Helmer PC100i User manual

HELMER SCIENTIFIC

14400 Bergen Boulevard

Noblesville, IN 46060 USA

PH +1.317.773.9073

FAX +1.317.773.9082

USA and Canada 800.743.5637

0086

ISO 13485:2003 CERTIFIED

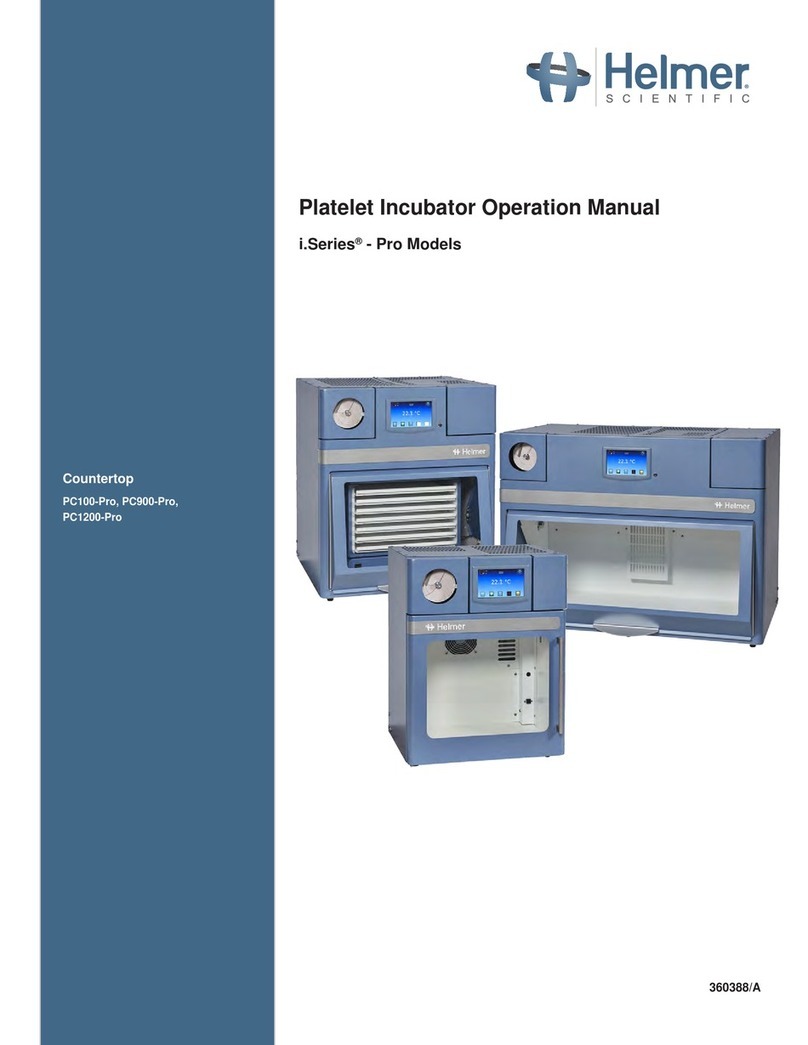

Platelet Incubator Operation Manual

i.Series®and Horizon Series™

360093-1/P

Model Group i.Series Horizon Series

Countertop PC100i, PC900i, PC1200i (Version A) PC100h, PC900h, PC1200h (Version A)

Floor PC2200i, PC3200i, PC4200i (Version A) PC2200h, PC3200h, PC4200h (Version A)

360093-1/P i

Document History

Revision Date CO Supersession Revision Description

L 28 JUN 2013 8414

Supersedes A,

B, C, D, E, F, G,

H, I, J, K

Revised layout for ease of navigation and locating information.

M 23 DEC 2013 8965 M supersedes L

► Added 100 V information.

► Added caution note for remote alarm interface.

► Revised section I for consistency with existing manuals.

N 31 JAN 3014 9113 N supersedes M Changed voltage for remote alarm contacts.

O22 APR 2014* 9386 O supersedes N Revised voltage specication for remote alarm contacts.

P 22 MAY 2014* 9497 P supersedes O

► Added information to environmental/application specications

from technical audit.

► Added 0086 to CE certication.

* Date submitted for Change Order review. Actual release date may vary.

