Helm P32 User manual

PAGE

1

P32/42 C

HASSIS

P32/42 Rev. 12/98

BODY BUILDERS INSTRUCTIONS

TheIncompleteVehicleDocument(IVD)issuppliedwitheachincompletevehicle,and

providesinformationthatshouldbeusedbyintermediateandfinalstagemanufacturers

in determining conformity to applicable Federal Motor Vehicle Safety Standards

(FMVSS). TheIVDalsoincludesinformationwhichmustbefollowedinordertoensure

thatEnvironmental ProtectionAgency (EPA)andCalifornia emissionscertification re-

quirements and NHTSA Fuel Regulations are met.

TheBodyBuildersBookcontainsinformationthatmaybeusedinadditiontotheIVDfor

anymanufacturermakingalterationstoancomplete/incompletevehicle. Noalteration

shouldbemadetotheincompletevehiclewhicheitherdirectlyorindirectlyresultsinany

component,assemblyorsystembeinginnonconformancewithanyapplicableFederal

Motor Vehicle Safety Standard or Emission Regulation. Intermediate and final stage

manufacturersshould be familiarwith allFederal Motor VehicleSafety Standardsand

Emission Regulations and aware of their specific responsibilities as manufacturers.

For further assistance contact SVIE at: 1 (800) 875-4742

All notes are applicable to all models except where specifically stated other-

wise.

Section 0 – General Instructions

Check for proper clearance between body members and chassis components which

mayinanywayaffectthereliabilityandperformanceofthevehiclebydevelopingabra-

sion and wear points from moving parts or degradation from extreme environment or

thermalexposureormayincreaseinteriornoise. Anyattachmentsmustconsiderchas-

sis components for jounce and rebound motion at Maximum GVW.

Checkheadlampaimandallvehicleilluminationsystemsforproperoperationwhenthe

vehiclehasbeencompleted. Re-aimheadlampswhennecessary. Checkforproperop-

eration of windshield washer, wipers and defroster system.

Extreme care must be taken when working on vehicles equipped with Engine Control

Module (ECM), Powertrain Control Module (PCM), Transmission Control Module

(TCM), Vehicle Control Module (VCM), Anti-lock Braking System Model (ABS) or any

electronic unit associated with an inflatable restraint system. (See Owner’s Manual).

If arc-welding is employed on the chassis, precautions must be taken to protect all ve-

hicle components, especially brake, fuel lines, front suspension air cylinders and fuel

tankassembly,electricalwiringandECM/PCM/TCM,VCMorABS. Toavoidelectronic

componentdamage,disconnectbattery(batteries);disconnectthenegativecablefirst,

followedbythepositive. Toreconnectcables;connectthepositivefirst,thenthenega-

tive.

Alllabelsonthevehicle(anymessageappliedtothevehicleorvehiclecomponentthat

informs,instructs,orwarns)mustappearonthecompletedvehiclesotheusercanread

them easily and without obstruction.

Service and service replacement parts for your add-on systems may not be available

fromaGMdealer. Thoseinstallingaftermarketsystemsshouldprovideinformationas

to where and how to obtain service.

Section 1 – Body

Accessoryitemssuchasrefrigerator,hotwaterheater,furnace,etc., whichoperateon

liquid propane gas should be located and protected to prevent exposure to any flame.

Bodystructures,interiorandaccessoryarrangementsmustbedesignedintothevehicle

toprovideforproperloadcapacityanddistributiononbothaxlesandnottoexceedany

grossaxleweightratings. Lateralloadequalizationmustalsobemaintained. Theresul-

tant Center of Gravity of the unladen vehicle must be within the limits tabulated in the

FMVSS 105 section of the Incomplete Vehicle Document.

BodyinsulationprovidedbyGeneralMotorsshould notberemoved.Thisincludesany

thermalorunderbodyheatshields. Thisinsulationisprovidedtoprotectthevehiclebody

andoccupantsfromexcessiveheatand/orprovidenoiseattenuation. Anyreplacement

materialinternaltotheoccupant compartmentmustbecertifiedforMVSS standardon

flammability. Areas of specific concern, but not limited to are:

DUnderbody exhaust, muffler and tailpipe shields and insulators.

DRear load floor interior insulation.

DFront floor interior insulation.

DDash mat insulation.

DEngine cowl insulation–interior and exterior.

DEngine cover insulation.

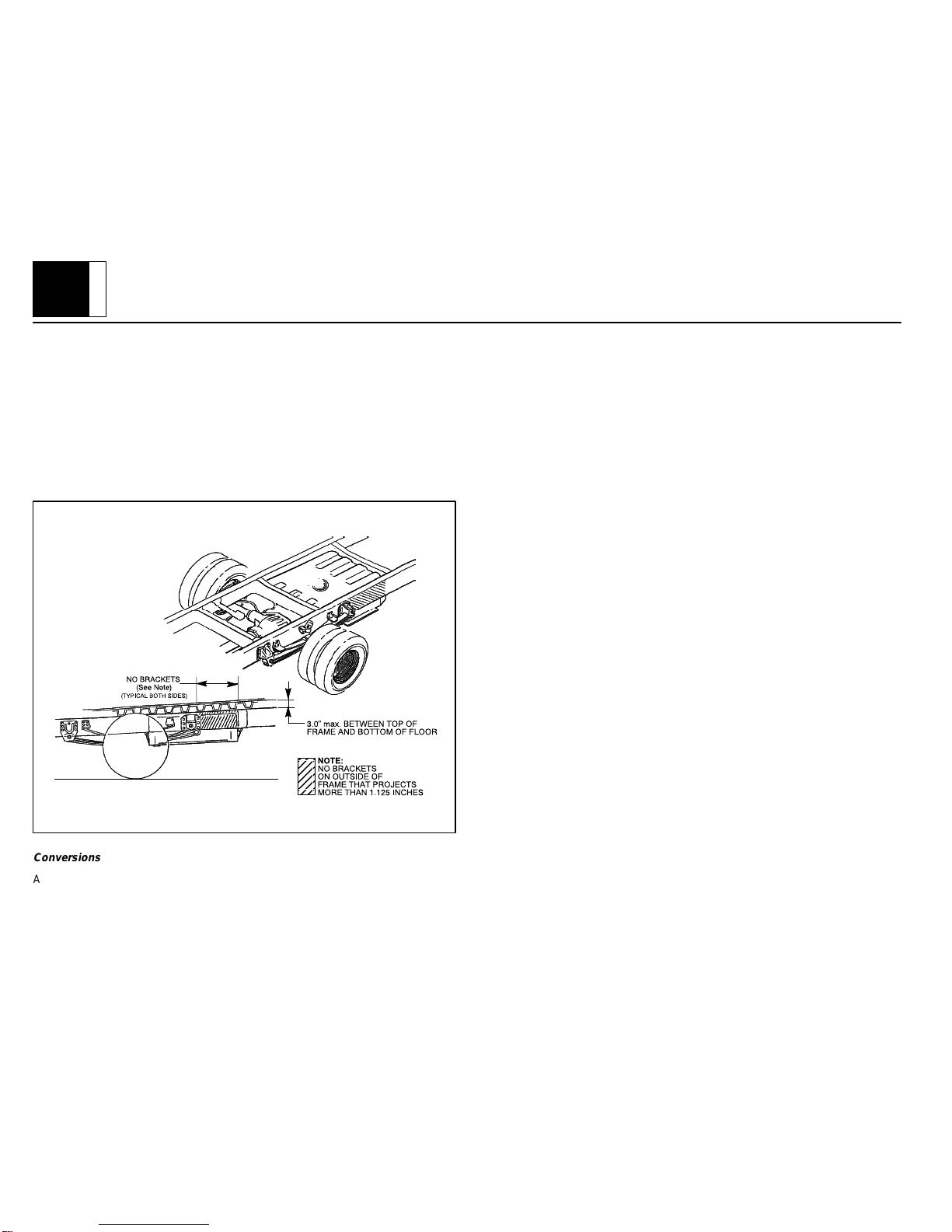

The following statement applies to P 30042 (school bus) model only

The fuel system for the school bus chassis is certified to FMVSS 301 Barrier Perfor-

mancerequirementsbasedonabodyfloorheightnotexceed3”abovethetopofframe.

The 3” maximum dimension is to be measured from the bottom surface of the interior

bodyfloortothetopoftheframe. Theheightofanycrosssupportsandspacersbetween

thebottomofthefloorsurfaceandthetop offramearenottoexceedthis3”dimension.

PAGE

2

P32/42 C

HASSIS

P32/42 Rev. 12/98

No body support brackets that project more than 1.125” outside of the frame are to be

attached to the frame rail adjacent to the area of the fuel tank.

1. Any body installed by a subsequent manufacturer is mounted securely to ab-

sorb loads and prevent movement relative to the frame which could cause any

fuel system component to be punctured, separated or otherwise damaged

when tested to the applicable procedures of FMVSS 301.

2. No installed components or vehicle modifications by a subsequent manufac-

turer impinge on or cause distortion to the fuel system with sufficient energy to

puncture, separate. or otherwise damage the fuel system when tested to the

applicable procedures of FMVSS 301. Care should be taken that the structur-

al integrity of the vehicle is restored following any structural modifications.

ÉÉÉ

ÉÉÉ

ÉÉÉ

ÉÉÉ

Conversions

Added bodies must be securely fastened to the basic vehicle structure. Do not attach

through side rails, but bolt securely through rail flange at floor and added reinforcing

plates. A minimum of 10_departure angle should be maintained if frame and/or body

is extended.

Chassis

Asshownonthechassisdrawings,therelationshipofthedashpanel,brakepedal,clutch

bracketandsteering columnmustbemaintained toensureproperoperation ofbrakes

and steering.

Bodystructuremustbeprovidedtofirmlysupportthesteeringcolumnandbrakepedal

braceintheforeandaftdirectionandlaterallysothattheangulardimensionalgeometry

shownon thechassis drawingis preserved. Onall “P”truck singleaxle models,provi-

sionsare incorporatedin thedash toe, andframe assemblyfor bodyassembly attach-

ments. It is imperative that the body assembly structure be integrated to the chassis

throughtheabovepartstoensurevehiclestructuralintegrity. Ifthisdesigncriteriaisnot

adheredtobythebodybuilders,GeneralMotorsCorporationcannotberesponsibleor

liableforchassiswarrantyresultingfrominadequateattachmentofthebodyorthechas-

sis.

Bodyunderside mustinclude innerfenders sothat engine compartment is adequately

shielded from wheel splash.

The following statement applies to P 30032 model only.

