Helmer i.series User manual

HELMER SCIENTIFIC

14400 Bergen Boulevard

Noblesville, IN 46060 USA

PH +1.317.773.9073

FAX +1.317.773.9082

USA and Canada 800.743.5637

0086

ISO 13485:2003 CERTIFIED

360117-1/E

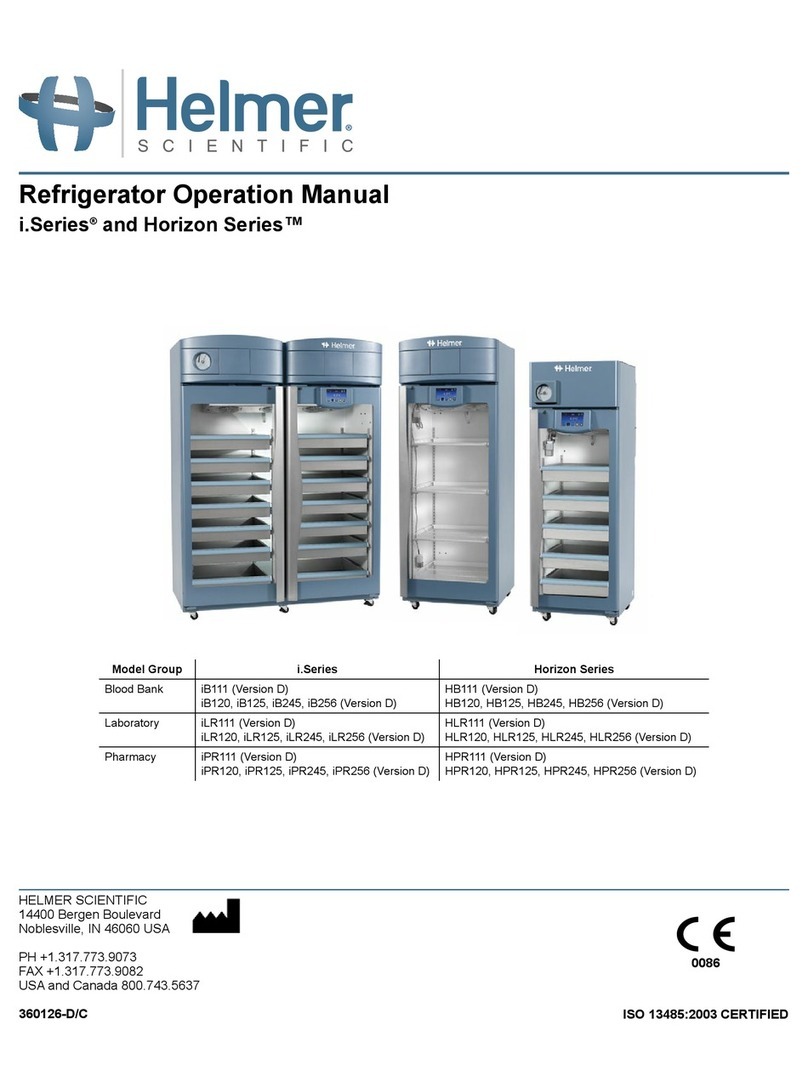

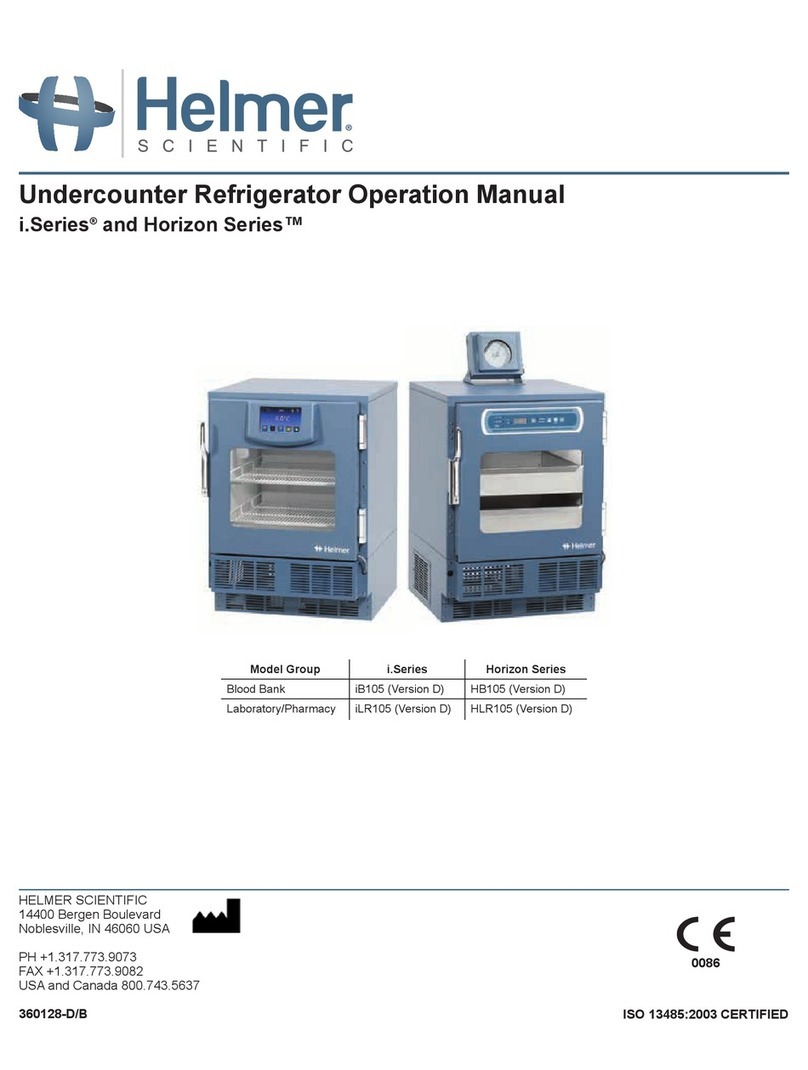

Model Group i.Series Horizon Series

Blood Bank iB105 (Version A) HB105 (Version A)

Laboratory/Pharmacy iLR105 (Version A) HLR105 (Version A)

Undercounter Refrigerator Service Manual

i.Series®and Horizon Series™

360117-1/E i

Document History

Revision Date CO Supersession Revision Description

E16 JAN 2014* 8580 Supersedes A,

B, C, D Revised layout for ease of navigation and locating information.

* Date submitted for Change Order review. Actual release date may vary.

360117-1/E ii

Contents

Section I: General Information ................................................... 6

1 About this Manual .......................................................... 6

1.1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Model References ......................................................................6

1.3 Copyright and Trademark ................................................................6

2 Safety .................................................................... 6

2.1 SafetyDenitions ......................................................................6

2.2 Product Labels ........................................................................6

2.3 Avoiding Injury.........................................................................7

3 Conguration .............................................................. 7

3.1 Model and Input Power ..................................................................7

3.2 Control System ........................................................................8

3.2.1 i.Series Control System ...........................................................8

3.2.2 Horizon Series Control System .....................................................8

3.3 Temperature Probes ....................................................................9

3.3.1 Fill Temperature Probe Bottle.......................................................9

3.3.2 Install Additional Probe Through Rear Port ............................................9

3.4 Chart Recorder ........................................................................9

3.4.1 Chart Recorder Access ..........................................................10

3.4.2 Install Chart Paper ..............................................................10

4 Alarm Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Compliance............................................................... 11

5.1 Regulatory Compliance.................................................................11