360093-1/P ii

Section I: General Information ........................................4

1 About this Manual .......................................................... 4

1.1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Model References ......................................................................4

1.3 Copyright and Trademark ................................................................4

2 Safety .................................................................... 4

2.1 Safety Denitions ......................................................................4

2.2 Product Labels ........................................................................5

2.3 Avoiding Injury.........................................................................5

3 General Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Intended Use..........................................................................6

3.2 General Use ..........................................................................6

3.3 Initial Loading .........................................................................6

4 Specications.............................................................. 6

5 Compliance................................................................ 7

5.1 Regulatory Compliance..................................................................7

5.2 WEEE Compliance .....................................................................7

6 Installation ................................................................ 8

6.1 Location Requirements ..................................................................8

6.1.1 Placement .....................................................................8

6.2 Chart Recorder ........................................................................8

6.2.1 Install and Change Chart Paper .....................................................9

7 Maintenance Schedule ..................................................... 10

Section II: i.Series®Models..........................................11

8 Operation ................................................................ 11

8.1 Initial Start Up ........................................................................11

8.2 Congure a Platelet Agitator for Use in an i.Series Incubator (Optional) ...........................11

8.3 Load the PC4200h Built-In Agitator ........................................................12

8.4 Main Screen Functions .................................................................13

8.5 Chamber Setpoint .....................................................................14

8.6 Temperature Monitor Setpoints ...........................................................14

8.6.1 Change System Password ........................................................15

8.6.2 Temperature Alarm Setpoints ......................................................15

8.6.3 Active Alarms ..................................................................15

8.6.4 Mute an Active Alarm ............................................................16

9 Components .............................................................. 16

9.1 Control Door .........................................................................16

9.2 Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.3 Alarm Panel..........................................................................17

9.4 Chamber ............................................................................17

Contents

360093-1/P iii

Section III: Horizon Series™ Models ..................................18

10 Operation ................................................................ 18

10.1 Initial Start Up ........................................................................18

10.2 Congure a Platelet Agitator for Use in a Horizon Series Incubator (Optional).......................18

10.3 Load the PC4200h Built-In Agitator ........................................................18

10.4 Chamber Setpoint .....................................................................19

10.5 Temperature Monitor Setpoints ...........................................................19

10.5.1 High Alarm Setpoint .............................................................19

10.5.2 Low Alarm Setpoint .............................................................20

10.6 Alarm Volume Settings .................................................................20

10.6.1 Temperature and Power Failure Alarm Volume ........................................20

10.6.2 Motion Alarm Volume (PC4200h) ...................................................21

10.7 Alarm Delay Settings...................................................................22

10.7.1 Temperature Alarm Delay.........................................................22

10.7.2 Motion Alarm Delay (PC4200h) ....................................................23

10.8 Mute Audible Alarms ...................................................................23

10.9 Enable or Disable Audible Alarms with the Alarm Key Switch....................................24

11 Components .............................................................. 25

11.1 Control Door .........................................................................25

11.2 Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.3 Alarm Panel..........................................................................26

11.4 Chamber ............................................................................26

360093-1/P 4

General Information

Section I: General Information

1 About this Manual

1.1 Intended Audience

This manual is intended for use by end users of the platelet incubator and authorized service technicians.

1.2 Model References

Generic references are used throughout this manual to group models that contain similar features. For

example, “PC100 models” refers to all models of that size (PC100i, PC100h). This manual covers all

platelet incubators, which may be identied singly, by their size, or by their respective “Series.”

1.3 Copyright and Trademark

Helmer®, i.Series®, Horizon Series™, AgiTrak™, and Rel.i™ are registered trademarks or trademarks of

Helmer, Inc. in the United States of America. Copyright © 2014 Helmer, Inc. All other trademarks and

registered trademarks are the property of their respective owners.

Helmer, Inc., doing business as (DBA) Helmer Scientic and Helmer.

2 Safety

The operator or technician performing maintenance or service on Helmer Scientic products must

(a) inspect the product for abnormal wear and damage, (b) choose a repair procedure which will not

endanger his/her safety, the safety of others, the product, or the safe operation of the product, and (c)

fully inspect and test the product to ensure the maintenance or service has been performed properly.

2.1 SafetyDenitions

The following general safety alerts appear with all safety statements within this manual. Read and abide

by the safety statement that accompanies the safety alert symbol.

WARNING The safety statement that follows this safety alert symbol indicates a hazardous situation

which, if not avoided, could result in serious injury.

CAUTION The safety statement that follows this safety alert symbol indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury.

