Nexion Molnar CM245-A Guide

Date: 19.06.2023

CM245-A

CM255-A

Read the operating

instructions before

working with the

unit

ALWAYS KEEP

operating instructions

ready to hand on the

unit

Installation, Operation &

Maintenance Instructions

2 / 44

Before

taking into operation

check system compo-

nents, control, emer-

gency stop and safety

equipment for conditi-

on, damage and

correct function!

Please read this manual before you get started.

You must read and understand the precautions for safety purposes and any damages that may occur

to your property.

If these installation instructions are not followed strictly, the hoist is not covered by warranty.

Address: 3 Graham Street

Export Park

South Australia 5950

Ph:

Fax:

Email:

Web:

+61 (08) 8234 3611

+61 (08) 8234 4322

www.molnarhoists.com.au

Specifications/images subject to change without prior notice, Images and sketches are for illustration purposes only.

CM245/55-A

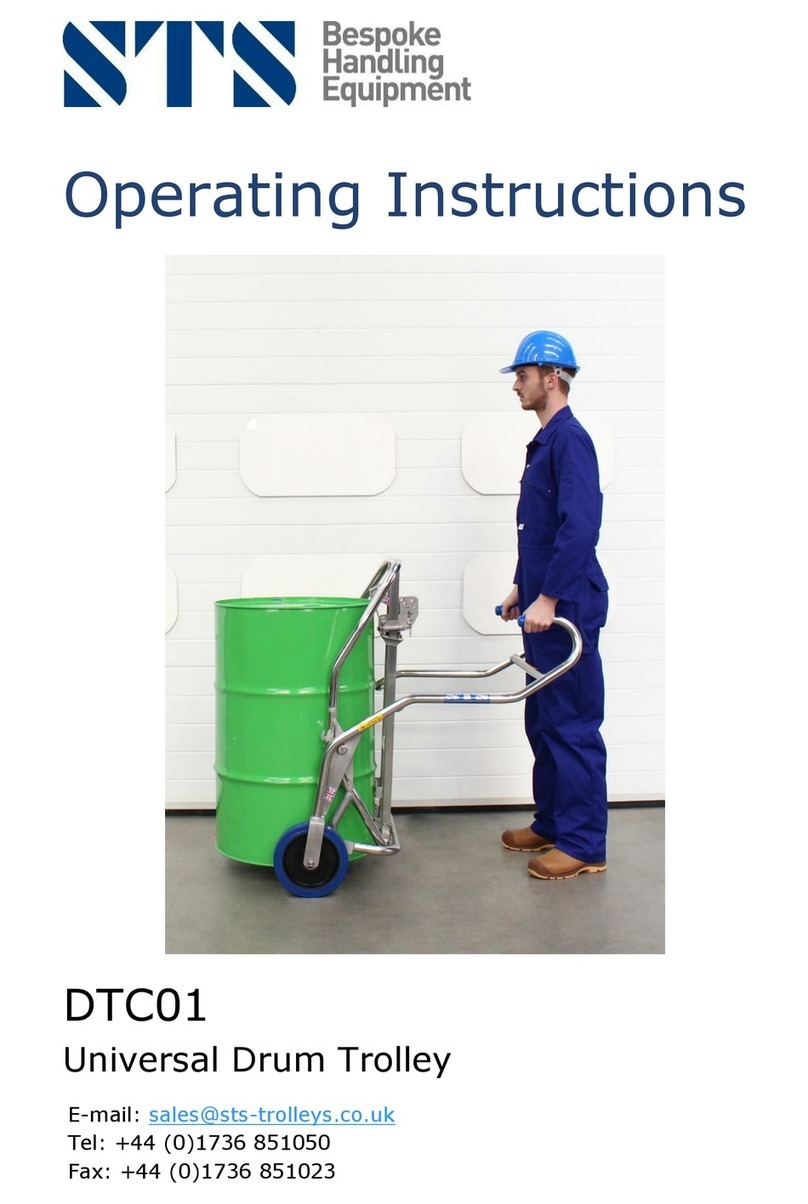

Forklifts are recommended during install

3 / 44

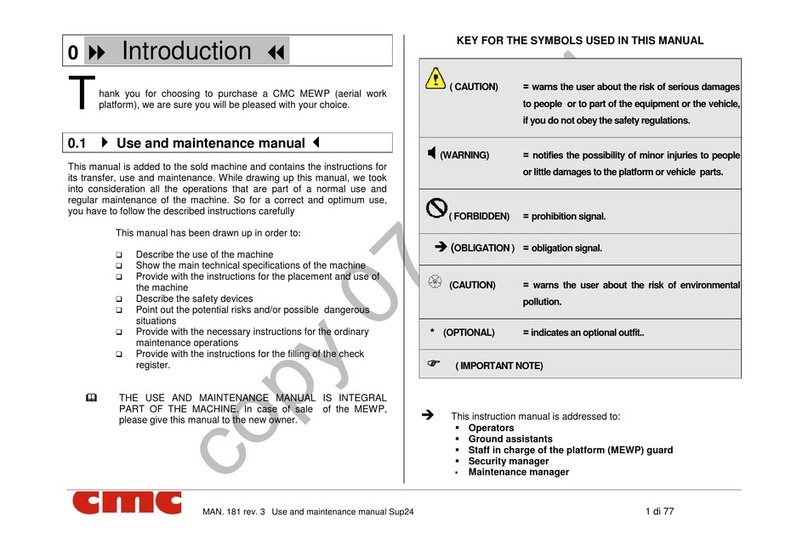

Printing characters and symbols

Throughout this manual, the following symbols and printing characters are used to facilitate reading:

Indicates the operations which need proper care

Indicates prohibition

Indicates a possibility of danger for the operators

Indicates the direction of access for motor vehicles to the lift

Bold type Important information

WARNING: before operating the lift and carrying out any adjustment, read care-

fully chapter 4 "Installation" where all proper operations for a better functioning

of the lift are described

THIS USER'S MANUAL IS WRITTEN IN THE MANUFACTURER'S LANGUAGE,

AND IN OTHER COMMUNITY LANGUAGES. IN CASE OF COMPLAINT, FOR LEGAL PUR-

POSES, THE VERSION IN ITALIAN LANGUAGE ONLY WILL APPLY. THE MANUFACTURER

DISCLAIMS ANY LIABILITY FOR DIRECT AND/OR INDIRECT DAMAGES CAUSED BY POOR

TRANSLATION OR WRONG TEXT INTERPRETATION.

CM245/55-A

4 / 44

Table of contents

Printing characters and symbols ...............................................................................................................3

Warranty ...................................................................................................................................................5

Disclaimer ..................................................................................................................................................5

General information ................................................................................................................................... 5

1. Technical data ..........................................................................................................................7

1.1 Lift description ............................................................................................................................8

1.2 Safetydevicesfittedonthelift ...................................................................................................9

1.3 Load distribution ....................................................................................................................... 10

1.4 Pictograms ............................................................................................................................... 11