5.2 WEEE Compliance ....................................................................11

6 Warranty ................................................................. 12

6.1 Rel.i™ Product Warranty USA and Canada .................................................12

6.1.1 Rapid Resolution ...............................................................12

6.1.2 Compressor ...................................................................12

6.1.3 Parts .........................................................................12

6.1.4 Labor ........................................................................12

6.1.5 Additional Warranty Information ....................................................12

6.2 Outside of USA and Canada .............................................................13

Section II: i.Series®Models .................................................... 14

7 ProductConguration...................................................... 14

7.1 Install Battery for Backup Power ..........................................................14

7.2 External Monitoring Devices .............................................................14

7.2.1 Connect to Remote Alarm Interface .................................................15

7.3 Move Drawers, Shelves, and Baskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.4 Drawer Labels ........................................................................16

7.5 Move Slides and Brackets...............................................................16

7.6 Level the Refrigerator ..................................................................16

7.7 Optional Adapter Kits for Medication Dispensing Locks ........................................17

360117-1/E iii

7.8 Reverse Door Hinge and Handle .........................................................17

7.8.1 Remove the Door and Hinges .....................................................17

7.8.2 Reinstall the Door and Hinges .....................................................19

7.9 Stacked Undercounter Units .............................................................21

8 Temperature Monitor Settings ............................................... 21

8.1 Home Screen ........................................................................21

8.1.1 Home Screen Functions..........................................................22

8.2 Main Screen .........................................................................22

8.3 Temperature Graph ....................................................................23

8.3.1 Enable or Disable the Temperature Graph............................................23

8.4 ChangeCongurationPassword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.5 Calibrate Chamber Temperature Probe ....................................................24