Thefrontcrossmemberextensionmustnotbeusedasabumper. BodyBuilder’sbum-

pershould beattached tothe frontcrossmember directlyopposite theside railsand to

thefrontcrossmemberoutboardofthesiderailsasrequired. ABSmoduleprotectorex-

tension must be maintained or replaced by equivalent part.

The following statement applies to P 30042 model only.

Ifthestandardfrontbumperisnotused,theBodyBuilder’sbumpershouldbeattached

to the side rails and outboard of the side rails as required. ABS module protector bar

must be maintained or replaced by equivalent part.

If the body builder installs seating other than that supplied with vehicle, it is the body

builder’s responsibility to ensure that the seating and restraint systems comply with

FMVSSrequirements. The restraintsystemssupplied withthe vehicleweredesigned

toaccommodatetheseatingreference pointsandseattraveloftheoriginalequipment

seats only.

Air Conditioning

For additional information refer to

Engine - Section 6.

NOTE: Air conditioning systems using R-134A refrigerant are equipped with metric

fittings to prevent interchange with R-12 refrigerant components. Do not

interchange R-134A components, refrigerant oil or service equipment with

R-12 components, refrigerant oil or service equipment.

PAGE

3

P32/42 C

HASSIS

P32/42 Rev. 12/98

Section 2 – Frame

Holedrilling,welding,modifications,oralterationstotheframeassemblyaretherespon-

sibilityofpersonsperformingthese operations. Thesesameindividualsassumecom-

pleteresponsibilityforframeassemblyreliability,performanceafteralterationsandcom-

pliance to applicable FMVSS requirements.

Thefollowingproceduresandspecificprecautionaryinstructionsarerecommendedfor

properinstallationofspecialbodies and/orequipmentonGMframes. Failuretofollow

these recommendations could result in serious damage to the basic vehicle.

Flanges

Do not drill holes in frame flanges:

DWithin 20 mm (0.75 in.) of radius tangent and 25 mm (1.0 in.) of raw edge.

DLarger than 12 mm (0.50 in.).

DCloser to each other than twice the hole diameter.

Holes

Holes to mount brackets, supports, and out-riggers must be drilled in the vertical side

rail web with the following restrictions:

DMaterialbetweenedgeofholeandinsideofupperorlowerflangemustnotbeless

than 37 mm (1.50 in.) for low carbon steel (36,000 PSI yield).

DTheminimumedgedistancebetweenanytwo(2)holesmustbelargerthantwice

the diameter of the larger hole.

DNo holes should exceed 20 mm (0.75 in.) in diameter.

DAll holes should be drilled in the frame using appropriate drilling practice and

safety precautions.

Welding

CAUTION: Fuel tank and fuel lines must be drained and all vapors purged to ensure

non-combustible mixture before any welding, brazing or soldering.

When welding low carbon steel side rails, crossmembers and brackets (32,000 or

36,000 PSI yield strength), emphasis is placed upon weld application techniques to

avoid stress risers that may adversely affect frame operating stresses.

Whenwelding is performedanywhere on thevehicle, precautionary measuresshould

be taken to prevent damage to electrical system wiring, front suspension air cylinders

orcomponents. Priortoanywelding,partsorcomponentswhichcouldbedamagedby

excessive temperatures must be removed or adequately shielded; the battery cables

shouldbedisconnectedatthebattery. Alsopriortowelding,theareato be weldedand

surroundingareamust becleanedofall frameprotectivecoating. Afterwelding, when

partsarecool,carefullyinspectwiringandelectricalcomponentsforshortsorotherdam-

agewhichcoulddrawexcessivecurrentsandpossiblycauseanelectricalsystemshort

whenthebattery isreconnected. Applyprotectivecoating toareaswhere coatingwas

removed.

Alterations

Ifthewheelbase ismodifiedthealterer musttakeresponsibilityfor compliancewithaf-

fectedmotorvehiclesafetystandardsandforwarrantyonitemssuchasdriveshafts,uni-

versal joints, center bearings and rear transmission tailshaft, transmission case frac-

tures, output shaft bushings, bearings, brakes, fuel systems and any other related

componentfailures. WheelbasemodificationscanaffecttheoperationoftheABSsys-

temandmayaltervehiclebrakingstabilityandorcompliancewithFMVSS105.Addition-

ally,thecustomermustbealerted inthemodifier’sownersmanualthatpartsforthere-

worked area are not available through the General Motors service parts system.

Shear Plate Attachments

Attachmentsof shearplates should beaccomplished byusing existing manufacturing

holesalreadyavailableintheframesiderails. Manufacturingholes,normally16mmin

diameter,areconsistentlyplacedalongtheframesidememberinthecenteroftheweb

on each frame.

Whenadditionalholesarerequiredforshearplateattachment,theyshouldbenolarger

than 20 mm (0.75 in.) in diameter. Holes are to be drilled no closer than 63.5 mm (2.5

in.)apart. Forholesdrilledforwardoftherearaxle,centersaretobenocloserthan63.5

mm(2.5in.)from thetoporbottom flanges andnocloserthan 89mm(3.5in.)from any

suspensionattachments. Forframeholesdrilledrearwardoftherearaxle, holecenters

aretobenocloserthan51mm(2.0in.)fromthetoporbottomflangeandnocloserthan

89 mm (3.5 in.) from suspension attachments.

No additional holes or notching of either top or bottom frame flanges is allowed.

PAGE

4

P32/42 C

HASSIS

P32/42 Rev. 12/98

Bodytie-downholesshouldonlybedrilledintopflangenolargerthan0.76indiameter;

centerlineofholesshouldbe1.0to1.12in.fromthewebsideoftheframerail. Minimum

distance between edges of the holes should be approximately 2.0 in.

Trailer Towing

TheIncompleteVehicleDocumentalsospecifiesthattheCGlocation bewithincertain

limits for proper brake balance, and may be more restrictive than the data mentioned

above. The Body Builder must use all appropriate data.

NOTE: Failure to keep body and payload CG at least 26” forward of centerline of rear

axle will result in degradation of trailer towing capacity. Consult with your Body

Builder/Final Stage Manufacturer to determine maximum tongue load for your

vehicle.

Section 3 – Front Suspension

Seechassisdatainformationforclearancesandassistanceincalculatingtrimheights.

Clearanceshouldbeprovidedforthetireusedwhileinfulljounce(upwardtravel)against

metal stops and at full left-hand and right-hand turn. The envelopes will be provided

upon request. See

Section 5 - Brakes

.

Allowance for the tire chain clearance shown on a maximum grown tire must allow for

(1.66in.)clearancetothesidesofthetireand(2.5in.)tothetopofthetire. Besuresuffi-

cientclearanceisprovidedforsuspension,axleandtire andwheelinfullverticaltravel

(up and down).

NOTE: Notification to the consumer may be required in certain states if tire chains

cannot be used.

Vehicles equipped with 3650 lbs. low height independent front suspension (IFS). The

urethaneaircylindersmust bemaintainedat70psi. Ifthevehicleisalsoequippedwith

option 9Q6, right side air cylinder should be set at 50 psi instead of 70 psi. Vehicles

equippedwith4500and5000lbs.independentfrontsuspension(IFS)urethaneaircylin-

dersmustbemaintainedat50PSI;with5500lbs.independentfrontsuspension,aircyl-

indersmustbemaintainedat90psi. Aircylinderswhenprovidedmustbeshieldeddur-

ing welding operations.

Since there is a large variation in completed vehicle front weight due to differences in

body weight and equipment, the front suspension alignment (caster, camber and toe)

mustbecheckedandresetifnecessaryafterthevehicleiscompleted. Thesuspension

must be reset by the Body Builder if it is found that the setting’s do not conform to the

specifications as outlined in the “P” Chassis Service Manual. On P 30042 trucks with

I-beams, camber and caster is designed into the axle/suspension and cannot be ad-

justed.

See Truck Service Manual for complete alignment procedure, specifications under

“Diagnosis and Front Alignment” section.

The following statement applies to P 30042 models with I-beam front axle.

Thefront crossmember steeringgear attachment isa weldment. Under noconditions

maytheflangesbecutornotchedoutinanymanner. Anyalterationwouldseverelyaf-

fect steering attachment capabilities.

Section 4 – Rear Suspension

Clearancetobodyshouldbeprovidedforthesuspension,axle,driveshaftandtiresun-

der the following conditions: (1) Axle in full jounce against the metal-to-metal stop, (2)

Axleat4.5_rollwithonesideofaxleinfulljounceatthemetaltometalstopand(3)Axle

atdesignposition. Allowance for thetirechainclearance shownonamaximum grown

tire must allow for (1.66 in.) clearance to the sides of the tire and (2.5 in.) to the top of

thetire. Besuresufficientclearanceisprovidedforsuspension,axleandtireandwheel

in full vertical travel (up and down).

NOTE: Notification to the consumer may be required in certain states if tire chains

cannot be used.

Pipes,wiring,conduitsandanyotherrelatedcomponentsmustnotbeplacedwherethey

crossthe path ofmotion ofthe rear axle, driveshaft, axlebrake pipes,hoses, spring or

tires. Suchcrossingcouldresultinrupture, wear-through,orseparationduetonormal

axle motion.

Seechassisdatainformationforadditionalclearancesandforassistanceincalculating

trim heights.

Section 5 – Brakes

See Truck Service Manual for brake specifications.

Duetothecriticalnatureofbrakesystems,anyonemakingmodificationsoralterations

mustassumecompleteresponsibilityforsystemreliability,performanceandcertification

to FMVSS 105 or FMVSS 121.

PAGE

5

P32/42 C

HASSIS

P32/42 Rev. 12/98

Itismandatorythatnochangebemadetothebrakemaincylinderlocation,brakepedal

push rod length or pedal position.

Ensure that hydraulic brake system is free of air and hydraulic leaks. Bleed brakes if

required,followingproceduresasoutlinedintruckchassisservicemanual. Ensurethat

vacuum booster system or hydroboost system is functional and free of leaks.

Check master cylinder fluid level and fill as necessary. (Refer to Owner’s Manual)

Checkpowersteeringfluidlevelformodelsequippedwithhydroboostbrake. (Referto

Owner’s Manual)

Addedfloorcoveringorcarpetingmustnotrestrictserviceorparkingbrakepedaltravel

from released position to full pedal travel.

The body builder must provide access to brake master cylinder to enable fluid level

check and the ability to add fluid as required. Clearance to master cylinder should be

providedtoenableitseasyremovalandreplacementifeverrequired. Visualaccessto

warnings printed on master cylinder reservoir must be provided per FMVSS 105.

