Heng Hui IAD-H600 User manual

Intelligence Aided

Lifting Equipment

User Manual

(V4.71)

November 2018

Intelligence Aided Lifting Equipment

2

Preface

Thank you for choosing our product! This User Manual provides information in respect of the

intelligence aided lifting equipment covering the following:

Safety

Product overview

Start-up

Function description

Extended Function

Menu setting

Maintenance & service

Revision:

Adjustment on dual suspension. (Version V8024 or above required)

Additional functions of no-load deceleration, separate reset of soft limit, etc. (Version V8025 or

above required)

Additional control modes for fall prevention function, etc. (Version V8026 or above required)

Newly-added display on handle side of servo driver alarm codes. (Version V8027 or above

required)

Newly-added function for separate definition of soft limit under Grip and Suspension modes.

(Version V8028 or above required)

Newly-added instructions of all-touch handle and coaxial pressure handle.

Tips

If this is the first time you use this product, please carefully read this User Manual. For any doubt

with regard to functions or performance, please don’t hesitate to contact our technicians for

assistance.

Please make this User Manual readily accessible for reference at any time.

Shaoxing Henghui Robot Technology Co., Ltd. reserves all rights of this User Manual. In no case

should, without our written authorization, any technical specification, drawing or diagram be

wholly or partially copied, distributed, used for competition or provided to any third party.

We are committed to continuous improvement on intelligence aided lifting equipment, hence

changes may occur to any information provided by us without prior notice, and we appreciate your

understanding.

Intelligence Aided Lifting Equipment

3

Table of Contents

Chapter I Safety ........................................................................................................................6

1.1 Safety precautions.....................................................................................................6

1.2 Safety signs ...............................................................................................................8

1.3 Safety protection device............................................................................................9

1.3.1 Limit switch ......................................................................................................9

1.3.2 Steel cable locking device.................................................................................9

1.3.3 Overload prevention device ............................................................................10

1.3.4 Forced cooler...................................................................................................10

1.3.5 Emergency stop button....................................................................................11

Chapter II Overview.................................................................................................................12

2.1 Introduction.............................................................................................................12

2.2 Major application and scope ...................................................................................12

2.3 Main components and functions .............................................................................12

2.4 Types of handles......................................................................................................13

2.5 Signal connection line.............................................................................................14

2.5.1 Wire map of signal connection line.................................................................14

2.6 H360 Sliding Circle.................................................................................................15

2.7 Composition and meanings of model......................................................................16

2.8 Nameplate ...............................................................................................................16

2.9 Basic operation interface.........................................................................................17

2.10 Main technical parameters ......................................................................................18

2.11 Basic dimensions.....................................................................................................19

2.12 Main components....................................................................................................20

Chapter III Start.........................................................................................................................21

3.1 Power supply...........................................................................................................21

3.2 Connection of transformer ......................................................................................22

3.3 Description of signal cable pins of the host ............................................................23

3.4 Initial start ...............................................................................................................23

Chapter IV Basic function..........................................................................................................25

4.1 Mode of manual hold..............................................................................................25

4.1.1 Operation mode...............................................................................................25

4.1.2 Infrared sensor.................................................................................................25

Intelligence Aided Lifting Equipment

4

4.1.3 Adjust the maximum operating speed in mode of manual hold......................25

4.1.4 No-load deceleration function.........................................................................26

4.2 Suspension mode.....................................................................................................27

4.2.1 Operation mode...............................................................................................27

4.2.2 Notes to suspension mode...............................................................................27

4.3 Levitation unloading mode......................................................................................28

4.3.1 Operation steps................................................................................................28

4.3.2 Suspension unloading mode description.........................................................28

4.4 Automatic suspension function...............................................................................28

4.4.1 Operation steps................................................................................................29

4.5 Unloading function..................................................................................................29

4.5.1 Operation Method ...........................................................................................29

4.6 Soft limit .................................................................................................................30

4.6.1 Operation steps................................................................................................30

4.6.2 Precautions......................................................................................................30

4.7 Inching button operation.........................................................................................31

4.8 Function switch.......................................................................................................32

Chapter V Extended Function ..................................................................................................34

5.1 Inching function......................................................................................................34

5.1.1 Usage mode.....................................................................................................34

5.1.2 Fast gear and slow gear speed adjustment.......................................................35

5.2 Switching of modes.................................................................................................35

5.2.1 Usage mode.....................................................................................................35

5.3 Double limit function..............................................................................................36

5.3.1 Usage Method .................................................................................................36

5.4 Double suspension function....................................................................................37

5.4.1 Double suspension weight setting...................................................................37

5.4.2 Double suspension mode setting.....................................................................37

5.4.3 Signal selection ...............................................................................................38

5.4.4 Protection settings for dual suspension...........................................................40

5.5 Anti-drop function...................................................................................................40

5.5.1 Anti-drop threshold setting..............................................................................41

5.5.2 Signal setting...................................................................................................41

5.5.3 Clamping protection function..........................................................................41

5.6 Auto homing function.............................................................................................43

Intelligence Aided Lifting Equipment

5

5.6.1 Homing Weight Setting...................................................................................43

5.6.2 Usage method..................................................................................................43

5.7 Palletizing function .................................................................................................43

