Henderson ICE CONTROL FSM AUGER User manual

08/22/18

ICE CONTROL SPREADER

MODEL: FSM AUGER

SERIAL #:

MANUAL # 134376

INSTRUCTIONS FOR ORDERING PARTS

Order parts from the authorized dealer covering your area.

DEALER:

Phone #:

ALWAYS GIVE THE MODEL AND SERIAL NUMBER.

To obtain parts promptly, give part name and part number.

Give post office address, town, and state where the parts are to be shipped. UPS (United

Parcel Service) and other carriers will not ship to a post office box. You must use a street

address. Also be sure to specify whether material is to be shipped by freight, express, parcel

post, or UPS. All UPS shipments will be normal surface routing unless specified otherwise.

Confirm all telephone or FAX orders in writing.

Credit for new parts not needed must be obtained from the dealer from whom they were

purchased.

Unless claims for shortages or errors are made immediately upon receipt of goods, they will not

be considered.

Inspect all goods received immediately upon receipt. When damaged goods are received,

insist that a full description of the damage be made by the carrier agent on the freight bill. If

this description is insisted upon, full damage can be collected from the transportation company.

No responsibility is assumed for delay or damage to merchandise while in transit. Dealer’s

responsibility ceases upon delivery of shipment to the transportation company from whom a

receipt is received showing that shipment was in good condition when delivered to them.

Therefore, claims (if any) should be filed with the transportation company and not with the

dealer.

08/22/18

5/2012

COMPLETE WARRANTY POLICY

A. PARTS REPLACEMENT AND REPAIR:

Henderson Products, Inc. warrants its manufactured products to be free from defects in material or

workmanship for a period of one year after delivery to the original user, or 18 months after factory

invoice, whichever occurs first. This warranty of our products under normal use and service is limited

to replacement or repair at the company's factory of any parts which are returned to the factory freight

prepaid, and upon examination found to be defective.

B. EXCLUSIONS:

1. This warranty is expressly limited to parts replacement and repair, and is not transferable. Any

expressed warranty not herein provided, and any remedy for breach of contract is excluded and

disclaimed. The implied warranties of merchantability and of fitness for any particular purpose are

limited to one year from delivery to the original user, or 18 months from factory invoice, whichever

occurs first.

2. Any component or part manufactured by others will carry that manufacturer’s warranty, and in no

case will Henderson Products, Inc. be liable, either expressed or implied, for warranties in excess

of those made by the original manufacturer.

3. Henderson Products, Inc. shall not be liable for loss of time, manufacturing costs, labor,

material, loss of profits, incidental, special or consequential damages, direct or indirect,

because of defective products, whether due to claims arising under the contract of sale or

independently thereof, and whether or not such claim is based on contract, tort or warranty.

4. Repairs or modifications done by others, or parts from other sources outside the company's

factory are not covered by this warranty.

5. No agent, employee, or representative of Henderson Products, Inc. has any authority to make any

affirmation, representation, or warranty concerning Henderson Products, Inc. products, except as

specifically stated above.

WARRANTY PROCEDURE

1. Prior authorization by Henderson Products, Inc. must be obtained for all warranty work.

2. Contact our distributor or Henderson Products, Inc. giving complete details of your request, the unit

involved, including serial number, date purchased, who purchased from, and the nature of or reason

for the claim.

3. A Claim number will be assigned, and is required, whenever any warranty is to be paid either in the

form of credit, replacement of parts, or service work. The assignment of this does not guarantee

warranty will be allowed. This number is to identify the request and track parts that may need to be

returned.

4. When warranty replacement parts are shipped, you may be required to return defective part(s) for

inspection by Henderson Products, Inc. or the original manufacturer. In this case, you will be invoiced

for shipment of new components until the old unit is returned.

STD Warranty Card 08/18

HENDERSON PRODUCTS, INC.

WARRANTY CARD

Warranty card must be in the files of HENDERSON PRODUCTS, INC. within 14 days after

delivery to the initial user. The Dealer is responsible to see that the card is completed with

information required and returned.

HENDERSON PRODUCTS, INC. will not be obligated to warranty machines unless this

registration is on file. For future reference and records, please record the model and serial

number of your unit.

MODEL NUMBER _____________________

SERIAL NUMBER _____________________

Web Site: www.hendersonproducts.com

PLEASE PRINT INFORMATION BELOW AND RETURN TO:

Henderson Products, Inc.

Attention: Customer Service

1085 South Third Street

Manchester, Iowa 52057

SERIAL NO. ________________________

MODEL NO. ________________________

CUSTOMER NAME OR FIRM: ______________________________________________

CUSTOMER ADDRESS: ___________________________________________________

_______________________________________________________________________

DATE OF DELIVERY TO CUSTOMER: _______________________________________

DEALER: _______________________________________________________________

LOCATION: _____________________________________________________________

_______________________________________________________________________

MAIL WITHN 14 DAYS AFTER DELIVERY OF UNIT

TO HENDERSON PRODUCTS, INC.