NOTICE The safety statement that follows this safety alert symbol indicates a situation which, if

not avoided, could result in damage to the product or stored inventory.

360093-1/P 5

General Information

2.2 Product Labels

The following general safety and information alerts appear on the product to identify potential hazards to

the operator or service technician.

Caution: Risk of damage

to equipment or danger to

operator

Caution: Unlock all casters

Caution: Hot surface Earth / ground terminal

Caution: Shock/electrical

hazard

Protective earth / ground

terminal

2.3 Avoiding Injury

► Review safety instructions before installing, using, or maintaining the equipment.

► Before moving unit, remove contents from the drawers (if applicable).

► Do not open multiple drawers at the same time (if applicable).

► Before moving unit, ensure door(s) are closed and casters (if applicable) are unlocked and free of

debris.

► Before moving unit, disconnect the AC power cord and secure the cord.

► When moving unit, use assistance from a second person.

► Never physically restrict any moving component.

► Avoid removing electrical service panels and access panels unless so instructed.

► Keep hands away from pinch points when closing the door or when agitation motion is enabled (if

applicable).

► Avoid sharp edges when working inside the electrical compartment.

► Ensure biological materials are stored at recommended temperatures determined by standards,

literature, or good laboratory practices.

► Proceed with caution when adding and removing samples from the platelet incubator.

► Use supplied power cord only.

► Using the equipment in a manner not specied by Helmer Scientic may impair the protection

provided by the equipment.

► Decontaminate parts prior to sending for service or repair. Contact Helmer Scientic or your

distributor for decontamination instructions and a Return Authorization Number.

► Ensure biological materials are stored safely, in accordance with all applicable organizational,

regulatory, and legal requirements.

► The platelet incubator is not considered to be a storage cabinet for ammable or hazardous materials.

360093-1/P 6

General Information

3 General Recommendations

3.1 Intended Use

Helmer platelet incubators are intended to provide the controlled temperature environment required for

the storage of platelet products.

The devices are intended to be operated by personnel who have procedures in place for meeting FDA,

AABB, EU or any other applicable regulations for the processing and storage of platelet products.

3.2 General Use

Allow platelet incubator to come to room temperature before switching power on.

During initial startup, motion alarm may sound if the motion is disabled, and low temperature alarm may

sound while platelet incubator reaches operating temperature.

3.3 Initial Loading

After platelet incubator reaches room temperature, allow chamber temperature to stabilize at the setpoint

before storing product.

4 Specications

PC100 PC900 PC1200 PC2200 PC3200 PC4200

Physical

Height 25.00” (635 mm) 30.25” (768 mm) 30.25” (768 mm) 60.00” (1524 mm) 75.50” (1918 mm) 75.50” (1918 mm)

Width 21.25” (540 mm) 26.50” (673 mm) 40.75” (1035 mm) 40.25” (1022 mm) 40.25” (1022 mm) 40.25” (1022 mm)

Depth 23.50” (597 mm) 27.75” (705 mm) 27.75” (705 mm) 30.25” (768 mm) 30.25” (768 mm) 30.25” (768 mm)

Weight 105 lbs (48 kg) 159 lbs (72 kg) 208 lbs (94 kg) 363 lbs (165 kg) 431 lbs (196 kg) 663 lbs (301 kg)

Electrical

Input Voltage

and Frequency 100 V, 50/60 Hz / 115 V, 50/60 Hz / 230 V, 50/60 Hz 115 V, 50/60 Hz / 230 V, 50/60 Hz

Voltage

Tolerance ±10%

Circuit

Breakers

12.0 A (100 V, 115 V)

6.0 A (230 V, quantity 2) 15.0 A, 2 A (115 V) 20.0 A,

5.0 A (115 V)

Fuses n/a 10.0 A (230 V, quantity 2) 10.0 A (230 V,

quantity 2)

Power

Consumption (1)

8.0 A (100 V, 115 V)

5.0 A (230 V)

8.0 A (100 V)

9.0 A (115 V)

4.5 A (230 V)

8.0 A (100 V)

9.0 A (115 V)

4.5 A (230 V)

11.5 A (115 V)

7.0 A (230 V)

12.0 A (115 V)

7.0 A (230 V)

14.5 A (115 V)

8.3 A (230 V)

Power Source (2) Varies (refer to product specication label)

Agitation

Speed (3)

(cycles/minute)

n/a

60 (115 V)