Thebodybuildermustalsoprovideaccesstoauto-applyparkingbrakeactuatorswitch

on all 16,500 lb. GVW chassis. Opening for service in brake shield on chassis below

drivers island must remain clear.

Nobodypartorchassis-mountedcomponentincludingwheelhouseshieldsmaybelo-

cated within 2.0 in. of brake hose routing and/or wheel speed sensor wire in all wheel

and axle positions. All exhaust system components must also have a minimum of 2.0

in.clearancetobrakehosesinclosestpositions. (Besuretoaccountforbrakehoseand

sensor wire travel with suspension).

Bodybuilderistoverifythatthebrakelightswitchandbrakewarningswitchisoperative.

This includes both the brake system differential pressure and parking brake actuator

switch. Any ABS system codes that may have been set due to the body build process

must be checked and cleared prior to customer delivery.

The following statement applies to models with B3D school bus option only.

Hydroboostsystemsareequippedwith abrakefluidflowindicator.Alarm systemmust

be completed by the body builder. Shipped in a loose parts box are a buzzer module,

time delay module and wire harness, which must be installed per instructions shipped

with the loose parts box.

Floorboardandtoepanpositioncannotbealtered,asitwillinterferewithbrakeandac-

celerator pedal movement or cause driver discomfort. The floor may be covered with

normalpad and carpeting only(except P30032/42 models). Nofloor covering should

beundertheacceleratorpedal areaitwillinterferewithacceleratorcontrol movement.

Carpetingmusthave1”minimumclearancetotheacceleratorpedalandshouldbecut-

pile only. Carpeting must be properly secured to prevent any movement.

Parking brake installation and adjustment procedure:

1. Secure vehicle in place with hoist or wheel chocks and place vehicle transmis-

sion in park position.

2. Front cable routing throughout body must have a minimum radius of 6 in. and

be protected from all moving components and sharp edges.

3. For transmission mounted parking brake:

The following applies to all P 30042 models with the exception of P 31842 & MT9

Hand lever

1. Release parking brake handle and remove cotter pin, washer and clevis pin

inserted from outboard side of vehicle. Mount handle convenient to driver

comfort range.

2. Feed cable through body and reattach to handle with clevis pin inserted from

outboard side of vehicle.

3. Readjust parking lever knob to give a definite snap-over feel (approx. 60 lbs.)

when the lever is applied. With the lever in the applied position, the forward

edge of the clevis pin head should be approximately 5/8 in. from the end of the

adjusting slot on the bracket.

4. Do not alter the drum or cable adjustment at transmission unless routine ser-

vice is required in order to obtain the desired setting above. No drag should

be present after parking brake handle is released.

The following applies to all P 30032 models and P 30042 & MT9

Foot pedal

1. Release foot pedal and remove cotter pin, washer and clevis pin inserted from

outboard side of vehicle. Mount pedal coinvent to driver comfort range.

2. Feed cable through body and reattach to handle with clevis pin inserted from

outboard side of vehicle.

3. Readjust parking brake pedal to give a firm pedal at 2-5 clicks (P 30032) and

at 8-16 clicks(P 30042 & MT9) when the pedal is applied. With the pedal in

the applied position the forward edge of the clevis pin head should be approxi-

mately 5/8 in. from the end of the adjusting slot on the bracket.

4. Do not alter the drum or cable adjustment at transmission unless routine ser-

vice is required in order to obtain the desired setting above. No drag should

be present after Parking brake is released.

PAGE

6

P32/42 C

HASSIS

P32/42 Rev. 12/98

For rear axle mounted parking brakes (P 30800, P 31100, P 31432 with out JF9):

1. Release parking brake handle and remove connector between front and inter-

mediate parking brake cables. Remove front cable from frame bracket and

floor pan assembly.

2. Feed cable and handle assembly through body and re-attach handle to body

convenient to driver’s comfort range.

3. Feed cable back into frame bracket and making sure tangs lock into position.

Place connector back on front and intermediate brake cables.

4. With lever in the applied position, turn adjusting knob to give 5/8 in. clearance

from forward edge of clevis pin head to end of adjusting slot in bracket.

5. Do not alter rear brake drum adjustment or cable equalizer unless routine ser-

vice is required in order to obtain the desired settings above.

Auxiliary Braking Systems

If add-on braking systems are installed to control either tag axle or trailer braking sys-

tems, the body builder is responsible for the integrity of the system. This may require

runningFMVSScertificationtests.AnychangetotheGVWRnecessitate,recertification

toFMVSS. Caremustbetaken toassurethatflowrateofthe brakefluidisnotaffected

bythemodification,asthiscouldreducetheeffectivenessoftheABSsystem. Therec-

ommendationsoftheauxiliarybrakedevicemanufactureshouldbefollowedinmaking

themodifications. Formostsystemsthatrequireatap-inisbestdoneneartherearaxle

ofthe vehicle. Thisallowsany proportioningofthe rearbrakes to becommunicated to

theauxiliarybrakes. Thistap-inshouldnotrequiremorethan.02cu.in.offluid,andbe

capableofwithstandingpressuresupto3000psi. Auxiliarybrakes mustbecapableof

takingtheproportionofthebrakingload,forwhich,theyaredesignedtoprovideforthe

overall vehicle (combination) irrespective of fade or other operating effects.

Section 6 – Engine

For additional information refer to

Section 1 – Body.

Air conditioning and auxiliary belt-driven equipment installation recommendations:

Noalterationsor additionstothe accessorydrivebelt systemwillbe warrantedonser-

pentine belt systems.

Theserpentinebelttypeofdriveisdesignedasatotalsystem,incorporatingasinglepoly

V-belt and an automatic tensioner. In this type of system, degrees of pulley wrap, belt

tension,andpulleyalignmentareverycriticalfactors. Modificationisnotrecommended.

Duetothecriticalnatureoftheacceleratorsystem,anyonemakingmodificationsoral-

terationsassumescompleteresponsibilityforsystemreliability,performanceandcom-

pliancetoFMVSS124. Cautionmustbeexercisedsothattheacceleratorcableisprop-

erly routed. Specifications are as follows:

DRoutecabletomaximizeallbendradii. Innocaseshouldbendradiibelessthan

3 in. (76 mm).

DMinimum distance from exhaust manifold to be 6.0 in. (150 mm), unless a heat

shield is provided.

DDo not use accelerator cable or clips to route wires, harnesses or other cables.

Cablesheath mustbeclipped soas nottopinch innercable. Cable mustnotbe

loose in clip allowing sheath to move when accelerator pedal is applied and

released.

DCable must not be subjected to kinking or routing across any sharp edges.

DCable routing must be perpendicular to the surface of the front-of-dash at the

dashfitting. Noobjectsorroutingsshouldforcecabletohaveabendatthedash

fitting. Flexible components (hoses, wires, conduits, etc. ) must not be routed

within 2.0 in. (50 mm) of moving parts or accelerator linkage unless routing is

positively controlled.

DCaution must be taken so that the accelerator pedal remains properly located.

Guidelines for accelerator pedal locations are as follows:

— Ensure that the accelerator can freely operate from idle to wide-open throttle

position and return. Make sure that the pedal will not hang up on any nearby

items such as carpets, floor, screws, wiring harnesses, etc. Engine cover

should have at least one inch (25 mm) clearance to side of accelerator pedal

withthecarpetmatinstalled. Nofloorcoveringshouldbeinstalledunderpedal

area.

— Accelerator to brake pedal relationship has been designed to provide mini-

mum driver movement and should not be altered in any way.

Gasolineengineinductionand/orignitionsystemiscertifiedincompliancewiththeFed-

eralVehicleEmissionStandards. Anyalterations tothesystemsorcomponentscould

void compliance and render the vehicle illegal. System includes:

DFuelsystem–SequentialportfuelInjection(SPFI),centralportinjector(CPI)and

associated tubes, hoses and pipes, air cleaner outside air hose, fuel pump and

inlet manifold and fuel vapor canister.

DExhaust system.

DIgnitionsystemdistributorandinitialsparktimingsetting,sparkplugs,sparkplug

wires.

PAGE

7

P32/42 C

HASSIS

P32/42 Rev. 12/98

DCrankcase ventilation system.

Diesel engine induction and injector pump system is certified to be in compliance with

theFederalVehicleEmissionStandardsand/orNoiseStandards. Anyalterationstothe

systemorcomponentscouldvoidcomplianceandrenderthevehicleillegal. Systemin-

cludes:

DFuelsystem – Injectionpump, injectorlinesand injectors,fuelreturn hosesand

pipes,aircleaner,outsideairhose,fuelpump,fuelfilter,fuelheaterassemblyand

intake manifold.

DExhaust system.

DCrankcase pressure regulation system.

DExternalengine components suchas aircleaner,crankcase pressureregulator

valve, alternator, injection pipes, fuel return hoses from injectors, exhaust

manifolds,oil fillpipe, etc.mustbe providedwith sufficientclearanceforengine

roll and torque.

DWhenavehicleisequippedwithaelectronicfuelinjection(EFI)engine,ithasan

engine control module ECM/PCM/TCM or VCM. This ECM/PCM/TCM or VCM

must be maintained at a temperature below 185_F at all times. This is most

essentialifthevehicleisputthroughapaintbakingprocess.TheECM/PCM/TCM

orVCM willbecome inoperativeif itstemperatureexceeds 185_F. Therefore, it

isrecommendedthattemporaryinsulationbeplacedaroundtheECM/PCM/TCM

orVCMduring thetimethevehicle isinapaint ovenorundergoinganother high

temperature process.

Enginestartinginstructionlabellocation. Labelshouldbeinstalled2in.abovedriver’s

sunvisor bracket and 2 1/2 in. to the left of the right hand bracket.

The following statement applies to models with remote mounted air cleaners:

TheBodyBuildermustinstalltheairinletductsuchthatitprovidescooldryairtotheair

cleaner. Radiator baffling must be provided to prevent recirculation of air through the

radiator. The air inlet must be shielded from water and snow that may come from the

road, tires and through the grille.

Theair cleanerposition and ductingbetween theair cleanerand engineshould notbe

modified.

The following applies to P models with L29/L31/L35 engines:

TherelationshipoftheaircleanerassemblytotheMassAirFlowsensor(MAF)asposi-

tionedbytheaircleanerelbowcannotbealtered. TheMAFsensorblackelectronicmod-

ule must remain 30_forward of vertical.

The following statement applies to P 30032 models with a 6.5L turbo diesel engine.

CAUTION: Do not run the engine with the air cleaner or ducting to the turbo removed.

Serious personal injury or damage to the engine could result.

Apply a Caution label on the turbo inlet ducting.

Apply Starting Fluid Warning label in a visible area near air intake duct inlet.