8.6 Factory Default Settings ................................................................25

8.7 Restore Factory Default Settings .........................................................26

8.8 Alarm Settings........................................................................26

8.8.1 Alarm Volume ..................................................................26

8.8.2 Alarm Pulse ...................................................................26

8.8.3 High Chamber Temperature Alarm..................................................27

8.8.4 Low Chamber Temperature Alarm ..................................................27

8.8.5 Condenser Temperature Alarm ....................................................27

8.8.6 Door Ajar Alarm ................................................................28

8.8.7 Power Failure Alarm .............................................................28

8.8.8 Chart Paper Alarm ..............................................................28

8.9 Test Alarms ..........................................................................29

8.9.1 Automatic Chamber Temperature Alarm Test..........................................29

8.9.2 Manual Chamber Alarm Test ......................................................30

8.9.3 Power Failure Alarm Test .........................................................31

8.9.4 Door Ajar Alarm Test.............................................................31

8.9.5 No Battery Alarm Test............................................................31

8.10 Additional System Settings ..............................................................32

8.10.1 Screen Contrast ................................................................32

8.10.2 Date and Time .................................................................32

8.10.3 Display Language...............................................................32

8.10.4 Temperature Units ..............................................................33

8.11 Event Log ...........................................................................34

8.11.1 Event Details ..................................................................35

8.12 Upgrade System Firmware ..............................................................35

8.13 Reset the i.Center Monitoring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.14 View Manufacturer and Product Information.................................................36

9 Temperature Controller Setpoints ............................................ 36

9.1 Operational (Level 1) Parameters and Values (OU) ...........................................37

9.2 Control (Level 2) Parameters and Values (Cn) ...............................................37

9.3 Security (Level 3) Parameters and Values (SE) ..............................................37

9.4 Error Codes..........................................................................37

9.5 Change the Refrigerator Setpoint .........................................................38

9.6 Change the Control Sensor Offset ........................................................38

9.7 Change the Hysteresis Value ............................................................38

10 Maintenance .............................................................. 39

10.1 Recharge Refrigerant ..................................................................39

10.2 Test Monitoring System Backup Batteries...................................................39

360117-1/E iv

10.3 Replace Monitoring System Backup Batteries ...............................................40

10.4 Replace the LED Lamp Strip.............................................................40

10.5 Clean the Refrigerator..................................................................40

10.5.1 Condenser Grill ................................................................40

10.5.2 Exterior .......................................................................40

10.5.3 Interior .......................................................................40

10.5.4 Door Gaskets ..................................................................40

10.6 Unit Cooler Cover Removal and Installation .................................................41

10.6.1 Remove the Unit Cooler Cover ....................................................41

10.6.2 Install the Unit Cooler Cover ......................................................42

10.7 Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11 Troubleshooting........................................................... 42

11.1 General Operation Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.2 Chamber Temperature Problems .........................................................43

11.3 Alarm Activation Problems ..............................................................44

11.4 Testing Problems......................................................................47

11.5 Condensation Problems ................................................................48

12 Parts .................................................................... 49

12.1 Front ...............................................................................49

12.1.1 Monitoring System ..............................................................49

12.1.2 i.Center Display Parts............................................................50

12.1.3 Lower Panel ...................................................................51

12.2 Rear................................................................................52

12.2.1 Electrical Tray..................................................................53

12.3 Interior ..............................................................................54

12.3.1 Lighting.......................................................................55

12.3.2 Unit Cooler ....................................................................55

12.4 Door Hinges .........................................................................56

12.5 Side Access Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13 Schematics ............................................................... 58

13.1 i.Series Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

14 i.Center Screen Reference .................................................. 59

Section III: Horizon Series™ Models ............................................. 61