60 (230 V, 50 Hz)

72 (230 V, 60 Hz)

Remote Alarm

Capacity

i.Series: 0.5 A at 30 V (RMS); 1.0 A at 24 V (DC)

Horizon Series: 0.25 A at 30 V (RMS); 0.25 A at 60 V (DC)

Internal Outlet

Maximum

Current Draw (4)

0.5 A n/a

Control and Monitoring

Interface i.Series: Monitoring and display system and separate temperature control system

Horizon Series: Temperature control and display system

Alarms

i.Series: High, low, and condenser temperature; door open; low battery; no battery; AC power failure;

change chart paper; agitator 1, 2, and 3 motion

Horizon Series: High and low temperature; AC power failure; agitator motion (PC4200h)

360093-1/P 7

General Information

PC100 PC900 PC1200 PC2200 PC3200 PC4200

Environmental

Application

► Indoor use only

► Altitude (maximum): 2000 m

► Ambient temperature range: 15 °C to 35 °C

► Relative humidity (maximum for ambient temperature): 80% for temperatures up to 31 °C, decreasing

linearly to 50% at 40 °C

► Temperature control range: 20 °C to 35 °C

► Overvoltage category: II

► Pollution degree: 2

► Mains supply voltage: ±10% of nominal voltage

(1) Power consumption is measured in full-load Amperes.

(2) Product specication label is located on the back of the platelet incubator.

(3) Agitation speed is ±10% of nominal speed.

(4) PC4200 platelet incubators do not include an internal outlet(s).

CAUTION ► The interface on the remote alarm monitoring system is intended for connection to

the end user’s central alarm system(s) that uses normally-open or normally-closed

dry contacts.

► If an external power supply exceeding 30 V (RMS) or 60 V (DC) is connected to the

remote alarm monitoring system’s circuit, the remote alarm will not function properly;

may be damaged; or may result in injury to the user.

5 Compliance

5.1 Regulatory Compliance

This device complies with the requirements of directive 93/42/EEC concerning

Medical Devices, as amended by 2007/47/EC. 0086

Sound level is less than 70 dB(A).

EC REP Emergo Europe

Molenstraat 15

2513 BH

The Hague, Netherlands

5.2 WEEE Compliance

The WEEE (waste electrical and electronic equipment) symbol (right) indicates

compliance with European Union Directive WEEE 2002/96/EC and

applicable provisions. The directive sets requirements for the labeling and

disposal of certain products in affected countries.

When disposing of this product in countries affected by this directive:

► Do not dispose of this product as unsorted municipal waste.

► Collect this product separately.

► Use the collection and return systems available locally.

For more information on the return, recovery, or recycling of this product, contact your local distributor.

360093-1/P 8

General Information

6 Installation

6.1 Location Requirements

► Has a sturdy, level surface.

► Has a grounded outlet meeting national electric code (NEC) and local electrical requirements.

► Is clear of direct sunlight, high temperature sources, and heating and air conditioning vents.

► Countertop models: Minimum 4” (102 mm) above and behind.

► Floor models: Minimum 4” (102 mm) on left and right sides.

► Meets limits specied for ambient temperature and relative humidity.

6.1.1 Placement

WARNING To prevent tipping, ensure the casters are unlocked (oor models).

1 Ensure all casters are unlocked (oor models).

2 Place platelet incubator on study surface or roll platelet incubator into place and lock casters (oor

models).

3 Ensure platelet incubator is level.

6.2 Chart Recorder

A B F

C

D

E

Chart recorder with paper and battery installed.

Label Description Function

A Left and Right Arrow

buttons

Adjust settings and stylus position

B LED Indicates status of chart recorder in operating mode, or selected

temperature range in paper change mode

C Chart change button Adjust position of stylus when changing chart paper, or run a test pattern

D Stylus Mark temperature line on paper

E Reset button Restart chart recorder

F Backup battery Provides power during AC power failure. Connect prior to use.

360093-1/P 9

General Information

6.2.1 Install and Change Chart Paper

1 Press and hold C button. When stylus begins to move left, release button. The LED ashes to

indicate current temperature range.

2 When stylus stops moving, remove chart knob then move knob up and away from chart paper.

3 Place new chart paper on chart recorder.

4 Gently lift stylus and rotate paper so current time line corresponds to time line groove.

5 Hold chart paper and reinstall chart knob.

NOTE For accurate temperature reading, ensure that current time is aligned with time line

groove when chart knob is tightened.