5.7.1 Signal setting...................................................................................................44

5.7.2 Operation steps................................................................................................44

5.8 Wireless Remote Control Module...........................................................................45

5.8.1 Operation methods for the wireless remote control ........................................45

5.9 Expansion interface.................................................................................................45

5.9.1 Host extension interface..................................................................................45

5.7.2 Handle extension interface..............................................................................47

5.9.3 External Expansion Board Interface................................................................51

Chapter VI Menu setting............................................................................................................55

6.1 Overview.................................................................................................................55

6.1.1 Operation mode...............................................................................................55

6.2 Description of menu functions................................................................................56

Chapter VII Maintenance............................................................................................................66

7.1 Inspection & Maintenance Timetable......................................................................66

7.2 Basic failure diagnosis ............................................................................................66

7.3 Servo driver battery replacement ............................................................................73

7.3.1 Operation steps................................................................................................73

7.4 Calibrate the handle holder .....................................................................................73

Chapter VIII Annex..............................................................................................................75

8.1 Use of wireless remote controller and receiver.......................................................75

8.2 Dimensional drawing of H360 sliding circle ..........................................................76

8.3 Dimensional drawing of indefinitely variable speeds handle..................................76

8.4 Extended box...........................................................................................................77

8.5 Remote installation sliding handle..........................................................................77

Intelligence Aided Lifting Equipment

6

Chapter I Safety

1.1 Safety precautions

1. The users must be familiar with and abide by the following safety matters before the

storage, installation, operation, inspection and maintenance of the products.

2. Prompt: Non-conformance to the safety precautions may cause severe personal

injury or even death or damage to the equipment.

3. DO NOT attach any cable, air pipe or the like to steel wire sleeves or spring cables.

Such attachment may compromise the accuracy of a safety sensor and damage the

equipment.

4. Please make sure you are familiar with this User Manual before any operation.

5. Do not operate the equipment in case of any discomfort.

6. An operator must focus on the equipment during operation.

7. DO NOT lift any weight beyond the rated capability of the equipment.

8. DO NOT use any lifting hook without a latch or that is damaged.

9. This product is not designed and manufactured for man riding but for products, hence

man riding is prohibited.

10. DO NOT have anyone stay in the activity range of load lifting.

11. DO NOT prolong the lifting of any weight, otherwise the life of steel wire will be

shortened and the risk of personal injury may occur.

12. DO NOT operate any intelligence aided lifting equipment with any electrical or

mechanical flaw.

13. Please do not cut off the power supply during lifting.

14. DO NOT install any object on the sliding handle. It may become an obstruction to the

normal operation of the equipment.

15. Please do not wash the equipment or clean it with wet rag.

16. Please do not frequently switch on and off the equipment.

17. Please do not conceal or remove any sign attached to the equipment.

18. Please do not trigger the infrared sensor for long when the equipment is not in use.

19. Please do not dismantle or fix the product unless you are a professional maintenance

man.

20. DO NOT maintain the equipment if it’s electrified.

21. Please wait for no less than 10 minutes after cutting off the power prior to perform any

maintenance or service.

22. Check whether the hook and the load steel wire rope are damaged or not before use.

Intelligence Aided Lifting Equipment

7

23. The load steel wire rope needs to be kept clean and in good condition.

24. Prior to any operation, please check the load steel wire rope for any loop, knot, twist,

bend or foreign matter.

25. A steel wire rope provided by us is needed when modifying one.

26. Please press the emergency button ONLY in case of an emergency if the equipment is

operating in a high speed.

27. Upon installation of a lifting hook, its thread must be screwed to the depth of 40 mm to

avoid risks as a result of insufficient installation depth.

28. Inching buttons are for equipment maintenance and steel cable replacement only and

shall not be used during normal operation.

29. A limit switch is to prevent lifting movement beyond the position limit and shall not be

used as a stroke limit.