1.5 Pictograms application diagram ...............................................................................................12

1.6 Hazardous areas ...................................................................................................................... 13

2. Foreword ................................................................................................................................. 14

2.1 ECcertification .........................................................................................................................14

2.2 Testing ......................................................................................................................................14

3. General safety and accident prevention rules ....................................................................15

3.1 Set-up and clothing ..................................................................................................................16

3.2 Environment and pollution ........................................................................................................16

3.3 Lift scrapping ............................................................................................................................ 17

3.4 Danger levels ...........................................................................................................................17

3.5 Hazardous areas ...................................................................................................................... 18

3.6 Liftidentificationandpictogramdescription .............................................................................18

3.7 Intended use ............................................................................................................................18

4. Transport and installation .....................................................................................................19

4.1 Unpacking ................................................................................................................................19

4.2 Installation area ........................................................................................................................ 19

4.3 Installation ................................................................................................................................20

4.3.1 Beam installation ......................................................................................................................23

4.4 Connecting to the electricity mains ..........................................................................................24

4.5 Electromagnet ..........................................................................................................................25

4.6 Electrical connection between the two pillars ...........................................................................26

4.7 Hydraulic connection ................................................................................................................27

4.8 Connection cables of sync .......................................................................................................28

4.9 Fitting of arms ..........................................................................................................................31