15ProductConguration ...................................................... 61

15.1 Install Battery for Backup Power ..........................................................61

15.2 External Monitoring Devices .............................................................61

15.2.1 Connect to Remote Alarm Interface .................................................62

15.3 Move Drawers, Shelves, and Baskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

15.4 Move Slides and Brackets...............................................................63

15.5 Level the Refrigerator ..................................................................63

15.6 Optional Adapter Kits for Medication Dispensing Locks ........................................63

15.7 Reverse Door Hinge and Handle .........................................................64

15.7.1 Remove the Door and Hinges .....................................................64

15.7.2 Reverse the Cable Routing in the Door ..............................................66

15.7.3 Reinstall the Door and Hinges .....................................................68

15.8 Stacked Undercounter Units .............................................................71

360117-1/E v

16 Settings.................................................................. 71

16.1 Monitor and Controller Interface ..........................................................71

16.2 Refrigerator Setpoint ...................................................................72

16.3 Temperature Alarm Setpoints ............................................................72

16.3.1 High Temperature Alarm..........................................................73

16.3.2 Low Temperature Alarm ..........................................................73

16.4 Temperature Calibration Setpoints ........................................................73

16.4.1 Monitor Offset..................................................................74

16.4.2 Control Sensor Offset............................................................75

16.4.3 Hysteresis.....................................................................75

16.5 Test Alarms ..........................................................................75

16.5.1 Chamber Temperature Alarm ......................................................75

16.5.2 Power Failure Alarm .............................................................76

16.5.3 Door Open Alarm ...............................................................76

17 Maintenance .............................................................. 77

17.1 Recharge Refrigerant ..................................................................77

17.2 Test Monitoring System Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

17.3 Replace LED Lamp Strip (Optional) .......................................................78

17.4 Clean the Refrigerator..................................................................78

17.4.1 Condenser Grill ................................................................78

17.4.2 Exterior .......................................................................78

17.4.3 Interior .......................................................................78

17.4.4 Door Gaskets ..................................................................78

17.5 Unit Cooler Cover Removal and Installation .................................................79

17.5.1 Remove the Unit Cooler Cover ....................................................79

17.5.2 Install the Unit Cooler Cover ......................................................79

17.6 Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

18 Troubleshooting ........................................................... 81

18.1 General Operation Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

18.2 Chamber Temperature Problems .........................................................81

18.3 Alarm Activation Problems ..............................................................82

18.4 Condensation Problems ................................................................84

19 Parts .................................................................... 86

19.1 Front ...............................................................................86

19.1.1 Control System Display ..........................................................86

19.1.2 Control and Monitoring ...........................................................87

19.1.3 Lower Panel ...................................................................87

19.2 Rear................................................................................88

19.2.1 Electrical Tray..................................................................89

19.3 Interior ..............................................................................90

19.3.1 Lighting (Optional) ..............................................................91

19.3.2 Unit Cooler ....................................................................91

19.4 Door Hinges .........................................................................92

19.5 Side Access Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

20 Schematics ............................................................... 94

20.1 Horizon Series Schematic...............................................................94

360117-1/E 6

General Information

Section I: General Information

1 About this Manual

1.1 Intended Audience

This manual is intended for use by end users of the refrigerator and authorized service technicians.

1.2 Model References

Generic references are used throughout this manual to group models that contain similar features. For

example, “105 models” refers to all models of that size (iB105, iLR105, HB105, HLR105). This manual

coversallundercounterrefrigerators,whichmaybeidentiedsingly,bytheirsize,orbytheirrespective

“Series.”

1.3 Copyright and Trademark

Helmer®, i.Series®, i.Center®, Horizon Series™, and Rel.i™ are registered trademarks or trademarks of

Helmer, Inc. in the United States of America. Copyright © 2014 Helmer, Inc. All other trademarks and

registered trademarks are the property of their respective owners.

Helmer,Inc.,doingbusinessas(DBA)HelmerScienticandHelmer.

2 Safety

Includes general safety information for refrigerator operation.

2.1 SafetyDenitions

The following general safety alerts appear with all safety statements within this manual. Read and abide

by the safety statement that accompanies the safety alert symbol.

WARNING The safety statement that follows this safety alert symbol indicates a hazardous situation

which, if not avoided, could result in serious injury.

CAUTION The safety statement that follows this safety alert symbol indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury.

NOTICE The safety statement that follows this safety alert symbol indicates a situation which, if

not avoided, could result in damage to the product or stored inventory.

2.2 Product Labels

Caution: Risk of damage

to equipment or danger to

operator

Caution: Unlock all casters

Caution: Hot surface Earth / ground terminal

Caution: Shock/electrical

hazard

Protective earth / ground

terminal

360117-1/E 7

General Information

2.3 Avoiding Injury

► Review safety instructions before installing, using, or maintaining the equipment.

► Before moving unit, ensure door is closed and casters (if installed) are unlocked and free of debris.

► Before moving unit, disconnect the AC power cord and secure the cord.

► Never physically restrict any moving component.

► Avoid removing electrical service panels and access panels unless so instructed.

► Keep hands away from pinch points when closing the door.

► Avoid sharp edges when working inside the electrical compartment and refrigeration compartment.

► Ensure biological materials are stored at recommended temperatures determined by standards,

literature, or good laboratory practices.

► Proceed with caution when adding and removing samples from the refrigerator.

► Use supplied power cord only.

► UsingtheequipmentinamannernotspeciedbyHelmerScienticmayimpairtheprotection

provided by the equipment.