30. Please do not involve a steel cable directly when it’s loose.

Intelligence Aided Lifting Equipment

8

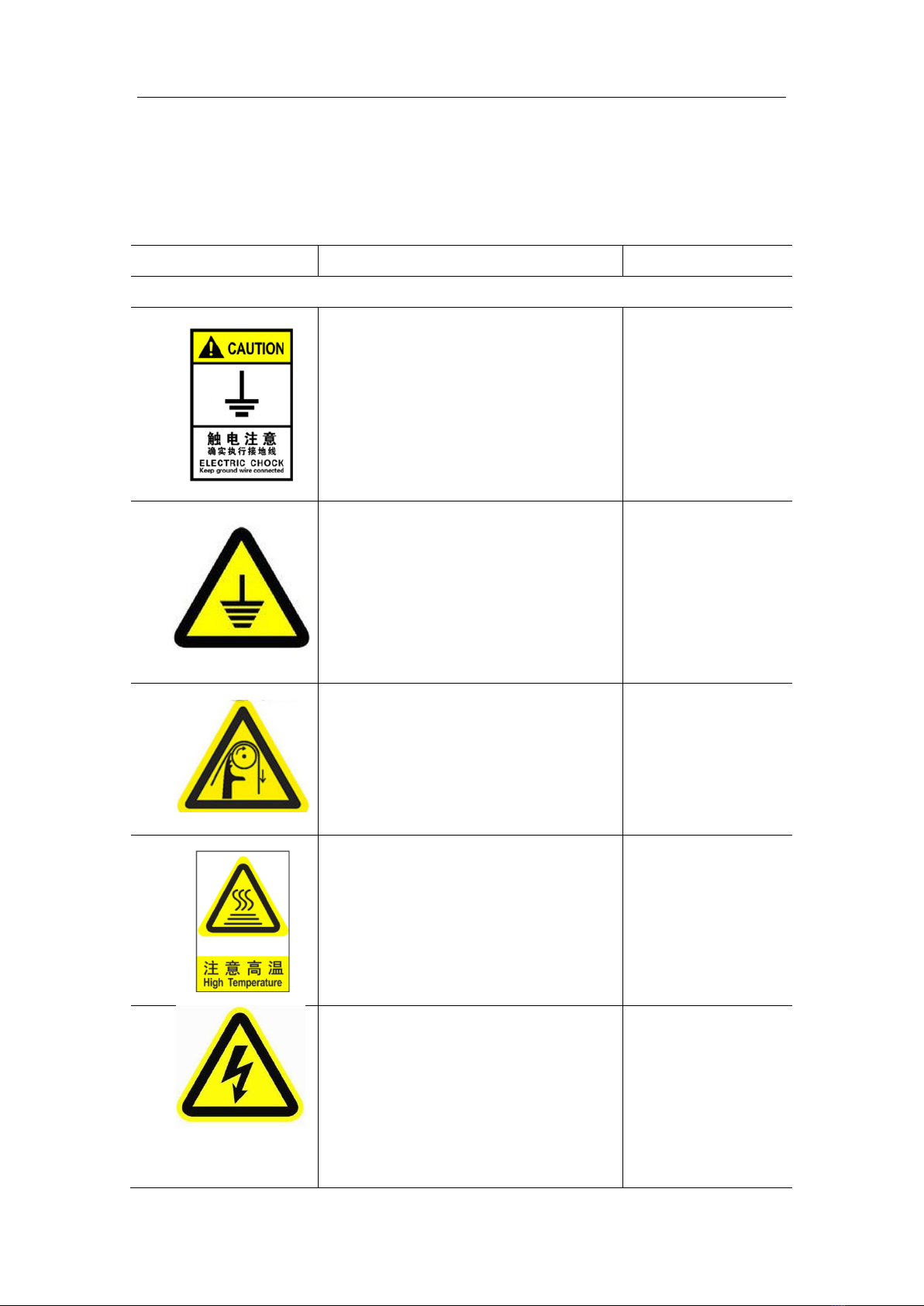

1.2 Safety signs

A safety sign reminds operators or servicemen of potential risks, and hence it is an important

facility for identifying and avoiding danger.

Sign

Name

Position

Warning signs

Grounding

Means the equipment must be grounded, otherwise

short circuit of equipment or personal injury may

occur. Even worse, lives may be endangered or

equipment damaged.

Transformers,

aviation connectors.

Earthing mark

Means protective earthing must be performed for

the parts on equipment, otherwise short circuit of

equipment or personal injury may occur. Even

worse, lives may be endangered or equipment

damaged.

Main unit enclosure

Entangling sign

Means an entangling risk exists in that area or

item, hence no touching is allowed. Disobeying

this rule will give rise to personal injury or even

death.

Protective jacket of

steel wire rope

Caution! Hot surface.

Means that area or item may be in high

temperature. Do not touch it. Disobeying this rule

may cause burns.

Regenerative (brake)

resistor

Beware of electric shock

Indicates that area or item may be electrified. Do

not touch it. Disobeying this rule may cause

electric shock, giving rise to short circuit of

equipment or personal injury. Even worse, lives

may be endangered or equipment damaged.

Terminals

Intelligence Aided Lifting Equipment

9

1.3 Safety protection device

A safety protection device is designed to prevent accidents of intelligence aided lifting

equipment, consisting of limit switches that limit movement, steel cable locking device, overload

prevention device and forced cooling devices.

1.3.1 Limit switch

The intelligence aided lifting equipment is provided with limit switches (Fig. 1. 1) to ensure

reliable operation. A stroke limit switch comprises of an upper and a lower limit switches. When

the equipment operates upward to some 10 cm before the upper limit, it starts to decelerate to

prevent the weight from breaking away from the lifting hook. If the equipment reaches the upper

limit position, the limit switch will be triggered and the equipment can only move downward. The

lower limit switch is designed to ensure at least two turns of steel cable stay on the reel. The

equipment can move upward only if the lower limit switch is triggered.

Fig. 1. 1 Stroke limit switch

1.3.2 Steel cable locking device

The intelligence aided lifting equipment is provided with a micro switch to detect steel cable

looseness (Fig. 1. 2). When a steel cable is loose in operating equipment, the micro switch will

detect such looseness and trigger relevant actions, and then the display on the handle will indicate

“steel cable looseness alert” and the equipment can only move upward.

