Table of Contents

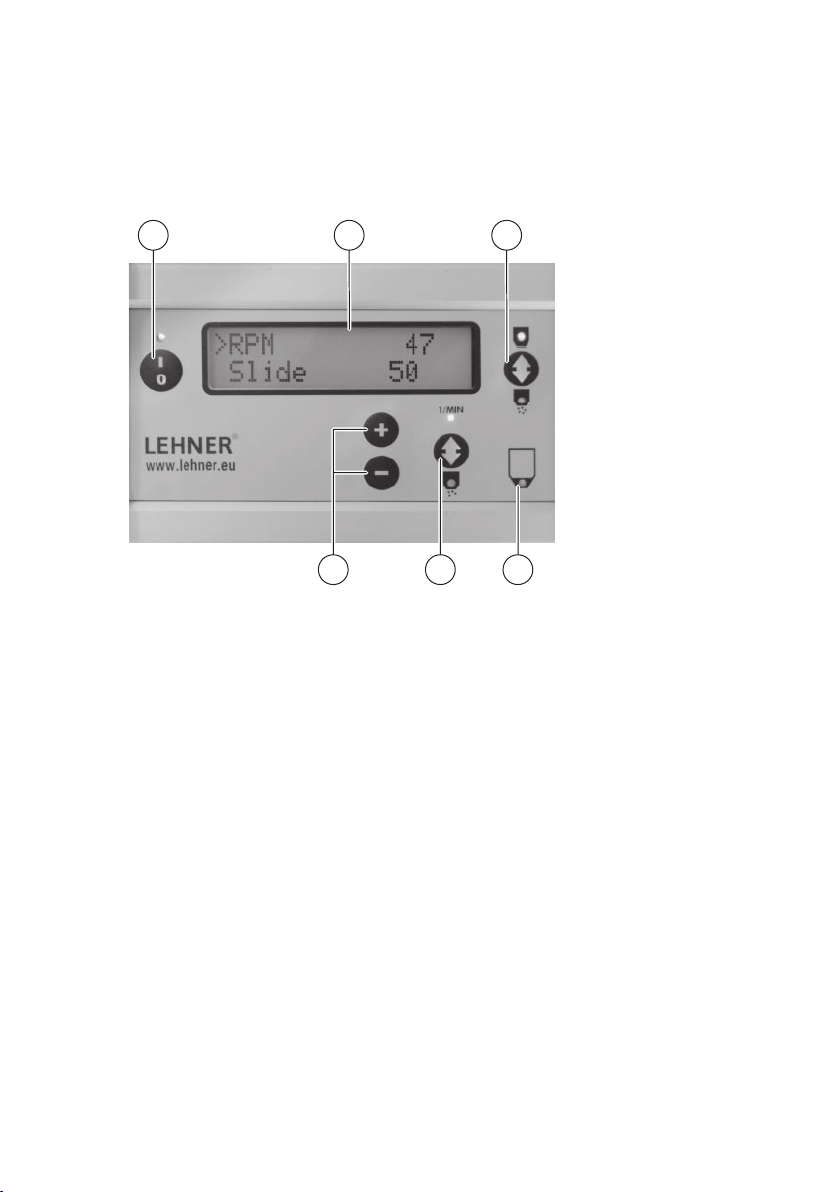

4 Settings and displays.......................................................18

4.1 Making settings ..................................................................................... 18

4.2 Language .............................................................................................. 18

4.3 Selecting the empty indicator ................................................................ 19

4.4 Setting signal for electronic lifting gear control (EHR)........................... 19

4.5 Setting cycle for electronic lifting gear control (EHR)

(special equipment for headland manager)........................................... 20