► Decontaminatepartspriortosendingforserviceorrepair.ContactHelmerScienticoryour

distributor for decontamination instructions and a Return Authorization Number.

► Ensure biological materials are stored safely, in accordance with all applicable organizational,

regulatory, and legal requirements.

► Therefrigeratorisnotconsideredtobeastoragecabinetforammableorhazardousmaterials.

3 Conguration

3.1 Model and Input Power

NOTE Service information varies depending on the model and power requirements.

Thisinformationappearsontheproductspecicationlabel,locatedontherearoftherefrigerator.The

model also appears on a label located in the chamber on the upper side of the right wall.

www.helmerinc.com

REF

SN

ILR105

000000

VER

A

REF

SN

Weight 200 lb / 75 kg

VOLT 115 V

ILR105

000000

VER

A

Pharmacy Refrigerator

Noblesville, IN USA

www.helmerinc.com

HZ 60

Amps 5 A

2009

0086

A

B

C

D

Left: Chamber label. Right: Product specication label (located on the rear at lower left).

Label Description

A Model (REF)

B Serial number (SN)

C Version

D Power requirements

360117-1/E 8

General Information

3.2 Control System

NOTE Service information varies depending on the control system.

Helmer refrigerators have one of two control systems installed. The type of control system varies by

model.

3.2.1 i.Series Control System

i.Series refrigerators are equipped with the i.Center monitoring system and independent temperature

controller.

i.Center monitor Independent temperature controller.

3.2.2 Horizon Series Control System

Horizon Series refrigerators feature the Horizon Series combined monitor and temperature controller. The

Horizon Series system controls chamber temperature and monitors and displays operational information.

Horizon Series combined monitoring and control system (user interface).

360117-1/E 9

General Information

3.3 Temperature Probes

Number and location of probes varies by model. External probes may be introduced through existing rear

port and immersed in existing probe bottle.

For each probe bottle, use:

► Approximately 4 oz. (120 mL) of product simulation solution (10:1 ratio of water to glycerin).

Left: Probe bottle with temperature probe. Right: Access port on rear of refrigerator.

3.3.1 Fill Temperature Probe Bottle

NOTICE Temperature probes are fragile; handle with care.

1 Remove all probes from bottle and remove bottle from bracket.

2 Removecapandllwithapproximately4oz.(120mL)ofproductsimulationsolution.

3 Install cap and place bottle in bracket.

4 Replace probes, immersing at least 2” (50 mm) in solution.

3.3.2 Install Additional Probe Through Rear Port

1 Peel back putty to expose port.

2 Insert probe through port into chamber.

3 Insert probe into bottle.

4 Replace putty, ensuring a tight seal.

3.4 Chart Recorder

If installed, refer to the Temperature Chart Recorder Operation and Service Manual on CD.

The chart recorder has a battery system, enabling a period of continuous operation if power is lost.

Battery life varies by manufacturer as well as voltage level remaining. Providing full power is available,

backup power for the temperature chart recorder is available for up to 14 hours.

Prior to use:

► Connect the chart recorder to AC power.

► Install battery.

► Add paper.

► Install the chart recorder probe in the probe bottle, through the rear port.

► Calibrate chart recorder to match chamber temperature.

360117-1/E 10

General Information

3.4.1 Chart Recorder Access

Open door by pulling door open.

3.4.2 Install Chart Paper

1 Press and hold C button.Whenstylusbeginstomoveleft,releasebutton.TheLEDashesto

indicate current temperature range.

2 When stylus stops moving, remove chart knob then move knob up and away.

3 Place chart paper on chart recorder.

4 Gently lift stylus and rotate paper so current time line corresponds to time line groove.

5 Hold chart paper and reinstall chart knob.

NOTE For accurate temperature reading, ensure that current time is aligned with time line

groove when chart knob is tightened.

6 Conrmtemperaturerangeissettothecorrectvalue.

7 Press and hold C button. When stylus begins to move right, release button.

8 Conrmstylusismarkingtemperaturecorrectly.

360117-1/E 11

General Information

4 Alarm Reference

If an alarm condition is met, an alarm activates. Some alarms are visual only; others are visual and

audible. Some alarms are sent through the remote alarm interface.

The table indicates if an alarm is audible (A), visual (V), or sent through the remote alarm interface (R).

Alarm Alarm Type

High Temperature A, V, R

Low Temperature A, V, R

Compressor Temperature A, V, R (i.Series)

Door Open (Time) A, V, R

Power Failure A, V, R

Low Battery V (i.Series)

No Battery A, V, R (i.Series)

Probe Failure A, V, R

Chart paper V (i.Series)

5 Compliance

5.1 Regulatory Compliance

This device complies with the requirements of directive 93/42/EEC concerning

Medical Devices, as amended by 2007/47/EC.