Fig. 1. 2 Micro switch to detect the looseness of steel cable

Intelligence Aided Lifting Equipment

10

1.3.3 Overload prevention device

The intelligence aided lifting equipment is provided with a weighing sensor (Fig. 1. 3). When

the weight to be lifted exceeds the set value or rated bearing capacity, lifting will stop and

“Overload Alarm” be displayed on the screen, in which the equipment can move downward only

(overload weight < 150% of bearing capacity).

Fig. 1. 3 Weighing sensor

1.3.4 Forced cooler

The intelligence aided lifting equipment is provided with a temperature sensor (Fig. 1. 4). It

is configured to detect the real-time temperature of braking resistor. In case that the detected

temperature is above 50 °C, the DC fan will produce forced air to cool the braking resistor. While

in the event that such temperature is above 100 °C, system operation will be suspended until the

temperature drops back to 80 °C. This device is applied only for 200 KG, 300 KG and 600 KG

types.

Intelligence Aided Lifting Equipment

11

Fig. 1. 4 Forced cooling device

1.3.5 Emergency stop button

By pressing the emergency stop button on the handle (Fig. 1. 5), manual operation or

suspension lifting of the equipment will be disabled other than menu viewing or editing. While the

emergency stop brakes the equipment by direct control of the motor through hardware!

In case that maintenance and service, parameter setting, system upgrade and power-on

standby are performed with the equipment electrified, the emergency stop button must be kept

pressed and locked.

Note:

If the emergency stop button is pressed during equipment movement, it will be forced to stop

immediately. Therefore, please do not press the emergency stop button at will other than a true

emergency under heavy-load or fast movement, otherwise equipment damage or personal injury

may occur!

Fig. 1. 5 Emergency stop button

Intelligence Aided Lifting Equipment

12

Chapter II Overview

2.1 Introduction

The intelligence aided lifting equipment is a material handling device that conforms to

human engineering, comprising of servo drives, servo motors, decelerators, sensors and relevant

structures and controlled by a micro-processor. It features easy operation, high precision,

intelligence, controllable speed, safety and reliability, etc.. The intelligence aided lifting

equipment produced by us includes four types by rated lifting capacity, i.e. 80KG, 200KG, 300KG

and 600KG.

2.2 Major application and scope

Automobile industry (including engines, gearboxes, new energy battery assembly, etc.)

Finish machining

Machinery manufacturing and processing

Energy industry

Handling work with high repeatability

Parts assembly

Warehouse loading and unloading

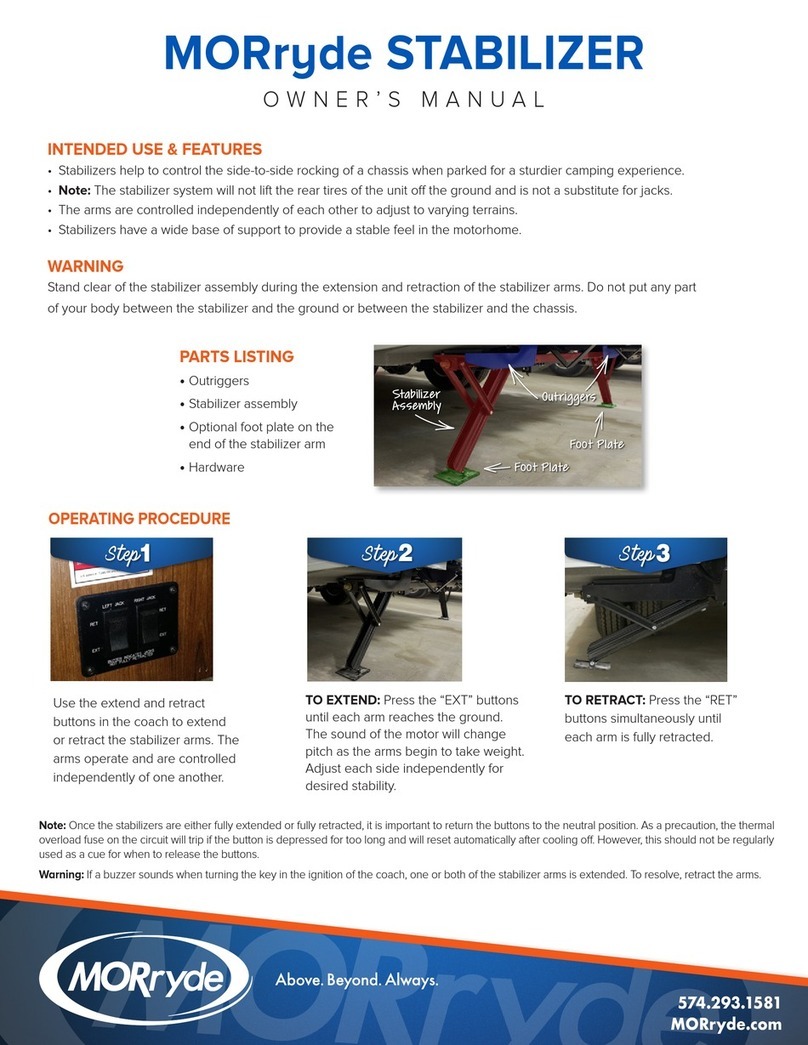

2.3 Main components and functions

Intelligence aided lifting equipment consists of three major parts as follows1:

Main engine (Fig. 2 1): The main engine comprises mainly of a servo drive, a servo motor, a

decelerator, sensors and a main control panel. It is designed to provide power necessary for the

device to achieve accurate control and lifting, and to process signals.