4.6 Adjusting the empty indicator ................................................................ 20

4.7 Displaying the spreader type................................................................. 21

4.8 Checks .................................................................................................. 21

4.9 Spreading width and turning procedure ................................................ 22

5 Special accessories..........................................................23

5.1 Attach standard rail ............................................................................... 23

5.2 Attach Vario rail ..................................................................................... 23

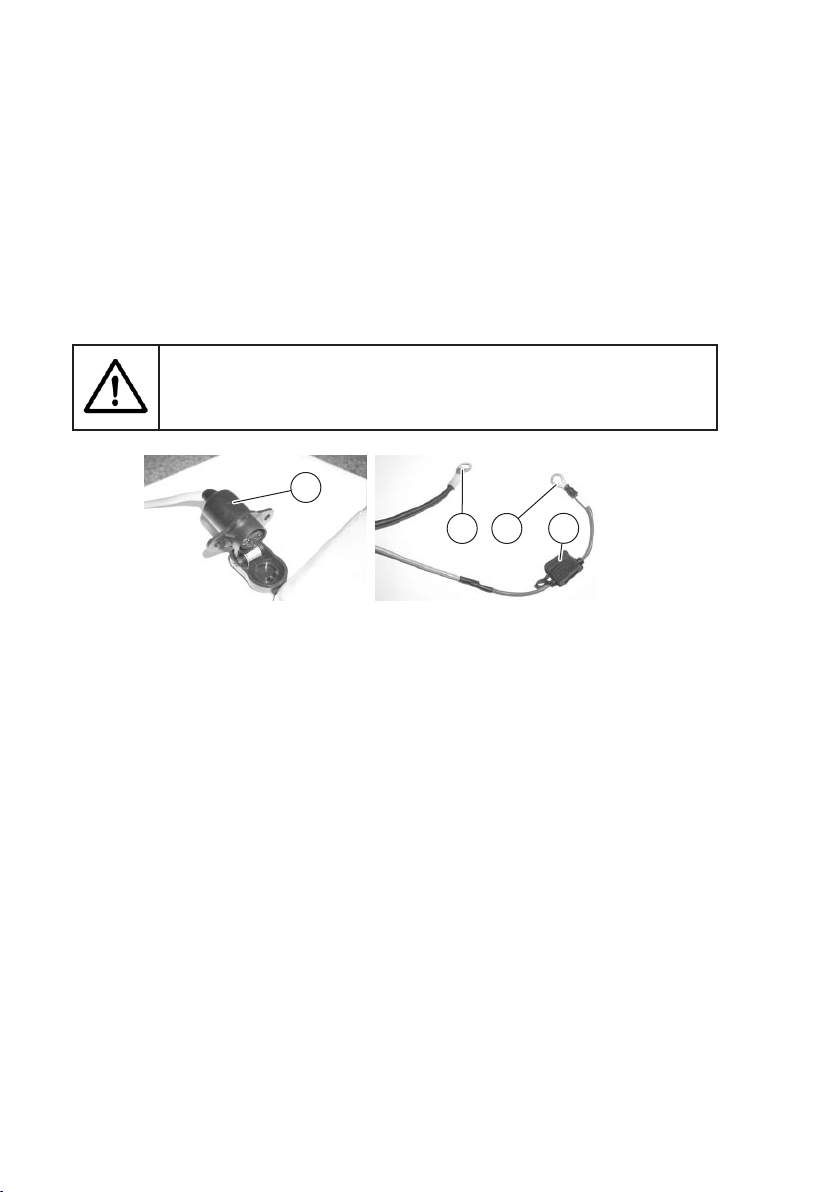

5.3 Headland manager................................................................................ 24

6 Maintenance and cleaning ...............................................26

6.1 Service .................................................................................................. 26

6.2 Cleaning ................................................................................................ 26

7 Appendix ...........................................................................27

7.1 EU Declaration of Conformity................................................................ 27

7.2 Distribution box reference list................................................................ 28

7.3 List of spare parts.................................................................................. 29

7.4 Troubleshooting..................................................................................... 33

7.5 Spreading charts ................................................................................... 34

7.6 Slide settings ......................................................................................... 43