0086

Sound level is less than 70 dB(A).

EC REP Emergo Europe

Molenstraat 15

2513 BH

The Hague, Netherlands

5.2 WEEE Compliance

The WEEE (waste electrical and electronic equipment) symbol (right) indicates

compliance with European Union Directive WEEE 2002/96/EC and

applicable provisions. The directive sets requirements for labeling and

disposal of certain products in affected countries.

When disposing of this product in countries affected by this directive:

► Do not dispose of this product as unsorted municipal waste.

► Collect this product separately.

► Use collection and return systems available locally.

For more information on the return, recovery, or recycling of this product, contact your local distributor.

360117-1/E 12

General Information

6 Warranty

6.1 Rel.i™ Product Warranty USA and Canada

For technical service needs, please contact Helmer at 800-743-5637 or www.helmerinc.com. Have the

model and serial number available when calling.

6.1.1 Rapid Resolution

When a warranty issue arises it is our desire to respond quickly and appropriately. The service department

atHelmeristhereforyou.Helmerwilloverseethehandlingofyourwarrantyservicefromstarttonish.

Therefore, Helmer must give advance authorization for all service calls and/or parts needs relating to a

warranty issue. Any repeat service calls must also be authorized as well. This allows for proper diagnosis

and action. Helmer will not be responsible for charges incurred for service calls made by third parties prior

toauthorizationfromHelmer.Helmerretainstherighttoreplaceanyproductinlieuofservicingitintheeld.

6.1.2 Compressor

For the warranty period listed below, Helmer will supply the refrigeration compressor, if it is determined

to be defective, at no charge, including freight. Helmer will not be liable for installation, refrigerant, or

miscellaneouschargesrequiredtoinstallthecompressorbeyondtherstyearofthewarrantyperiod.

► i.Series model compressor warranty period is seven (7) years.

► HorizonSeriesmodelcompressorwarrantyperiodisve(5)years.

6.1.3 Parts

For a period of two (2) years, Helmer will supply at no charge, including freight, any part that fails

due to defects in material or workmanship under normal use, with the exception of expendable items.

Expendableitemssuchasglass,lters,lightbulbs,anddoorgasketsareexcludedfromthiswarranty

coverage.InspectionofdefectivepartsbyHelmerwillbenalindeterminingwarrantystatus.Warranty

procedures must be followed in all events.

6.1.4 Labor

For a period of one (1) year, Helmer will cover repair labor costs (including travel) and the cost of

refrigerant and supplies necessary to perform authorized repairs. Repair service must be performed by

an authorized Helmer service agency following the authorization process detailed above. Alternatively,

your facility’s staff may work with a Helmer technician to make repairs. Labor costs for repairs made by

unauthorized service personnel, or without the assistance of a Helmer technician, will be the responsibility

of the end user.

6.1.5 Additional Warranty Information

The time periods set forth above begin two (2) weeks after the original date of shipment from Helmer.

Warranty procedures set forth above must be followed in all events.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. NO WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR PARTICULAR PURPOSE SHALL APPLY.

THE LIABILITY, IF ANY, OF HELMER FOR DIRECT DAMAGES WHETHER ARISING FROM A

BREACH OF ANY SALES AGREEMENT, BREACH OF WARRANTY, NEGLIGENCE, OR INDEMNITY,

STRICT LIABILITY OR OTHER TORT, OR OTHERWISE WITH RESPECT TO THE GOODS OR ANY

360117-1/E 13

i.Series® Models

SERVICES IS LIMITED TO AN AMOUNT NOT TO EXCEED THE PRICE OF THE PARTICULAR GOODS

OR SERVICES GIVING RISE TO THE LIABILITY. IN NO EVENT SHALL HELMER BE LIABLE FOR

ANY INDIRECT, INCIDENTAL, CONSEQUENTIAL, OR SPECIAL DAMAGES, INCLUDING WITHOUT

LIMITATION DAMAGES RELATED TO LOST REVENUES OR PROFITS, OR LOSS OF PRODUCTS.

Thiswarrantydoesnotcoverdamagescausedintransit,duringinstallationbyaccident,misuse,re,ood,or

acts of God. Further, this warranty will not be valid if Helmer determines that the failure was caused by a lack

of performing recommended equipment maintenance (per Helmer manual) or by using the product in a manner

other than for its intended use. Installation and calibration are not covered under this warranty agreement.

6.2 Outside of USA and Canada

Consult your local distributor for warranty information.