4.10 Control of motor rotation direction ............................................................................................33

4.11 Airexhaustoffhydraulicsystem ..............................................................................................33

5. Instructions for use ................................................................................................................34

5.1 Start up .....................................................................................................................................34

5.1.1 Adjustment of the lifting time for release of the safety locks ................................................... 34

5.2 Operation .................................................................................................................................34

5.3 Emergency procedures ............................................................................................................36

6. Maintenance ...........................................................................................................................37

6.1 Cleaning ...................................................................................................................................37

6.2 Storage .....................................................................................................................................37

6.3 Environmental information .......................................................................................................37

6.4 Firefightingequipmenttobeused ............................................................................................38

7. Troubleshooting .....................................................................................................................39

8. Diagrams .................................................................................................................................40

8.1 Electrical diagram .....................................................................................................................41

8.2 Hydraulic connection diagram ..................................................................................................41

8.3 Hydraulic diagram ....................................................................................................................42

9. Procedure for the adjustment and testing of the lift ...........................................................43

CM245/55-A

5 / 44

Warranty

The manufacturer warrants lifts and the relevant accessories for 3 years after purchase date. This warranty

consists in the repair or replacement - free of charge - of those parts that, after a careful analysis by the Ma-

nufacturer's Technical Service, turn out to be faulty from origin. All electrical parts are excluded. Warranty is

limited to material defects and becomes null and void if the returned parts are tampered with or disassembled

byunauthorizedstaff.Anyliabilityfordirectandindirectinjuriestopeople,animalsorpropertyduetomachine

failure or malfunction are excluded from warranty. The expenses deriving from lubricants replacement, trans-

portcharges,andanycustomsduty,VATandanyotherexpensenotspeciedinthesupplycontractareat

the purchaser's charge. The replacement and repair of parts under warranty, anyway, do not extend warranty

terms.Thepurchaserwillneverthelessbeentitledtoassertitsrightsonwarranty,speciedinthesupplycon-

tract. Should the parties not be willing to submit any dispute arising from the supply contract to arbitration, or

in anyothercasewherethejudgmentofabodyoftheordinarycompetentcourtisrequired.

Disclaimer

Upon delivery, please check that the product has not been damaged during transportation, and that the acces-

soriescomingwithitareintactandcomplete.Anycomplaintshallbefiledwithin8daysafterliftdeliverydate.

Besides the cases envisaged by the supply contract, the warranty becomes null and void:

•In case of a maneuver error caused by the operator.

•If the damage is caused by poor maintenance.

•If the envisaged capacity is exceeded.

•Ifthemachinehasbeensomehowmodified,andthedamagehasbeencausedbysuchamodification,due

torepairoperationsbytheuserwithouttheauthorizationofthemanufacturerorafterfittingnon-original

spare parts.

•If the instructions described in the user's manual are not complied with.

General information

This chapter contains warning instructions to properly operate the lift and prevent injury to operators or property.

This manual has been written to be used by workshop technicians in charge of the lift

(OPERATOR) and routine maintenance technician (MAINTENANCE OPERATOR). The operating instructions

are considered to be an integral part of the machine and must remain with it for its whole useful life. Read every

section of this manual carefully before operating the lift and unpacking, since it gives helpful information about:

•SAFETY OF PEOPLE

•SAFETY OF THE LIFT

•SAFETY OF LIFTED VEHICLES

The company is not liable for possible problems, damage, accidents, etc. resulting from failure to fol-

low the instructions contained in this manual.

Only skilled technicians of AUTHORIZED DEALERS or SERVICE CENTRES AUTHORIZED by the manufac-

turer shall be allowed to carry out lifting, transport, assembling, installation, adjustment, calibration, settings,

extraordinary maintenance, repairs, overhauling and dismantling of the lift.

The manufacturer is not responsible for possible damage to people, vehicles or objects if said operati-

ons are carried out by unauthorized personnel or if the lift is improperly used.

Any use of the machine made by operators who are not familiar with the instructions

and procedures contained herein shall be forbidden.

CM245/55-A

6 / 44

Manual keeping

For a proper use of this manual, the following is recommended:

•Keep the manual near the lift, in an easily accessible place.