Spring cable (Fig. 2 2): transmit signals between the main control and the handle, including

lifting orientation, lifting speed, emergency stop and fault signals.

Coaxial sliding handle (Fig. 2 3): consists of control panel, display, handle sliding circle,

displacement sensor and infrared sensor. A handle serves as the main interface between operators

and lifting equipment, by which users may control the lifting of equipment. Users may also

acquire the applicable information through the display.

1A non-derivative combination

Intelligence Aided Lifting Equipment

13

Fig. 2 1 Main unit

Fig. 2 2 Spring cable

Fig. 2 3 Coaxial sliding handle

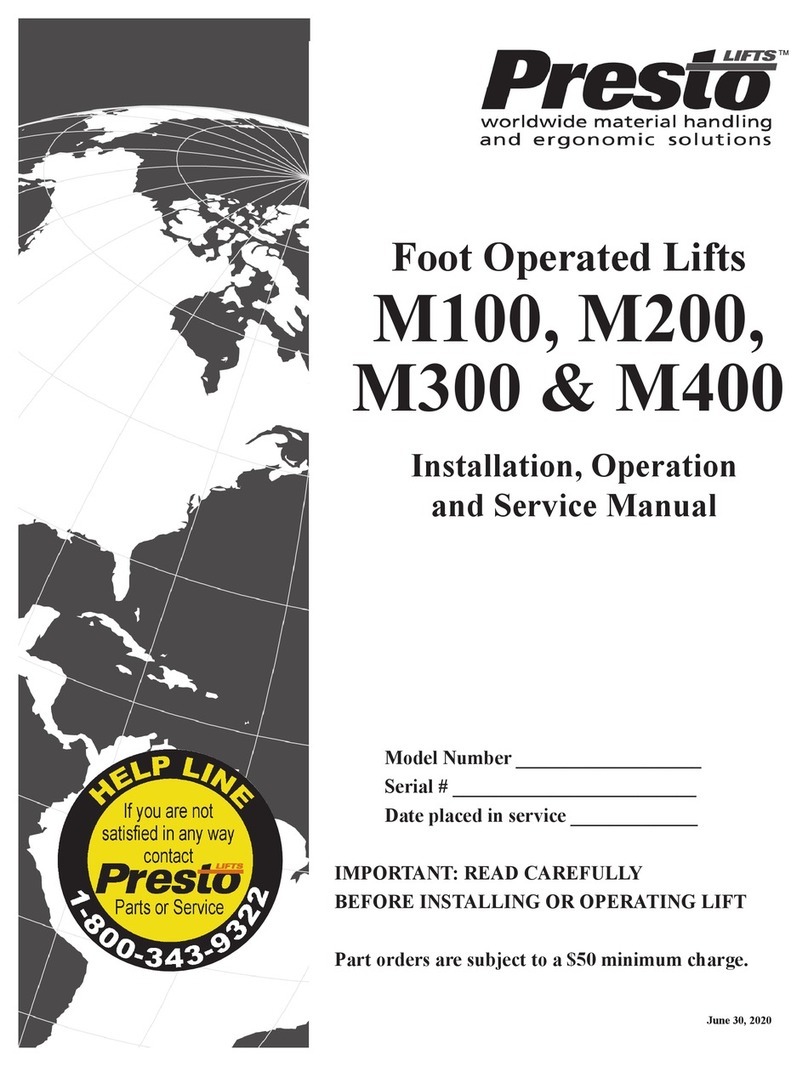

2.4 Types of handles

Apart from a coaxial sliding handle, the intelligence aided lifting equipment may be provided

with a CVT handle, a remote installation sliding handle, an all-touch handle, a wireless handle and

a coaxial pressure handle, depending on the varying station requirements.

CVT handle (Fig. 2. 4): applies to a workplace with limited height and inaccessible to

operators. Users can control equipment lifting through UP and DOWN and acquire corresponding

information through the display. This type of handles may be integrated into the terminal fixture or

hung vertically beneath the main engine.

Sliding handle for remote installation (Fig. 2. 5): applies to a workplace with limited height

and inaccessible to operators. This type of handles can be integrated into the fixture of or secured

externally on a terminal. Its functions resemble a coaxial sliding handle.

All-touch handle (Fig. 2. 6): provided with a built-in pressure sensor. When the force applied

on the handle varies, the equipment moves.

Wireless handle (Fig. 2. 7): allows to remotely control the main engine, applicable to a

workplace inaccessible to operators. This kind of handles provides functions of Fast Gear

Operation, Slow Gear Operation, Suspension Switch and Suspension Unloading Switch.