6 Conrm the temperature range is set to the correct value.

7 Press and hold button C. When the stylus begins to move right, release the button.

8 Conrm the stylus is marking the temperature correctly.

360093-1/P 10

General Information

7 Maintenance Schedule

Maintenance tasks should be completed according to the following schedule. Refer to the service manual

for more detail on the various tasks.

NOTE These are recommended minimum requirements. Regulations for your organization or

physical conditions at your organization may require maintenance items to be performed

more frequently, or only by designated service personnel.

Task Frequency

Quarterly Annually As Needed

Test the high and low temperature alarms.

Test the power failure alarm (as required by your organization’s

protocols).

Test the door open alarm. (i.Series)

Test the no battery alarm. (i.Series)

Test the motion alarm (i.Series platelet incubators with platelet

agitators installed, and PC4200 platelet incubator).

Check the temperature calibration for the temperature monitor

and change it if necessary.

Check the temperature calibration for the temperature controller

and change it if necessary.

Check the backup battery for the motion alarm system after an

extended power failure and change it if necessary, or change

the battery if it has been in service for one year (PC4200).

(Models with chart recorders)

Check the backup battery for the chart recorder after an

extended power failure and change it if necessary, or change

the battery if it has been in service for one year. Refer to the

Temperature Chart Recorder Operation and Service Manual.

Clean the condenser grill.

Clean the exterior and interior.

Clean the door gaskets.

(PC4200)

Check agitation wheels, wheel bearings, and drive rod assembly

for wear. Clean and lubricate moving parts.

Replace moving parts if worn or when prompted by the agitation

maintenance reminder (i.Series).

NOTE ► i.Series: During a power failure, the backup battery provides power to the monitoring

system and the power failure alarm. If the backup battery is not functioning, the

power failure alarm will not be activated.

► If the backup battery does not provide power to the monitoring system during the

power failure alarm test, replace the battery.

► If batteries have been in service for one year, replace batteries.

360093-1/P 11

i.Series® Models

Section II: i.Series®Models

8 Operation

8.1 Initial Start Up

1 Plug the power cord into a grounded outlet that meets the electrical requirements on the product

specication label.

2 Switch the AC ON/OFF switch ON.

3 Connect the backup batteries for the monitoring system and alarms.

4 Connect the backup battery for the temperature chart recorder.

5 Install the alarm check tube (PC100i). Position the tube below the probe tip.

6 Select the display language.

► When the platelet incubator is powered on, the System Options is displayed.

► Press the INC or DEC buttons to select the language.

► Press the HOME button.

7 Press the MUTE button if the Low Temperature alarm sounds.

NOTE ► When the door switch is bypassed, the incubator and door open alarm continue to

operate as if the door is closed.

► The door switch controls power to the built-in agitator on PC4200i platelet incubator,

and controls power to the internal outlets on all other models.

► The door switch may be bypassed by opening the door and pulling the switch

cylinder.

8.2 CongureaPlateletAgitatorforUseinani.SeriesIncubator(Optional)

Helmer i.Series platelet agitators may be installed in a stand-alone conguration, or in Helmer i.Series

platelet incubators.

► Motion data is transmitted from the platelet agitator, through the data cable, to the platelet incubator.

► The platelet incubator interprets the motion data and generates its own motion alarm, based on its

own alarm delay period.

► If the motion alarm is not disabled on the platelet agitator, the motion alarms on both devices will

sound.

NOTE ► Disable the platelet agitator motion alarm when installing the platelet agitator in a

Helmer i.Series platelet incubator.

► Refer to the platelet agitator service manual for information regarding the installation

of a platelet agitator in a platelet incubator.

360093-1/P 12

i.Series® Models

8.3 Load the PC4200h Built-In Agitator

NOTE ► This chapter applies to PC4200h models only.

► For instsructions in loading all other platelet agitator models, refer to the platelet

agitator operation manual.

Model Capacity

Random Bags Apheresis Bags

PF4200i 396 132

CAUTION When opening drawer, grasp handle (not label holder). Open one drawer at a time.

Open the drawer to be loaded and lay the platelet bags at.

► Avoid stacking bags.

► Maintain enough space around each bag for air circulation. For thicker bags, remove drawers.

► Place the tubing under or around the bag.