360117-1/E 14

i.Series® Models

Section II: i.Series®Models

7 ProductConguration

7.1 Install Battery for Backup Power

The monitoring system and chart recorder each have a battery system, enabling a period of continuous

operation if power is lost.

NOTE The monitoring system will not start on battery power alone. If the refrigerator was

previously not connected to AC power and the batteries are installed, the monitoring

system will not run on battery power.

Battery life varies by manufacturer as well as voltage level remaining. Providing full power is available

and no battery-related alarms are active, backup power for the monitoring system is available for up to

two hours.

NOTICE Wheninstallingreplacementbatteries,useonlybatterieswhichmeetsthespecications

outlined in chapter 10.7 (Supplies).

The batteries are located below the chamber, behind the front cover.

Monitoring system backup batteries.

Five batteries are installed and one battery is taped next to the backup battery holder. Install the sixth

battery to provide power to the monitoring system in the event of an AC power failure.

7.2 External Monitoring Devices

CAUTION ► The interface on the remote alarm monitoring system is intended for connection to

the end user’s central alarm system(s) that uses normally-open or normally-closed

dry contacts.

► If an external power supply exceeding 30 V (RMS) or 60 V (DC) is connected to the

remote alarm monitoring system’s circuit, the remote alarm will not function properly;

may be damaged; or may result in injury to the user.

NOTE In the event of a power failure, the power failure alarm condition is transmitted through

the remote alarm contacts.

The remote alarm interface is a relay switch with three terminals:

► Common (COM)

► Normally Open (NO)

► Normally Closed (NC)

360117-1/E 15

i.Series® Models

Terminals are dry contacts and do not supply voltage. Interface circuit is either normally open or normally

closed, depending on terminals used. Requirements for your alarm system determine which alarm wires

must connect to terminals.

The terminals on the remote alarm interface have the following maximum load capacity:

► 0.5 A at 125 V (AC): 1 A at 250 V (DC)

7.2.1 Connect to Remote Alarm Interface

1 Switch AC ON/OFF switch OFF. Remove one battery from the monitoring system backup battery

holder.

2 On back of refrigerator, locate the remote alarm terminals.

3 Connect remote alarm wires to appropriate terminals, according to requirements for your alarm

system.

4 Use a cable tie to relieve strain on alarm wires (as necessary).

5 Reinstall the battery in the monitoring system backup battery holder. Switch AC ON/OFF switch ON.

6 Touch MUTE to disable the high temperature alarm while refrigerator reaches operating temperature.

7.3 Move Drawers, Shelves, and Baskets

Storage features.

CAUTION ► Keep hands away from pinch points when closing the door.

► Before moving drawers, ensure they are completely empty for safe lifting.

► Maximum basket, drawer, or shelf load is 100 lbs (46 kg).

NOTICE Before moving storage components, protect stored items in refrigerator from extended

exposure to adverse temperature.

Remove a drawer or basket:

1 Pull drawer or basket out until it stops.

2 On the right rail, locate the release tab and press downward.

3 While holding the right release tab downward, locate the release tab on the left rail and press upward.

4 Pull drawer or basket free of the slides.

Install a drawer or basket:

1 Align end guides on drawer or basket with the slides.

2 Gently push drawer or basket into chamber until it stops.

3 Pull drawer or basket out until it stops; check for smooth operation.

360117-1/E 16

i.Series® Models

Remove a shelf:

1 With one hand, lift front edge of the shelf from the front brackets.

2 With the other hand, reach under the shelf and bump rear edge of the shelf upward to disengage rear

brackets.

Install a shelf:

1 Insert shelf into chamber, placing it on brackets.

2 Gently bump rear edge of the shelf downward to engage brackets.

3 Pulling shelf forward gently; shelf should not disengage from rear brackets.

7.4 Drawer Labels

Drawer with sample label (not provided).

7.5 Move Slides and Brackets

Remove drawer slides:

1 Using a screwdriver, remove front bracket retainers.

2 Tap front brackets upward to disengage standards.

3 Remove slides from standards.

Install drawer slides:

1 Insert slides into standard at appropriate height.

2 Tap front brackets downward to engage standards.

3 Using a screwdriver, install front bracket retainers.

Remove shelf brackets:

1 Using a screwdriver, remove front bracket retainers.

2 Tap front brackets upward to disengage standards.

3 Remove front brackets from standards.

Install shelf brackets:

1 Insert front brackets into standard at appropriate height.

2 Tap front brackets downward to engage standards.

3 Using a screwdriver, install front bracket retainers.

7.6 Level the Refrigerator

NOTE ► Leveling feet are optional.

► Helmer recommends the use of leveling feet.