•Keep the manual in an area protected from damp.

•Use this manual properly without damaging it.

•Donotmakeanychangestothismanual;anymodificationsandupdatesshallbemadebythesupplying

company only.

This manual is an integral part of the lift: it shall be given to the new owner if and when the lift is resold.

Obligations in case of malfunction

In case of machine malfunction, follow the instructions contained in the fol-

lowing chapters.

Cautions for the safety of the operators

Operatorsmustnotbeundertheinfluenceofsedatives,drugsoralcoholwhenoperatingthemachine.

Before operating the lift, operators must be familiar with the position and

function of all controls, as well as with the machine features shown in chap-

ter “Operation and use”.

Warnings

Unauthorized changes and/or modifications to the machine relieve the ma-

nufacturer from any liability for possible damage to objects or people. Do not

remove or make inoperative the safety devices, this would cause a violation

of law and regulations on safety at work.

Any other use which differs from that provided for by the manufacturer of the

machine is strictly forbidden.

The use of non-original parts may cause damage to people or objects.

Declaration of warranty and limitation of liability

The manufacturer has paid proper attention to the preparation of this manual. However, nothing contained

hereinmodifiesoralters,inanyway,thetermsandconditionsofthemanufactureragreementbywhichthislift

was purchased, nor increases, in any way, manufacturer’s liability towards the customer.

To the reader

Everyefforthasbeenmadetoensurethattheinformationcontainedinthismanualiscorrect,completeand

updated. The manufacturer is not liable for any mistakes made when drawing up this manual and reserves the

righttomakeanychangesrequiredduetothedevelopmentoftheproduct,atanytime.

CM245/55-A

7 / 44

1. Technical Data

**) For further informations - see foundation plan

ThespecificsoftheresponsiblestructuralEngineerareauthoritative

THE LIFT IS SUPPLIED STANDARD WITH 400V-3PH-50HZ POWER SUPPLY.

CM245-A

Max. capacity Kg 4,500

Lifting time when loaded s

Lowering time when loaded s

Minimum height mm

Lifting height mm

Distance between the columns mm

Lift max. height mm

Three-phase electric motor Volt-Hz-

Amp

Three-phase motor power kW/HP

Single-phase electric motor Volt-Hz-

Amp

Single-phase motor power kW/HP

Max. operating hydraulic pressure Bar

Controls circuit voltage Volt

Total weight of lift Kg

Min. thickness of concrete mm

Recommended hydraulic oil Tipo

Hydraulic system oil quantity Lt

Fixing to the floor with screw anchors N°10

Weight electric / electronic materials Kg

Motor weight Kg

Average weighed sound level LpAm dB(A)

Average sound level at the operator's

workstation LpA dB(A)

Acoustic power LwA dB(A)

5,500

CM255-A

88.6

72

68.2

15

8

9 (optional)

Hilti HST3-M20x170

46

1200

24

200

3

220V – 50Hz -19.5

220V – 60 Hz -20,5

3

230/400V –

50/60Hz - 8.2

Approx. 50 seconds

Approx. 50 seconds

105mm

1990mm

2898mm

2005mm

Approx. 30 seconds

Approx. 30 seconds

90mm

1990mm

2520mm

2005mm

230/400V –

50/60Hz - 8.2

3

220V – 50Hz -19.5

220V – 60 Hz -20,5

3

200

24

1200

46

9 (optional)

Hilti HST3-M20x170

8

15

68.2

72

88.6

CM245/55-A

140 140

8 / 44

1.1 Lift description

1 P1 Column 7 Beam

2 P2 Column 8 Electric motor

3 Column Extension L=600mm(optional) 14 Hydraulic pump unit

4 Column Extension L=1200mm(optional) 15 Control unit

5 Carriage 17 Electromagnet for unlocking mechanical safe-

ty devices

6 3 Stage lifting arm

CM245/55-A

9 / 44

Easy and simple operation by means of "dead-man controlled" pushbuttons placed on the control box - see the

belowfigure.

1.2 Safety devices fitted on the lift

Part Description

Safety ratchet The safety lock is attached to the side of the post and prevents the lowering of the lift

in the event of a hydraulic circuit damage.