360093-1/P 13

i.Series® Models

8.4 Main Screen Functions

All screens on the monitoring system are accessible from the Main screen. Press the UP or DOWN

buttons to highlight a menu option, then press the SELECT button to display the selected option.

Left: Temperature graph screen (displayed by default). Center: Home screen. Right: Main screen.

Option Function

Event Log View historical information: alarms and operational events

System alarm test and status ► Start or stop automatic alarm test

► View number of days left before TCR paper change

► View door status (open or closed)

► View condenser temperature

Edit conguration settings Access the Conguration screen (with password) and edit:

► Text language

► Date and time and/or format

► Temperature units

► Volume and pattern of audible alarms

► Enable or disable chart paper timer

► Enable or disable temperature graph display

► Change alarm-related setpoints and timers

► Calibrate temperature probe monitor reading

► Change some settings to factory default values

► Change password

► Congure AgiTrak system to monitor agitation

View conguration ► Date and time formats

► Alarm-related setpoints and timers

► Volume and pattern for audible alarms

► Setting for the chart paper timer

► Setting for the temperature graph display

► Settings for agitator alarms

Product/company information ► Software versions for the control and display components

of the monitoring system

► Helmer contact information

i.Help ► View real-time agitation speed and cycle counts

► View historical agitation event logs and details

► Reset agitator cycle counters

NOTE Refer to the platelet incubator service manual for a complete list of i.Center monitoring

system functions, settings, and screens.

360093-1/P 14

i.Series® Models

8.5 Chamber Setpoint

Temperature monitor/controller display and buttons.

NOTE ► Default setpoint is 22.0 °C

► Displayed chamber temperature may be different than setpoint.

► Refer to the service manual for program parameters and default parameter values.

1 On the temperature controller, press and hold *.

► The temperature controller displays the current setpoint.

2 While holding *press Up Arrow or Down Arrow to change the temperature setpoint.

► Setpoint changes in 0.1 ºC increments.

3 Release all buttons; the temperature setpoint is changed.

8.6 Temperature Monitor Setpoints

Left: Home screen. Right: Main screen.

Information displayed on the Home screen:

► Current readings from temperature probe(s)

► Remaining battery charge

► Current date and time

► Active alarm status

Features accessible from the Homescreen:

► Access the Main screen to view and change settings

► View active alarms

► Mute audible alarms

► View a graph of the chamber temperature (past 24 hours of operation)

► Adjust the screen contrast (center button)

360093-1/P 15

i.Series® Models

Features accessible from the Main screen:

► View Event Log data

► Start or stop system alarm tests and view incubator status

► View and edit conguration settings

► View product and company information

► Access the i.Help system

8.6.1 Change System Password

The default password is 1234. Passwords must be four digits, ranging from 1 to 5.

Change the password:

1 On the Home screen, press the MAIN button.

2 Press the DOWN button to select Edit Conguration. Press the SELECT button.

3 Enter the password when prompted.

4 Press the DOWN button to select Change Password. Press the SELECT button.

5 Enter the new password, then re-enter the new password when prompted.

► If password entries match, the “update” message is displayed.

► If password entries do not match, the “incorrect match” message is displayed. Repeat the

procedure to change the password.

8.6.2 Temperature Alarm Setpoints

1 Press the MAIN button.

2 Press the DOWN button to highlight Edit Conguration. Press the SELECT button.

4 Enter the password when prompted.

5 Press the DOWN button to highlight Alarm Setpoints. Press the SELECT button.

6 Press the DOWN button to highlight the desired temperature alarm setting.

7 Press the INC or DEC buttons to set the temperature alarm setpoint.

8 Press the BACK button to return to the Edit Conguration screen, or press the HOME button to exit.

The new settings are saved.

8.6.3 Active Alarms

The Home screen identies active alarms. If multiple alarms are active, the display will indicate the

number of alarms and will cycle through multiple alarms.

Home screen with one active alarm (Low Temp), highlighted.

360093-1/P 16

i.Series® Models

8.6.4 Mute an Active Alarm

► By default audible alarms are set to ON.

► Alarms that are activated while existing alarms are muted are audible.

► The mute timer may be reset with each new active alarm.

► Muting an alarm does not clear the visual alarm.

NOTE Muting an alarm clears the signal sent through the remote alarm interface.

► If an alarm is still active when the mute timer expires, the active alarm is sent through the remote

alarm interface.