► A bubble level may be used to ensure the refrigerator is level.

Leveling feet must be adjusted to provide unit cooler drainage.

360117-1/E 17

i.Series® Models

Front-to-back:

1 Rotate the leveling feet to raise or lower leveling feet.

2 When refrigerator is properly leveled, bottom of the unit cooler will slope downward from front to back

(toward the condensate drain line).

Side-to-side:

1 Rotate the leveling feet to raise or lower leveling feet.

2 Whenrefrigeratorisproperlyleveled,bottomoftheunitcoolerwillbehorizontal(paralleltotheoor).

7.7 Optional Adapter Kits for Medication Dispensing Locks

Contact Helmer Technical Service or your distributor for service documentation pertaining to medication

dispensing locks.

7.8 Reverse Door Hinge and Handle

NOTICE Before reversing door hinge and handle, protect stored items in refrigerator from

extended exposure to adverse temperature.

NOTE Refrigeratormustbeontheoororonanelevatedworksurfacewithenoughspacein

front of the refrigerator to lay the door face-down for disassembly.

7.8.1 Remove the Door and Hinges

1 Open the lower front control panel. Switch AC ON/OFF switch OFF. Remove one battery from the

backup battery holder.

2 Remove the door handle assembly.

a Remove four screws holding the door handle assembly on the door.

b Set the door handle assembly aside.

Remove

Door handle assembly.

360117-1/E 18

i.Series® Models

3 Remove door latch / door catch.

a Remove two screws holding the door latch plates and spacer bar on the cabinet.

b Set the latch plates and spacer bar aside.

Strike plate

Remove

2 screws

Cabinet

Door latch plate.

4 With the door shut, remove the cover plate from both hinges.

5 Remove the spring assembly from the lower hinge.

a Use a J-hook tool to engage the left-most hole in the spring cap and rotate the spring cap from

left to right, and hold.

b Remove the pin from the spring cap.

c Allow the spring to relax.

d Use a J-hook tool to engage any hole in the spring cap compress spring downward.

e Remove spring assembly from the lower hinge.

f Set the spring assembly aside.

NOTICE A second person should assist by supporting the door while the hinges are removed.

NOTE The two screws holding the hinge on the door are longer than the three screws holding

the hinge on the cabinet. The screws must be installed in the same location when

moving the hinge to the opposite side of the door.

6 Remove the lower hinge.

a Support the door.

b Removevescrewsattachingthelowerhingetothedoorandcabinet.

c Remove the lower hinge.

d Reverse the hinge manually (as if moving the hinge from a fully-closed to a fully-open position).

e Set the lower hinge aside.

f Continue to support the door.

7 Remove the upper hinge.

a Removevescrewsattachingtheupperhingetothedoorandcabinet.

b Remove the upper hinge.

c Reverse the hinge manually (as if moving the hinge from a fully-closed to a fully-open position).

d Set the upper hinge aside.

360117-1/E 19

i.Series® Models

Shim

Remove 2

screws (long)

Remove 3

screws (short)

Cabinet

Hinge plate

Hinge

Door

Hinge removal (lower hinge shown with spring removed).

8 Lay the door face-down in front of the cabinet.

7.8.2 Reinstall the Door and Hinges

1 Install the hinges and hinge plates on the door.

a Hand-thread two screws through each hinge and into the door.

b Leave the screws slightly loose.

c If a shim was used on the lower hinge, transfer the shim to the new hinge location.

NOTE Ensure that the upper and lower hinges are not interchanged when moving the hinges to

the opposite side of the door.

2 screws

(long)

Hinge plate

Shim

Door

Hinge

Attach hinge to door (lower hinge shown).

NOTICE A second person should assist by supporting the door while the hinges are installed.

2 Install the door on the cabinet.

a Lift the door to the cabinet.

b Align the holes in the hinges with the corresponding holes in the cabinet.

c Hand-thread three screws through each hinge and into the cabinet.

d Do not allow the weight of the door to rest on the hinges.

3 screws

(short)

Hinge

Cabinet

Attach hinge to cabinet (lower hinge shown).

Other manuals for i.series

10

This manual suits for next models

5

Table of contents

Other Helmer Refrigerator manuals

Helmer

Helmer i Series Installation and user guide

Helmer

Helmer i.series User manual

Helmer

Helmer iB105 User manual

Helmer

Helmer i.series User manual

Helmer

Helmer i Series User manual

Helmer

Helmer i.series User manual

Helmer

Helmer i Series User manual

Helmer

Helmer iB111 (Version A) User manual

Helmer

Helmer i.series User manual

Helmer

Helmer iBX020 User manual