Coaxial pressure handle: provided with a built-in pressure sensor. When the force applied to

the rubber handle varies, the equipment moves.

Intelligence Aided Lifting Equipment

14

Fig. 2. 4 CVT handle

Fig. 2. 5 Sliding handle for

remote installation

Fig. 2. 6 All-touch

handle

Fig. 2. 7 Wireless

handle

2.5 Signal connection line

In addition to spring wires, the straight connection wires of stepless handles (straight or spring

wires), folding extension wires, H360-handle connection wire A, and H360--handle connection

wire C, depending on different models and handles, can also be used for the connection between

the host and the handles of the intelligent lifting equipment, with the following functions:

Spring wires: connecting the host with a coaxial sliding handle or H360 sliding circle.

Straight connection wires of stepless handles: connecting the host with stepless speed-changing

handle.

Folding extension wires: generally used for the connection of the host and the spring wires

(straight connection wires of stepless handles) in a folded arm

H360-handle connection wire A: connecting H360 sliding circle and remotely installed sliding

handle.

H360-handle connection wire C: connecting H360 sliding circle and stepless speed-changing

handle or all-touch handle.

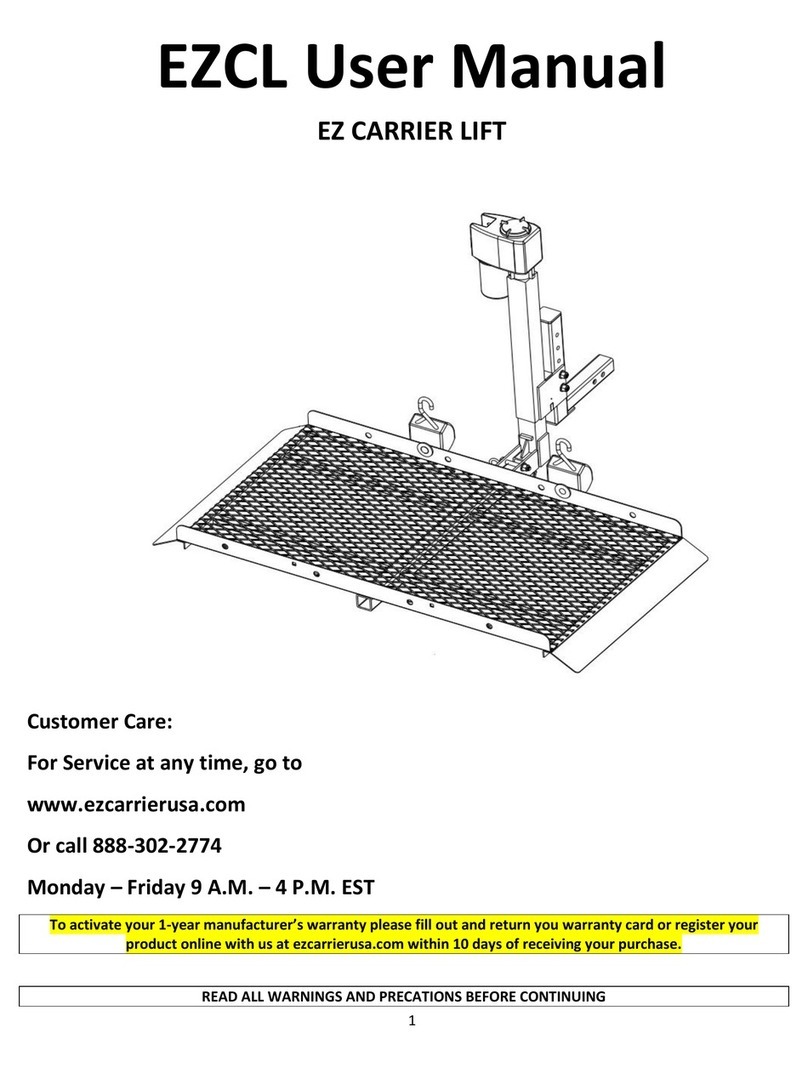

2.5.1 Wire map of signal connection line

Numbering and definition of the pins for 8-core connector and 12-core connector are given in

Fig. 2.8.

Hole-type, 8-core

Needle-type, 8-core

Hole-type, 12-core

Needle-type, 12-core

Fig. 2. 8 Numbering and definition of pins

The wire map of pins for connectors at both ends of spring wires, folding extension wires and

straight connection wires of stepless handles is shown below:

Intelligence Aided Lifting Equipment

15

Needle

Hole

The wire map of pins for connectors at both ends of H360-handle connection wire A is shown

below:

Hole

Hole

The wire map of pins for connectors at both ends of H360-handle connection wire C is shown

below:

Hole

Hole

2.6 H360 Sliding Circle

The H360 sliding circle (Fig. 1. 6) is used in combination with a remote installation sliding

handle, CVT handle or all-touch handle. Its built-in sliding circle and air tube connector

effectively eliminate the twist of signal cables and air tubes.