RefertoinformationintheLoose PartsBoxforlabelingandairinletductpart numbers.

Section 7 – Transmission

Lightdutymodelsequippedwithmanualtransmissionhaveaclutch-operatedstartsafe-

tyswitch. Startershould operatewhenevertheignition isturnedtostartand theclutch

isfullydepressed. Theclutch-operatedstartsafetyswitchisintegralwiththeclutchmas-

ter cylinder push rod. It is

not

adjustable.

Modelsequippedwithautomatictransmissionsandcolumnshiftcontrolhaveasteering

columnmountedneutral/parkstartsafetymechanicallockoutfeature,whichinterfaces

withthe steeringcolumnignition switch. Starterwillonly operatewhengear shiftlever

isin the neutralor park position. Re-adjustthe shift linkageif necessaryas outlined in

the Truck Service Manual.

Transmission shiftcable must berouted andclipped properlyto avoid contact withhot

surfaces such as exhaust manifold or EGR pipe.

NOTE: Remove the shift cable clearance tag from the EGR tube after shift cable

routing.

Modelsequippedwithbrake-transmissionshiftinterlock(BTSI)mustfullyapplytheregu-

lar brakes before you can shift from park when the ignition key is in the run position.

Modelsequippedwithmanualtransmissionuseahydraulicclutchactuator. Checkfluid

levelas outlined inthe vehicleownersmanual. Attach manualtransmissionshiftlever

boot to floor using four 11514843 screws or equivalent.

It is mandatory that no change be made to the clutch master cylinder location, clutch

master cylinder push rod length, or pedal position.

Afterinstallation ofthe body,vehicles withautomatic transmissionsshould havethe shift

linkage checked and adjusted if necessary as outlined in the Truck Service Manual.

PAGE

8

P32/42 C

HASSIS

P32/42 Rev. 12/98

Shift Cables

DControlcablesshouldbesupportedoranchoredtopreventsagwhensuspended

overhead and to prevent movement where the routing bends.

DOn long control runs the conduit should be clamped to supporting structure at

least every 48 inches.

DSupports should be placed at the end of the straight runs, and not in the middle

of a bend.

DCare must be taken that the clamps do not collapse the conduit and increase

control friction.

DControlsshould berouted sothat theywill avoidrubbing, pinchingand extreme

heat, cold or vibration.

DBend radius to be 6.0 in. minimum.

Section 8 – Fuel and Exhaust

Fuel Systems

Any body installed must be mounted securely to absorb loads and prevent movement

relativetotheframewhichcouldcauseanyfuelsystemcomponenttobepunctured,sep-

aratedorotherwisedamagedwhentestedtotheapplicableproceduresofFMVSS301.

Nootherinstalled componentsormodificationsare allowedwhichcouldimpinge onor

causedistortiontothefuelsystemwithsufficientenergytopuncture,separateorother-

wisedamagethefuelsystemwhentestedtotheapplicableproceduresofFMVSS301.

Duetothecriticalnatureofthefuelsystem,anyonemakingmodificationsoralterations

totheexistingsystem,exceptasspecifiedintheIncompleteVehicleDocumentorinthis

manual, must assume complete responsibility for the systems reliability, performance

and compliance to FMVSS 301.

Assemblyofanyfuelsystem componentsmayrequireapplicationofa lubricanttopre-

vent contamination of the fuel system, only GM lubricant 9985784 may be used.

Thefuelevaporativeemissioncontrolequipmentiscertifiedtobeincompliancewiththe

FederalandCaliforniaVehicleEmissionStandards. Metalfuellinesandfueltankshave

asurfacecoatingtoreducecorrosiononinsideandoutsidesurfacestocomplywithuse-

fulliferequirements. Allfuelhosesaremadeofalowpermeationmultilayermaterialto

complywithenhancedevaporativeemissionrequirements. Anyalterationstosystems

orcomponentsincludingmaterials,hoselengthsandtheirlocation,exceptasdescribed

in the fuel fill system modifications section, could void compliance.

The system includes:

DFueltank,fuellevelsender,fuelfillandventhosesandpipes,emissioncanisters,

fuel feed, fuel return and vapor lines, purge control solenoids, fuel fill cap and

canister vent solenoid.

For these reasons,

NO ALTERATION OF THE FUEL SYSTEM IS RECOMMENDED

Temporary Tank

Thetemporaryfuelcontainermustbereplacedwithapermanentfueltankpriortoplac-

ingthevehicleintouse. Thereplacementtanksupplierand/orbodybuilderisresponsi-

ble for certifying evaporative emissions.

The following statement applies to motorhome chassis only.

The unit is fueled during shipping (gas engines only) from a temporary fuel tank which

contains the tank unit for the main tank. The temporary tank is to be removed and

scrapped. Transfer the tankunitwithO–ringsealtothemain tank. Thefuelcapforthe

main tank filler neck is the same as on the temporary tank. Remove the tank unit hole

cover and lock ring. Discard

only

the tank unit hole cover and the lock ring. Reinstall

the seal, lock ring and the tank unit assembly.

The75gallonfueltank(RPONJ9)asreceivedhasaventedplugmarked“ForShipping

Purposes Only”. This plug is to be removed and a solid steel plug shipped in the ship

loose box must be installed in place of the plug removed.

The75gallonfueltank(RPONJ9)isprovidedwithrearshieldstoprovideprotectionfor

thedepartureangleshownonthefueltankarrangementdrawing. Anyalterationordele-

tion of these shields requires that an equivalent departure angle of protection be pro-

vided by the completed vehicle.

The following statement applies to commercial models with option B3D only.

TheCPIfuelsystemforstandardmodelsisconnectedtotheregularfueltank. Thefuel

systemforoptionB3Dgasolineanddieselschoolbusmodelsisalsoequippedthisway.

Afusible plugis included inthe looseparts box. Thismust be installedinto thetagged

hole in the tank to replace a plastic shipping plug.

Fuel Fill

Fueltankfillerpipelocationshouldbesosituatedandconstructedastopreventgasoline

vaporfromemittingtoventsofpilotflameddevicesandtobodyandenginecompartment

air inlets.

PAGE

9

P32/42 C

HASSIS

P32/42 Rev. 12/98

Itis recommendedthat whenmounting thefuelfiller pipeassembly andvent hosethat

a minimum of 3” clearance be provided to any body component to prevent contact be-

tween hoses and/or mating parts and that retention be provided to ensure routing and

preventfailureduetowearandfatigue. Fillerpipeandventlinemusthaveagravityfuel

flowtotankatall times;nofueltrapsareallowed. Alterations offuellineroutingscould

affecttheabilityofthecompletedvehicleandare,therefore,notdesirable. Thecomplete

fuel system must comply with FMVSS 301.

Ifadditionalnewhoseisrequiredwheninstallingfueltankfillerneck,thishosemustbe

suitableforusewithunleadedfuelsordieselfuelrespectivelyandmustallowthevehicle

to meet enhanced evaporative emissions requirements.

Thefuelfillinletpipeassemblyattachedtothebodymustbegroundedtotheframestruc-

ture with the ground strap and fasteners provided in the shipped loose box.

Fuel Lines

Fuel line routing precautions:

D12 in. minimum clearance to exhaust system is required or a metal shield must

be provided.

DFuellinesshouldbeclippedtochassistopreventchafing. Metalclipsmusthave

rubber or plastic liners.

DUse corrosion resistant steel tubing with short sections of approved hose to

connect components. Hose-to-tube connections should be clamped for diesel

systems. Steel tube ends should be beaded for hose retention. Fuel supply is

pressurized by an in-tank pump for CPI systems. Coupled hose or nylon

quick-connectsmustbeused. ClampedhoseisnotacceptableforCPIsystems.

All engines require a fuel return system which returns excess fuel from the injection

pumpandinjectornozzlesbacktofueltanks. Careshouldbetakenthattheselinesare

not blocked nor their hoses pinched. The engine may run poorly or stall if these lines

are restricted or blocked.

Allgasolineenginevehiclesareequippedwithfuelevaporativeemissioncontrolequip-

mentwhichiscertifiedto beincompliancewiththeFederal orapplicableCaliforniave-

hicle emission standards. Alterations to fuel tank and metering unit, lines, canister or

canisters, canister filters, canister purge control valves, relay switches, tank auxiliary

ventvalve,enginespeedcontroller,orotherdevices/systemsarethereforenotallowable

since vehicle adherence to C.A.R.B. and Federal regulations may be affected.

Diesel powered vehicles incorporate water drain provisions inthe fuel system. These

valvesareonlytobeopenedwhensiphoningwaterandcontaminantsfromthefuelsys-

tem.

Fuel Tank

Forvehicleswithfullframes,thetankmusthaveaminimumclearanceof2in.top,front,

rear and sides to body and other supports.

Tank may be pressurized with nitrogen (Do not use air with fuel in the system) to 1.25

PSImaximumtocheckforfinallineleakageorforforcingfuelthroughthesystem. Pres-

sures greater than this amount may be detrimental and affect tank durability.

The following statement applies to commercial models only.

Tapping into the main fuel supply line to get fuel for a powered motor generator is not

recommendedsincethiscouldresultinfuelstarvation,vaporlockproblemsandrunning

thefueltankdry. Itisnotpermissibletodrawfuelfromafuelreturnline. Thefuelmeter

assemblyhasaanti-siphonfeatureinthereturnlinethatpreventsfuelfrombeingdrawn

out.

The following statement applies to motorhome models only.

The40, 60&75 gallongasolinetanks willincludea fueldrawtube inthetop ofthetank

assembly. This is provided for body builders to use for generators. The body builder

should remove the pipe plug in this fitting and plumb system to the generator from this

pickuppoint. Addedauxiliarypowerunitmust usethesamefuelasthechassisengine

or a separate fuel system will be required.

Theuseofauxiliaryfueltanksisnotrecommended.

Ifanauxiliaryfueltankisadded,

the alterer must take responsibility for compliance with affected motor vehicle safety

standards. Also,ifanauxiliaryfueltankisaddedtoagasoline-poweredvehicle,thefuel

must be drawn through a pipe at the top of the tank (balance line between tanks is not

permitted).

Gasolinefueled vehiclesare nowequipped witha fuelpump returnline. If anauxiliary

tankisadded,thetankselectorvalvemustincludeareturnportwhichreturnsfueltothe

tank from which the fuel is being drawn.

Ingasolineenginesthefuelpumpislocatedinthefueltank. Thebatterymustbediscon-

nected before starting any work on the fuel system.