08/23/18

TABLE OF CONTENTS

FSM AUGER Spreader

Manual #134376

Page No.

Title Page

Customer Service Page

Warranty Information

Warranty Card

Table of Contents

I. Safety Information...............................................................................................1-00

A. Safety Information............................................................................. 1-01 - 1-02

B. Decal and Serial Number Locations .............................................................1-03

II. Installation/General Operating Procedures..........................................................2-00

A. Mounting Instructions ...................................................................................2-01

B. FSM Hydraulic Requirements.......................................................................2-02

C. Screen Installation Parts ..............................................................................2-03

D. Instructions for Spinner Use.........................................................................2-04

E. Material Spread Pattern................................................................................2-05

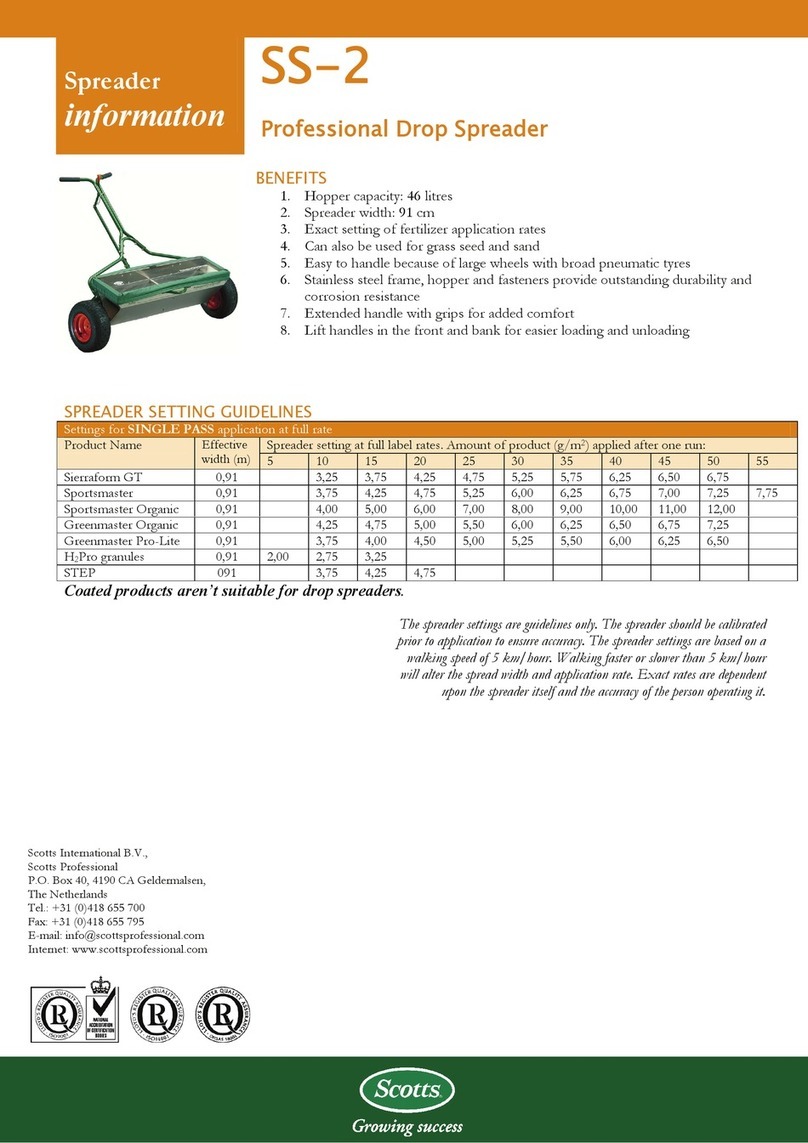

F. Application Rates, Salt and Sand.................................................................2-06

III. Service and Maintenance....................................................................................3-00

A. Spreader Lubrication....................................................................................3-01

B. Lubrication Chart..........................................................................................3-02

C. Maintenance.................................................................................................3-03

IV. Parts ...................................................................................................................4-00

A. Auger Idler Bearing Assembly......................................................................4-01

B. Conveyor Assembly......................................................................................4-02

C. Trunnion Latch Option..................................................................................4-03

D. Tip Up Spinner Chute Assembly...................................................................4-04

E. Spinner Chute Assembly..............................................................................4-05

F. Spinner Assembly, 18” Poly4-06 ..................................................................4-06

G. Extended Grease Tube ................................................................................4-07

H. Auger Safety Interlock..................................................................................4-09

I. Lights ................................................................................................ 4-10 - 4-11

J. FSM Stands ...................................................................................... 4-12 - 4-13

08/23/18

V. General Information ............................................................................................5-00

A. Bolt Torque Data..........................................................................................5-01

B. Dimension Chart...........................................................................................5-02

C. Approximate Density of Common Materials..................................................5-03

D. Table of Weights and Measures...................................................................5-04

08/18 Page 1-00

FSM

SAFETY

INFORMATION

08/18

THIS PAGE

IS LEFT BLANK

INTENTIONALLY.