The safety lock is not in operation in the lower part of the lift range beneath the lock

position. (Safety lock is operational at heights above 570 mm).

Check valve The check valve ensures that the rated lifting capacity is not exceeded.

Cable The cable connects the 2 lift carriages left and right to ensure synchronization at all

times and to ensure that they remain at the same horizontal level.

CE-stop When lowering the lift stops at approx. 300 mm from bottom position and a warning

buzzer is activated.

See chapter 5.2 for more detailed description.

Emergency stop Main switch is also the emergency stop

Push button

DOWN

Push button

PARKING

Push button

DOWN (within

CE-stop height)

Push button UP

Main Switch

CM245/55-A

10 / 44

1.3 Load distribution

Fv

Fh

Front load ratio (Fv) : rear load ratio (Fh)

FV : Fh = 60 : 40 and 60 : 40

This assumption is based on a vehicle with a chassis width of 1,00 m.

= Recommended drive-on direction

CM245/55-A

11 / 44

1.4 Pictograms

CM245/55-A

12 / 44

1.5 Pictograms application diagram

CM245/55-A

13 / 44

1.6 Hazardous areas

CM245/55-A

14 / 44

2. Foreword

This manual includes the instructions relating to the installation, use and maintenance of the lift system called

"Vehicle Lift". The vehicle lifts described in this manual are designed and constructed solely to lift vehicles for

repair, maintenance and inspection purposes. Lift operation, economy and duration depend on the compliance

with the instructions given in this manual. The parts that can be supplied also as spare parts are listed in the

last section of the manual. To make instructions reading easier, vehicle lift will be hereinafter simply called "lift".

2.1 EC certification

2006/42/ECDirective,commonlyknownasthe"MachinesDirective"specifiestheconditionstoberespected

before a machine can be put into the market. This Directive provides that all machines can be marketed and

commissioned only if they do not jeopardise people, pets or property safety and health. To certify lift compliance

with Directive provisions, before marketing, the manufacturer subjected a machine specimen to the audit of a

notifiedbody.

Lift, manufactured in compliance with 2006/42/EC Directive provisions, and can thus be marketed without jeo-

pardising user's safety.

Lift is thus delivered to the customer with:

•EC Declaration of Conformity

•Instructions for use

•Inspection records

2.2 Testing

The lift has undergone static and dynamic tests based on the procedures included in the EN 1493:2010. Con-

cerning lift testing, please refer to the relevant section in the Inspection records.

The instructions given in this manual shall be compulsorily respected: the

Manufacturer will not be held responsible under any circumstances arising

from negligence, from non-compliance with the instructions and from an im-

proper or inconsiderate use of the lift. Failure to comply with the instructions

given in the manual makes the warranty directly become null and void.

The Company also disclaims any liability for damages caused by lift improper use and/or due to changes made

without the manufacturer’s authorization.

CM245/55-A

15 / 44

3. General safety and accident prevention rules

FOR A SAFE USE OF THE VEHICLE LIFT DESCRIBED IN THIS MANUAL

THE FOLLOWING IS ALLOWED:

•Using lift only to lift vehicles for inspection, maintenance and/or repair operations.

•Using lift only to lift vehicles respecting capacity limits and loads distribution indicated in this manual.

•Only authorized personnel, in good health conditions, responsible and duly trained on the allowed uses and

risks originated by lift use may operate the lift.

•The operator is allowed to use the vehicle lift only after he has thoroughly read, understood and assimilated

the contents of this manual.

•Using lift only inside closed premises, protected against atmospheric agents such as: rain, snow, wind, etc.

•Only one operator at a time may use the lift in the safety position in the indicated area, close to the control

panel

IS REQUIRED:

•Liftinstallationandmaintenanceoperationsshallbecompulsorilycarriedoutbyqualifiedpersonnelonly,

and in full compliance with the instructions given in this manual.

•Before installing lift, you shall compulsorily check that the premises where you wish to position it are well

aerated and lit. (avoid blinding light sources).

•Youshallcompulsorilycheckthatthefloorwhereyouwishtoinstallliftissolid,flat,andperfectlylevelledin

all directions.