In the use of dual fuel systems, the vehicle operator should strictly adhere to the

manufacturer’sproceduresfor switchingfromgasoline togaseous fueloperation. Im-

properswitchingproceduresmayresultinoverheatinganddamagetotheexhaustsys-

temandthevehicle. Thegaseousfueltankshouldnotbemountedinanenclosedarea

ofthevehicle, suchasthe passengercompartment,truck, etc.,andthesystem should

beventedtotheoutsideofthevehicle. Inaddition,vehiclesconvertedtogaseousfuels

shouldnotbestoredinenclosedplacessuchasgarages. Further,GeneralMotorscau-

PAGE

10

P32/42 C

HASSIS

P32/42 Rev. 12/98

tionspurchasersthatthedesign,locationandinstallationofanytypeoffuelstoragesys-

teminvolvessignificanttechnicalandengineeringconsiderationsandthatthesestate-

ments on gaseous fuel conversions should not be interpreted to be an approval by

General Motors of any modification to the original equipment fuel system.

Conversions to gaseous fuel should be made in conformance with applicable Federal

andStateregulations. Removalofemission-controlcomponents,ortheadditionofgas-

eousfuelsystemswhichcoulddamageorreducethelongevityofthosecomponentsand

could also cause the mechanical and emission performance warranty to be voided.

Exhaust System

Particularcare shouldbe takento preventthe possibilityof exhaustfumesand carbon

monoxideexposuretovehicleoccupantsinunitscompletedbybodybuilders.Holesand

openingsthroughthefloorandallotherpartsofthebodymustbepermanentlyandade-

quately sealed by the body builder to avoid exhaust intrusion into any occupant area.

If it is necessary to changethe exhaust outlet location, the exhaust discharge must be

unobstructedand directedawayfrom occupantareas. Alteration oftheexhaust outlet

orits positionmayincrease exhaustnoiseand renderthevehicle illegalinthoseareas

with pass-by noise regulations. All vehicles >10,000 lbs. GVWR come under Federal

noiseregulations,vehicles<10,000lbs.GVWRareregulatedbyvariousstateandlocal

regulationsoftheEnvironmentalProtectionAgency;seethoseregulationsforrules,test

procedure and noise levels permitted.

Tailpipeoutletlocationmustbetestedstaticallyandwiththevehicleinmotiontoensure

that exhaust gases do not penetrate side or rear windows or under body seams and

holes. Auxiliarypowerplantsshouldalsobetestedunderthesameconditions. Tailpipe

extensionmust extend2.0to 2.5in.outboard ofbodyside panels. Tailpipeexit ahead

of rear wheels is not recommended.

Check for leaks in exhaust systems and repair as required.

Exhaust temperatures can exceed 1600_F under extreme operating conditions, with

pipesurfacetemperaturesslightlylessthanthis. Extremecaremustbeusedwhenplac-

ingbodycomponentsintheproximityoftheexhaustsystemsoasnottoexceedtherated

temperature limits of the components. Due to variants in underbody configurations of

the vehicles, we are not in a position to make recommendations on how to insulate or

design components in the proximity of the exhaust system.

Each manufacturer must make temperature checks of critical areas of his vehicle and

adjusthisdesignaccordingly,or provideshieldingtoensuresafe operationofhisbody

components.

The same can be said for the engine compartment. Obviously there will be additional

heatradiatedfromtheengine. Howmuchisretainedintheareawilldependonhowwell

thisareaisventilatedinyourindividualdesigns. Hereagain,temperaturechecksofinte-

riorareassurroundingtheengineshouldbemadetodetermineifyourinsulationisade-

quate. Thisisthesameengineeringpracticewehavefollowedonourcompletevehicles

incorporating these exhaust systems.

Exhaust system materials are selected and tested to withstand the operating environ-

ment of the vehicle. Do not modify the exhaust system in any way. The tail pipes are

made of 409 stainless steel or aluminized 409 stainless steel.

Heatshieldsaremountedtotheunderbodyand/orexhaustsystemcomponents(catalyt-

icconverter andmuffler). Shields forthe propshafthanger bearingsare alsoprovided

in some vehicles.

Section 9 – Steering

Check power steering fluid level and system operations. (Refer to Owner’s Manual)

Steering wheel and horn pad must not be altered or replaced.

The following statement applies to motorhome chassis only.

Steeringwheelandshaftmustbelocatedandsupportedasshownonthebodybuilders

drawing.

Section 10 – Tires/Wheels

Check wheel lug nuts for proper torque; specifications are provided in the Owner’s

Manual.

Substitutionoftiresof greatercapacitythanthoseofferedasoriginalequipment byve-

hiclemanufacturerisnotapprovedforuseonoriginalequipmentwheels. Anyusageof

higher capacity tires must be accompanied by higher capacity wheels. However, the

wheel offset and distance from centerline of rim to wheel mounting face must be the

sameasthereplacedoriginalequipmentwheeltoensureproperwheelbearingloading

and clearance of tires to body and chassis components.

IncreasingtireandwheelcapacitydoesnotnecessarilyincreasevehicleGVWratings.

Itisrecommendedthattirechainclearanceguideline,J683fromtheSocietyofAutomo-

tive Engineers be adhered to in designing rear wheelhouse clearance.

Checktiresandinflatetorecommendedtirepressureaccordingtothetirepressureinfor-

mationdisplayedonthecertification/tirelabelprovidedwiththevehiclebeforeshipment

of vehicle from Body builder.

Any substitution of tires may affect Speedometer/Odometer accuracy.

PAGE

11

P32/42 C

HASSIS

P32/42 Rev. 12/98

Ifthebodybuilderinstallswheelcoversonthevehicle,ventedcoversmustbeused. The

minimumvent area isto bethe greaterof 34in.2 or 90%of theoriginal vehicle’swheel

vent zone. Air flow through the wheel vent and cover vent must be direct.

Section 12 – Electrical Battery and Battery Cables

Thevehiclebatteryshouldbelocatedandpositionedtomakeuseoftheexistingbattery

cables.Ifthebatteryrequiresrelocationandlongercablesarerequired,aproportionate-

lylargergaugewiremustbeused. Ifinrelocatingthebatterythenegativegroundcable

isattachedtoframerail,acableofsimilargaugebeprovidedbetweentheframerailand

the engine. This is required due to the heavy electrical loads imposed by the starting

circuit. To ensure proper operation of the battery cables the following chart on length,

gauge and materials must be strictly adhered to:

Combined Length of Positive and Negative

Cable Gauge Cable in Inches (Copper)

4 66

2 107

0 170

Ifthebatteryrequiresrelocationintheenginecompartment,theOEMsuppliedgenera-

torwithflat-compensatedregulatormustbereplacedwithageneratorwithtemperature

compensatedregulatorto regulatesystemvoltagecompatiblewith underhoodbattery

temperatures.

Underhood Battery Location

OEM Part No. Substitute Part No.

10480170 (105 A) 10480168 (105 A)

10480267 (124 A) 10480255 (124 A)

If the battery is relocated in the engine compartment without replacing generator as

statedabove,itwilleffectthebatterylifeandwillbereducedby50%oftheaveragebat-

tery life.

Battery Installation

The battery and cable installation, provided by the body upfitter, must comply with the

followingguidelines.Non-compliancemayresultinafailureofthevehicleelectricalcom-

ponent system, the shutdown of the engine, loss of backupbrake system, loss of ABS

braking control, and the possibility of fire.

DThe cables must not contact any sharp edge(s), in either the normal (stored) or

slid (maintenance) position (school bus application).

DThe cables must not be bent in a radius of smaller than 10 times the cable

diameter. Insulation failure can occur if this happens.

DThecablemustbesupported byclipsspacedatadistanceofnot morethan450

mm. Inthis clipping, theyshall nothavea freemovementthat willallowrubbing

on any vehicle component, either fixed or moveable.

DAll clips used must be of the rubber-lined type, not rubber dipped.

DDonotsplicethebatterycables. Cablemodificationscanresultinvehiclestarting

problems and loss of other key systems.

DThecables must beclipped tothe battery traysuch thatthe cable pullloads are

not transferred into the battery posts due to slide tray movement. Failure to do

so can result in loose terminals, poor starting and battery failure. Battery acid

leakage could result around posts not properly relieved of strain.

DThe cable attachments at the battery terminal must not cause undue strain at

theseconnections.Thereshouldbenosharpbendsinthecablesadjacenttothe

connections. The cables should be routed down from the terminals rather than

horizontally from the terminals to prevent a lever action that may loosen

connections. Terminal corrosion inhibitors and other coatings should not be

applied to the sealed electrical contact areas. Terminal torque of the sealed

terminal shall be 10/20 N-M freedom, 14/20 N-M linehaul.

DMounting Base (Tray):

Thetrayshouldbeofsubstantialmaterial(minimum1.75mmthickorsufficiently

reinforced)toresistflexingandcracking. Thetraymustprovidefirm,continuous

support of the battery and not amplify vibration levels. There must be no

protrusionsorprojectionsinthetrayormountingsthatwoulddamagethebattery.

Cantileveredmountings arenotrecommended andthe trayshouldbe mounted

flat so as not to aggravate electrolyte spillage or lead fatigue. A rounded lip of

adequateheighttoensurestiffnessandretentionshouldbeprovidedaroundthe

perimeter of the tray. With the battery mounted in a vehicle, a static force of 22

kg applied to a 6.54 sq. cm. area at any corner should not move the battery any

more than .25 mm.

DFreedom Battery:

The hold-down must be able to prevent the battery movement relative to the

mountingbaseorhold-down.Torqueatthebatteryhold-downshallbe15/20N-m

(133-177lbs.-in)at thebaseclampor 2.3/4.5N-m(20-40lbs.-in.) atthetop bar.

Abottomhold-downcentrallylocatedatthesidesofthebatteryisrecommended.

DLinehaul Battery:

A tight, secure hold-down is essential. Hold-down brackets must retain the

batteryata22G-3millisecondshockloading. Atophold-downshouldbespaced

PAGE

12

P32/42 C

HASSIS

P32/42 Rev. 12/98

aminimumof15mmfromterminalpoststoavoidpossiblegroundpaths. Ifatop

hold-down is used, a non-corrosive, non-conductive coating is desirable.

Location:

The battery should be located in a well ventilated area where a temperature

build-updoesnotoccur.Thelocationshouldalsoprovideprotectiontothebattery

to prevent damage from foreign objects. The ends of the battery in the area of

theventportsshouldbefreeofobstructionssothatthegassesgeneratedduring

charging can be freely dissipated into the atmosphere.

