it is due to a sensor or wire failure. Detach

the sensor plug and measure the sensor resistance with a multi-meter and compare

with the chart below for appropriate reading values. Because they are inversely

related to temperature, a short reads as a very hot temperature, and an open reads

as a very cold temperature.

1.7.0. On/Off Test

This test verifies the controller will turn on and off. Switch the controller ‘ON,’ power

is applied to the Normally Open relay point, terminal 2. This may be verified with an

DC voltmeter across terminals 2 and 3. If a pump is connected, it should turn on.

With the switch in the ‘OFF’ position, power is applied to the normally closed relay

point, terminal 1. This may be verified with a voltmeter across terminals 1 and 3.

When the switch is ‘ON’, the pump LED indicator should be on. If not, consult the

manufacturer.

1.7.1. Basic Function Test

This test verifies the BIT settings are working correctly. The BIT switches (figure 2)

for a particular function must be on to test for that function.

Place BIT switches 1 on and 2 off (remaining switches can be either on or off.)

Switch controller to ‘AUTO.’ Allow the sensors to come to thermal equilibrium

(about one half hour.) Short the screws in positions (see figure 4) 1 and 2 and the

controller should turn on. Next, place the collector sensor in a cup of hot water;

this should turn the controller on. With the storage sensor screws shorted (positions

3 and 4), the controller should turn off. If the controller does not respond to these

tests, consult the manufacturer.

2.0. Warranty

HELIODYNE shall provide a one-year warranty for defects in compliance with the purchased goods

delivered after 3/1/2008 as follows: Objects are warranted at HELIODYNE’s discretion by repair of

the object of purchase or replacement of defective parts, exchange or reduction of price. The right of

the contractor to convert objects is ceded by common consent. Replaced parts become the property

of HELIODYNE. Wages and costs spent on installation and disassembly must be covered by the

client. This provision similarly applies to all warranty agreements. It is at HELIODYNE’s discretion

to replace defective goods with similar, faultless goods. In this case, any rights to cancel the

agreement cease. The client expressly waives the right for it and its legal successors to assert claims

for damages or loss of profit (including without limitation special, indirect, loss of use, contingent,

or consequential damages) due to defects or nonconformity in the purchased good. The warranty

set forth above constitutes the sole and exclusive remedy against HELIODYNE for the furnishing

of any nonconforming or defective goods. THE ABOVE WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY

WARRANTY AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE.

Damage resulting from improper or negligent treatment is excluded from the warranty. Claims on

warranty will only be admitted and considered if they are announced in writing immediately after the

defect was first noticed. Oral communication or communication by telephone are not sufficient.

For collectors (except broken glass and collector accessories e.g. sheet metal edgings) and storage

tanks (except attached components), HELIODYNE replaces materials that demonstrably fail to

meet one of the requirements of the ASHRAE standard 93-77 at no charge, works within five years

for storage tanks and ten years for collectors, of the date of the invoice issued by the company

HELIODYNE. HELIODYNE is not liable, however, for damage caused by mechanical stress and/

or changes caused by weather-related influences. Minor variations in color and/or damage to the

surface that have no effect on the function of the collector are also not covered in the warranty.

The warranty excludes damage caused by force majeure and malfunction that are due to improper

assembly, and/or product installation. HELIODYNE is not liable for possible costs resulting from

defects. In order for HELIODYNE to accept liability:

– Installation must have been carried out by a licensed specialized company (heating contractor or

plumber) following the version of installation instructions in force;

– HELIODYNE or its representative was given the opportunity to check complaints on site

immediately after any defect occurred;

– Confirmation exists that the system was commissioned properly and that the system was checked

and maintenance was performed annually by a specialized company licensed for this purpose. The

warranty agreed by HELIODYNE is only valid for their clients.

SOLAR HOT WATER

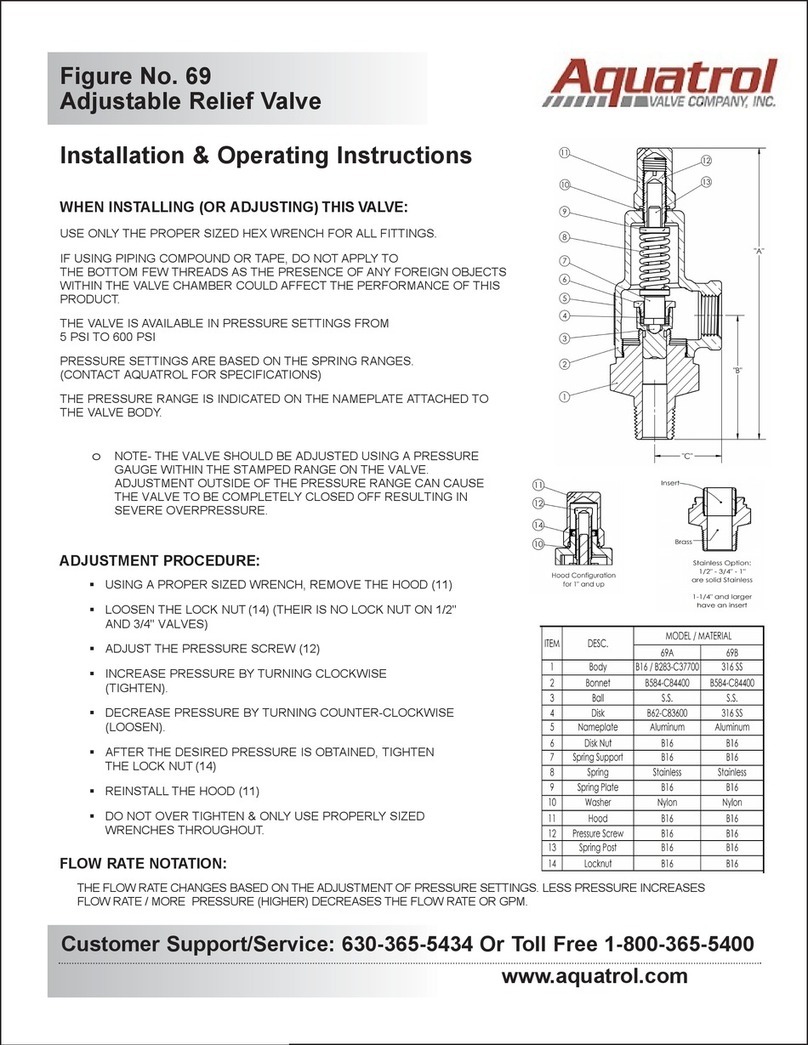

Ωvs °F

0

50

100

150

200

250

0 5,000 10,000 15,000 20,000 25,000 30,000 35,000

SENSOR TEMPERATURE °F

MEASURED RESISTANCE Ω

Heliodyne, Inc. • 4910 Seaport Avenue • Richmond, CA 94804

T: 510.237.9614 • F: 510.237.7018

www.heliodyne.com

4.61”

SCALE = 1:1

2.56”

1.57”

5.64”

3.15”

Delta-T Case Mounting Template

This manual suits for next models

1

Table of contents

Other Heliodyne Control Unit manuals

Popular Control Unit manuals by other brands

Cooper Security

Cooper Security Scantronic 9853 Update guide

Flowserve

Flowserve NAF-Setball Maintenance and installation instructions

Franke

Franke ZAQUA029 Installation and operating instructions

Ross Controls

Ross Controls CrossCheck CC4 Series Integration guide

Addi-Data

Addi-Data MSX-E1701 manual

Emerson

Emerson Keystone 990 Installation, operation and maintenance guide