08/18 Page 1-01

SAFETY

The Safety-Alert Symbol.

This symbol is on safety signs on the

equipment and in the manual.

This symbol indicates to you the potential for

personal injury and/or property damage.

Hazard Seriousness Levels.

The DANGER signal word indicates -

immediate hazards which WILL result in

severe personal injury or death.

DANGER

The WARNING signal word indicates -

hazards or unsafe practices which COULD

result in severe personal injury or death.

WARNING

The CAUTION signal word indicates -

hazards or unsafe practices which COULD

result in minor personal injury or product or

property damage.

CAUTION

Persons who install, mount, operate, or service this equipment must be properly instructed and

warned. Do not let anyone operate equipment without instruction.

Read operator manuals completely before operating equipment. Learn how to operate controls

properly.

Read decal instructions, cautions, and warnings. Read the safety messages in this manual and

on safety signs on the spreader unit. Replace missing or damaged safety signs.

Check spreader to ensure that all shields and grates are in place.

Page 1-02 08/18

SAFETY

Persons who install, mount, operate, or service this equipment must be properly instructed

and warned.

Read operator manuals completely before operating equipment.

Read decal instructions, cautions, and warnings. Decals and decal locations are shown on

the following page.

Check spreader to ensure that all shields and grates are in place.

Use care when mounting and dismounting.

The drive shafts, conveyor and spinner assemblies transmit great amounts of power, and

accordingly, are hazardous when in operation. All maintenance, inspections or operator

adjustments must be made with all power off.

Keep spreader and surrounding area clear of personnel and property when operating.

When traveling, especially fully loaded, this machine may have a high center of gravity. To

avoid overturning your vehicle, care should be exercised to use slow speed when turning or

driving on banked surfaces. Avoid driving on side slopes or bumpy surfaces when loaded.

Do not leave unit unattended and running. Completely disengage spreader, stop engine, and

remove the key before leaving truck.

If unit is equipped with a stand the hopper and tanks are to be completely empty prior to using

the stand.

DECAL/SERIAL#

08/18 Page 1-03

DECAL AND SERIAL NUMBER LOCATIONS

OPPOSITE SIDE

THIS SIDE

XXXX

SERIAL NUMBER

REAR VIEW

SIDE VIEW

6

PARTS LIST

DESCRIPTIONQTYPART#ITEM

DECAL,CAUTION,MOUNT/DISMOUNT4

50983

1

DECAL, CAUTION, KEEP HANDS OUT150986

2

DECAL,AUGER,SAFETY373800

3

PLATE,SERIAL

1744744

DECAL,LOGO, 2.7 X 6.82812265

DECAL,LOGO, 2.7 X 6.8,LH181226L

6

DECAL, NOTICE, HYD

185276

7

315

5

3

2

7

1

4

DECAL, WARNING, STAY CLEAR1523718

89

DECAL, SAFETY (ICE)

1752509

3

Page 1-04 08/18

THIS PAGE

IS LEFT BLANK

INTENTIONALLY.

08/18 Page 2-00

FSM

INSTALLATION/GENERAL

OPERATING PROCEDURES

08/18

THIS PAGE

IS LEFT BLANK

INTENTIONALLY.

A

B

489868* STRAP,RATCHET,HOLDOWN

DESCRIPTIONPART NO.

QTY.

ITEM

PARTS LIST

**

1TRUNNION LATCH KIT

* OPTIONAL ACCESSORIES

** SEE TRUNNION LATCH OPTION

Mtginstr

08/18

MOUNTING INSTRUCTIONS

Page 2-01

INSTALL STRAPS ON HOOKS AT FRONT AND REAR CORNERS OF SPREADER.

FRONT AND REAR STRAPS SHOULD BE PULLING IN OPPOSITE DIRECTIONS.

DEALER TO SUPPLY HOOK POINTS ON BODY

A

A

B

Page 2-02 09/18

FSM HYDRAULIC REQUIREMENTS

AUGER MOTOR:

•Char-Lynn 11.9 CIR motor.

•Maximum 20 GPM @ 2250 PSI.

SPINNER MOTOR

•Char-Lynn 2.2 CIR Motor.

•Maximum 10 gpm @ 1800 PSI.

MINIMUM PUMP REQUIREMENTS:

•15 gallon hydraulic oil reservoir (minimum).

•Gas engine - 10 GPM @ 1000 RPM.

•Diesel engine - 12 GPM @ 1000 RPM.

Table of contents

Popular Spreader manuals by other brands

Roth Manufacturing

Roth Manufacturing MS23A Owner's and operator's manual

Gardena

Gardena Comfort 500 Assembly instructions

Neilsen

Neilsen CT2215 Original instructions

Rauch

Rauch SA 250 Operator's manual

Trynex International

Trynex International SnowEx SL-80 Owner's/operator's manual

SnowEx

SnowEx SP-85 Owner's manual and installation instructions