DAccessibility:

Thehold-downshouldbeconvenient fortoolsandhandssothat personalinjury

does not occur. There should be clearance at the insulated and grounded

terminalssothatwrenchescanbeusedsothataccidentalgroundsorshortswill

notoccur. Terminalpolaritymarkings,warninglabelsandtesthydrometershould

be visible. The battery “ground” connection must be readily accessible for

disconnection, as required for vehicle electrical service requirements.

DTilt Angles:

Fornormalvehicleoperation(atGVW),thebatteryshouldnotbetilted(0_). For

installationorremoval,itshouldnotbenecessarytotiportiltthebatteryinexcess

of40_. This isto prevent acidspillage. For shortduration vehicle shipment,do

not tilt the battery more than 19_from the horizontal.

DTemperature:

The temperature of the electrolyte should not exceed 52_C. Infrequent peak

temperaturesto75_Ccanbetoleratedinsoaksituationsonly. Shieldingmaybe

required to protect the battery from a source of excessive heat.

DBattery Trays:

Batterytraysaresuppliedwiththechassis. Inthecaseofmotorhomesanddiesel

school busses, the trays are secured to the frame rail (for shipping only).

The trays shipped on the rails may be relocated to other areas on the vehicle,

keeping in mind the recommendations noted above.

DBattery Storage:

Today’s vehicles have several electronic devices which result in very small but

continuouscurrentdrainsontheirbatteries,commonlyreferredtoas“parasitic”

loads. Vehicles that are not used for an extended period of time may develop

extremely discharged and/or permanently damaged batteries resulting from

theseparasitic loads. Dischargedbatteries canfreeze attemperatures ashigh

as 20_F causing permanent damage.

To alleviate this condition, check to make sure green dot is visible, recharge as

necessary,thendisconnectthenegativebatterycableonvehicleswhicharenot

goingtobeinservicewithina30dayperiod. Ifthisisnotpossible,batteriesshould

be recharged periodically (every 30-60 days) until the green dot is visible.

NOTE: The ignition switch must be off when connecting or disconnecting battery

cables or hangers (jumper cables). Failure to do so may overstress or damage

the ECM/PCM/TCM, VCM, ABS or other electronic components.

Modifications/add-onwiringmustbecarefullyreviewedtoensurecompatibilitywiththe

basevehiclewiringbyreviewingthevehicleelectricalsystemmechanizationprints,de-

tailed harness prints and Delphi–Packard electric division connection system design

qualityguidelines. Duetothewiderangeofmodificationsthatmayberequiredforvoca-

tionalneeds, itisnot feasibleforthe O.E.M.totake intoaccount allpotentialrevisions.

Forthisreason,anypersonmodifyingexistingvehiclewiringmustassumeresponsibility

thattherevisionshavenotdegradedtheelectricalsystemperformance. Anyadd-onwir-

ingmustbeproperlyfusedandroutedtopreventcut,pinch,andchafeproblems,aswell

asavoidexposuretoexcessiveheat. Caremustbeexercisedthatexistingvehicleinter-

facesdonothavetheircurrentloadcapabilitiesexceeded,andthattherespectivecon-

troldevices are notoverloaded. Added wiresize should beat leastas large as the the

wire to which it is attaching in order for fuse protection to be maintained.

APackardelectricwiringrepairkitisavailablethroughKent–Moore(GMP/N12085264,

Kent–Moore P/N J38125-4). This kit contains instructions, tools and components for

makingrepairs to wiringharness components. Thiskit would alsogreatly assistin ac-

complishingnecessary add-on wiringsuch asbody marker lamps,so thatsystem reli-

ability/durability is maintained.

ElectricalwiringcomponentscanbeobtainedthroughyourauthorizedGMdealer.Many

Packard Electric components are also available through Pioneer Standard Company

(1-800-PACKARD). Pioneermayalsobeabletoassistinmakingnecessarywiringaddi-

tions by providing custom wiring stubs or jumpers to your specifications.

Fusible Link Repair Procedure:

1. Cut damaged fusible link from wiring harness assembly splice.

2. Strip insulation from harness wire as required to splice on new fusible link.

3. Fabricate a new fusible link wire approximately 6 to 8 in. long from the same

wire size as the original link. (Acceptable fusible link material will be imprinted

with the wire size and the wording to identify it as fusible link. Fusible link

cable is not the same as normal vehicle wiring.)

4. Terminate fusible link harness wire with a suitable compression splice clip, and

solder with an electrical grade rosin core solder. Wrap splice area with tape to

provide electrical insulation, as well as mechanical strain relief at the splice.

5. Strip, terminate, solder, and insulate remaining end of fusible link with ap-

propriate termination to be compatible with the rest of the electrical system.

6. For further information, refer to the instruction manual in the wiring repair kit

referenced elsewhere in this section.

PAGE

13

P32/42 C

HASSIS

P32/42 Rev. 12/98

Section 13 – Heating/Cooling

To provide satisfactory engine cooling, the following conditions must be met:

DThe minimum frontal area for the Chevrolet/GMC is 360 square inches, to be

directlyin front ofthe radiator. Ifthe vehiclegrille areaisnot directlyin linewith

the radiator face, filler panels between the radiator and grille must be used to

directtheairthroughtheradiator. Anyareaoutsideofa45_anglefromtheedge

of the radiator should not be considered as grille open area, for cooling.

DThe grille opening should be ‘open’ in configuration. Small holes for the grille

openingtendtorestrictairflowmorethanlargeholesalthoughbothmayhavethe

same frontal area.

DCoolingcanbeimprovedbyinsertingfillerpanelsbetweentheouterverticalside

edges of the radiator and grille. In addition, a filler panel should be fitted

horizontallyfromthebottomoftheradiatorouttothebottomofthegrille. Thiswill

preventairfromby-passingtheradiatorandexitingthroughthefrontwheelhouse

area or under the radiator. These panels will force the air through the radiator.

DAflexibleair-tightsealmustbeprovidedbetweentheupperradiatorsupportand

the body to aid idle cooling and prevent hot air recirculation. The seal assures

thatincoming ‘ramair’ mustgo throughthe radiatorcore ratherthanby passing

the radiator core (going up and over the core).

DBug screens should be avoided if at all possible. If conditions require a bug

screen, motor home owners are advised to be alert to possible engine

overheating problems as well as temperature changes. The screen’s mesh

should be-at most-half as dense as that of standard household screening.

Household screening will create an overheating condition. The bug screen

should be removed immediately upon leaving the bug infested area.

Do not install any internal flow restrictors.

The 3 way or ‘H’ valve is not required in the heater system for port fuel injected

engines.

Coolant Recovery Bottle:

1. Mount the coolant recovery bottle in an easily accessible area with the top

approximately the same height as the radiator fill cap. The bottle must be sup-

ported by the two attaching embossments at the top and also by the rib at the

bottom of the bottle to prevent failure of the unit. You may use the supplied

bracket and rework as required for proper mounting.

2. Hose may be cut to proper length as required to reach from the radiator over-

flow tube just under the radiator cap to the larger diameter nipple on the cool-

ant recovery bottle cap. Retain the hose by using two 5/8 in. hose clamps.

3. For the initial fill of the coolant recovery bottle, fill to the “hot” mark on the

bottle. This allows the system to initially purge itself and maintain the proper

coolant level. Refer to the Owner’s Manual for proper mixture.

The following statement applies to P 30042 models only.

Radiatorsupport assembly isnot astructural member. No bodymounting supportsor

other attachments used for structural purposes are to be fastened to radiator support

assembly. Example: Hornsshould not be mounted on the radiator supportassembly.

The following statement applies to P 30032/42 diesel models only.

Fordieselengines,ade-aerationtank isaddedtothecoolingsystem. Thissystemwill

passnormalcombustiongasesoutofthecoolingsystem. Thede-aerationcoolingsys-

tem includes a de-aeration tank, radiator, fitting and hoses.

Heater

Be sure to add coolant to system after adding capacity to system (heaters).

Ifaheaterisinstalledonthevehicle,ableedervalvemustbeaddedtotheheaterreturn

lineattheheaterinthereturnlinetotheengine,valvemustbeatthispointsinceitisthe

highestpointinthesystem. Thepurposeforthebleederistobleedairfromthesystem

aftertheheaterandlinesareinstalled. Failingtodosocancausewaterpumpsealdam-

age.

Proper bleed procedure are as follows:

1. Open bleeder valve and fill cooling system with coolant until coolant exits

valve.

2. Close valve and continue filling system until full.

3. With radiator cap off, start engine and run for approximately two minutes at

medium RPM.

4. Shut engine off, open bleeder valve and fill system as above and run again for

two minutes.