Intelligence Aided Lifting Equipment

16

Fig. 1. 6 H360 sliding circle

2.7 Composition and meanings of model

The following is the model composition and meanings of a main engine of intelligence aided

lifting equipment.

2.8 Nameplate

1. Type and model

The type and model of the said equipment.

2. Rated capacity

Rated lifting capacity of the equipment.

3. Lifting height

Maximum stroke of the equipment.

4. Product No.

Sequential figures indicating the production number of a product.

5. Input voltage

The power supply voltage of the said type, at 50HZ.

6. Rated power

IAD-H080-500-A10

Product Version

Length of steel cable (cm):

Hoisting capacity (kg):

Product code: IntelligenceAided Lifting Equipment

Intelligence Aided Lifting Equipment

17

The rated power of the said type.

7. Operation speed

The maximum operation speed of the equipment.

8. QR code and CE certification

Product information can be acquired by scanning the QR code. This product has passed CE certification.

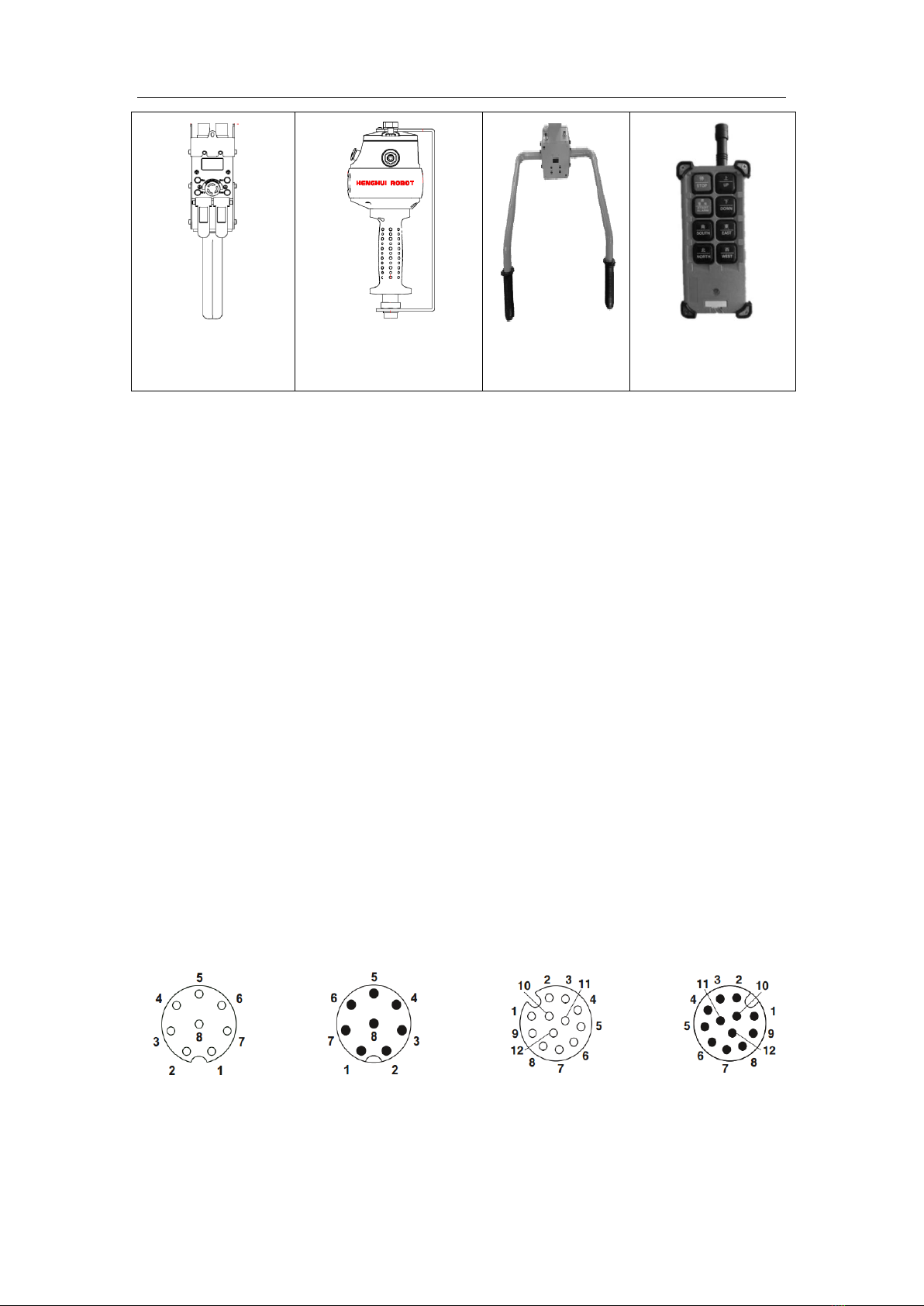

2.9 Basic operation interface

The basic operation interface of intelligence aided lifting equipment (Fig. 2. 9) comprises of

an emergency stop button, “UP”button, “DOWN”button, “ESC” button, “ENT” button, LCD

display and status indication lamps. Users may carry out operations on the system through

external buttons and acquire corresponding information through the LCD display. Refer to Table 1

for details.