•Youshallcompulsorilycheckthatthefloorhasbeenconstructedtowithstandthemax.allowedloads,inclu-

ding the lift, on lift resting areas.

•Lift shall be compulsorily positioned far from heat sources or devices that could generate electromagnetic

radiation.

•Lift shall be compulsorily positioned so that, during standard operation, with the vehicle loaded on it, it does

notinterferewithorsquashanynearbyfixedormovingpart.Takespecialcaretopower,waterandgas

systems.

•The lifting or handling operations of lift or of any lift parts shall be compulsorily carried out under full safety

conditionswithsuitableliftingequipment,asenvisagedbytheNationalprevailingregulations.

•Liftshallbecompulsorilysecuredtotheflooronlyusinganchorsandscrewsofthetyperecommendedby

the manufacturer (for lifts, where envisaged).

•Before using the lift, the wholeness of lifting elements shall be compulsorily checked.

•Before using the lift, you shall compulsorily check that safety devices are perfectly installed and in good

operating conditions.

•Vehicle shall be compulsorily positioned as shown in the table of the manual and/or the table stuck to lift.

•Vehicleshallbecompulsorilyliftedfromtherestingpointsspecifiedbythevehiclemanufacturer.

•Whenmovingvehicleup,afterthefirst200mmandbeforecontinuingtheraising,loadstabilityshallbe

compulsorily checked in all directions.

•During the whole raising movement, load stability and lift correct and linear movement shall be compulsorily

checked.

•Before accessing the working area, lift shall be compulsorily put in mechanical safety position with the spe-

cial command (where applicable).

•Before accessing the working area, lift shall be compulsorily disconnected from power sources by turning to

0 (zero) the lockable rotating disconnector positioned onto control panel.

•You shall compulsorily check that the disassembling of some of the parts of the vehicle positioned onto lift

does not originate any load unbalance.

•Before starting lift lowering, you shall compulsorily check that no people, animals or things that could inter-

fere with the moving parts are under and around the working area.

•During lowering, you shall compulsorily and constantly check lift and lift load movement. In case of failure,

immediately turn emergency disconnector.

•In case of irregular noise or operating failures, you shall compulsorily stop lift operation, and check the cau-

se of such irregularity. In case of doubt, contact the manufacturer’s service department.

•Power supply shall be compulsorily sectioned whenever adjustment, repair or maintenance operations

havetobecarriedoutontheequipment.

•All danger signaling decals present onto the lift shall be compulsorily cleaned or changed.

•Liftshallbecompulsorilycleanedandalloilspotsonthefloorcleanedout,astheyareverydangerous.

CM245/55-A

16 / 44

•All ordinary and extraordinary maintenance operations shall be compulsorily and thoroughly carried out, as

indicated in this manual; also periodical checks to be recorded on the special "inspection records" coming

with the lift shall be compulsorily carried out.

•You shall always compulsorily use the manufacturer’s original spare parts.

IT IS FORBIDDEN:

•Itisforbiddentomisuseliftaswellastouseinanyothermannernotspecifiedinthe"INTENDEDUSE"

section of this manual.

•It is forbidden to lift loads with just some of lift parts (one runway only, or two arms only).

•Itisforbiddentoinstallliftinhazardouspremisescontaininginflammableand/orexplosivesubstances,or

whereinflammablegasesorvaporscanbecreated.

•It is forbidden to install lift inside premises exposed to atmospheric agents.

•It is forbidden to install lift in premises where washing or sandblasting operations are carried out, or in very

dusty premises.

•It is forbidden to install lift on vehicles or watercrafts.

•Itisforbiddentouseliftinpresenceofstrongmagneticfields.

•Itisforbiddentouselifttoliftobjectsotherthanthespecifiedones(cases,containersorpallets)ortouseit

as a hoist.

•It is forbidden to use lift to lift people or animals.

•It is forbidden to lift vehicles with people or animals onboard.

•It is forbidden to use the lift if the room temperature is below 5°C or above 40°C.

•It is forbidden to voluntarily cause load oscillations during raising or lowering maneuvers, or while load is

lifted.

•It is forbidden to access work area under the lift without having enabled safety mechanical devices, and

turned disconnector to 0.