5. Shut engine off, top off coolant and install radiator cap.

6. Check for leaks at connections.

PAGE

14

P32/42 C

HASSIS

P32/42 Rev. 12/98

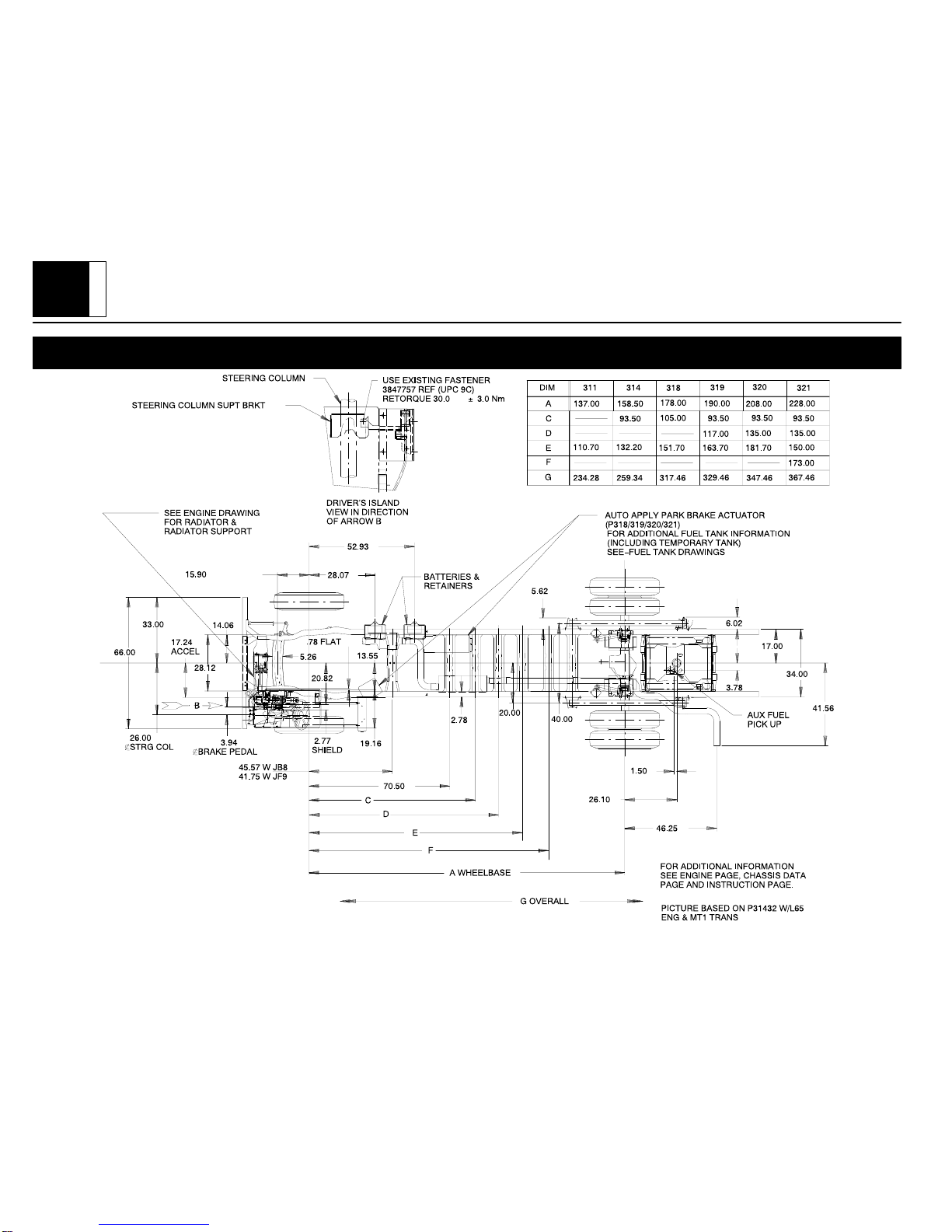

P 30032 General Arrangement, Diesel Engine, Option L65, 6.5L Turbo HO

PAGE

15

P32/42 C

HASSIS

P32/42 Rev. 12/98

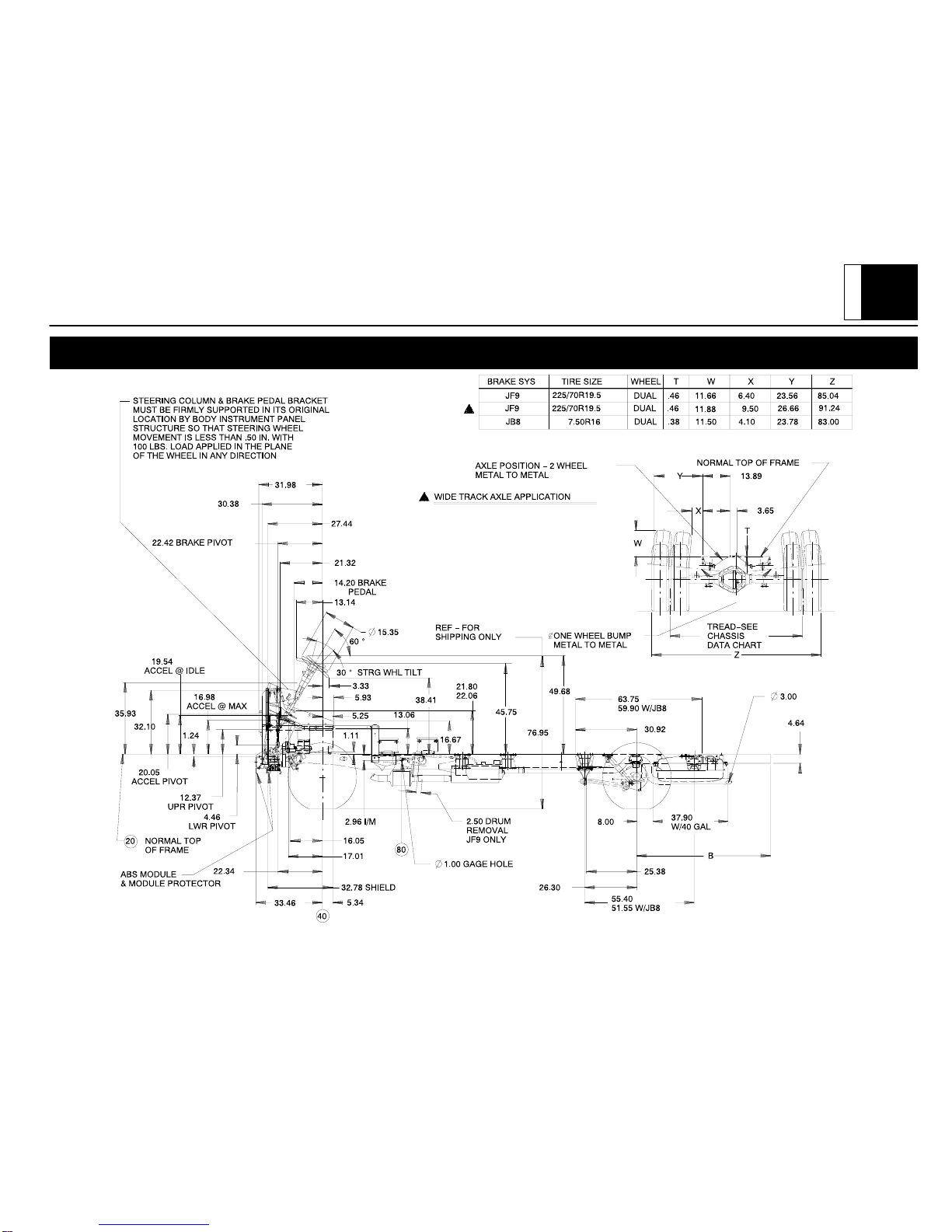

P 30032 General Arrangement, Diesel Engine, Option L65, 6.5L Turbo HO

PAGE

16

P32/42 C

HASSIS

P32/42 Rev. 12/98

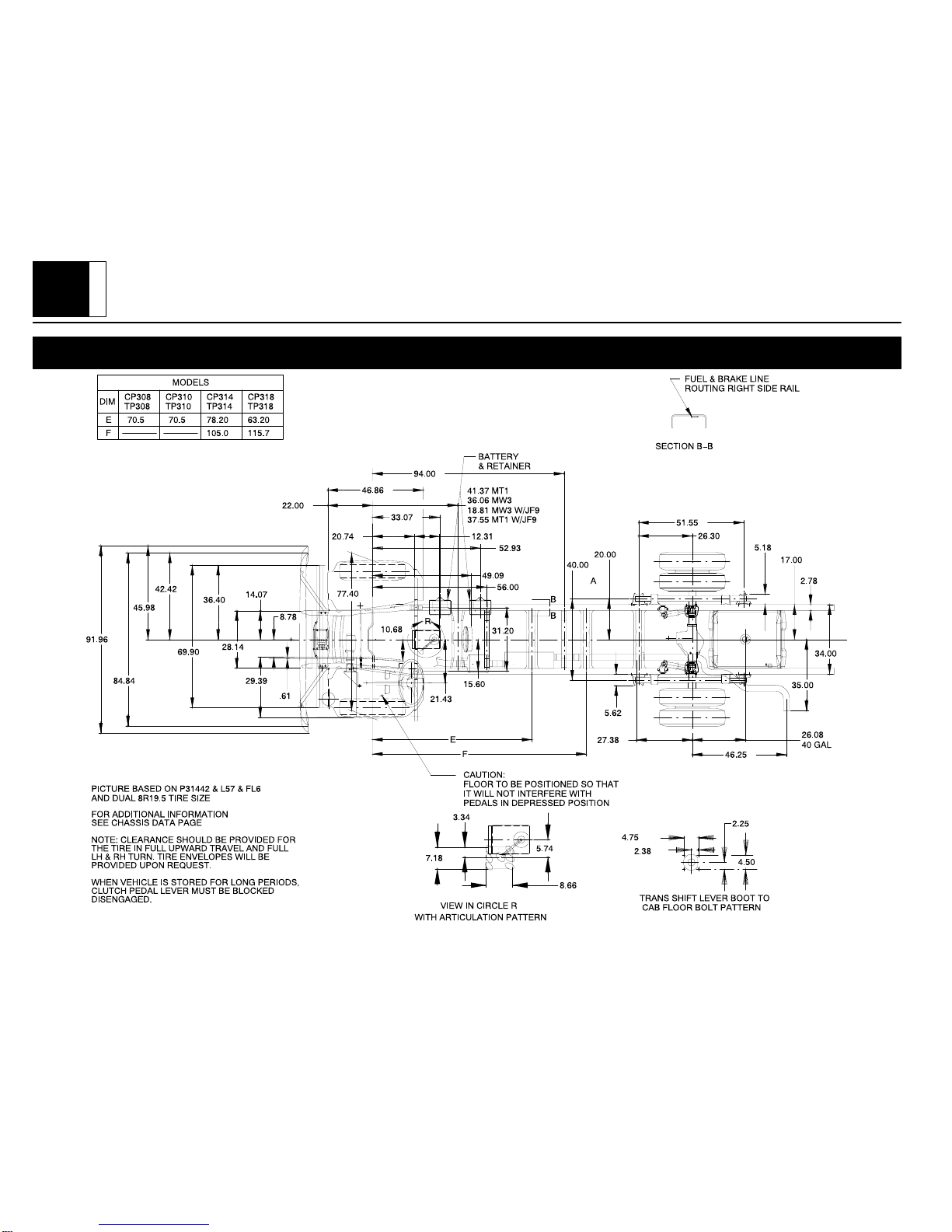

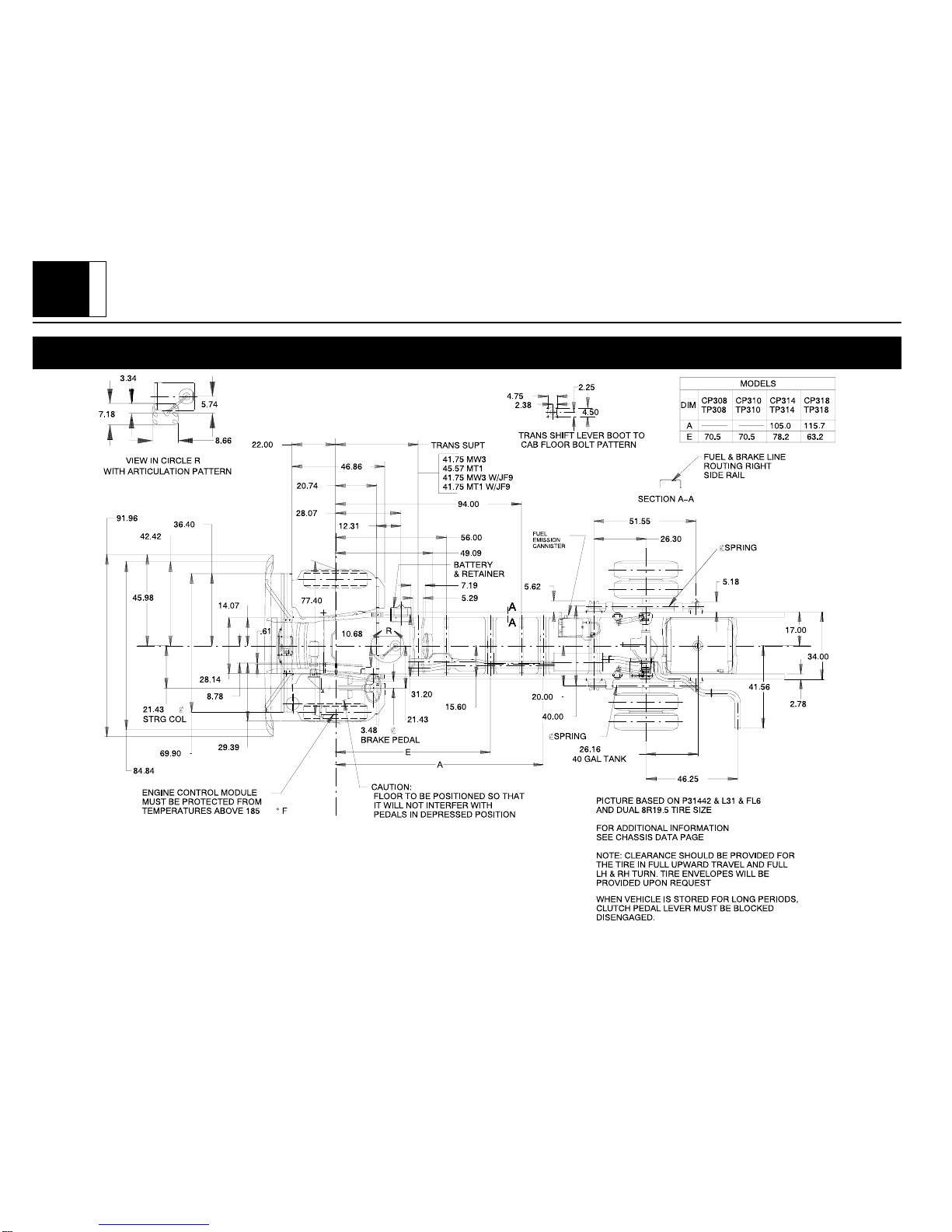

P 30042 General Arrangement, Diesel Engine, Option L57, 6.5L HO w/FL6 Independent Front Suspension

PAGE

17

P32/42 C

HASSIS

P32/42 Rev. 12/98

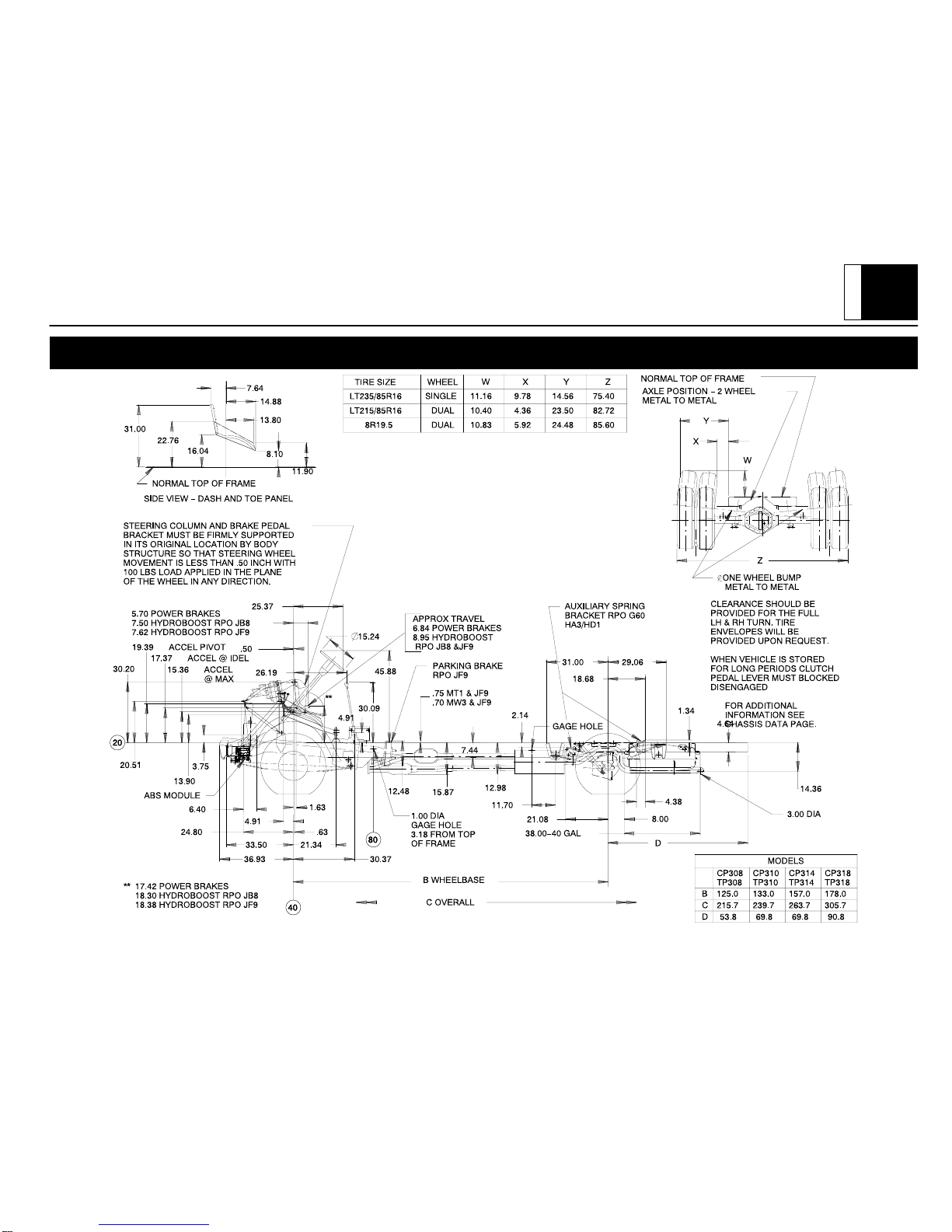

P 30042 General Arrangement, Diesel Engine, Option L57, 6.5L HO w/FL6 Independent Front Suspension

PAGE

18

P32/42 C

HASSIS