Mute an active alarm:

1 On the Home screen, press the MUTE button once to mute the alarm for ve minutes.

2 Press the MUTE button multiple times to extend the mute timer (up to 60 minutes).

9 Components

9.1 Control Door

Control door (circled).

9.2 Control Panel

A

B

C

Control panel, behind control door.

Label Description

A Main power switch

B Temperature controller

C Backup battery key switch

360093-1/P 17

i.Series® Models

9.3 Alarm Panel

A B C G H I

D

E

F

E

Left: PC1200i (230 V) alarm panel. Right: PC2200i alarm panel.

Label Description

A Flash port

B RS-232 COM port (optional)

C Remote alarm interface

DAlarm buzzer

E Circuit breakers

F Power connector

G Flash port

HAlarm buzzer

I Remote alarm interface

9.4 Chamber

A B A B D

C

Chamber probes (multiple models shown).

Label Description

A Temperature control and temperature chart recorder probe

B Temperature monitoring probe

C Tube for alarm checks (PC100i)

D Lower probe (PC2200i, 3200i, and 4200i)

360093-1/P 18

Horizon Series™ Models

Section III: Horizon Series™ Models

10 Operation

10.1 Initial Start Up

1 Plug the power cord into a grounded outlet that meets the electrical requirements on the product

specication label.

2 Switch the AC ON/OFF switch ON.

3 Connect the backup battery for the Power Failure alarm.

4 Connect the backup battery for the Motion alarm (PC4200h only).

5 Connect the backup battery for the temperature chart recorder.

6 Install the alarm check tube (PC100h). Position the tube below the probe tip.

7 Press the MUTE button if the Low Temperature alarm sounds.

NOTE ► When the door switch is bypassed, the incubator will continue to operate as if the

door is closed.

► The door switch controls power to the built-in agitator on PC4200h, and controls

power to the internal outlets on all other models.

► The door switch may be bypassed by opening the door and pulling the switch

cylinder.

10.2 CongureaPlateletAgitatorforUseinaHorizonSeriesIncubator(Optional)

Helmer Horizon Series platelet agitators may be installed in a stand-alone conguration, or in Helmer

Horizon Series platelet incubators.

NOTE Refer to the platelet agitator service manual for information regarding the installation of a

platelet agitator in a platelet incubator.

10.3 Load the PC4200h Built-In Agitator

NOTE ► This chapter applies to PC4200h models only.

► For instsructions in loading all other platelet agitator models, refer to the platelet

agitator operation manual.

Model Capacity

Random Bags Apheresis Bags

PF4200h 396 132

CAUTION When opening drawer, grasp handle (not label holder). Open one drawer at a time.

Open the drawer to be loaded and lay the platelet bags at.

► Avoid stacking bags.

► Maintain enough space around each bag for air circulation. For thicker bags, remove drawers.

► Place the tubing under or around the bag.

360093-1/P 19

Horizon Series™ Models

10.4 Chamber Setpoint

Temperature monitor/controller display and buttons.

NOTE ► Default setpoint is 22.0 °C

► Displayed chamber temperature may be different than setpoint.

► Refer to the service manual for program parameters and default parameter values.

1 On the temperature controller, press and hold *.

► The temperature controller displays the current setpoint.

2 While holding *press Up Arrow or Down Arrow to change the temperature setpoint.

► Setpoint changes in 0.1 ºC increments.

3 Release all buttons; the temperature setpoint is changed.

10.5 Temperature Monitor Setpoints

Temperature monitor/controller display and buttons.

Features accessible on the monitoring and control system:

► View current chamber temperature and active alarms

► View and change monitor temperature offset

► View and change temperature alarm setpoints

► View and change alarm delay settings

10.5.1 High Alarm Setpoint

NOTE ► Default setpoint is 24.0 °C.

► Alarm activates if the chamber temperature is greater than the alarm setpoint

► Refer to the service manual for program parameters and default parameter values.

Change the setpoint:

1 On the temperature monitor/controller, press and hold Up Arrow and Down Arrow. “tunE” and “oFF”

will ash on the display.

► The temperature monitor/controller is now in Level 1 program mode.

2 Press Up Arrow or Down Arrow as necessary to select the “AL.HI” parameter.

3 Hold *and press Up Arrow or Down Arrow to change the parameter.

4 Release all buttons; the parameter value is changed.

Other manuals for PC100i

1

This manual suits for next models

11

Table of contents

Other Helmer Accessories manuals