Fig. 2. 9 Basic operation interface

Table 1

S/N

Corresponding

function

Function description

1

Emergency stop

switch

If pressed, equipment enters emergency stop mode, under

which equipment lifting will be banned;

2

Failure indicating

lamp

Off: equipment operates normally;

On: Equipment fails or is under emergency stop mode;

3

Running indicator

Blinking slowly: equipment operates normally (lock mode

and emergency stop mode);

Blinking quickly: Unloading mode;

Shining constantly: Suspension/suspension unloading mode;

4

“UP”button

Select “UP”button on the menu;

By holding it (for 2 s) under the lock mode, the equipment

enters “suspension unloading mode”;

5

“ESC”button

Return to the previous menu;

By holding it (for 2 s) under the lock mode, the equipment

Intelligence Aided Lifting Equipment

18

enters “suspension mode”;

6

“DOWN”button

Select “DOWN”button on the menu;

By holding it (for 2 s) under the lock mode, the equipment

enters “unloading mode”;

7

“ENT”button

Enter the next menu;

Execute the saving operation;

8

LCD screen

Displays operation modes, relative weight, relative position

and fault alarms;

2.10 Main technical parameters

The main technical parameters of the intelligence aided lifting equipment are shown in Table 2.

Table 2

Main engine model

IAD-H80

IAD-H200

IAD-H300

IAD-H600

Load (weight and tool)

(KG)

80

200

300

600

Maximum lifting speed

under manual hold mode

- no load (m/Min)

40

30

15

7.5

Maximum lifting speed

under manual hold mode

- full load (m/Min)

30

23

12.8

6.8

Maximum lifting speed

under suspension mode -

no load (m/Min)

36

27

13.5

6.75

Maximum lifting speed

under suspension mode -

full load (m/Min)

27

20.7

12.15

6.08

Maximum lifting height

(m)

3.50

3.50

3.50

1.70

Main power supply

(VAC)

Single phase

200 - 230 V

Single phase

200 - 230 V

Three-phase

200 - 230 V

Three-phase

200 - 230 V

Frequency of main power

supply (HZ)

50HZ

50HZ

50HZ

50HZ

Maximum current (A)

10

12

15

15

Lifting medium (stainless

∅5.00 mm

∅5.00 mm

∅5.00 mm

∅6.50 mm

Intelligence Aided Lifting Equipment

19

steel cable)

Working environment

temperature range

-10-60℃

-10-60℃

-10-60℃

-10-60℃

Humidity range of

working environment (no

condensation)

0-93%

0-93%

0-93%

0-93%

Soft limit

Yes

Yes

Yes

Yes

Weight display accuracy

(KG)

1% * rated

load

1% * rated

load

1% * rated load

1% * rated load

CE certified

Yes

Yes

Yes

Yes

Cooling method

Natural wind

Natural wind

and forced

wind

Natural wind

and forced wind

Natural wind

and forced wind

2.11 Basic dimensions

80KG, 200KG, 300KG Intelligence Aided Lifting Equipment Basic Dimensions Table 3 (Fig.

2 10right). See attachments for detailed dimensions.

600KG Intelligence Aided Lifting Equipment Basic Dimensions 3 (Fig. 2 10left). See

attachments for detailed dimensions.

Note: D is the min. size.

Table 3

Model

IAD-H80

IAD-H200/IAD-H300

IAD-H600

A (mm)

285

312

312

B (mm)

670

670

670

C (mm)

462

462

477

D (mm)

610

610

1085

E (mm)

410

410

410

F (mm)

122

122

122

G (mm)

142

142

142

H (mm)

141

141

141

Intelligence Aided Lifting Equipment

20

Fig. 2 10 Dimension

2.12 Main components

Intelligence Aided Lifting Equipment Main Components Information Table 4.

Table 4

Model

IAD-H80

IAD-H200

IAD-H300

IAD-H600

Servo drivers

Delta (0.75KW)

Delta (1.5KW)

Delta (2KW)

Delta

(2KW)

Servo motor

Delta (0.75KW)

Delta (1.5KW)

Delta

(2KW)

Delta

(2KW)

Gear reducer

Planetary gear

Planetary gear

Planetary

gear

Planetary

gear

Switching power

supply

LRS-100-24

(MEAN WELL)

LRS-100-24

(MEAN

WELL)

LRS-100-24

(MEAN

WELL)

LRS-100-24

(MEAN

WELL)

Main control

board

Henghui

Henghui

Henghui

Henghui

Structural Parts

Henghui

Henghui

Henghui

Henghui

This manual suits for next models

3

Table of contents

Popular Lifting System manuals by other brands

Presto Lifts

Presto Lifts M100 Installation, operation and service manual

Freedom Lift Systems

Freedom Lift Systems Trus-T-Lift 750 Owner's operation manual

Nexion

Nexion Molnar CM245-A Installation, operation & maintenance instructions

TradeQuip

TradeQuip 6007T owner's manual

unicraft

unicraft SHB 3 instruction manual

EZ Carrier

EZ Carrier EZCL user manual