•It is forbidden to leave the lift unattended without having positioned it at the min. height or in mechanical

safety position. Then section power supply, and lock disconnector using a padlock.

•It is forbidden to remove or change lift protections or safety devices.

•It is forbidden to change lift or lift parts, any tampering with or change will immediately invalidate warranty,

and will relieve manufacturer of any direct or indirect liability for damages due to such tampering or chan-

ging operations.

•It is forbidden to use parts or accessories not supplied by the manufacturer.

3.1 Set-up and clothing

Set up a space suitable for the machine, and the working environment, by carefully evaluating the following

aspects:

•The position shall be safe, free from any hinder, and protected against atmospheric agents. From the con-

trol position, the operator shall be able to see the whole system and the working area, and to immediately

detect the presence of unauthorized persons and objects that could originate any danger.

•The min. distance of the hazardous area from the walls of the premises where the vehicle lift is installed

shall be at least 70 cm. Lighting shall be good, but without blinding or intense lights, and there shall be no

sourcesorprocessesthatcoulddevelopgasesorflammablevapors.

•Avoid wearing unsuitable clothing. They could get entangled in lift moving parts. As disposed by the Na-

tional prevailing rule, besides wearing clothes suitable to the work site, the operator will have to compul-

sorily wear complementary protective accessories to prevent any injury, such as: helmet, goggles, gloves,

suitable shoes, etc.

3.2 Environment and pollution

•Lift shall not be used for vehicle washing, degreasing, sandblasting and grinding.

•Comply with the National prevailing standards relating to the use and disposal of the products used for lift

cleaning and maintenance, respecting the manufacturer’s recommendations.

•Trapsanddrainageditchesshalldischargefluids,whereandasindicatedbytheNationalprevailingstan-

dards.

CM245/55-A

17 / 44

3.3 Lift scrapping

As for products disposal upon lift scrapping, DO NOT disperse parts in the environment, but contact a company

specialized in waste storage. To avoid any environmental pollution risks, take the following precautions:

•The oil contained inside hydraulic control unit, relative circuit and cylinders shall be fully collected. (if avai-

lable).

•Disassemble lift parts by dividing them into groups of the same material in order to proceed to their separa-

te disposal.

•Exhausted hydraulic oil, rubber parts, and iron scraps are special waste. Dispose of or temporarily store

them in compliance with the National prevailing anti-pollution standards.

3.4 Danger levels

The removal or tampering with the safety devices involves a violation of the European Safety Standards.

•Theuseofthemachineisallowedonlyinplaceswithoutriskofexplosionorfire;

•The use of original accessories is recommended. Our machines are designed to accept only the original

accessories;

•Installationmustbecarriedoutbyqualifiedpersonnelinfullcompliancewiththeinstructionsbelow;

Check that during the maneuvers there are no dangerous conditions: stop the machine immediately if any func-

tional irregularities are found, and contact the authorized dealer's assistance service

Payspecialattentiontothefollowingdangersignwhenyoufinditinthismanual,andfollow

the safety recommendations. Danger signals have three levels:

DANGER: this signal warns that, if the described operations are not carried out correctly, they

cause severe injury, death or health long-term risks.

WARNING: this signal warns that, if the described operations are not carried out correctly, they

may cause severe injury, death or health long-term risks.

CAUTION: this signal warns that, if the described operations are not carried out correctly, they

may cause machine damage and/or personal injuries.

WARNING: carefully read the following rules; whoever does not put into practice the recom-

mendations described hereinafter may be subject to irreparable damages or cause them to

people, animals or property.

The Company disclaims any and whatever liability arising from the failure to comply with the

safety and accident-prevention rules described hereinafter. The Company also disclaims any

liability for damages caused by lift improper use and/or due to changes made without the ma-

nufacturer’s authorization.

WARNING

Theequipmentisintendedtobeusedbyonlyoneoperatoratatime.

WARNING

Electricalsysteminterventions,evenminorones,requiretheinterventionofprofessionally

qualifiedpersonnel(seespecificlegislationonthesubject).

CM245/55-A

18 / 44

3.5 Hazardous areas

Before using the lift, make sure that no unauthorized persons nor animals are present within the hazardous

area delimited by the yellow stripe.