P32/42 Rev. 12/98

P 30042 General Arrangement, Gas Engine, Option L31, 5.7L V8 w/FK4, I-Beam Front Suspension

PAGE

19

P32/42 C

HASSIS

P32/42 Rev. 12/98

P 30042 General Arrangement, Gas Engine, Option L31, 5.7L V8 w/FK4 I–Beam Front Suspension, Option FK4

PAGE

20

P32/42 C

HASSIS

P32/42 Rev. 12/98

P 30042 General Arrangement, Gas Engine, Option L31, 5.7L V8, w/FL6 Independent Front Suspension

This manual suits for next models

1

Table of contents

Popular Automobile Accessories manuals by other brands

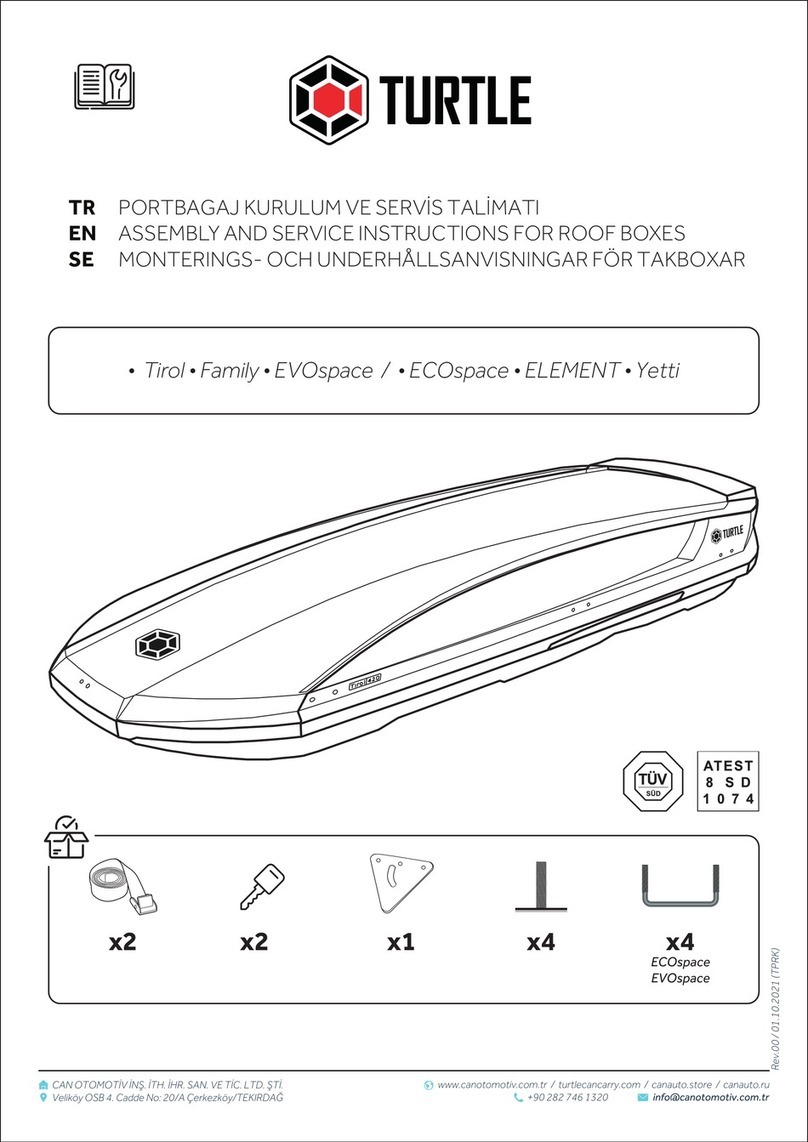

Turtle

Turtle Tirol Assembly and service instructions

American International

American International TOYK932GB quick guide

Mont Blanc

Mont Blanc FK204 Fitting instructions

Altera

Altera SIGNO 044 298 manual

EMOVE

EMOVE EM203 manual

Fiamma

Fiamma SUN VIEW SIDE CARAVANSTORE/F35 Installation and usage instructions