Persons or animals shall by no means stop or pass within the hazardous area delimited by the yellow stripe,

when using lift even for small movements, and whenever the Emergency Switch/OFF is not depressed.

Eachliftissuppliedwiththeidentificationplatesrelatingtothedifferentversions.

3.6 Lift identification and pictogram description

The safety signals described in this manual are applied onto the lift (Fig. 6), and warn about unsafe and ha-

zardous situations. Decals shall be kept clean and, if detached or damaged, they shall be immediately chan-

ged.

Carefully read the meaning of the safety signals, and memorise it

Eachliftissuppliedwithidentificationplatesrelatingtothedifferentversions.Datamustalwaysbementioned

for any need for assistance and spare parts.

3.7 Intended use

The vehicle lifts described in this manual are designed and manufactured for lifting vehicles for inspection,

maintenance and/or repair purposes only.

The vehicle lift should be used only for lifting vehicles within the load capacity limits given in the IDENTIFICATI-

ON PLATE and in the paragraph 1.3 "LOAD DISTRIBUTION"

CAREFULLY READ THE INSTRUCTIONS GIVEN IN THIS MANUAL BEFORE USING THE

LIFT

CM245/55-A

19 / 44

4. Transport and installation

Since the lift is packed in a special wooden crate, it can only be handled using a pallet truck or fork-lift truck,

fittingtheforksintotheslotsasshowninfigure2.

Packing dimensions

A 550mm

B 1000mm

C 4050mm

4.1 Unpacking

Afterremovingthepackingmaterials,carefullyinspectthevariouscomponentsoftheequipment,checkingfor

anyvisiblydamagedparts(controlunit,liftframe).Incaseofdamagedonotusetheequipment(thelift)and

callinaqualifiedtechnician(yourlocaldealer).

WARNING

The box containing the accessories is packed inside the crate:

DO NOT THROW IT AWAY WITH THE PACKAGING

The packing materials (plastic bags, expanded polystyrene, nails, screws, wood blocks etc.) must never be left

within the reach of children as they constitute a potential hazard. Dispose of these materials in the designated

collection centers if they are polluting or non-biodegradable.

4.2 Installation area

Anareaofatleast4330x4000mm,withaceilingheightofatleast4150mm,isrequiredforinstallationofthe

lift.

From the operator position, the operator is able to monitor the entire lift and its surrounding area. He must en-

sure that there are no unauthorized persons, or objects which may cause hazards, in this area.

Beforeinstallingthelift,checkthespecificationsofthesupportingsurfaceavailable,orprepareasurfacewith

the minimum characteristics stated below

CM245/55-A

20 / 44

4.3 Installation

After unpacking, handle the pillars with the aid of suitable slings.

Anchor bolt installation procedure:

1. Place the two pillars in the installation zone.

2. Straighten the pillars to the vertical position and then position them so that they are properly aligned with

the distance between them as in the sketch below.

3. Ifnecessary,placeshimsunderneaththebasesofthepillarssothattheyarefirmlysupportedandthe

pillars are perfectly vertical.

4. Drillholesinthefloorthroughbedplates.Drillwithø20onalengthofmin.140mm,andcleantheholes

thoroughly.

5. FittheHiltiHST3-M20x170orequivalentanchorboltsintheholesandthentightenwithatorqueat180

Nm.

Afterafewcycleswithfullload,checkthattheanchorboltsarestillfirmlytightened.Thischeckmustberepea-

ted every 3 months.

WARNING

The manufacturer declines liability for any

damages resulting from failure to follow the

above instructions, which may invalidate

the warranty.

CM245/55-A

Other manuals for Molnar CM245-A

1

This manual suits for next models

1

Table of contents

Other Nexion Lifting System manuals

Popular Lifting System manuals by other brands

Bike-Lift

Bike-Lift LEVANTE-50 Use and maintenance manual

QUALITY LIFTS

QUALITY LIFTS Q4P07 Installation, operation & maintenance manual

AAT

AAT c-max C141 Translation of the original user manual

Peak

Peak MR06 Installation and service manual

CMC

CMC S19 Use and maintenance manual

AJ

AJ 30035 operating instructions